POLYLACTIC ACID - Plastic Engineering Associates Licensing, Inc.

POLYLACTIC ACID - Plastic Engineering Associates Licensing, Inc.

POLYLACTIC ACID - Plastic Engineering Associates Licensing, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

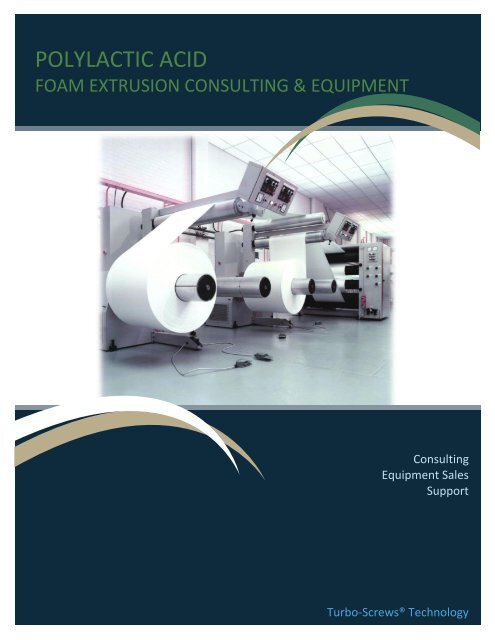

<strong>POLYLACTIC</strong> <strong>ACID</strong><br />

FOAM EXTRUSION CONSULTING & EQUIPMENT<br />

Consulting<br />

Equipment Sales<br />

Support<br />

Turbo-Screws® Technology

Technology at work for you<br />

CONNECTING YOUR BUSINESS TO THE TECHNOLOGY RESOURCES YOU<br />

NEED<br />

<strong>Plastic</strong> <strong>Engineering</strong> <strong>Associates</strong> <strong>Licensing</strong>, <strong>Inc</strong>. (PEAL) is the only preferred PLA foam<br />

equipment supplier for the world’s largest PLA resin producer, NatureWorks, LLC. PEAL<br />

developed the world’s first commercially viable foam feed screw extrusion technology,<br />

Turbo-Screws® technology, for extruding PLA foam sheet, in 2005. No one has more<br />

extruded PLA foam sheet experience than us! Leverage your time and money by hiring the<br />

best PLA foam extrusion technology in the world. Why re-invent the wheel<br />

PEAL is the world’s only provider of comprehensive, integrated solutions to industry’s PLA<br />

foam extrusion needs, including consulting, product development, process technology,<br />

equipment design & support.<br />

SUPPORT SOLUTIONS<br />

• Consulting<br />

• PLA Foam Equipment, Extruders<br />

• Product Development<br />

• Process Technology<br />

• Support<br />

flexible solutions for your business needs<br />

TECHNOLOGY CONSULTING PROVIDES A TOTAL END TO END SOLUTION.<br />

Consulting<br />

<strong>Plastic</strong> <strong>Engineering</strong> <strong>Associates</strong>, <strong>Inc</strong>. (PEA) has been in continuous service to the<br />

thermoplastics extruded foam industry since 1968. Jim Fogarty (Chem. Eng.) was<br />

instrumental in developing the modern tandem foam extruder and is the founder of PEA.<br />

In his long and storied foam career, Jim has been a consultant, manufacturer, inventor<br />

and innovator. His client’s list is a veritable who’s who in the industry, and includes Shell,<br />

Mobil, Pactiv, Sekesui, Japan Styrene Paper, Daicel Chemical, Sealed Air, Nova Chemicals,<br />

and many, many more. PEA has designed & commissioned several turnkey foam plants<br />

throughout the world. Jim’s three sons, David, Bill and Matthew, work with Jim in the<br />

business. Combined, they have collectively over 150 years of foam experience. PEA’s<br />

sister company, <strong>Plastic</strong> <strong>Engineering</strong> <strong>Associates</strong> <strong>Licensing</strong>, <strong>Inc</strong>. (PEAL) was incorporated in<br />

1998 and licenses Jim’s patented Turbo- Screws® feed screw technology for polystyrene<br />

and poly lactic acid foam extrusion.<br />

PLA Foam Equipment & Extruders<br />

Since we have the inventor of the modern tandem foam extruder as our founder, and<br />

have spent six years developing extruded PLA foam equipment and process technology<br />

with the world’s largest PLA resin manufacturer, NatureWorks, LLC, we like to think we<br />

have learned a thing or two about what a PLA tandem foam extruder should look like in<br />

terms of its equipment, configuration, design and function. We have already designed the<br />

ancillary equipment for extruded PLA foam (screws, dies, etc.). We’ve written the<br />

specifications for the ultimate PLA foam extrusion system. We think there will be a<br />

tremendous market for PLA tandem foam equipment and extruders in the future. If you<br />

presently are a foam equipment manufacturer, or a company which wants to participate<br />

in the greening of the extruded polystyrene foam industry, contact us for a confidential<br />

discussion.<br />

Simplify your PLA Foam Development

PRODUCT DEVELOPMENT<br />

Product development is our specialty. Many opportunities exist in extruded PLA foam for<br />

food packaging and have yet to be capitalized. We are experts in closed and open cell<br />

foam extrusion. Your company can be in the extruded foam PLA business for cold case<br />

meat trays, for example, in under two years starting from scratch. If you’re an existing<br />

manufacturer of thermoplastic food packaging meat trays, your company can be up and<br />

running making extruded PLA foam in as little as six months.<br />

PROCESS TECHNOLOGY<br />

PLA Foam Extrusion 1<br />

Process technology is available for all aspects of your extruded PLA foam needs. PEA<br />

personnel will commission your equipment and process, provide you with recipes and<br />

train your personnel.<br />

SUPPORT<br />

PEA provides as little or as much support as your company needs. Your success is<br />

important to us. We truly believe and practice our motto “Your Success is Our<br />

Success”. We are well known for our fast response time.<br />

Turbo-Screws® Technology

CONSULTING<br />

PLA FOAM EQUIPMENT, EXTRUDER<br />

PRODUCT DEVELOPMENT<br />

PROCESS TECHNOLOGY<br />

SUPPORT<br />

Please contact us for all of your extruded polystyrene, polyethylene, and<br />

poly lactic acid foam needs.<br />

<strong>Plastic</strong> <strong>Engineering</strong> <strong>Associates</strong> <strong>Licensing</strong>, <strong>Inc</strong>.<br />

www.turboscrews.com<br />

Contact: Click Here<br />

<strong>Plastic</strong> <strong>Engineering</strong> <strong>Associates</strong>, <strong>Inc</strong>.<br />

www.pea.cc<br />

Contact: Click Here<br />

Turbo-Screws® Technology<br />

<strong>Plastic</strong> <strong>Engineering</strong> <strong>Associates</strong>, <strong>Inc</strong>.<br />

<strong>Plastic</strong> <strong>Engineering</strong> <strong>Associates</strong> <strong>Licensing</strong>, <strong>Inc</strong>.<br />

Boca Raton, Florida<br />

Phone 561.866.5825