Chapter A General rules of electrical installation design

Chapter A General rules of electrical installation design

Chapter A General rules of electrical installation design

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2008<br />

http://theguide.schneider-electric.com<br />

Technical Series<br />

Electrical<br />

<strong>installation</strong> guide<br />

According to IEC International Standards

This technical guide is the result <strong>of</strong><br />

a collective effort.<br />

Technical advisor:<br />

Serge Volut - Jacques Schonek<br />

Illustrations and production:<br />

AXESS - Valence -France<br />

Printing:<br />

Les Deux-Ponts - France<br />

Edition<br />

March 2008<br />

Price: 90 �<br />

ISBN: 978.2.9531643.0.5<br />

N° dépôt légal: 1er semestre 2008<br />

© Schneider Electric<br />

All rights reserved in all countries<br />

This guide has been written for <strong>electrical</strong> Engineers who have to<br />

<strong>design</strong>, realize, inspect or maintain <strong>electrical</strong> <strong>installation</strong>s in compliance<br />

with international Standards <strong>of</strong> the International Electrotechnical<br />

Commission (IEC).<br />

“Which technical solution will guarantee that all relevant safety <strong>rules</strong> are<br />

met?” This question has been a permanent guideline for the elaboration <strong>of</strong><br />

this document.<br />

An international Standard such as the IEC 60364 “Electrical Installation<br />

in Buldings” specifies extensively the <strong>rules</strong> to comply with to ensure<br />

safety and predicted operational characteristics for all types <strong>of</strong> <strong>electrical</strong><br />

<strong>installation</strong>s. As the Standard must be extensive, and has to be applicable<br />

to all types <strong>of</strong> products and the technical solutions in use worldwide, the<br />

text <strong>of</strong> the IEC <strong>rules</strong> is complex, and not presented in a ready-to-use order.<br />

The Standard cannot therefore be considered as a working handbook, but<br />

only as a reference document.<br />

The aim <strong>of</strong> the present guide is to provide a clear, practical and stepby-step<br />

explanation for the complete study <strong>of</strong> an <strong>electrical</strong> <strong>installation</strong>,<br />

according to IEC 60364 and other relevant IEC Standards. Therefore, the<br />

first chapter (B) presents the methodology to be used, and each chapter<br />

deals with one out <strong>of</strong> the eight steps <strong>of</strong> the study. The two last chapter are<br />

devoted to particular supply sources, loads and locations, and appendix<br />

provides additional information. Special attention must be paid to the<br />

EMC appendix, which is based on the broad and practical experience on<br />

electromagnetic compatibility problems.<br />

We all hope that you, the user, will find this handbook genuinely helpful.<br />

Schneider Electric S.A.<br />

The Electrical Installation Guide is a single document covering the<br />

techniques, regulations and standards related to <strong>electrical</strong> <strong>installation</strong>s.<br />

It is intended for <strong>electrical</strong> pr<strong>of</strong>essionals in companies, <strong>design</strong> <strong>of</strong>fices,<br />

inspection organisations, etc.<br />

This Technical Guide is aimed at pr<strong>of</strong>essional users and is only intended<br />

to provide them guidelines for the definition <strong>of</strong> an industrial, tertiary or<br />

domestic <strong>electrical</strong> <strong>installation</strong>. Information and guidelines contained in this<br />

Guide are provided AS IS. Schneider Electric makes no warranty <strong>of</strong> any<br />

kind, whether express or implied, such as but not limited to the warranties<br />

<strong>of</strong> merchantability and fitness for a particular purpose, nor assumes any<br />

legal liability or responsibility for the accuracy, completeness, or usefulness<br />

<strong>of</strong> any information, apparatus, product, or process disclosed in this Guide,<br />

nor represents that its use would not infringe privately owned rights.<br />

The purpose <strong>of</strong> this guide is to facilitate the implementation <strong>of</strong> International<br />

<strong>installation</strong> standards for <strong>design</strong>ers & contractors, but in all cases the<br />

original text <strong>of</strong> International or local standards in force shall prevail.<br />

This new edition has been published to take into account changes in<br />

techniques, standards and regulations, in particular <strong>electrical</strong> <strong>installation</strong><br />

standard IEC 60364.<br />

We thank all the readers <strong>of</strong> the previous edition <strong>of</strong> this guide for their<br />

comments that have helped improve the current edition.<br />

We also thank the many people and organisations, to numerous to name<br />

here, who have contributed in one way or another to the preparation <strong>of</strong> this<br />

guide.

Guiding tools for more efficiency in <strong>electrical</strong><br />

distribution <strong>design</strong><br />

Technical knowledge Pre-<strong>design</strong> help for budget<br />

approach<br />

10-30mn eLearning modules for<br />

individual training<br />

Articles giving base skills about<br />

general subjects: “Cahiers<br />

Techniques”<br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008<br />

Selection criterias & method<br />

to follow in order to pre-define<br />

project specification:<br />

b Architecture guide<br />

b ID-Spec s<strong>of</strong>tware<br />

Solutions and examples with<br />

recommended architectures in<br />

Solution guides:<br />

b airport<br />

b automative<br />

b food<br />

b retail<br />

b <strong>of</strong>fice<br />

b industrial buildings<br />

b healthcare<br />

b ...

Design support Specification help Help in <strong>installation</strong>, use &<br />

maintenance<br />

Practical data & methods<br />

through major <strong>design</strong> guides:<br />

b Electrical Installation Guide<br />

b Protection guide<br />

b Industrial <strong>electrical</strong> network<br />

<strong>design</strong> guide<br />

b ...<br />

Product presentation <strong>of</strong> technical<br />

characteristics in all Schneider<br />

Electric product Catalogues<br />

Design S<strong>of</strong>tware:<br />

b My Ecodial<br />

Ecodial s<strong>of</strong>tware provides a<br />

complete <strong>design</strong> package for<br />

LV <strong>installation</strong>s, in accordance<br />

with IEC standards and<br />

recommendations.<br />

Main features:<br />

v Create diagrams<br />

v Optimise circuit breakers curves<br />

v Determine source power<br />

v Follow step by step calculation<br />

v Print the project <strong>design</strong> file<br />

b SISPRO building<br />

b ...<br />

Drawing source files for<br />

connection, dimension, diagram,<br />

mounting & safety: CAD library<br />

Technical specification on<br />

products & solutions for tender<br />

request<br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008<br />

Product <strong>installation</strong> data<br />

Product how to use data<br />

Product maintenance data

<strong>General</strong> <strong>rules</strong> <strong>of</strong> <strong>electrical</strong><br />

<strong>installation</strong> <strong>design</strong><br />

Connection to the MV utility<br />

distribution network<br />

Connection to the LV utility<br />

distribution network<br />

MV & LV architecture selection<br />

guide<br />

LV Distribution<br />

Protection against electric<br />

shocks<br />

Sizing and protection <strong>of</strong><br />

conductors<br />

LV switchgear: functions &<br />

selection<br />

Protection against voltage<br />

surges in LV<br />

Energy Efficiency in <strong>electrical</strong><br />

distribution<br />

Power factor correction and<br />

harmonic filtering<br />

Harmonic management<br />

Characteristics <strong>of</strong> particular<br />

sources and loads<br />

Residential and other special<br />

locations<br />

EMC guidelines<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

G<br />

H<br />

J<br />

K<br />

L<br />

M<br />

N<br />

P<br />

Q

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

G<br />

H<br />

<strong>General</strong> contents<br />

<strong>General</strong> <strong>rules</strong> <strong>of</strong> <strong>electrical</strong> <strong>installation</strong> <strong>design</strong><br />

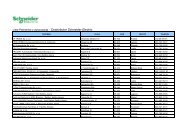

1 Methodology A2<br />

2 Rules and statutory regulations A4<br />

3 Installed power loads - Characteristics A10<br />

4 Power loading <strong>of</strong> an <strong>installation</strong> A15<br />

Connection to the MV utility distribution network<br />

1 Supply <strong>of</strong> power at medium voltage B2<br />

2 Procedure for the establishment <strong>of</strong> a new substation B14<br />

3 Protection aspect B16<br />

4 The consumer substation with LV metering B22<br />

5 The consumer substation with MV metering B30<br />

6 Constitution <strong>of</strong> MV/LV distribution substations B35<br />

Connection to the LV utility distribution network<br />

1 Low voltage utility distribution networks C2<br />

2 Tariffs and metering C16<br />

MV & LV architecture selection guide<br />

1 Stakes for the user D3<br />

2 Simplified architecture <strong>design</strong> process D4<br />

3 Electrical <strong>installation</strong> characteristics D7<br />

4 Technological characteristics D11<br />

5 Architecture assessment criteria D13<br />

6 Choice <strong>of</strong> architecture fundamentals D15<br />

7 Choice <strong>of</strong> architecture details D19<br />

8 Choice <strong>of</strong> equiment D24<br />

9 Recommendations for architecture optimization D26<br />

10 Glossary D29<br />

11 ID-Spec s<strong>of</strong>tware D30<br />

12 Example: <strong>electrical</strong> <strong>installation</strong> in a printworks D31<br />

LV Distribution<br />

1 Earthing schemes E2<br />

2 The <strong>installation</strong> system E15<br />

3 External influences (IEC 60364-5-51) E25<br />

Protection against electric shocks<br />

1 <strong>General</strong> F2<br />

2 Protection against direct contact F4<br />

3 Protection against indirect contact F6<br />

4 Protection <strong>of</strong> goods due to insulation fault F17<br />

5 Implementation <strong>of</strong> the TT system F19<br />

6 Implementation <strong>of</strong> the TN system F25<br />

7 Implementation <strong>of</strong> the IT system F31<br />

8 Residual current differential devices RCDs F38<br />

Sizing and protection <strong>of</strong> conductors<br />

1 <strong>General</strong> G2<br />

2 Practical method for determining the smallest allowable G7<br />

cross-sectional area <strong>of</strong> circuit conductors<br />

3 Determination <strong>of</strong> voltage drop G20<br />

4 Short-circuit current G24<br />

5 Particular cases <strong>of</strong> short-circuit current G30<br />

6 Protective earthing conductor G37<br />

7 The neutral conductor G42<br />

8 Worked example <strong>of</strong> cable calculation G46<br />

LV switchgear: functions & selection<br />

1 The basic functions <strong>of</strong> LV switchgear H2<br />

2 The switchgear H5<br />

3 Choice <strong>of</strong> switchgear H10<br />

4 Circuit breaker H11<br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008

J<br />

K<br />

L<br />

M<br />

N<br />

P<br />

Q<br />

<strong>General</strong> contents<br />

Protection against voltage surges in LV<br />

1 <strong>General</strong> J2<br />

2 Overvoltage protection devices J6<br />

3 Standards J11<br />

4 Choosing a protection device J14<br />

Energy Efficiency in <strong>electrical</strong> distribution<br />

1 Introduction K2<br />

2 Energy efficiency and electricity K3<br />

3 One process, several players K5<br />

4 From <strong>electrical</strong> measurement to <strong>electrical</strong> information K10<br />

5 Communication and Information System K16<br />

Power factor correction and harmonic filtering<br />

1 Reactive energy and power factor L2<br />

2 Why to improve the power factor? L5<br />

3 How to improve the power factor? L7<br />

4 Where to install power correction capacitors? L10<br />

5 How to decide the optimum level <strong>of</strong> compensation? L12<br />

6 Compensation at the terminals <strong>of</strong> a transformer L15<br />

7 Power factor correction <strong>of</strong> induction motors L18<br />

8 Example <strong>of</strong> an <strong>installation</strong> before and after power factor correction L20<br />

9 The effects <strong>of</strong> harmonics L21<br />

10 Implementation <strong>of</strong> capacitor banks L24<br />

Harmonic management<br />

1 The problem: M2<br />

Why is it necessary to detect and eliminate harmonics?<br />

2 Standards M3<br />

3 <strong>General</strong> M4<br />

4 Main effects <strong>of</strong> harmonics in <strong>installation</strong>s M6<br />

5 Essential indicators <strong>of</strong> harmonic distortion and M11<br />

measurement principles<br />

6 Measuring the indicators M14<br />

7 Detection devices M16<br />

8 Solutions to attenuate harmonics M17<br />

Characteristics <strong>of</strong> particular sources and loads<br />

1 Protection <strong>of</strong> a LV generator set and the downstream circuits N2<br />

2 Uninterruptible Power Supply Units (UPS) N11<br />

3 Protection <strong>of</strong> LV/LV transformers N24<br />

4 Lighting circuits N27<br />

5 Asynchronous motors N42<br />

Residential and other special locations<br />

1 Residential and similar premises P2<br />

2 Bathrooms and showers P8<br />

3 Recommendations applicable to special <strong>installation</strong>s and locations P12<br />

EMC guidelines<br />

1 Electrical distribution Q2<br />

2 Earthing principles and structures Q3<br />

3 Implementation Q5<br />

4 Coupling mechanism and counter-measures Q14<br />

5 Wiring recommendations Q20<br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008

2<br />

3<br />

4<br />

<strong>Chapter</strong> A<br />

<strong>General</strong> <strong>rules</strong> <strong>of</strong> <strong>electrical</strong><br />

<strong>installation</strong> <strong>design</strong><br />

Contents<br />

Methodology A2<br />

Rules and statutory regulations A4<br />

2.1 Definition <strong>of</strong> voltage ranges A4<br />

2.2 Regulations A5<br />

2.3 Standards A5<br />

2.4 Quality and safety <strong>of</strong> an <strong>electrical</strong> <strong>installation</strong> A6<br />

2.5 Initial testing <strong>of</strong> an <strong>installation</strong> A6<br />

2.6 Periodic check-testing <strong>of</strong> an <strong>installation</strong><br />

2.7 Conformity (with standards and specifications) <strong>of</strong> equipment<br />

A7<br />

used in the <strong>installation</strong> A7<br />

2.8 Environment A8<br />

Installed power loads - Characteristics A 0<br />

3.1 Induction motors<br />

3.2 Resistive-type heating appliances and incandescent lamps<br />

A10<br />

(conventional or halogen) A12<br />

Power loading <strong>of</strong> an <strong>installation</strong> A 5<br />

4.1 Installed power (kW) A15<br />

4.2 Installed apparent power (kVA) A15<br />

4.3 Estimation <strong>of</strong> actual maximum kVA demand A16<br />

4.4 Example <strong>of</strong> application <strong>of</strong> factors ku and ks A17<br />

4.5 Diversity factor A18<br />

4.6 Choice <strong>of</strong> transformer rating A19<br />

4.7 Choice <strong>of</strong> power-supply sources A20<br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008<br />

A<br />

© Schneider Electric - all rights reserved

© Schneider Electric - all rights reserved<br />

A2<br />

A - <strong>General</strong> <strong>rules</strong> <strong>of</strong> <strong>electrical</strong> <strong>installation</strong> <strong>design</strong><br />

A - <strong>General</strong> <strong>rules</strong> <strong>of</strong> <strong>electrical</strong> <strong>installation</strong> <strong>design</strong><br />

B – Connection to the MV utility distribution<br />

network<br />

C - Connection to the LV utility distribution<br />

network<br />

D - MV & LV architecture selection guide<br />

E - LV Distribution<br />

F - Protection against electric shocks<br />

G - Sizing and protection <strong>of</strong> conductors<br />

H - LV switchgear: functions & selection<br />

Methodology<br />

For the best results in <strong>electrical</strong> <strong>installation</strong> <strong>design</strong> it is recommended to read all the<br />

chapters <strong>of</strong> this guide in the order in which they are presented.<br />

Listing <strong>of</strong> power demands<br />

The study <strong>of</strong> a proposed <strong>electrical</strong> <strong>installation</strong> requires an adequate understanding <strong>of</strong><br />

all governing <strong>rules</strong> and regulations.<br />

The total power demand can be calculated from the data relative to the location and<br />

power <strong>of</strong> each load, together with the knowledge <strong>of</strong> the operating modes (steady<br />

state demand, starting conditions, non simultaneous operation, etc.)<br />

From these data, the power required from the supply source and (where appropriate)<br />

the number <strong>of</strong> sources necessary for an adequate supply to the <strong>installation</strong> are<br />

readily obtained.<br />

Local information regarding tariff structures is also required to allow the best choice<br />

<strong>of</strong> connection arrangement to the power-supply network, e.g. at medium voltage or<br />

low voltage level.<br />

Service connection<br />

This connection can be made at:<br />

b Medium Voltage level<br />

A consumer-type substation will then have to be studied, built and equipped. This<br />

substation may be an outdoor or indoor <strong>installation</strong> conforming to relevant standards<br />

and regulations (the low-voltage section may be studied separately if necessary).<br />

Metering at medium-voltage or low-voltage is possible in this case.<br />

b Low Voltage level<br />

The <strong>installation</strong> will be connected to the local power network and will (necessarily) be<br />

metered according to LV tariffs.<br />

Electrical Distribution architecture<br />

The whole <strong>installation</strong> distribution network is studied as a complete system.<br />

A selection guide is proposed for determination <strong>of</strong> the most suitable architecture.<br />

MV/LV main distribution and LV power distribution levels are covered.<br />

Neutral earthing arrangements are chosen according to local regulations, constraints<br />

related to the power-supply, and to the type <strong>of</strong> loads.<br />

The distribution equipment (panelboards, switchgears, circuit connections, ...) are<br />

determined from building plans and from the location and grouping <strong>of</strong> loads.<br />

The type <strong>of</strong> premises and allocation can influence their immunity to external<br />

disturbances.<br />

Protection against electric shocks<br />

The earthing system (TT, IT or TN) having been previously determined, then the<br />

appropriate protective devices must be implemented in order to achieve protection<br />

against hazards <strong>of</strong> direct or indirect contact.<br />

Circuits and switchgear<br />

Each circuit is then studied in detail. From the rated currents <strong>of</strong> the loads, the level<br />

<strong>of</strong> short-circuit current, and the type <strong>of</strong> protective device, the cross-sectional area<br />

<strong>of</strong> circuit conductors can be determined, taking into account the nature <strong>of</strong> the<br />

cableways and their influence on the current rating <strong>of</strong> conductors.<br />

Before adopting the conductor size indicated above, the following requirements must<br />

be satisfied:<br />

b The voltage drop complies with the relevant standard<br />

b Motor starting is satisfactory<br />

b Protection against electric shock is assured<br />

The short-circuit current Isc is then determined, and the thermal and electrodynamic<br />

withstand capability <strong>of</strong> the circuit is checked.<br />

These calculations may indicate that it is necessary to use a conductor size larger<br />

than the size originally chosen.<br />

The performance required by the switchgear will determine its type and<br />

characteristics.<br />

The use <strong>of</strong> cascading techniques and the discriminative operation <strong>of</strong> fuses and<br />

tripping <strong>of</strong> circuit breakers are examined.<br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008

A - <strong>General</strong> <strong>rules</strong> <strong>of</strong> <strong>electrical</strong> <strong>installation</strong> <strong>design</strong><br />

J – Protection against voltage surges in LV<br />

K – Energy efficiency in <strong>electrical</strong> distribution<br />

L - Power factor correction and harmonic filtering<br />

M - Harmonic management<br />

N - Characteristics <strong>of</strong> particular sources and<br />

loads<br />

P - Residential and other special locations<br />

Q - EMC guideline<br />

(1) Ecodial is a Merlin Gerin product and is available in French<br />

and English versions.<br />

Methodology<br />

Protection against overvoltages<br />

Direct or indirect lightning strokes can damage <strong>electrical</strong> equipment at a distance<br />

<strong>of</strong> several kilometers. Operating voltage surges, transient and industrial frequency<br />

over-voltage can also produce the same consequences.The effects are examined<br />

and solutions are proposed.<br />

Energy efficiency in electrial distribution<br />

Implementation <strong>of</strong> measuring devices with an adequate communication system<br />

within the <strong>electrical</strong> <strong>installation</strong> can produce high benefits for the user or owner:<br />

reduced power consumption, reduced cost <strong>of</strong> energy, better use <strong>of</strong> <strong>electrical</strong><br />

equipment.<br />

Reactive energy<br />

The power factor correction within <strong>electrical</strong> <strong>installation</strong>s is carried out locally,<br />

globally or as a combination <strong>of</strong> both methods.<br />

Harmonics<br />

Harmonics in the network affect the quality <strong>of</strong> energy and are at the origin <strong>of</strong> many<br />

disturbances as overloads, vibrations, ageing <strong>of</strong> equipment, trouble <strong>of</strong> sensitive<br />

equipment, <strong>of</strong> local area networks, telephone networks. This chapter deals with the<br />

origins and the effects <strong>of</strong> harmonics and explain how to measure them and present<br />

the solutions.<br />

Particular supply sources and loads<br />

Particular items or equipment are studied:<br />

b Specific sources such as alternators or inverters<br />

b Specific loads with special characteristics, such as induction motors, lighting<br />

circuits or LV/LV transformers<br />

b Specific systems, such as direct-current networks<br />

Generic applications<br />

Certain premises and locations are subject to particularly strict regulations: the most<br />

common example being residential dwellings.<br />

EMC Guidelines<br />

Some basic <strong>rules</strong> must be followed in order to ensure Electromagnetic Compatibility.<br />

Non observance <strong>of</strong> these <strong>rules</strong> may have serious consequences in the operation <strong>of</strong><br />

the <strong>electrical</strong> <strong>installation</strong>: disturbance <strong>of</strong> communication systems, nuisance tripping<br />

<strong>of</strong> protection devices, and even destruction <strong>of</strong> sensitive devices.<br />

Ecodial s<strong>of</strong>tware<br />

Ecodial s<strong>of</strong>tware (1) provides a complete <strong>design</strong> package for LV <strong>installation</strong>s, in<br />

accordance with IEC standards and recommendations.<br />

The following features are included:<br />

b Construction <strong>of</strong> one-line diagrams<br />

b Calculation <strong>of</strong> short-circuit currents<br />

b Calculation <strong>of</strong> voltage drops<br />

b Optimization <strong>of</strong> cable sizes<br />

b Required ratings <strong>of</strong> switchgear and fusegear<br />

b Discrimination <strong>of</strong> protective devices<br />

b Recommendations for cascading schemes<br />

b Verification <strong>of</strong> the protection <strong>of</strong> people<br />

b Comprehensive print-out <strong>of</strong> the foregoing calculated <strong>design</strong> data<br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008<br />

A3<br />

© Schneider Electric - all rights reserved

© Schneider Electric - all rights reserved<br />

A<br />

A - <strong>General</strong> <strong>rules</strong> <strong>of</strong> <strong>electrical</strong> <strong>installation</strong> <strong>design</strong><br />

2 Rules and statutory regulations<br />

Low-voltage <strong>installation</strong>s are governed by a number <strong>of</strong> regulatory and advisory texts,<br />

which may be classified as follows:<br />

b Statutory regulations (decrees, factory acts,etc.)<br />

b Codes <strong>of</strong> practice, regulations issued by pr<strong>of</strong>essional institutions, job specifications<br />

b National and international standards for <strong>installation</strong>s<br />

b National and international standards for products<br />

2.1 Definition <strong>of</strong> voltage ranges<br />

IEC voltage standards and recommendations<br />

Three-phase four-wire or three-wire systems Single-phase three-wire systems<br />

Nominal voltage (V) Nominal voltage (V)<br />

50 Hz 60 Hz 60 Hz<br />

– 120/208 120/240<br />

– 240 –<br />

230/400 (1) 277/480 –<br />

400/690 (1) 480 –<br />

– 347/600 –<br />

1000 600 –<br />

(1) The nominal voltage <strong>of</strong> existing 220/380 V and 240/415 V systems shall evolve<br />

toward the recommended value <strong>of</strong> 230/400 V. The transition period should be as short<br />

as possible and should not exceed the year 2003. During this period, as a first step, the<br />

electricity supply authorities <strong>of</strong> countries having 220/380 V systems should bring the<br />

voltage within the range 230/400 V +6 %, -10 % and those <strong>of</strong> countries having<br />

240/415 V systems should bring the voltage within the range 230/400 V +10 %,<br />

-6 %. At the end <strong>of</strong> this transition period, the tolerance <strong>of</strong> 230/400 V ± 10 % should<br />

have been achieved; after this the reduction <strong>of</strong> this range will be considered. All the<br />

above considerations apply also to the present 380/660 V value with respect to the<br />

recommended value 400/690 V.<br />

Fig. A1 : Standard voltages between 100 V and 1000 V (IEC 60038 Edition 6.2 2002-07)<br />

Series I Series II<br />

Highest voltage Nominal system Highest voltage Nominal system<br />

for equipment (kV) voltage (kV) for equipment (kV) voltage (kV)<br />

3.6 (1) 3.3 (1) 3 (1) 4.40 (1) 4.16 (1)<br />

7.2 (1) 6.6 (1) 6 (1) – –<br />

12 11 10 – –<br />

– – – 13.2 (2) 12.47 (2)<br />

– – – 13.97 (2) 13.2 (2)<br />

– – – 14.52 (1) 13.8 (1)<br />

(17.5) – (15) – –<br />

24 22 20 – –<br />

– – – 26.4 (2) 24.94 (2)<br />

36 (3) 33 (3) – – –<br />

– – – 36.5 34.5<br />

40.5 (3) – 35 (3) – –<br />

These systems are generally three-wire systems unless otherwise indicated.<br />

The values indicated are voltages between phases.<br />

The values indicated in parentheses should be considered as non-preferred values. It is<br />

recommended that these values should not be used for new systems to be constructed<br />

in future.<br />

Note 1: It is recommended that in any one country the ratio between two adjacent<br />

nominal voltages should be not less than two.<br />

Note 2: In a normal system <strong>of</strong> Series I, the highest voltage and the lowest voltage do<br />

not differ by more than approximately ±10 % from the nominal voltage <strong>of</strong> the system.<br />

In a normal system <strong>of</strong> Series II, the highest voltage does not differ by more then +5 %<br />

and the lowest voltage by more than -10 % from the nominal voltage <strong>of</strong> the system.<br />

(1) These values should not be used for public distribution systems.<br />

(2) These systems are generally four-wire systems.<br />

(3) The unification <strong>of</strong> these values is under consideration.<br />

Fig. A2 : Standard voltages above 1 kV and not exceeding 35 kV<br />

(IEC 60038 Edition 6.2 2002-07)<br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008

A - <strong>General</strong> <strong>rules</strong> <strong>of</strong> <strong>electrical</strong> <strong>installation</strong> <strong>design</strong><br />

2 Rules and statutory regulations<br />

2.2 Regulations<br />

In most countries, <strong>electrical</strong> <strong>installation</strong>s shall comply with more than one set <strong>of</strong><br />

regulations, issued by National Authorities or by recognized private bodies. It is<br />

essential to take into account these local constraints before starting the <strong>design</strong>.<br />

2.3 Standards<br />

This Guide is based on relevant IEC standards, in particular IEC 60364. IEC 60364<br />

has been established by medical and engineering experts <strong>of</strong> all countries in the<br />

world comparing their experience at an international level. Currently, the safety<br />

principles <strong>of</strong> IEC 60364 and 60479-1 are the fundamentals <strong>of</strong> most <strong>electrical</strong><br />

standards in the world (see table below and next page).<br />

IEC 60038 Standard voltages<br />

IEC 60076-2 Power transformers - Temperature rise<br />

IEC 60076-3 Power transformers - Insulation levels, dielectric tests and external clearances in air<br />

IEC 60076- Power transformers - Ability to withstand short-circuit<br />

IEC 60076-10 Power transformers - Determination <strong>of</strong> sound levels<br />

IEC 601 6 Semiconductor convertors - <strong>General</strong> requirements and line commutated convertors<br />

IEC 602 Electrical relays<br />

IEC 6026 -1 High-voltage switches - High-voltage switches for rated voltages above 1 kV and less than 52 kV<br />

IEC 60269-1 Low-voltage fuses - <strong>General</strong> requirements<br />

IEC 60269-2 Low-voltage fuses - Supplementary requirements for fuses for use by unskilled persons (fuses mainly for household and similar applications)<br />

IEC 60282-1 High-voltage fuses - Current-limiting fuses<br />

IEC 60287-1-1 Electric cables - Calculation <strong>of</strong> the current rating - Current rating equations (100% load factor) and calculation <strong>of</strong> losses - <strong>General</strong><br />

IEC 6036 Electrical <strong>installation</strong>s <strong>of</strong> buildings<br />

IEC 6036 -1 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Fundamental principles<br />

IEC 6036 - - 1 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Protection for safety - Protection against electric shock<br />

IEC 6036 - - 2 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Protection for safety - Protection against thermal effects<br />

IEC 6036 - - 3 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Protection for safety - Protection against overcurrent<br />

IEC 6036 - - Electrical <strong>installation</strong>s <strong>of</strong> buildings - Protection for safety - Protection against electromagnetic and voltage disrurbance<br />

IEC 6036 - - 1 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Selection and erection <strong>of</strong> <strong>electrical</strong> equipment - Common <strong>rules</strong><br />

IEC 6036 - - 2 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Selection and erection <strong>of</strong> <strong>electrical</strong> equipment - Wiring systems<br />

IEC 6036 - - 3 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Selection and erection <strong>of</strong> <strong>electrical</strong> equipment - Isolation, switching and control<br />

IEC 6036 - - Electrical <strong>installation</strong>s <strong>of</strong> buildings - Selection and erection <strong>of</strong> <strong>electrical</strong> equipment - Earthing arrangements<br />

IEC 6036 - - Electrical <strong>installation</strong>s <strong>of</strong> buildings - Selection and erection <strong>of</strong> <strong>electrical</strong> equipment - Other equipments<br />

IEC 6036 -6-61 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Verification and testing - Initial verification<br />

IEC 6036 -7-701 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Requirements for special <strong>installation</strong>s or locations - Locations containing a bath tub or shower basin<br />

IEC 6036 -7-702 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Requirements for special <strong>installation</strong>s or locations - Swimming pools and other basins<br />

IEC 6036 -7-703 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Requirements for special <strong>installation</strong>s or locations - Locations containing sauna heaters<br />

IEC 6036 -7-70 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Requirements for special <strong>installation</strong>s or locations - Construction and demolition site <strong>installation</strong>s<br />

IEC 6036 -7-70 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Requirements for special <strong>installation</strong>s or locations - Electrical <strong>installation</strong>s <strong>of</strong> agricultural and horticultural<br />

premises<br />

IEC 6036 -7-706 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Requirements for special <strong>installation</strong>s or locations - Restrictive conducting locations<br />

IEC 6036 -7-707 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Requirements for special <strong>installation</strong>s or locations - Earthing requirements for the <strong>installation</strong> <strong>of</strong> data<br />

processing equipment<br />

IEC 6036 -7-708 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Requirements for special <strong>installation</strong>s or locations - Electrical <strong>installation</strong>s in caravan parks and caravans<br />

IEC 6036 -7-709 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Requirements for special <strong>installation</strong>s or locations - Marinas and pleasure craft<br />

IEC 6036 -7-710 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Requirements for special <strong>installation</strong>s or locations - Medical locations<br />

IEC 6036 -7-711 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Requirements for special <strong>installation</strong>s or locations - Exhibitions, shows and stands<br />

IEC 6036 -7-712 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Requirements for special <strong>installation</strong>s or locations - Solar photovoltaic (PV) power supply systems<br />

IEC 6036 -7-713 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Requirements for special <strong>installation</strong>s or locations - Furniture<br />

IEC 6036 -7-71 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Requirements for special <strong>installation</strong>s or locations - External lighting <strong>installation</strong>s<br />

IEC 6036 -7-71 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Requirements for special <strong>installation</strong>s or locations - Extra-low-voltage lighting <strong>installation</strong>s<br />

IEC 6036 -7-717 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Requirements for special <strong>installation</strong>s or locations - Mobile or transportable units<br />

IEC 6036 -7-7 0 Electrical <strong>installation</strong>s <strong>of</strong> buildings - Requirements for special <strong>installation</strong>s or locations - Temporary <strong>electrical</strong> <strong>installation</strong>s for structures,<br />

amusement devices and booths at fairgrounds, amusement parks and circuses<br />

IEC 60 27 High-voltage alternating current circuit-breakers<br />

IEC 60 39-1 Low-voltage switchgear and controlgear assemblies - Type-tested and partially type-tested assemblies<br />

IEC 60 39-2 Low-voltage switchgear and controlgear assemblies - Particular requirements for busbar trunking systems (busways)<br />

IEC 60 39-3 Low-voltage switchgear and controlgear assemblies - Particular requirements for low-voltage switchgear and controlgear assemblies intended to<br />

be installed in places where unskilled persons have access for their use - Distribution boards<br />

IEC 60 39- Low-voltage switchgear and controlgear assemblies - Particular requirements for assemblies for construction sites (ACS)<br />

IEC 60 6 Basic and safety principles for man-machine interface, marking and identification - Identification <strong>of</strong> conductors by colours or numerals<br />

IEC 60 39- Low-voltage switchgear and controlgear assemblies - Particular requirements for assemblies intended to be installed outdoors in public places<br />

- Cable distribution cabinets (CDCs)<br />

IEC 60 79-1 Effects <strong>of</strong> current on human beings and livestock - <strong>General</strong> aspects<br />

IEC 60 79-2 Effects <strong>of</strong> current on human beings and livestock - Special aspects<br />

IEC 60 79-3 Effects <strong>of</strong> current on human beings and livestock - Effects <strong>of</strong> currents passing through the body <strong>of</strong> livestock<br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008<br />

(Continued on next page)<br />

A<br />

© Schneider Electric - all rights reserved

© Schneider Electric - all rights reserved<br />

A6<br />

A - <strong>General</strong> <strong>rules</strong> <strong>of</strong> <strong>electrical</strong> <strong>installation</strong> <strong>design</strong><br />

2 Rules and statutory regulations<br />

IEC 60 29 Degrees <strong>of</strong> protection provided by enclosures (IP code)<br />

IEC 606 Spécification for high-voltage fuse-links for motor circuit applications<br />

IEC 6066 Insulation coordination for equipment within low-voltage systems<br />

IEC 6071 Dimensions <strong>of</strong> low-voltage switchgear and controlgear. Standardized mounting on rails for mechanical support <strong>of</strong> <strong>electrical</strong> devices in switchgear<br />

and controlgear <strong>installation</strong>s.<br />

IEC 6072 Short-circuit temperature limits <strong>of</strong> electric cables with rated voltages <strong>of</strong> 1 kV (Um = 1.2 kV) and 3 kV (Um = 3.6 kV)<br />

IEC 607 <strong>General</strong> requirements for residual current operated protective devices<br />

IEC 60787 Application guide for the selection <strong>of</strong> fuse-links <strong>of</strong> high-voltage fuses for transformer circuit application<br />

IEC 60831 Shunt power capacitors <strong>of</strong> the self-healing type for AC systems having a rated voltage up to and including 1000 V - <strong>General</strong> - Performance, testing<br />

and rating - Safety requirements - Guide for <strong>installation</strong> and operation<br />

IEC 609 7-1 Low-voltage switchgear and controlgear - <strong>General</strong> <strong>rules</strong><br />

IEC 609 7-2 Low-voltage switchgear and controlgear - Circuit-breakers<br />

IEC 609 7-3 Low-voltage switchgear and controlgear - Switches, disconnectors, switch-disconnectors and fuse-combination units<br />

IEC 609 7- -1 Low-voltage switchgear and controlgear - Contactors and motor-starters - Electromechanical contactors and motor-starters<br />

IEC 609 7-6-1 Low-voltage switchgear and controlgear - Multiple function equipment - Automatic transfer switching equipment<br />

IEC 61000 Electromagnetic compatibility (EMC)<br />

IEC 611 0 Protection against electric shocks - common aspects for <strong>installation</strong> and equipment<br />

IEC 61 7-1 Electrical safety in low-voltage distribution systems up to 1000 V AC and 1500 V DC - Equipment for testing, measuring or monitoring <strong>of</strong> protective<br />

measures - <strong>General</strong> requirements<br />

IEC 61 7-8 Electrical safety in low-voltage distribution systems up to 1000 V AC and 1500 V DC - Equipment for testing, measuring or monitoring <strong>of</strong> protective<br />

measures<br />

IEC 61 7-9 Electrical safety in low-voltage distribution systems up to 1000 V AC and 1500 V DC - Equipment for insulation fault location in IT systems<br />

IEC 61 8-2-6 Safety <strong>of</strong> power transformers, power supply units and similar - Particular requirements for safety isolating transformers for general use<br />

IEC 62271-1 Common specifications for high-voltage switchgear and controlgear standards<br />

IEC 62271-100 High-voltage switchgear and controlgear - High-voltage alternating-current circuit-breakers<br />

IEC 62271-102 High-voltage switchgear and controlgear - Alternating current disconnectors and earthing switches<br />

IEC 62271-10 High-voltage switchgear and controlgear - Alternating current switch-fuse combinations<br />

IEC 62271-200 High-voltage switchgear and controlgear - Alternating current metal-enclosed switchgear and controlgear for rated voltages above 1 kV and up to<br />

and including 52 kV<br />

IEC 62271-202 High-voltage/low voltage prefabricated substations<br />

2. Quality and safety <strong>of</strong> an <strong>electrical</strong> <strong>installation</strong><br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008<br />

(Concluded)<br />

In so far as control procedures are respected, quality and safety will be assured<br />

only if:<br />

b The initial checking <strong>of</strong> conformity <strong>of</strong> the <strong>electrical</strong> <strong>installation</strong> with the standard and<br />

regulation has been achieved<br />

b The <strong>electrical</strong> equipment comply with standards<br />

b The periodic checking <strong>of</strong> the <strong>installation</strong> recommended by the equipment<br />

manufacturer is respected.<br />

2. Initial testing <strong>of</strong> an <strong>installation</strong><br />

Before a utility will connect an <strong>installation</strong> to its supply network, strict precommissioning<br />

<strong>electrical</strong> tests and visual inspections by the authority, or by its<br />

appointed agent, must be satisfied.<br />

These tests are made according to local (governmental and/or institutional)<br />

regulations, which may differ slightly from one country to another. The principles <strong>of</strong><br />

all such regulations however, are common, and are based on the observance <strong>of</strong><br />

rigorous safety <strong>rules</strong> in the <strong>design</strong> and realization <strong>of</strong> the <strong>installation</strong>.<br />

IEC 60364-6-61 and related standards included in this guide are based on an<br />

international consensus for such tests, intended to cover all the safety measures and<br />

approved <strong>installation</strong> practices normally required for residential, commercial and (the<br />

majority <strong>of</strong>) industrial buildings. Many industries however have additional regulations<br />

related to a particular product (petroleum, coal, natural gas, etc.). Such additional<br />

requirements are beyond the scope <strong>of</strong> this guide.<br />

The pre-commissioning <strong>electrical</strong> tests and visual-inspection checks for <strong>installation</strong>s<br />

in buildings include, typically, all <strong>of</strong> the following:<br />

b Insulation tests <strong>of</strong> all cable and wiring conductors <strong>of</strong> the fixed <strong>installation</strong>, between<br />

phases and between phases and earth<br />

b Continuity and conductivity tests <strong>of</strong> protective, equipotential and earth-bonding<br />

conductors<br />

b Resistance tests <strong>of</strong> earthing electrodes with respect to remote earth<br />

b Verification <strong>of</strong> the proper operation <strong>of</strong> the interlocks, if any<br />

b Check <strong>of</strong> allowable number <strong>of</strong> socket-outlets per circuit

A - <strong>General</strong> <strong>rules</strong> <strong>of</strong> <strong>electrical</strong> <strong>installation</strong> <strong>design</strong><br />

Conformity <strong>of</strong> equipment with the relevant<br />

standards can be attested in several ways<br />

2 Rules and statutory regulations<br />

b Cross-sectional-area check <strong>of</strong> all conductors for adequacy at the short-circuit<br />

levels prevailing, taking account <strong>of</strong> the associated protective devices, materials and<br />

<strong>installation</strong> conditions (in air, conduit, etc.)<br />

b Verification that all exposed- and extraneous metallic parts are properly earthed<br />

(where appropriate)<br />

b Check <strong>of</strong> clearance distances in bathrooms, etc.<br />

These tests and checks are basic (but not exhaustive) to the majority <strong>of</strong> <strong>installation</strong>s,<br />

while numerous other tests and <strong>rules</strong> are included in the regulations to cover<br />

particular cases, for example: TN-, TT- or IT-earthed <strong>installation</strong>s, <strong>installation</strong>s based<br />

on class 2 insulation, SELV circuits, and special locations, etc.<br />

The aim <strong>of</strong> this guide is to draw attention to the particular features <strong>of</strong> different types<br />

<strong>of</strong> <strong>installation</strong>, and to indicate the essential <strong>rules</strong> to be observed in order to achieve<br />

a satisfactory level <strong>of</strong> quality, which will ensure safe and trouble-free performance.<br />

The methods recommended in this guide, modified if necessary to comply with any<br />

possible variation imposed by a utility, are intended to satisfy all precommissioning<br />

test and inspection requirements.<br />

2.6 Periodic check-testing <strong>of</strong> an <strong>installation</strong><br />

In many countries, all industrial and commercial-building <strong>installation</strong>s, together with<br />

<strong>installation</strong>s in buildings used for public gatherings, must be re-tested periodically by<br />

authorized agents.<br />

Figure A3 shows the frequency <strong>of</strong> testing commonly prescribed according to the<br />

kind <strong>of</strong> <strong>installation</strong> concerned.<br />

Type <strong>of</strong> <strong>installation</strong> Testing<br />

frequency<br />

Installations which b Locations at which a risk <strong>of</strong> degradation, Annually<br />

require the protection fire or explosion exists<br />

<strong>of</strong> employees b Temporary <strong>installation</strong>s at worksites<br />

b Locations at which MV <strong>installation</strong>s exist<br />

b Restrictive conducting locations<br />

where mobile equipment is used<br />

Other cases Every 3 years<br />

Installations in buildings According to the type <strong>of</strong> establishment From one to<br />

used for public gatherings, and its capacity for receiving the public three years<br />

where protection against<br />

the risks <strong>of</strong> fire and panic<br />

are required<br />

Residential According to local regulations<br />

Fig A3 : Frequency <strong>of</strong> check-tests commonly recommended for an <strong>electrical</strong> <strong>installation</strong><br />

2.7 Conformity (with standards and specifications)<br />

<strong>of</strong> equipment used in the <strong>installation</strong><br />

Attestation <strong>of</strong> conformity<br />

The conformity <strong>of</strong> equipment with the relevant standards can be attested:<br />

b By an <strong>of</strong>ficial mark <strong>of</strong> conformity granted by the certification body concerned, or<br />

b By a certificate <strong>of</strong> conformity issued by a certification body, or<br />

b By a declaration <strong>of</strong> conformity from the manufacturer<br />

The first two solutions are generally not available for high voltage equipment.<br />

Declaration <strong>of</strong> conformity<br />

Where the equipment is to be used by skilled or instructed persons, the<br />

manufacturer’s declaration <strong>of</strong> conformity (included in the technical documentation),<br />

is generally recognized as a valid attestation. Where the competence <strong>of</strong> the<br />

manufacturer is in doubt, a certificate <strong>of</strong> conformity can reinforce the manufacturer’s<br />

declaration.<br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008<br />

A7<br />

© Schneider Electric - all rights reserved

© Schneider Electric - all rights reserved<br />

A8<br />

A - <strong>General</strong> <strong>rules</strong> <strong>of</strong> <strong>electrical</strong> <strong>installation</strong> <strong>design</strong><br />

2 Rules and statutory regulations<br />

Note: CE marking<br />

In Europe, the European directives require the manufacturer or his authorized<br />

representative to affix the CE marking on his own responsibility. It means that:<br />

b The product meets the legal requirements<br />

b It is presumed to be marketable in Europe<br />

The CE marking is neither a mark <strong>of</strong> origin nor a mark <strong>of</strong> conformity.<br />

Mark <strong>of</strong> conformity<br />

Marks <strong>of</strong> conformity are affixed on appliances and equipment generally used by<br />

ordinary non instructed people (e.g in the field <strong>of</strong> domestic appliances). A mark <strong>of</strong><br />

conformity is delivered by certification body if the equipment meet the requirements<br />

from an applicable standard and after verification <strong>of</strong> the manufacturer’s quality<br />

management system.<br />

Certification <strong>of</strong> Quality<br />

The standards define several methods <strong>of</strong> quality assurance which correspond to<br />

different situations rather than to different levels <strong>of</strong> quality.<br />

Assurance<br />

A laboratory for testing samples cannot certify the conformity <strong>of</strong> an entire production<br />

run: these tests are called type tests. In some tests for conformity to standards,<br />

the samples are destroyed (tests on fuses, for example).<br />

Only the manufacturer can certify that the fabricated products have, in fact,<br />

the characteristics stated.<br />

Quality assurance certification is intended to complete the initial declaration or<br />

certification <strong>of</strong> conformity.<br />

As pro<strong>of</strong> that all the necessary measures have been taken for assuring the quality <strong>of</strong><br />

production, the manufacturer obtains certification <strong>of</strong> the quality control system which<br />

monitors the fabrication <strong>of</strong> the product concerned. These certificates are issued<br />

by organizations specializing in quality control, and are based on the international<br />

standard ISO 9001: 2000.<br />

These standards define three model systems <strong>of</strong> quality assurance control<br />

corresponding to different situations rather than to different levels <strong>of</strong> quality:<br />

b Model 3 defines assurance <strong>of</strong> quality by inspection and checking <strong>of</strong> final products.<br />

b Model 2 includes, in addition to checking <strong>of</strong> the final product, verification <strong>of</strong> the<br />

manufacturing process. For example, this method is applied, to the manufacturer <strong>of</strong><br />

fuses where performance characteristics cannot be checked without destroying the<br />

fuse.<br />

b Model 1 corresponds to model 2, but with the additional requirement that the<br />

quality <strong>of</strong> the <strong>design</strong> process must be rigorously scrutinized; for example, where it is<br />

not intended to fabricate and test a prototype (case <strong>of</strong> a custom-built product made to<br />

specification).<br />

2.8 Environment<br />

Environmental management systems can be certified by an independent body if they<br />

meet requirements given in ISO 14001. This type <strong>of</strong> certification mainly concerns<br />

industrial settings but can also be granted to places where products are <strong>design</strong>ed.<br />

A product environmental <strong>design</strong> sometimes called “eco-<strong>design</strong>” is an approach <strong>of</strong><br />

sustainable development with the objective <strong>of</strong> <strong>design</strong>ing products/services best<br />

meeting the customers’ requirements while reducing their environmental impact<br />

over their whole life cycle. The methodologies used for this purpose lead to choose<br />

equipment’s architecture together with components and materials taking into account<br />

the influence <strong>of</strong> a product on the environment along its life cycle (from extraction <strong>of</strong><br />

raw materials to scrap) i.e. production, transport, distribution, end <strong>of</strong> life etc.<br />

In Europe two Directives have been published, they are called:<br />

b RoHS Directive (Restriction <strong>of</strong> Hazardous Substances) coming into force on<br />

July 2006 (the coming into force was on February 13th , 2003, and the application<br />

date is July 1st , 2006) aims to eliminate from products six hazardous substances:<br />

lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBB) or<br />

polybrominated diphenyl ethers (PBDE).<br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008

A - <strong>General</strong> <strong>rules</strong> <strong>of</strong> <strong>electrical</strong> <strong>installation</strong> <strong>design</strong><br />

2 Rules and statutory regulations<br />

b WEEE Directive (Waste <strong>of</strong> Electrical and Electronic Equipment) coming into<br />

force in August 2005 (the coming into force was on February 13 th , 2003, and<br />

the application date is August 13 th , 2005) in order to master the end <strong>of</strong> life and<br />

treatments for household and non household equipment.<br />

In other parts <strong>of</strong> the world some new legislation will follow the same objectives.<br />

In addition to manufacturers action in favour <strong>of</strong> products eco-<strong>design</strong>, the contribution<br />

<strong>of</strong> the whole <strong>electrical</strong> <strong>installation</strong> to sustainable development can be significantly<br />

improved through the <strong>design</strong> <strong>of</strong> the <strong>installation</strong>. Actually, it has been shown that an<br />

optimised <strong>design</strong> <strong>of</strong> the <strong>installation</strong>, taking into account operation conditions, MV/LV<br />

substations location and distribution structure (switchboards, busways, cables),<br />

can reduce substantially environmental impacts (raw material depletion, energy<br />

depletion, end <strong>of</strong> life)<br />

See chapter D about location <strong>of</strong> the substation and the main LV switchboard.<br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008<br />

A9<br />

© Schneider Electric - all rights reserved

A10<br />

© Schneider Electric - all rights reserved<br />

A - <strong>General</strong> <strong>rules</strong> <strong>of</strong> <strong>electrical</strong> <strong>installation</strong> <strong>design</strong><br />

An examination <strong>of</strong> the actual apparentpower<br />

demands <strong>of</strong> different loads: a<br />

necessary preliminary step in the <strong>design</strong> <strong>of</strong> a<br />

LV <strong>installation</strong><br />

The nominal power in kW (Pn) <strong>of</strong> a motor<br />

indicates its rated equivalent mechanical power<br />

output.<br />

The apparent power in kVA (Pa) supplied to<br />

the motor is a function <strong>of</strong> the output, the motor<br />

efficiency and the power factor.<br />

Pa = Pn<br />

ηcosϕ 3 Installed power loads -<br />

Characteristics<br />

The examination <strong>of</strong> actual values <strong>of</strong> apparent-power required by each load enables<br />

the establishment <strong>of</strong>:<br />

b A declared power demand which determines the contract for the supply <strong>of</strong> energy<br />

b The rating <strong>of</strong> the MV/LV transformer, where applicable (allowing for expected<br />

increased load)<br />

b Levels <strong>of</strong> load current at each distribution board<br />

3.1 Induction motors<br />

Current demand<br />

The full-load current Ia supplied to the motor is given by the following formulae:<br />

b 3-phase motor: Ia = Pn x 1,000 / (√3 x U x η x cos ϕ)<br />

b 1-phase motor: Ia = Pn x 1,000 / (U x η x cos ϕ)<br />

where<br />

Ia: current demand (in amps)<br />

Pn: nominal power (in kW)<br />

U: voltage between phases for 3-phase motors and voltage between the terminals<br />

for single-phase motors (in volts). A single-phase motor may be connected phase-toneutral<br />

or phase-to-phase.<br />

η: per-unit efficiency, i.e. output kW / input kW<br />

cos ϕ: power factor, i.e. kW input / kVA input<br />

Subtransient current and protection setting<br />

b Subtransient current peak value can be very high ; typical value is about 12<br />

to 15 times the rms rated value Inm. Sometimes this value can reach 25 times Inm.<br />

b Merlin Gerin circuit-breakers, Telemecanique contactors and thermal relays are<br />

<strong>design</strong>ed to withstand motor starts with very high subtransient current (subtransient<br />

peak value can be up to 19 times the rms rated value Inm).<br />

b If unexpected tripping <strong>of</strong> the overcurrent protection occurs during starting, this<br />

means the starting current exceeds the normal limits. As a result, some maximum<br />

switchgear withstands can be reached, life time can be reduced and even some<br />

devices can be destroyed. In order to avoid such a situation, oversizing <strong>of</strong> the<br />

switchgear must be considered.<br />

b Merlin Gerin and Telemecanique switchgears are <strong>design</strong>ed to ensure the<br />

protection <strong>of</strong> motor starters against short-circuits. According to the risk, tables show<br />

the combination <strong>of</strong> circuit-breaker, contactor and thermal relay to obtain type 1 or<br />

type 2 coordination (see chapter N).<br />

Motor starting current<br />

Although high efficiency motors can be found on the market, in practice their starting<br />

currents are roughly the same as some <strong>of</strong> standard motors.<br />

The use <strong>of</strong> start-delta starter, static s<strong>of</strong>t start unit or variable speed drive allows to<br />

reduce the value <strong>of</strong> the starting current (Example : 4 Ia instead <strong>of</strong> 7.5 Ia).<br />

Compensation <strong>of</strong> reactive-power (kvar) supplied to induction motors<br />

It is generally advantageous for technical and financial reasons to reduce the current<br />

supplied to induction motors. This can be achieved by using capacitors without<br />

affecting the power output <strong>of</strong> the motors.<br />

The application <strong>of</strong> this principle to the operation <strong>of</strong> induction motors is generally<br />

referred to as “power-factor improvement” or “power-factor correction”.<br />

As discussed in chapter L, the apparent power (kVA) supplied to an induction motor<br />

can be significantly reduced by the use <strong>of</strong> shunt-connected capacitors. Reduction<br />

<strong>of</strong> input kVA means a corresponding reduction <strong>of</strong> input current (since the voltage<br />

remains constant).<br />

Compensation <strong>of</strong> reactive-power is particularly advised for motors that operate for<br />

long periods at reduced power.<br />

kW input<br />

As noted above cos � = so so that a kVA input reduction in will kVA increase input will<br />

kVA input<br />

increase (i.e. improve) (i.e. improve) the value the <strong>of</strong> cos value ϕ. <strong>of</strong> cos<br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008

A - <strong>General</strong> <strong>rules</strong> <strong>of</strong> <strong>electrical</strong> <strong>installation</strong> <strong>design</strong><br />

3 Installed power loads -<br />

Characteristics<br />

The current supplied to the motor, after power-factor correction, is given by:<br />

cos �<br />

I=<br />

Ia<br />

cos �'<br />

where cos �ϕ<br />

is the power factor before compensation and cos ϕ’ is the power factor<br />

after compensation, Ia being the original current.<br />

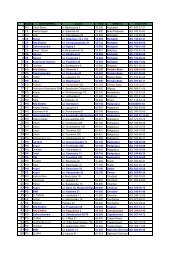

Figure A4 below shows, in function <strong>of</strong> motor rated power, standard motor current<br />

values for several voltage supplies.<br />

kW hp 230 V 380 - 400 V 440 - 500 V 690 V<br />

415 V 480 V<br />

A A A A A A<br />

0.18 - 1.0 - 0.6 - 0.48 0.35<br />

0.25 - 1.5 - 0.85 - 0.68 0.49<br />

0.37 - 1.9 - 1.1 - 0.88 0.64<br />

- 1/2 - 1.3 - 1.1 - -<br />

0.55 - 2.6 - 1.5 - 1.2 0.87<br />

- 3/4 - 1.8 - 1.6 - -<br />

- 1 - 2.3 - 2.1 - -<br />

0.75 - 3.3 - 1.9 - 1.5 1.1<br />

1.1 - 4.7 - 2.7 - 2.2 1.6<br />

- 1-1/2 - 3.3 - 3.0 - -<br />

- 2 - 4.3 - 3.4 - -<br />

1.5 - 6.3 - 3.6 - 2.9 2.1<br />

2.2 - 8.5 - 4.9 - 3.9 2.8<br />

- 3 - 6.1 - 4.8 - -<br />

3.0 - 11.3 - 6.5 - 5.2 3.8<br />

3.7 - - - - - - -<br />

4 - 15 9.7 8.5 7.6 6.8 4.9<br />

5.5 - 20 - 11.5 - 9.2 6.7<br />

- 7-1/2 - 14.0 - 11.0 - -<br />

- 10 - 18.0 - 14.0 - -<br />

7.5 - 27 - 15.5 - 12.4 8.9<br />

11 - 38.0 - 22.0 - 17.6 12.8<br />

- 15 - 27.0 - 21.0 - -<br />

- 20 - 34.0 - 27.0 - -<br />

15 - 51 - 29 - 23 17<br />

18.5 - 61 - 35 - 28 21<br />

- 25 - 44 - 34 -<br />

22 - 72 - 41 - 33 24<br />

- 30 - 51 - 40 - -<br />

- 40 - 66 - 52 - -<br />

30 - 96 - 55 - 44 32<br />

37 - 115 - 66 - 53 39<br />

- 50 - 83 - 65 - -<br />

- 60 - 103 - 77 - -<br />

45 - 140 - 80 - 64 47<br />

55 - 169 - 97 - 78 57<br />

- 75 - 128 - 96 - -<br />

- 100 - 165 - 124 - -<br />

75 - 230 - 132 - 106 77<br />

90 - 278 - 160 - 128 93<br />

- 125 - 208 - 156 - -<br />

110 - 340 - 195 156 113<br />

- 150 - 240 - 180 - -<br />

132 - 400 - 230 - 184 134<br />

- 200 - 320 - 240 - -<br />

150 - - - - - - -<br />

160 - 487 - 280 - 224 162<br />

185 - - - - - - -<br />

- 250 - 403 - 302 - -<br />

200 - 609 - 350 - 280 203<br />

220 - - - - - - -<br />

- 300 - 482 - 361 - -<br />

250 - 748 - 430 - 344 250<br />

280 - - - - - - -<br />

- 350 - 560 - 414 - -<br />

- 400 - 636 - 474 - -<br />

300 - - - - - - -<br />

Fig. A4 : Rated operational power and currents (continued on next page)<br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008<br />

A11<br />

© Schneider Electric - all rights reserved

A12<br />

© Schneider Electric - all rights reserved<br />

A - <strong>General</strong> <strong>rules</strong> <strong>of</strong> <strong>electrical</strong> <strong>installation</strong> <strong>design</strong><br />

3 Installed power loads -<br />

Characteristics<br />

kW hp 230 V 380 - 400 V 440 - 500 V 690 V<br />

415 V 480 V<br />

A A A A A A<br />

315 - 940 - 540 - 432 313<br />

- 540 - - - 515 - -<br />

335 - - - - - - -<br />

355 - 1061 - 610 - 488 354<br />

- 500 - 786 - 590 - -<br />

375 - - - - - - -<br />

400 - 1200 - 690 - 552 400<br />

425 - - - - - - -<br />

450 - - - - - - -<br />

475 - - - - - - -<br />

500 - 1478 - 850 - 680 493<br />

530 - - - - - - -<br />

560 - 1652 - 950 - 760 551<br />

600 - - - - - - -<br />

630 - 1844 - 1060 - 848 615<br />

670 - - - - - - -<br />

710 - 2070 - 1190 - 952 690<br />

750 - - - - - - -<br />

800 - 2340 - 1346 - 1076 780<br />

850 - - - - - - -<br />

900 - 2640 - 1518 - 1214 880<br />

950 - - - - - - -<br />

1000 - 2910 - 1673 - 1339 970<br />

Fig. A4 : Rated operational power and currents (concluded)<br />

3.2 Resistive-type heating appliances and<br />

incandescent lamps (conventional or halogen)<br />

The current demand <strong>of</strong> a heating appliance or an incandescent lamp is easily<br />

obtained from the nominal power Pn quoted by the manufacturer (i.e. cos ϕ = 1)<br />

(see Fig. A5).<br />

Fig. A5 : Current demands <strong>of</strong> resistive heating and incandescent lighting (conventional or<br />

halogen) appliances<br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008<br />

Nominal Current demand (A)<br />

power 1-phase 1-phase 3-phase 3-phase<br />

(kW) 127 V 230 V 230 V 400 V<br />

0.1 0.79 0.43 0.25 0.14<br />

0.2 1.58 0.87 0.50 0.29<br />

0.5 3.94 2.17 1.26 0.72<br />

1 7.9 4.35 2.51 1.44<br />

1.5 11.8 6.52 3.77 2.17<br />

2 15.8 8.70 5.02 2.89<br />

2.5 19.7 10.9 6.28 3.61<br />

3 23.6 13 7.53 4.33<br />

3.5 27.6 15.2 8.72 5.05<br />

4 31.5 17.4 10 5.77<br />

4.5 35.4 19.6 11.3 6.5<br />

5 39.4 21.7 12.6 7.22<br />

6 47.2 26.1 15.1 8.66<br />

7 55.1 30.4 17.6 10.1<br />

8 63 34.8 20.1 11.5<br />

9 71 39.1 22.6 13<br />

10 79 43.5 25.1 14.4

A - <strong>General</strong> <strong>rules</strong> <strong>of</strong> <strong>electrical</strong> <strong>installation</strong> <strong>design</strong><br />

(1) Ia in amps; U in volts. Pn is in watts. If Pn is in kW, then<br />

multiply the equation by 1,000<br />

(2) “Power-factor correction” is <strong>of</strong>ten referred to as<br />

“compensation” in discharge-lighting-tube terminology.<br />

Cos ϕ is approximately 0.95 (the zero values <strong>of</strong> V and I<br />

are almost in phase) but the power factor is 0.5 due to the<br />

impulsive form <strong>of</strong> the current, the peak <strong>of</strong> which occurs “late”<br />

in each half cycle<br />

3 Installed power loads -<br />

Characteristics<br />

The currents are given by:<br />

b 3-phase case: I a = Pn<br />

3 U<br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008<br />

(1)<br />

(1)<br />

b 1-phase case: I a = Pn<br />

U<br />

where U is the voltage between the terminals <strong>of</strong> the equipment.<br />

where U is the voltage between the terminals <strong>of</strong> the equipment.<br />

For an incandescent lamp, the use <strong>of</strong> halogen gas allows a more concentrated light<br />

source. The light output is increased and the lifetime <strong>of</strong> the lamp is doubled.<br />

Note: At the instant <strong>of</strong> switching on, the cold filament gives rise to a very brief but<br />

intense peak <strong>of</strong> current.<br />

Fluorescent lamps and related equipment<br />

The power Pn (watts) indicated on the tube <strong>of</strong> a fluorescent lamp does not include<br />

the power dissipated in the ballast.<br />

The current is is given by: by:<br />

P +<br />

I a = ballast Pn<br />

U cos �<br />

If no power-loss value is indicated for the ballast, a figure <strong>of</strong> 25% <strong>of</strong> Pn may be used.<br />

Where U = the voltage applied to the lamp, complete with its related equipment.<br />

If no power-loss value is indicated for the ballast, a figure <strong>of</strong> 25% <strong>of</strong> Pn may be used.<br />

Standard tubular fluorescent lamps<br />

With (unless otherwise indicated):<br />

b cos ϕ = 0.6 with no power factor (PF) correction (2) capacitor<br />

b cos ϕ = 0.86 with PF correction (2) (single or twin tubes)<br />

b cos ϕ = 0.96 for electronic ballast.<br />

If no power-loss value is indicated for the ballast, a figure <strong>of</strong> 25% <strong>of</strong> Pn may be used.<br />

Figure A6 gives these values for different arrangements <strong>of</strong> ballast.<br />

Arrangement Tube power Current (A) at 230 V Tube<br />

<strong>of</strong> lamps, starters (W) (3) Magnetic ballast Electronic length<br />

and ballasts ballast (cm)<br />

Without PF With PF<br />

correction correction<br />

capacitor capacitor<br />

Single tube 18 0.20 0.14 0.10 60<br />

36 0.33 0.23 0.18 120<br />

58 0.50 0.36 0.28 150<br />

Twin tubes 2 x 18 0.28 0.18 60<br />

2 x 36 0.46 0.35 120<br />

2 x 58 0.72 0.52 150<br />

(3) Power in watts marked on tube<br />

Fig. A6 : Current demands and power consumption <strong>of</strong> commonly-dimensioned fluorescent<br />

lighting tubes (at 230 V-50 Hz)<br />

Compact fluorescent lamps<br />

Compact fluorescent lamps have the same characteristics <strong>of</strong> economy and long life<br />

as classical tubes. They are commonly used in public places which are permanently<br />

illuminated (for example: corridors, hallways, bars, etc.) and can be mounted in<br />

situations otherwise illuminated by incandescent lamps (see Fig. A7 next page).<br />

A13<br />

© Schneider Electric - all rights reserved

A14<br />

© Schneider Electric - all rights reserved<br />

A - <strong>General</strong> <strong>rules</strong> <strong>of</strong> <strong>electrical</strong> <strong>installation</strong> <strong>design</strong><br />

The power in watts indicated on the tube <strong>of</strong><br />

a discharge lamp does not include the power<br />

dissipated in the ballast.<br />

Fig. A8 : Current demands <strong>of</strong> discharge lamps<br />

3 Installed power loads -<br />

Characteristics<br />

Fig. A7 : Current demands and power consumption <strong>of</strong> compact fluorescent lamps (at 230 V - 50 Hz)<br />

Discharge lamps<br />

Schneider Electric - Electrical <strong>installation</strong> guide 2008<br />

Type <strong>of</strong> lamp Lamp power Current at 230 V<br />

(W) (A)<br />

Separated 10 0.080<br />

ballast lamp 18 0.110<br />

26 0.150<br />

Integrated 8 0.075<br />

ballast lamp 11 0.095<br />

16 0.125<br />

21 0.170<br />

Figure A8 gives the current taken by a complete unit, including all associated<br />

ancillary equipment.<br />

These lamps depend on the luminous <strong>electrical</strong> discharge through a gas or vapour<br />

<strong>of</strong> a metallic compound, which is contained in a hermetically-sealed transparent<br />

envelope at a pre-determined pressure. These lamps have a long start-up time,<br />

during which the current Ia is greater than the nominal current In. Power and current<br />

demands are given for different types <strong>of</strong> lamp (typical average values which may<br />

differ slightly from one manufacturer to another).<br />

Type <strong>of</strong> Power Current In(A) Starting Luminous Average Utilization<br />

lamp (W) demand PF not PF Ia/In Period efficiency timelife <strong>of</strong><br />

(W) at corrected corrected (mins) (lumens lamp (h)<br />

230 V 400 V 230 V 400 V 230 V 400 V per watt)<br />

High-pressure sodium vapour lamps<br />

50 60 0.76 0.3 1.4 to 1.6 4 to 6 80 to 120 9000 b Lighting <strong>of</strong><br />

70 80 1 0.45 large halls<br />

100 115 1.2 0.65 b Outdoor spaces<br />

150 168 1.8 0.85 b Public lighting<br />

250 274 3 1.4<br />

400 431 4.4 2.2<br />

1000 1055 10.45 4.9<br />

Low-pressure sodium vapour lamps<br />

26 34.5 0.45 0.17 1.1 to 1.3 7 to 15 100 to 200 8000 b Lighting <strong>of</strong><br />

36 46.5 0.22 to 12000 autoroutes<br />

66 80.5 0.39 b Security lighting,<br />

91 105.5 0.49 station<br />

131 154 0.69 b Platform, storage<br />

areas<br />

Mercury vapour + metal halide (also called metal-iodide)<br />

70 80.5 1 0.40 1.7 3 to 5 70 to 90 6000 b Lighting <strong>of</strong> very<br />

150 172 1.80 0.88 6000 large areas by<br />

250 276 2.10 1.35 6000 projectors (for<br />

400 425 3.40 2.15 6000 example: sports<br />

1000 1046 8.25 5.30 6000 stadiums, etc.)<br />

2000 2092 2052 16.50 8.60 10.50 6 2000<br />

Mercury vapour + fluorescent substance (fluorescent bulb)<br />

50 57 0.6 0.30 1.7 to 2 3 to 6 40 to 60 8000 b Workshops<br />

80 90 0.8 0.45 to 12000 with very high<br />

125 141 1.15 0.70 ceilings (halls,<br />

250 268 2.15 1.35 hangars)<br />

400 421 3.25 2.15 b Outdoor lighting<br />

700 731 5.4 3.85 b Low light output (1)<br />

1000 1046 8.25 5.30<br />