Microchip Manufacturing

Microchip Manufacturing

Microchip Manufacturing

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Silicon Nitride (Si 3 N 4 ) Deposition<br />

Process and the Virtual Chemical<br />

Vapor Deposition Program

Chemical Vapor Deposition A Closer Look: Si 3 N 4<br />

Overall Reaction:<br />

3 SiCl 2 H 2 (g) + 10 NH 3 (g) Si 3 N 4 (s)<br />

Dichlorosilane<br />

(DCS)<br />

Ammonia<br />

Silicon<br />

nitride<br />

+<br />

6 NH 4 Cl (g) +<br />

Ammonium chloride<br />

6 H 2 (g)<br />

Hydrogen<br />

NH 3 (gas)<br />

NH 4 Cl (gas)<br />

H 2 (gas) SiCl 2 H 2 (gas)<br />

Silicon<br />

nitride<br />

SiCl 2 H 2 (gas)<br />

NH 3 (gas)<br />

Graphics copy-write Pro. Milo Koretsky, Chemical Engineering Department at OSU<br />

Photo Courtesy of Silicon Run Educational Video

Chemical Vapor Deposition A Closer Look:<br />

Factors that Effect Film Thickness and Uniformity<br />

• Absolute flow rates of ammonia<br />

to DCS<br />

• Ratio of ammonia to DCS (fixed)<br />

• Temperature (5 zones)<br />

• Reaction time<br />

• Pressure (fixed)<br />

We’ll explore the results of changing<br />

some of these factors.<br />

DCS (gas)<br />

NH 3 (gas)<br />

NH 4 Cl (gas)<br />

H 2 (gas)<br />

NH 3 (gas)<br />

DCS (gas)<br />

Thickness<br />

Film<br />

Substrate

Virtual CVD Overview<br />

Choosing the Virtual CVD reactor parameters<br />

Pressure<br />

is Fixed<br />

Each run costs $

Film Thickness [A]<br />

Film Thickness [A]<br />

Measurement – Thickness & Uniformity<br />

• Film thickness is determined by the amount of material<br />

that reacts and is grown on the wafer<br />

• Uniformity describes the evenness of film thickness on<br />

the wafer<br />

45% Uniformity 100% Uniformity<br />

1000<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

0<br />

-150 -50 50 150<br />

x position<br />

800<br />

600<br />

400<br />

200<br />

0<br />

-150 -50 50 150<br />

x position

Wafer #<br />

Measurement – Thickness & Uniformity<br />

• Film thickness is determined by the amount of material<br />

that reacts and is grown on the wafer<br />

• Uniformity describes the evenness of film thickness on<br />

the wafer<br />

NH 4 Cl (gas)<br />

H 2 (gas)<br />

NH 3 (gas)<br />

200<br />

150<br />

50% Overall Efficiency<br />

SiCl 2 H 2 (gas)<br />

0<br />

100<br />

50<br />

SiCl 2 H 2 (gas)<br />

NH 3 (gas)<br />

79% Overall Efficiency<br />

0 2000 4000 6000 8000 10000<br />

Thickness [A]

Measurement via Ellipsometer<br />

• The ellipsometer is used to measure the<br />

thickness and refractive index of<br />

transparent films.<br />

• It is made of a light source and polarizer<br />

on one side and a analyzer and detector<br />

on the other side.<br />

Detector<br />

Analyzing<br />

Polarizer<br />

Substrate<br />

Light Control<br />

Light Source<br />

Polarizing<br />

Sheet<br />

Analyzer &<br />

Detector<br />

Light Source,<br />

Control &<br />

Polarizing<br />

Sheet<br />

• Light from the source is polarized<br />

and reflected off the film.<br />

• The analyzer is rotated till no light<br />

passes through it.<br />

• The angle of rotation depends on the<br />

thickness of the film.

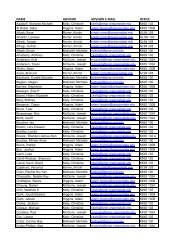

Virtual CVD Overview<br />

Choosing the locations on the wafer to measure<br />

Each measurement costs $

Virtual Chemical Vapor Deposition<br />

(VCVD) Program<br />

VCVD Program<br />

Semiconductor <strong>Manufacturing</strong> Fab<br />

Photo Courtesy of http://webmedia.national.com/gallery/06/06_rgb.jpg

Your Objectives:<br />

•Optimize “Recipe”<br />

◦high uniformity (within wafer and between wafers)<br />

◦meets a target thickness of 1000 Angstroms<br />

•Minimize Cost

Let’s Get Started<br />

•Open VCVD Program...