(JBED) - Summer 2006 - The Whole Building Design Guide

(JBED) - Summer 2006 - The Whole Building Design Guide

(JBED) - Summer 2006 - The Whole Building Design Guide

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>JBED</strong><br />

<strong>Summer</strong> <strong>2006</strong><br />

Journal of <strong>Building</strong> Enclosure <strong>Design</strong><br />

An official publication of the <strong>Building</strong> Enclosure Technology and Environment<br />

Council (BETEC) of the National Institute of <strong>Building</strong> Sciences (NIBS)<br />

PRSRT STD<br />

U.S. Postage<br />

PAID<br />

Pembina, ND<br />

Permit No. 14<br />

Comfort and Productivity:<br />

<strong>The</strong> Fenestration Factor

<strong>JBED</strong><br />

Published For:<br />

NIBS / BETEC<br />

1090 Vermont Avenue, NW, Suite 700<br />

Washington, DC 20005-4905<br />

Phone: (202) 289-7800<br />

Fax: (202) 289-1092<br />

nibs@nibs.org<br />

www.nibs.org<br />

Published by:<br />

MATRIX GROUP PUBLISHING<br />

Please return all undeliverable addresses to:<br />

16516 El Camino Real<br />

Suite 413, Houston, TX 77062<br />

Phone: (866) 999-1299<br />

Fax: (866) 244-2544<br />

PRESIDENT & CEO<br />

Jack Andress<br />

PUBLISHER<br />

Maurice P. LaBorde<br />

mlaborde@matrixgroupinc.net<br />

EDITOR-IN-CHIEF<br />

Shannon Lutter<br />

shannonl@matrixgroupinc.net<br />

EDITOR<br />

Jon Waldman<br />

FINANCE/ACCOUNTING &<br />

ADMINISTRATION<br />

Shoshana Weinberg, Pat Andress<br />

DIRECTOR OF MARKETING &<br />

CIRCULATION<br />

Jim Hamilton<br />

SALES MANAGER<br />

Neil Gottfred<br />

SALES TEAM LEADER<br />

Donna Billey<br />

MATRIX GROUP PUBLISHING<br />

ACCOUNT EXECUTIVES<br />

Andrew Bond, Albert Brydges, Lewis Daigle,<br />

Declan O’Donovan, George Gibson,<br />

David Chew, Pauline McRae, Ken Percival,<br />

Rick Kuzie, Vicki Sutton, Jason Wikis,<br />

Nathan Redekop, Ron Morton, Tammy Davison<br />

ADVERTISING DESIGN<br />

James Robinson<br />

LAYOUT & DESIGN<br />

J. Peters<br />

<strong>2006</strong> Matrix Group Publishing. All rights<br />

reserved. Contents may not be reproduced by<br />

any means, in whole or in part, without the<br />

prior written permission of the publisher. <strong>The</strong><br />

opinions expressed in <strong>JBED</strong> are not necessarily<br />

those of Matrix Group Publishing.<br />

Features:<br />

10<br />

19<br />

26<br />

32<br />

37<br />

39<br />

Dynamic, Integrated Façade<br />

Systems for Energy Efficiency<br />

and Comfort<br />

All That Glass<br />

Architectural Glazing for Sound<br />

Isolation (an Acoustician’s<br />

Perspective)<br />

Occupant <strong>The</strong>rmal Comfort<br />

and Curtain Wall Selection<br />

Window Comfort & Energy<br />

Codes<br />

Messages:<br />

06<br />

08<br />

From NIBS President, David A. Harris<br />

From BETEC Chairman, Wagdy Anis<br />

Industry Updates:<br />

45<br />

46<br />

47<br />

Security<br />

Tax Credits Made Easy by Choosing<br />

ENERGY STAR®<br />

32<br />

39<br />

41<br />

Contents<br />

<strong>The</strong>rmal<br />

Comfort<br />

Laminated Glass, Providing<br />

Security against Terrorist Attacks<br />

How Does Fenestration Fit In<br />

41<br />

Fenestration<br />

Questions<br />

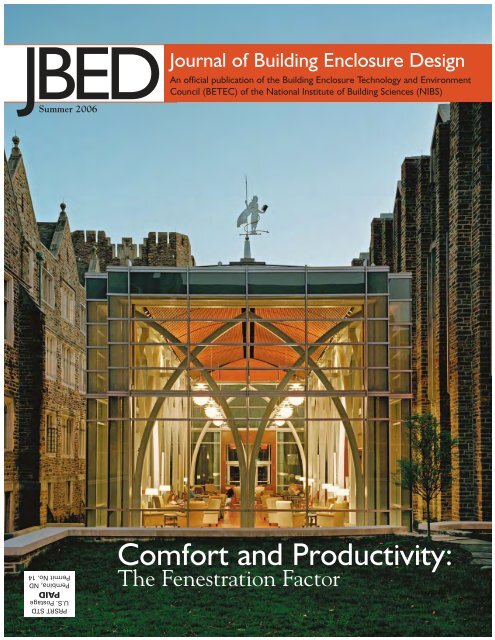

On the cover: <strong>The</strong> glass-<br />

NFRC Standards, Codes and Fenestration<br />

Research Activities<br />

BEC Corner<br />

50 Buyer’s <strong>Guide</strong><br />

enclosed von der Heyden<br />

pavilion at the Perkins Library,<br />

renovated and expanded by<br />

Shepley Bulfinch Richardson and<br />

Abbott at Duke University,<br />

creates transparency by<br />

connecting the interior with<br />

nature and outdoor campus<br />

activity.<br />

Photo by: Albert Vecerka/ESTO.<br />

<strong>Summer</strong> <strong>2006</strong> 5

Message from NIBS<br />

David A. Harris, FAIA<br />

With mold and<br />

other moisturerelated<br />

problems<br />

perpetuating,<br />

energy efficiency<br />

becoming more<br />

critical with<br />

escalating energy<br />

costs, and design<br />

professionals and<br />

constructors in<br />

need of reliable<br />

guidance, <strong>JBED</strong><br />

will fill a critical<br />

void.<br />

WELCOME TO THE JOURNAL OF <strong>Building</strong> Enclosure <strong>Design</strong> (<strong>JBED</strong>)! <strong>The</strong> National<br />

Institute of <strong>Building</strong> Sciences and its <strong>Building</strong> Enclosure Technology and Environment<br />

Council (BETEC) is pleased to team with Matrix Group Publishing to produce<br />

this inaugural issue of the Journal of <strong>Building</strong> Enclosure <strong>Design</strong>. This new and<br />

important magazine will become an essential information source on research and<br />

development issues related to building enclosure systems for North America.<br />

With mold and other moisture-related problems perpetuating, energy efficiency<br />

becoming more critical with escalating energy costs and design professionals<br />

and constructors in need of reliable guidance, <strong>JBED</strong> will fill a critical void.<br />

Through the multi-disciplinary professional members of BETEC and Matrix’s<br />

publishing capabilities, facility professionals across North America will have a new<br />

and reliable source of information through which to improve the performance of<br />

exterior walls, below-grade, roof and fenestration systems and the related impacts<br />

on indoor environments.<br />

NIBS’ and BETEC’s past contributions are featured content of the <strong>Whole</strong><br />

<strong>Building</strong> <strong>Design</strong> <strong>Guide</strong> (www.wbdg.org). <strong>The</strong>y include the results of numerous research<br />

initiatives and symposia, the Envelope <strong>Design</strong> <strong>Guide</strong> and form a substantial<br />

portion of the basis for technical and editorial content of our biannual journal. By<br />

distributing it widely to members of NIBS councils, corporate, government and<br />

association personnel, design and construction professionals, and researchers and<br />

academics throughout Canada and the United States, the value of BETEC’s contributions<br />

will be greatly expanded.<br />

In addition to BETEC’s focus on building enclosure issues, NIBS and its other<br />

councils have, for nearly 30 years, addressed the broad range of facility-related<br />

issues through hundreds of multi-disciplinary and cooperative initiatives. <strong>The</strong>y include<br />

health, safety, security, health care and educational facilities, natural and environmental<br />

hazard assessment and mitigation, information technology, standards<br />

and criteria development, facility life-cycle needs, life-lines research and information<br />

dissemination to name a few. Please visit NIBS website at www.nibs.org. We<br />

encourage your use of our products and seek your participation in our programs.<br />

Together we can successfully improve the performance of the built environment.<br />

We invite our readers to carefully review this inaugural issue and ask you to<br />

let us know how you like it. Please provide critical feed back to Matrix Group<br />

Publishing or NIBS so we can make this publication better and more responsive<br />

to your needs.<br />

David A. Harris, FAIA<br />

President<br />

National Institute of <strong>Building</strong> Sciences<br />

For NIBS membership information, go to www.nibs.org.<br />

WHAT IS NIBS<br />

NIBS is a non-profit, non-governmental organization bringing<br />

together representatives of government, the professions, industry,<br />

labor and consumer interests to focus on the identification and resolution<br />

of problems and potential problems that hamper the construction<br />

of safe, affordable structures for housing, commerce and<br />

industry throughout the United States.<br />

<strong>The</strong> Institute’s board of directors consists of 21 members. Six,<br />

which represent the public interest, are appointed by the President<br />

of the United States with the advice and consent of the U.S. Senate.<br />

<strong>The</strong> remaining 15 members are elected from the nation’s building<br />

community and include consumer and public interest representatives<br />

as well as representatives of industry. A majority of the<br />

NIBS’ board represents public interest sectors as prescribed in the<br />

authorizing legislation.<br />

For more information visit www.nibs.org.<br />

6 Journal of <strong>Building</strong> Enclosure <strong>Design</strong>

Message from BETEC<br />

Wagdy Anis, AIA, LEED A-P<br />

“<strong>The</strong> purpose of<br />

the Councils is to<br />

promote and<br />

encourage<br />

discussion, training,<br />

education,<br />

technology<br />

transfer, the<br />

exchange of<br />

information about<br />

local issues and<br />

cases, relevant<br />

weather conditions,<br />

and all matters<br />

concerning building<br />

enclosures and the<br />

related science.”<br />

WELCOME TO <strong>JBED</strong>, THE JOURNAL of <strong>Building</strong><br />

Enclosure <strong>Design</strong>.<br />

<strong>The</strong> <strong>Building</strong> Enclosure Technology and Environment<br />

Council (BETEC), one of the councils of<br />

the National Institute of <strong>Building</strong> Sciences, along<br />

with Matrix Group Publishing, is pleased to lead<br />

the effort to publish the Journal of <strong>Building</strong> Enclosure<br />

<strong>Design</strong>, <strong>JBED</strong>. This new publication will quickly become<br />

an essential vehicle for the dissemination of<br />

information on research and development issues<br />

related to building enclosure science and technology,<br />

in full alignment with BETEC’s mission.<br />

With losses due to hurricane damage and other<br />

natural disasters, mold affecting and triggering the<br />

burgeoning asthma population, moisture accumulation<br />

determining the durability of enclosures and<br />

shortening their useful service lives, fossil fuel energy<br />

sources becoming threatened and energy<br />

costs escalating and the design and construction<br />

community in need of useful information and guidance,<br />

<strong>JBED</strong> is offered to provide just that. <strong>The</strong><br />

United States represents all the climates of the<br />

world and designing enclosures for each climate<br />

and building use is a challenge this publication<br />

plans to address.<br />

One of BETEC’s important successes in the recent<br />

past is establishing the <strong>Building</strong> Enclosure<br />

Councils or “BECs” in different cities of the US, in<br />

partnership with the American Institute of Architects<br />

(AIA), following the successful precedent set<br />

in Canada. As of this writing, 13 BECs are in place<br />

in most of the climate zones, and at least 6 more<br />

are planned.<br />

I believe the BECs, as they mature, will help<br />

bring building science of the building enclosure to<br />

the mainstream. To contact the BEC’s, go to<br />

www.bec-national.org/ boardchairs.html.<br />

We will be bringing you news and events of the<br />

BECs on a regular basis in this publication through<br />

the “BEC Corner.”<br />

Another recent success of BETEC is the<br />

publishing of NIBS/ASHRAE <strong>Guide</strong>line 3: Commissioning<br />

the <strong>Building</strong> Enclosure. As of this writing, the<br />

publication is available for public review free for a<br />

limited time only, until July 21, <strong>2006</strong>:<br />

www.nibs.org/ GL3.html. For the first time, commissioning<br />

the building enclosure has been organized<br />

as a process, in conjunction with ASHRAE<br />

/NIBS <strong>Guide</strong>line 0, <strong>The</strong> Commissioning Process. This<br />

has been a substantial effort that lasted two years,<br />

and your feedback would be very helpful.<br />

<strong>The</strong> <strong>Building</strong> Enclosure <strong>Design</strong> <strong>Guide</strong>, a huge effort<br />

of over a thousand pages, is now published on<br />

the web as part of the <strong>Whole</strong> <strong>Building</strong> <strong>Design</strong><br />

<strong>Guide</strong>, www.wbdg.org and will be featured in future<br />

editions of <strong>JBED</strong>.<br />

This article will be a vehicle to bring you<br />

BETEC news and its directions in the future.<br />

BETEC membership is open to all organizations<br />

and individuals having an interest in BETEC’s<br />

goals. www.nibs.org/betecmem.html.<br />

We hope you enjoy this edition of <strong>JBED</strong>. Please<br />

send us your opinions and ideas regarding how to<br />

improve it. <strong>The</strong> <strong>JBED</strong> Editorial Board solicits the<br />

articles and submits them for peer review. It is important<br />

to make clear that in no way does NIBS or<br />

BETEC control or review the content or claims<br />

made by advertisers in <strong>JBED</strong>, nor is NIBS, BETEC<br />

or Matrix Group Publishing responsible for the use<br />

or application of any information provided in<br />

<strong>JBED</strong>.<br />

We look forward to hearing from you. Please<br />

encourage anyone you know who may be interested<br />

in receiving a copy of <strong>JBED</strong> to e-mail<br />

jbed@nibs.org.<br />

Thank you,<br />

Wagdy Anis, AIA, LEED A-P<br />

Chairman, BETEC<br />

Chairman, <strong>JBED</strong> Editorial Board<br />

Principal, Shepley Bulfinch Richardson and Abbott<br />

For BETEC membership<br />

information, go to<br />

www.nibs.org/betec<br />

All of Alaska in<br />

Zone 7 except for<br />

the following Borroughs<br />

in Zone 8:<br />

Bethel<br />

Northwest Arctic<br />

Dellingham<br />

Southeast Fairbanks<br />

Fairbanks N. Star<br />

Wade Hampton<br />

Nome<br />

Yukon-Koyukak<br />

North Slope<br />

Zone 1 includes:<br />

Hawaii<br />

Guam<br />

Puerto Rico<br />

<strong>The</strong> Virgin Islands<br />

Warm-humid below the<br />

white line<br />

8 Journal of <strong>Building</strong> Enclosure <strong>Design</strong>

Feature<br />

Dynamic, Integrated Façade Systems<br />

for Energy Efficiency and Comfort<br />

By Stephen Selkowitz and Eleanor Lee,<br />

Lawrence Berkeley National Laboratory<br />

SUMMARY<br />

In a world with growing concerns<br />

about global energy use and carbon emissions,<br />

and with limited short-term options<br />

for increasing renewable energy supplies,<br />

highly energy efficient and sustainable<br />

building design becomes a necessity.<br />

<strong>Building</strong>s use more than 1/3 of all U.S. energy<br />

and more than 2/3 of all electricity—<br />

it is therefore difficult to change national<br />

energy use and carbon emissions without<br />

addressing energy use patterns in buildings.<br />

Architects design buildings with highly<br />

glazed façades in climates worldwide. It is<br />

impossible to “optimize” building performance<br />

with static glazings alone since<br />

sunlight/daylight intensity varies dramatically<br />

with location, orientation, climate<br />

and time. Providing optimal energy efficiency<br />

for owners, and thermal and visual<br />

comfort for occupants, requires dynamic,<br />

interactive façade systems to actively control<br />

solar gain, daylight and glare. Successful<br />

solutions require proper technology<br />

selection, integration between building<br />

systems and optimized sensing and control<br />

strategies.<br />

Although the concepts are well<br />

known, these solutions are not commonly<br />

available today as affordable, specifiable<br />

and reliable packages. We describe recent<br />

project results following several technology<br />

pathways that have made progress toward<br />

the goal of dynamic façade solutions.<br />

Automated motorized blinds and shades,<br />

integrated with a daylight responsive, dimmable<br />

lighting system can provide solutions<br />

today.<br />

Working with the New York Times, a<br />

full-scale mockup of part of a typical floor<br />

of a 52-storey, all-glass building was constructed,<br />

and a variety of interior motorized<br />

roller shades and dimmable lighting<br />

options were extensively simulated,<br />

10 Journal of <strong>Building</strong> Enclosure <strong>Design</strong><br />

tested and optimized. Performance specifications<br />

were developed to guide competitive<br />

procurement and affordable new<br />

systems were developed that will shortly<br />

be installed and commissioned in the<br />

building, for occupancy in 2007. Looking<br />

forward, we also tested and simulated<br />

electrochromic “smart glass” façade prototypes<br />

in three side-by-side full size test<br />

rooms with integrated HVAC and lighting<br />

systems. Energy and demand impacts of<br />

alternate control strategies were also<br />

measured and occupant responses were<br />

also studied.<br />

<strong>The</strong> control and integration results<br />

from both projects demonstrate that dynamic<br />

façade technologies can provide desired<br />

energy performance levels, demand<br />

response and load management, and also<br />

reliably deliver visual and thermal comfort<br />

in indoor workspaces.<br />

INTRODUCTION AND BACKGROUND<br />

<strong>The</strong> “oil shocks” of the 1970s awakened<br />

many people to the realization that<br />

overall energy use in buildings could be<br />

reduced with better design and improved<br />

technology. In a nation where single glazing<br />

was the norm in most buildings, windows<br />

were commonly the thermally<br />

worst element from a perspective of both<br />

heat gain and loss. <strong>The</strong> regulatory response<br />

was typically to minimize window<br />

area and to require thermally improved<br />

technology, i.e. double glazing. <strong>The</strong> immediate<br />

crisis also stimulated a new look at<br />

passive solar heating and daylighting, two<br />

design approaches that attempt to capture<br />

benefits from window performance,<br />

but neither approach reached mainstream<br />

practice before energy availability and<br />

prices stabilized and the design profession<br />

returned to a largely “business-as-usual”<br />

approach.<br />

Thirty years later, new environmental<br />

challenges have made their way to the<br />

newspaper headlines and to the practice<br />

of building design and operations. At any<br />

given time, building designs reflect the influence<br />

of a wide range of issues and<br />

trends. <strong>The</strong>se include not only the technical<br />

constraints of available technologies<br />

but also economic, cultural and business<br />

trends and market drivers. Glass is recognized<br />

as a key element in the architectural<br />

expression of the building, provides occupants<br />

with a visual connection to the outdoors<br />

and provides daylight indoors to enhance<br />

the quality of the interior work<br />

environment. <strong>The</strong> building envelope<br />

serves an important functional role to help<br />

maintain proper interior working environments<br />

under highly variable external environmental<br />

conditions. <strong>The</strong> primary technical<br />

challenges of envelope environmental<br />

control include heating, cooling and lighting<br />

energy use and electric demand, and<br />

the final design decisions impact not only<br />

the owner who pays for the energy use<br />

but society at large due to resource depletion,<br />

carbon emissions, and other related<br />

regional and global environmental impacts.<br />

<strong>The</strong> conventional approach to façade<br />

design in the U.S. has been for the architect<br />

and owner, to determine glazing<br />

areas and orientation, leaving the engineering<br />

team to select a glazing solution<br />

that provides some degree of damage<br />

control using static thermal and solar control<br />

technology. <strong>The</strong> strategy then required<br />

provision of large (typically oversized)<br />

HVAC systems to provide thermal<br />

comfort and provision of interior shading<br />

to manage glare and provide visual comfort.<br />

When highly glazed façades have<br />

been specified in the past the glass selection<br />

was normally heat absorbing and/or<br />

reflective, thus providing some control of<br />

radiant gain but at the expense of daylight.

Prior to the 1980s, most glazing was single<br />

glazed, and although double glazing is now<br />

the dominant glazing choice, many designs<br />

still use thermally unbroken metal framing,<br />

resulting in relatively high conductive/convective<br />

loads that are neutralized<br />

by powerful HVAC systems at the building<br />

perimeter. <strong>The</strong>se peak perimeter zone<br />

heating and cooling loads are often the<br />

major factor in sizing building HVAC systems,<br />

adding significant cost to the building.<br />

Properly operated shades and blinds<br />

might reduce loads, but no engineer<br />

would trust that manual operation would<br />

consistently provide sufficient control to<br />

“rightsize” chillers and HVAC distribution<br />

systems.<br />

A variety of business, market and technical<br />

forces have conspired to change design<br />

practice over the last 20 years. <strong>Building</strong><br />

energy codes and standards have been<br />

tightened, reflecting a growing societal interest<br />

in energy efficient, sustainable designs.<br />

Owners have shown a renewed interest<br />

in providing more comfortable and<br />

productive work environments in the context<br />

of “green buildings”. Glass and façade<br />

manufacturers now offer a wider range of<br />

affordable double glazing system solutions<br />

that provide better thermal and solar control<br />

without sacrificing daylight e.g. spectrally<br />

selective low-E glazings.<br />

<strong>The</strong>se advances came at a fortuitous<br />

time because the growing interest in highly<br />

glazed façades makes new demands on<br />

designers and manufacturers. <strong>The</strong> new<br />

challenge is to provide a fully functional<br />

and integrated façade and lighting system<br />

that operates appropriately under a wide<br />

range of environmental conditions and addresses<br />

the full breadth of occupant subjective<br />

desires as well as objective performance<br />

requirements. <strong>The</strong>se rigorous<br />

performance goals must be achieved with<br />

solutions that are initially affordable and<br />

cost effective and then must operate over<br />

long periods with minimal maintenance if<br />

they are to be accepted and purchased by<br />

building owners. <strong>The</strong> current high level of<br />

uncertainly and risk, both real and perceived,<br />

must be reduced by generating<br />

objective performance data that demonstrates<br />

the viability of these solutions.<br />

In prior studies we used extensive<br />

computer simulation studies to analyze<br />

and optimize the designs of high performance<br />

façades. In this paper we describe<br />

recent results from two field tests of<br />

integrated, high performance façade systems<br />

that, in partnership with manufacturers<br />

and building owners, are contributing<br />

toward reaching these challenging performance<br />

goals.<br />

PERFORMANCE REQUIREMENTS IN<br />

HIGHLY GLAZED BUILDINGS<br />

If all owner, occupant and society<br />

performance needs must be<br />

met with high performance<br />

façades, glazing systems alone will<br />

be inadequate. Glass selection<br />

might provide good performance<br />

where glazing area is judiciously<br />

limited on an orientation basis in<br />

climates that are not severe, but if<br />

one chooses to use large glazed<br />

areas on most orientations in a<br />

wide range of climates then new<br />

performance capabilities must be<br />

added to even the best of today’s<br />

glazing technology.<br />

<strong>The</strong>rmal losses in winter can be addressed<br />

by specifying highly insulated glazings.<br />

A standard, U.S. glazing today is a<br />

double glazed unit with low-E coating and<br />

gas fill, attaining a center glass U-value of<br />

about 1.4 to 1.6 W/m 2 -C in typical constructions.<br />

Even lower conductance levels<br />

may be needed, not so much as an energy<br />

saving strategy but to minimize thermal<br />

discomfort and condensation. Furthermore<br />

the overall conductance of the complete<br />

façade system is typically worse than<br />

the glazing alone since it includes the<br />

metal framing elements and glass edge<br />

conditions, so overall façade conductance<br />

can be 10 per cent to 40 per cent higher<br />

than the glass conductance, depending<br />

upon framing details and glass areas. <strong>The</strong><br />

National Fenestration Rating Council<br />

(NFRC) has developed standardized, accurate<br />

methods to rate the performance<br />

of complete window and façade systems.<br />

Highly insulating glazings still require<br />

additional development but the bigger<br />

challenge is dynamic control of sunlight to<br />

modulate solar gain, daylight, view and<br />

glare. <strong>The</strong>re are two fundamental issues<br />

to address in control of sunlight: 1) the<br />

mechanism(s) to physically control intensity<br />

e.g. absorption, reflection; and 2) the<br />

control logic by which the change in<br />

transmittance is triggered and activated.<br />

Finally one should note the challenge of<br />

simultaneously controlling sunlight admittance<br />

while admitting adequate daylight to<br />

offset electric lighting needs. <strong>The</strong>se control<br />

issues are shown schematically in Figure<br />

1 below. In the remainder of this<br />

paper we focus on the sunlight/daylight<br />

control optimization issue.<br />

Figure 1<br />

Schematic of control logic to manage dynamic window system and dimmable<br />

lighting. A smart controller must be capable of responding effectively to a wide<br />

range of input conditions, shown on the left.<br />

THE CHALLENGE OF DYNAMIC CONTROL OF<br />

SOLAR GAIN AND DAYLIGHT IN ADVANCED<br />

FAÇADES<br />

We explored two pathways for developing<br />

high performance façades that are<br />

fully integrated with automated dimmable<br />

lighting systems, and are responsive to<br />

changing owner and occupant needs. We<br />

first examined technology that is widely<br />

available, although not commonly used,<br />

automated shades and blinds, to provide<br />

dynamic control of solar gain, daylight and<br />

glare. We then looked to the future and<br />

examined the use of emerging “smart<br />

glazings”, specifically electrochromic glazings.<br />

In both cases, integrated daylight<br />

dimming controls are essential to reduce<br />

lighting energy use, and in both cases control<br />

strategies that address occupant<br />

needs for comfort and performance are<br />

balanced against building owner needs to<br />

minimize building operating costs. While<br />

extensive parametric computer simulation<br />

of façade and building performance is a<br />

critical element of these studies, computer<br />

modeling alone is insufficient to address<br />

issues such as glare and subjective response<br />

to the indoor environment, and to<br />

understand and solve problems in a manner<br />

that leads to change in the marketplace.<br />

<strong>The</strong>refore, each of these research<br />

efforts relied on field tests and each includes<br />

studies of human factor issues as<br />

well as engineering optimization.<br />

<strong>Summer</strong> <strong>2006</strong> 11

1. COMMERCIALLY AVAILABLE<br />

SOLUTIONS: AUTOMATED BLINDS<br />

AND SHADES<br />

Blinds and shades are used in most<br />

U.S. buildings today but unlike European<br />

experience, virtually none are motorized<br />

and few are externally mounted. <strong>The</strong> assumption<br />

is that that these shading systems<br />

are available for occupants to control<br />

localized glare and solar gain but they<br />

are not relied on to control building envelope<br />

performance. Accordingly, most energy<br />

standards do not provide any credits<br />

for systems that rely on occupant action<br />

since the response is unknown and uncertain.<br />

Furthermore, engineers will generally<br />

size HVAC systems assuming worst case<br />

operating procedures—e.g. that the shading<br />

systems are not operated as planned.<br />

Large glazed areas, even if heavily tinted<br />

and reflective, may be insufficient to fully<br />

control glare on sunny days.<br />

the U.S., nor are systems that further link<br />

the blinds to dimmable lighting controls.<br />

Beginning with “off the shelf” blind and<br />

lighting components, we developed and<br />

tested an integrated, automated blind and<br />

daylighting system in two identical sideby-side<br />

test rooms in a southeast facing<br />

office building in Oakland, CA (Figures 2.1<br />

and 2.2). Large cooling and lighting energy<br />

savings were achieved, peak electrical savings<br />

were measured and the resultant automated<br />

systems were acceptable to occupants<br />

in a limited occupancy study.<br />

Despite the success of the demonstration,<br />

the lack of a cost-effective delivery system<br />

managed by a single vendor or groups of<br />

vendors continues to limit use of such systems.<br />

<strong>The</strong> project illustrated the market obstacles<br />

from a building owner and manufacturer<br />

perspective in terms of who<br />

serves the “systems integrator” role when<br />

Figures 2.1 and 2.2<br />

Smart controls on the automated blind systems (left photo) keep direct sun out of the space, reducing glare and cooling loads. <strong>The</strong> same hardware<br />

system with different control strategies (right photo) admits sunlight to offset heating loads but creates excessive glare.<br />

AUTOMATED VENETIAN BLIND AND<br />

INTEGRATED DAYLIGHTING SYSTEMS<br />

Venetian blind systems are widely<br />

specified for control of solar gain and<br />

glare. Because both the optical properties<br />

of the slats and their tilt can be controlled,<br />

they provide a wide range of optical and<br />

solar control. But a number of field studies<br />

have shown that manually operated<br />

blinds are rarely controlled in an optimal<br />

manner. Adding sensors and controls and<br />

automating the blind operation should<br />

permit better control of both energy use<br />

and comfort, assuming that the proper<br />

control strategies can be successfully developed,<br />

implemented and maintained.<br />

<strong>The</strong>se integrated, automated control<br />

systems are not yet commonly available in<br />

12 Journal of <strong>Building</strong> Enclosure <strong>Design</strong><br />

the different system elements are provided<br />

from different vendors. Development<br />

of smart, automated blind systems is<br />

more advanced in Europe and Japan. Although<br />

a growing number of these systems<br />

are now being installed in buildings it<br />

is still difficult to find measured performance<br />

data that clearly demonstrates the<br />

overall energy use of such systems.<br />

AUTOMATED MOTORIZED SHADE SYSTEMS<br />

AND INTEGRATED DAYLIGHTING CONTROLS:<br />

NEW YORK TIMES BUILDING<br />

A second widely used operable shading<br />

system is based on roller shades.<br />

Roller shade systems can utilize different<br />

fabrics encompassing a wide range of solar<br />

optical properties, ranging from blackout<br />

shades to highly transmissive veiling<br />

fabrics. Although mechanically simpler<br />

than blinds, once the fabric is chosen the<br />

shade systems have more limited optical<br />

control than blinds, largely based on their<br />

position between up and down. It is possible<br />

to layer blinds or use optically variable<br />

fabrics but this is not common practice.<br />

An extensive field test program was conducted<br />

using an automated shade system<br />

in conjunction with a high transmittance,<br />

all glass façade for the New York Times<br />

headquarters building, now under construction<br />

in New York City. <strong>The</strong> 52-storey,<br />

140,000 m 2 building will utilize fixed exterior<br />

shading and fritted glass in some locations<br />

(Figure 3.1) but will require interior<br />

shades for sun control and glare control<br />

and for thermal and visual comfort as well<br />

as energy management.<br />

<strong>The</strong> exterior of the building utilizes a<br />

transparent floor-to-ceiling, all-glass<br />

façade that encourages openness and<br />

communication with the external world,<br />

consistent with the owner’s dedication to<br />

creating a high quality work environment<br />

for their employees. Low partitions were<br />

used to reinforce the sense of openness<br />

and to let the daylight penetrate deeper<br />

into the space. <strong>The</strong> cruciform floor plan<br />

(Figure 3.2), with distances from interior<br />

offices to façade of less than 7.6 m, permits<br />

view in three directions from most

Figures 3.1 and 3.2<br />

Left (page 12): Exterior view of an all-glass façade and<br />

shading system. Above: cruciform floor plan showing enclosed<br />

offices located toward the core.<br />

locations within the perimeter zone. With<br />

a generous ceiling height, a window-toexterior-wall<br />

ratio of 0.76 and a glazing<br />

transmittance of Tv=0.75, daylight was<br />

anticipated to be abundant throughout the<br />

entire perimeter zone even with the exterior<br />

fixed shading system.<br />

Overall solar heat gain would be a concern<br />

in any highly glazed façade. In this design,<br />

it is controlled with spectrally selective<br />

glazing (the glass solar heat gain<br />

coefficient is 0.39 and the U-factor is 1.53<br />

W/m 2 -°K) and with an array of exterior<br />

fixed ceramic rods designed to block and<br />

diffuse some sunlight as shown above.<br />

Even with these systems, the owner understood<br />

that the transparency of the<br />

façade would generate potential glare and<br />

visibility problems for employees using<br />

computers, so the owner wanted to explore<br />

the use of automated roller shades<br />

as a means of managing window glare. As<br />

well, conventional manually operated interior<br />

shades may have degraded many of<br />

the key design features that made the architectural<br />

design so compelling in the<br />

first place.<br />

<strong>The</strong> building owner had sufficient foresight<br />

to begin addressing these critical<br />

lighting quality and façade issues early<br />

enough in the design process while there<br />

was still time to explore potential dynamic<br />

shading options and to evaluate and<br />

<strong>Summer</strong> <strong>2006</strong> 13

procure them for the final building. A survey<br />

of the marketplace by the design<br />

team did not locate any vendors with<br />

suitable products that fully addressed the<br />

thermal and luminous issues in an affordable,<br />

integrated, and reliable package.<br />

While dimmable lighting and motorized<br />

shades have long been used as niche market<br />

products in corporate boardrooms,<br />

the challenge for the owner was to push<br />

the marketplace to respond with solutions<br />

with new, improved functionality,<br />

suitable for an entire building but at lower<br />

cost.<br />

Based on LBNL’s prior research and<br />

field testing, a partnership was created<br />

between <strong>The</strong> New York Times, its design<br />

team and LBNL to address this problem.<br />

A full-scale 401 m 2 daylighting mockup<br />

was constructed near the building site and<br />

a number of vendors were invited to install<br />

their existing shading and daylighting<br />

equipment. <strong>The</strong> mockup was extensively<br />

monitored by LBNL in partnership with<br />

the vendors over an 18-month field test,<br />

with support from the New York State<br />

Energy and Research and Development<br />

14 Journal of <strong>Building</strong> Enclosure <strong>Design</strong><br />

Authority (NYSERDA).<br />

FAÇADE PERFORMANCE RESULTS FROM THE<br />

NEW YORK TIMES DAYLIGHTING MOCKUP<br />

<strong>The</strong> project was structured around the<br />

availability of this unique full scale mockup.<br />

<strong>The</strong> New York Times mockup test<br />

program was designed to: 1) enable vendors<br />

to demonstrate features of their systems;<br />

2) fine tune their systems to meet<br />

the evolving requirements of the building<br />

owner; and 3) understand the benefits<br />

and limitations of each manufacturer’s approach<br />

to shade management and daylighting<br />

controls. A further objective of<br />

the public agencies supporting the research<br />

was to help broaden the market<br />

interest in these systems and design approaches<br />

with visits to the mockup from<br />

other design firms and owners.<br />

<strong>The</strong> fully furnished, full scale mockup<br />

reproduced the southwest corner of a<br />

typical floor (Figures 4.1 and 4.2). <strong>The</strong><br />

mockup was divided into two test areas.<br />

Two different shade manufacturers and<br />

two different manufacturers of dimmable<br />

lighting systems installed systems in each<br />

area with different types of sensors and<br />

control strategies. <strong>The</strong> objective of the<br />

test was not to perform a side-by-side<br />

comparison of the two “competing” systems<br />

but rather to understand how vendor<br />

decisions regarding control infrastructure<br />

and design might impact actual field<br />

operation. <strong>The</strong> end goal of the monitoring<br />

phase was therefore not the selection of<br />

one or another of the manufacturers’<br />

products in the mockup but the development<br />

of a performance specification that<br />

would be open for bid by any vendor.<br />

Over 100 engineering parameters<br />

Figures 4.1 and 4.2<br />

Photograph of mockup interior (left) and RADI-<br />

ANCE nighttime rendering of the same space<br />

(right). RADIANCE simulations were used to explore<br />

shading and lighting issues for conditions that<br />

could not be tested in the mockup.<br />

were measured continuously (1x/min,<br />

24/7) in the mockup, including lighting energy<br />

use, work plane illuminance and distribution,<br />

various parameters related to<br />

visual comfort, control operations, exterior<br />

solar conditions, and other environmental<br />

parameters. Monitored data was<br />

collected over 9 months from December<br />

21 to September 21 to capture the full<br />

range of solar conditions. During this<br />

time, the manufacturers were permitted<br />

to tune their systems to obtain optimal<br />

performance and improve their designs.<br />

<strong>The</strong> building owner, upon seeing the effect<br />

of their initial control specifications,<br />

tweaked some control settings to obtain a<br />

system that better met their needs. In<br />

some cases, manufacturers altered their<br />

systems in response to interim performance<br />

data from LBNL when it was<br />

demonstrated that the owner’s specifications<br />

were not being met.<br />

At the end of the monitoring period,<br />

<strong>The</strong> New York Times incorporated what<br />

they learned into an open procurement<br />

specification. Procurement specifications<br />

for the lighting controls and for automated<br />

shading systems were let out to all eligible<br />

manufacturers for competitive bidding.<br />

<strong>The</strong> winning vendors were then invited in<br />

a further partnership with <strong>The</strong> New York<br />

Times and LBNL to demonstrate performance<br />

capabilities of their final systems<br />

in the daylighting mockup prior to installation<br />

in the headquarters building. <strong>The</strong> intent<br />

of this approach was to reduce risk<br />

and uncertainty in all aspects of the procurement<br />

process, leading to assured performance<br />

at lower costs, and motivating<br />

manufacturers to extend their product offerings.<br />

More detailed analysis<br />

of technical results<br />

is available on the<br />

LBNL website (see references).<br />

Initial testing<br />

demonstrated that the<br />

window and automated<br />

shade system provided<br />

useful daylight<br />

throughout the 13.4 m<br />

deep perimeter zone,<br />

enabling significant<br />

dimming of the electric<br />

lighting throughout<br />

much of the zone. For<br />

this building design,<br />

with its all-glass façade and minimal interior<br />

obstructions, even on the northwest<br />

side the daily lighting energy savings were<br />

20-40 per cent at 3.4 m from the window<br />

over the nine-month monitored period in<br />

Area A. <strong>The</strong> shading systems were controlled<br />

to provide a bright interior environment<br />

and control window glare. Lighting<br />

energy savings were substantially<br />

greater in zones daylit bilaterally from

oth the south and west façades in Area<br />

B. In this area of the mockup savings averaged<br />

from 50-80 per cent at 3 m from the<br />

façade and still achieved an average of 40<br />

per cent at 6 m.<br />

<strong>The</strong>se daylighting savings were<br />

achieved with a shading control strategy<br />

that consistently blocked direct sunlight<br />

and adverse sky glare but also reduced interior<br />

daylight levels, lighting energy savings,<br />

and access to view. <strong>The</strong> fabrics under<br />

consideration in the roller shade systems<br />

had an openness factor of three per cent<br />

with an associated visible transmittance of<br />

about six per cent.<br />

To extend the test results, extensive<br />

simulation studies of the impact of different<br />

shade control strategies were conducted.<br />

A prototypical virtual floor was<br />

constructed for use with the Radiance<br />

daylighting simulation model. <strong>The</strong> occupants’<br />

view conditions and glare at 22 different<br />

task locations on each floor were<br />

calculated for a lower floor (floor 6) with<br />

extensive external obstructions, and for<br />

floor 26 with largely unobstructed views.<br />

This modeling confirmed that specific<br />

shade fabric choices and control strategies<br />

would influence the magnitude of energy<br />

savings and likelihood of experiencing<br />

glare conditions.<br />

Controlled occupant studies were not<br />

conducted but over 200 Times employees<br />

had a chance to spend time in the mockup.<br />

<strong>The</strong> owner’s employees clearly preferred<br />

the brighter daylit space compared<br />

to the darker, less daylighted spaces that<br />

most currently occupy. <strong>The</strong>y found the<br />

quality of daylight to be palpably different<br />

in the morning versus the afternoon and<br />

were delighted with the subtle shifts in<br />

color, intensity, sparkle and mood<br />

throughout the day.<br />

Glare control and the competing desire<br />

for openness and daylight remains a<br />

challenge. <strong>The</strong> mockup provided very<br />

powerful testing capabilities, allowed extensive<br />

exploration of alternate control<br />

strategies under a range of sun and sky<br />

conditions. Based on both mockup test<br />

results and extended simulations, in the<br />

building the shading systems will be fully<br />

automated to respond to direct sun and<br />

window glare and thus be responsive at<br />

each task location to the specific requirements<br />

of the occupants and work groups,<br />

window orientation, and degree of<br />

<strong>Summer</strong> <strong>2006</strong> 15

obstruction and/or daylight reflection<br />

from the urban surroundings.<br />

<strong>The</strong> automated shading and dimmable<br />

lighting not only provide energy savings<br />

but a demand response potential as well.<br />

Studies are underway to determine how<br />

to use the smart controls to bring the<br />

building to a “low power” mode of operation<br />

that would allow essential building<br />

functions to continue while substantially<br />

reducing overall electric power use on a<br />

hot summer day if the stability of the grid<br />

was threatened. <strong>The</strong> automated shades<br />

and dimmable lighting are a key element<br />

in the demand response strategy. <strong>The</strong> final<br />

step in this project will be to commission<br />

the installed systems and verify that performance<br />

meets the design specifications.<br />

Major construction will be completed in<br />

<strong>2006</strong> with occupancy in 2007.<br />

2. THE ARCHITECTS’ HOLY GRAIL:<br />

SMART GLAZING SYSTEMS<br />

If the dynamic control of transmittance<br />

was incorporated directly into glazing layers,<br />

some of the limitations of motorized<br />

shades and blinds might be avoided. Researchers<br />

have been pursuing the quest<br />

for switchable “smart glazings” for over<br />

20 years and the laboratory accomplishments<br />

are now becoming available for initial<br />

purchase and use in buildings. As with<br />

shades and blinds, the actual energy and<br />

comfort performance in a building will depend<br />

on the interplay of the intrinsic<br />

properties of the materials and the operating<br />

strategy of the building. <strong>The</strong>se operating<br />

strategies must be developed not<br />

only for energy and load control but to<br />

meet occupant needs in terms of comfort<br />

and productivity. As with the shade and<br />

blind studies above, field studies in test<br />

rooms and mockups are an important adjunct<br />

to the extensive computer modeling<br />

studies that have already been completed<br />

to quantify performance benefits and potential<br />

energy savings.<br />

FIELD TESTS OF ELECTROCHROMIC “SMART<br />

WINDOWS”<br />

In 1999, the window systems in the<br />

two test rooms in Oakland were retrofitted<br />

with a first generation electrochromic<br />

window. <strong>The</strong> optical system changed from<br />

a clear state with a transmittance of 51<br />

per cent to a dark state transmission of 11<br />

per cent. <strong>The</strong> system performed well<br />

16 Journal of <strong>Building</strong> Enclosure <strong>Design</strong><br />

although full switching could take in excess<br />

of 15 minutes and the coatings had a<br />

noticeable blue tint in the switched mode.<br />

Detailed technical results are available on<br />

our website.<br />

In 2002 we constructed a new test facility<br />

at LBNL with three side-by-side test<br />

rooms with unobstructed south views.<br />

<strong>The</strong> entire glazed façade (3.5 m x 4 m) for<br />

each room can be replaced. <strong>The</strong> lighting<br />

power and the heating and cooling in each<br />

room is individually monitored and the<br />

rooms have a full array of illuminance and<br />

luminance sensors for monitoring. Two of<br />

the rooms were fitted with electrochromic<br />

samples over the complete<br />

façade as shown in Figure 5. Since the<br />

prototypes were of limited size the current<br />

façade requires 15 glazing panels.<br />

Extensive engineering tests in the facility<br />

were conducted over a two-year period<br />

to explore the energy savings achieved<br />

with different control strategies. We operated<br />

the electrochomics over their full dynamic<br />

range, testing different control<br />

strategies designed to optimize lighting<br />

savings, cooling savings and visual comfort.<br />

We compared lighting and cooling loads<br />

with automated electrochromics to results<br />

from the room with fixed glazing and<br />

shading, with and without daylighting controls.<br />

<strong>The</strong> electrochromic systems were<br />

able to consistently beat the energy use of<br />

the conventional façade design but the detailed<br />

results were highly dependent on<br />

operating assumptions and specific control<br />

strategies. <strong>The</strong> testing focused on the<br />

challenge of the control optimization between<br />

glare control and daylighting energy<br />

savings, with associated studies of cooling<br />

impacts and peak demand impacts.<br />

We also conducted human factor studies<br />

in this facility (Figure 6) to determine<br />

desired operating and control parameters<br />

of the glazing and lighting systems and to<br />

better understand the issues associated<br />

with smart glazing control strategies. Early<br />

results suggest that the lowest transmittance<br />

level of the current glazing prototypes,<br />

three to four per cent, is usually adequate<br />

for most glare situations although<br />

additional glare control was desired by<br />

some occupants. However, switching the<br />

entire façade to very low transmittance<br />

levels to control glare often requires that<br />

electric lights be turned to full power levels.<br />

New architectural design approaches<br />

such as separate vision and daylighting<br />

glazings, as well as improved switching<br />

control strategies were then studied to<br />

address this issue. Initial results show that<br />

it is desirable to divide the façade into two<br />

elements that would be designed and controlled<br />

differently. A lower “vision” window<br />

might have a lower transmittance<br />

and would be designed to manage glare at<br />

a perimeter workspace. This will tend to<br />

have low transmittance values when sun<br />

and sky glare are present so that LCD<br />

screen visibility is not compromised. <strong>The</strong><br />

upper “daylighting” window would have a<br />

higher visible transmittance and be managed<br />

dynamically to control solar gain but<br />

admit adequate daylight so that the primary<br />

room electric lighting is off or<br />

Figure 5<br />

Exterior view of LBNL Façade Test Facility. Two rooms<br />

at left have electrochromic prototypes installed, the room at<br />

right is a control room with spectrally selective glass and<br />

blinds.<br />

Figure 6<br />

Interior photo of façade test room configured for occupant<br />

response testing.

Figures 7.1 and 7.2<br />

CCD photo of workstation (left) and false color luminance<br />

map (right) produced from image at left and 5 additional<br />

photos. Luminance map provides a dynamic<br />

range of 5000:1<br />

dimmed as much as possible. This approach<br />

adds to the design and control<br />

complexity but delivers better amenity<br />

and increased energy savings.<br />

Better tools are needed to quantify the<br />

visual environment in conjunction with<br />

subjective and objective user studies in<br />

these spaces. We have developed new<br />

glare assessment approaches using CCD<br />

images and processing of high dynamic<br />

range image data to quantify, display and<br />

understand these complex environmental<br />

parameters that directly impact occupant<br />

comfort, satisfaction and performance<br />

(Figures 7.1 and 7.2). <strong>The</strong>se techniques<br />

can be used in the field to evaluate existing<br />

buildings as well as in a lab test environment.<br />

CONCLUSIONS<br />

A growing interest in daylighting and<br />

sustainable design has led architects in the<br />

direction of using highly glazed building<br />

façades. Balancing the need for view, glare<br />

control, thermal comfort with solar load<br />

control and daylighting energy savings is a<br />

complex challenge. In order for these designs<br />

to meet often contradictory performance<br />

objectives, they will need to<br />

have a degree of active, reliable management<br />

of solar/optical properties of the<br />

building envelope that has rarely been<br />

consistently and economically achieved in<br />

buildings. Some of the technologies to<br />

provide active control of fenestration<br />

transmittance and associated control of<br />

electric lighting in building interiors are<br />

now available and have been shown to be<br />

capable of good performance and others<br />

will emerge.<br />

However it will take better and cheaper<br />

hardware, additional exploration of systems<br />

integration solutions, new sensors<br />

and controls, improved commissioning, a<br />

better understanding of occupant needs<br />

and preferences, and better real time,<br />

adaptive controls to fully realize the potentials<br />

of these emerging technologies.<br />

Future building envelope design and operations<br />

will be increasingly integrated with<br />

other building systems to achieve these<br />

performance levels.<br />

REFERENCES<br />

Extensive additional information on<br />

these projects can be downloaded from<br />

several LBNL websites:<br />

• References for the New York Times<br />

project can be found at: http://<br />

windows.lbl.gov/comm_perf/newyorktimes.htm.<br />

• References for the Electrochromics<br />

project can be found at: http://windows.<br />

lbl.gov/comm_perf/electrochromic.<br />

• A complete searchable list of LBNL<br />

window and daylighting references,<br />

from which current papers can be<br />

downloaded can be found at:<br />

http://windows.lbl.gov.<br />

ACKNOWLEDGEMENTS<br />

We acknowledge the active support of<br />

numerous LBNL colleagues on the teams<br />

that carried out the projects described<br />

here, and the participation of other partners<br />

and consultants referenced at the<br />

websites above. This work was supported<br />

by the Assistant Secretary for Energy Efficiency<br />

and Renewable Energy, Office of<br />

<strong>Building</strong> Technology, State and Community<br />

Programs, Office of <strong>Building</strong> Systems of<br />

the U.S. Department of Energy under<br />

Contract No. DE-AC03-76SF00098, by<br />

the California Energy Commission, Public<br />

Interest Energy Research Program, and by<br />

the New York State Energy Research and<br />

Development Authority.<br />

■<br />

<strong>Summer</strong> <strong>2006</strong> 17

Feature<br />

All That Glass<br />

Is there an appropriate future for double skin façades<br />

By Donald B. Corner,<br />

Professor of Architecture, University of Oregon<br />

INTRODUCTION<br />

<strong>Building</strong> techniques have been shared<br />

across the Atlantic Ocean for hundreds of<br />

years. Anglo-American settlers preparing<br />

to move westward into the Appalachians<br />

were fortunate to have learned about log<br />

cabins from Scandinavian immigrants. Standardized<br />

2x4 light frame construction traveled<br />

from the United States to Europe and<br />

returned much later as the Swedish factory<br />

crafted house.<br />

In recent years we have seen the first<br />

landings of a new import, the double skin<br />

façade. American architects are attracted<br />

by the appearance and the performance of<br />

double skins, even though the benefits are<br />

hard to quantify. <strong>The</strong>y will pursue this new<br />

option despite a growing body of technical<br />

literature that questions the effectiveness<br />

of the form (Lee, LBNL, <strong>2006</strong>). We have<br />

had the same experience with the opening<br />

example of industrialized housing.<br />

<strong>The</strong>re is a field, littered with well documented<br />

failures, that designers visit again<br />

and again because it is so seductive in concept,<br />

if not reality. <strong>The</strong> double façade is an<br />

equally powerful concept. Thus, American<br />

architects will try on these new enclosures,<br />

and their reasons for doing so will<br />

be as varied as they have been in Europe.<br />

As in Europe, their motivations will go beyond<br />

effective control of daylight and thermal<br />

comfort.<br />

This narrative examines frames of reference<br />

that have shaped European applications<br />

of the double façade and from this<br />

body of experience, outlines a critical perspective<br />

on the future of this technology in<br />

the United States.<br />

façade that is the focus of this paper. Double<br />

skins of any form include an outer<br />

façade, an intermediate space and an inner<br />

façade. <strong>The</strong> outer leaf gives the building<br />

weather protection and acoustic isolation<br />

where high noise levels are present on the<br />

exterior. <strong>The</strong> intermediate space can be<br />

used to buffer thermal impacts on the interior.<br />

Through the use of open slots and<br />

operable dampers in the glass planes, it is<br />

possible to ventilate the interstitial space<br />

on warm days and admit sun warmed air<br />

to the interior rooms on cool days. In<br />

most cases operable shading devices are<br />

placed in the intermediate zone where<br />

they are protected from damage. Double<br />

glazing of the inner façade provides the<br />

optimum thermal barrier, while single glazing<br />

of the outer façade is sufficient to create<br />

the buffer space.<br />

Double skins require the designer to<br />

sort through an imposing array of choices.<br />

A decision tree must include the following<br />

fundamental questions:<br />

• How much of the outer façade is glass<br />

and what is the relationship of that glass<br />

to the primary structure and to the<br />

other elements of building enclosure<br />

• What types of control are needed over<br />

the passage of light, heat, air and sound<br />

at the transparent portions of the<br />

façade<br />

• How will the two façade layers and the<br />

space between them be developed in a<br />

rational and effective construction<br />

strategy<br />

• How will access be provided to clean<br />

the glass and maintain the operable<br />

components located inside the buffer<br />

space<br />

An expansion of these basic points,<br />

prepared by this author, will appear in the<br />

forthcoming <strong>The</strong> Green Studio Handbook<br />

(Kwok and Grondzik, in press). Case studies<br />

and details can be found in widely distributed<br />

European texts (Herzog et. al.,<br />

2005 and Oesterle, 2001).<br />

PLACE AND CULTURE<br />

As elements of architecture, enclosure<br />

A SUMMARY OF DOUBLE SKIN TECHNOLOGY<br />

Double skins are multiple leaf wall assemblies<br />

in the transparent or largely<br />

transparent portions of a building façade.<br />

<strong>The</strong>y range from the vernacular storm<br />

window to the closely coupled, all glass<br />

Figure 1 - Office Block Remodel, Stuttgart, Germany, 1996. Behnisch Sabatke Behnisch.<br />

<strong>Summer</strong> <strong>2006</strong> 19

systems have a significant and fascinating<br />

cultural component. Façade openings in<br />

Europe have always had numerous “switches”<br />

in them, operated by the building<br />

Figure 2 - Hannover Messe A.G., Hannover, Germany,<br />

1999. Thomas Herzog + Partner.<br />

Figure 3 - Helicon <strong>Building</strong>, London, UK, 2000. Sheppard<br />

Robson International.<br />

Figure 4 - Plantation Place, London, UK, 2005. Arup Associates.<br />

Architects.<br />

20 Journal of <strong>Building</strong> Enclosure <strong>Design</strong><br />

user. Traditional windows in Italy have an<br />

outer layer of louvered shutters, glass in a<br />

casement sash, light filtering curtains and a<br />

solid inner shutter of wood. Each can be<br />

deployed to block, filter or admit elements<br />

of the exterior world. In the United States<br />

we have used building technology to eliminate<br />

switches, as insulating glass eliminated<br />

the storm window.<br />

European double façades are expanding<br />

the benefits of switches, using technology<br />

to automate rather than eliminate<br />

them. In commercial buildings a large percentage<br />

of the glass remains operable with<br />

building ventilation coming directly<br />

through the façade. <strong>The</strong> first new applications<br />

of double skins were “re-wraps” of<br />

existing buildings, such that the operable<br />

outer leaf works in tandem with the original<br />

façade to enhance building performance<br />

through both the heating and cooling<br />

seasons (Figure 1). This strategy remains<br />

one of the most cost effective applications<br />

of the double skin.<br />

From these beginnings, the new<br />

façades rapidly progressed to become<br />

spectacularly intricate machines that contribute<br />

to a wide variety of building climate<br />

functions. Thomas Herzog’s Hannover<br />

Messe A.G. is a mature example of a “corridor<br />

façade,” with the inner glass leaf set<br />

back on the floor slab around the entire<br />

perimeter of the occupied space (Figure<br />

2). <strong>The</strong> façade expression is dominated by<br />

its role in the ventilation scheme. With the<br />

service cores removed from the central<br />

block, the buffer space accounts for 22 per<br />

cent of the remaining slab area. This is an<br />

investment in passive strategies that few in<br />

the U.S. would be willing to consider.<br />

<strong>The</strong> quality and performance expected<br />

of German buildings is part of their culture<br />

and manifest in their regulatory system.<br />

Office buildings must provide workers<br />

with daylight and fresh air through an operable<br />

window within a specified distance<br />

from each station. German texts make it<br />

clear how these requirements have fueled<br />

the development of double skins (Oesterle,<br />

2001). However, as energy conservation<br />

goals have risen, all the components<br />

and systems have improved and the potential<br />

for savings through the addition of a<br />

second skin has become less. As the examples<br />

will show, German architects have become<br />

more focused and strategic in their<br />

use of the double façade.<br />

THEMES OF PRACTICE<br />

In London, the exuberant use of technical<br />

systems has long been part of the commercial<br />

building culture. <strong>The</strong> Lloyd’s Bank<br />

(1986, Richard Rogers) and the New Parliamentary<br />

House (2000, Michael Hopkins)<br />

both have ventilated façade cavities in addition<br />

to their more famous expressive elements.<br />

<strong>The</strong> engineers and architects at<br />

Arup and Arup Associates have had a<br />

formative influence on “high tech” work.<br />

Using extruded sections and machined fittings,<br />

in the 1980’s Arup crafted robust<br />

and expressive external shading devices<br />

that cantilever off the building façade (One<br />

Finsbury Avenue, London, UK, 1984, Arup<br />

Associates). <strong>The</strong> work of Peter Rice added<br />

large expanses of suspended glazing to the<br />

British vocabulary. Once these two themes<br />

of practice were firmly established, the<br />

double skin became a logical progression.<br />

Adding a glass leaf to the outside face of<br />

the cantilevered shading structure allows<br />

the fixed louvers to be exchanged for<br />

much more effective operable systems and<br />

admit diffuse light on overcast days and<br />

track the sun when shading is an issue.<br />

<strong>The</strong> Helicon <strong>Building</strong> in London offers a<br />

dramatic example (Figure 3). Engineered<br />

by Arup, the building has a monumental<br />

double façade suspended over the south<br />

entry. Inside the stack ventilated cavity are<br />

gigantic louvers. Not far away, Plantation<br />

Place offers a different integration of the<br />

two venerable themes (Figure 4). <strong>The</strong><br />

façades are made with a repetitive unit<br />

curtain wall system. Close to street level<br />

the modules are matched to suspended<br />

external shades made of stone, in response<br />

to the context. As the floors<br />

mount, the plan steps back to form twin<br />

towers dominated by interactions through<br />

the skin. <strong>The</strong> same façade unit develops a<br />

cantilevered cavity with maintenance access<br />

and an outer leaf of glass shingles that<br />

are open jointed to discharge the heat absorbed<br />

in the small scale, operable louvers.<br />

This building does not function in all the<br />

modes of the German examples, but it<br />

also has far fewer moving parts. It is part<br />

of the trend in which architects are trying<br />

to capture the major benefits of a double<br />

skin through more efficient means.<br />

BRAND IDENTIFICATION<br />

<strong>The</strong> Arup offices in London occupy a rehabilitated<br />

building with a double skin

façade at the street corner. It is therefore<br />

one of the most potent of motivations,<br />

marketing. Arup is projecting a contemporary<br />

image of the environmentally responsive<br />

building that has enormous appeal to<br />

corporate clients. Returning to the Helicon<br />

<strong>Building</strong>, with the monumental façade, one<br />

must note that other faces are tempered by<br />

a much more reserved version of the same<br />

thermal chimney approach. <strong>The</strong> core of the<br />

building receives its light from an atrium<br />

space. <strong>The</strong> huge system above the entry<br />

hangs in front of a shallow band of offices<br />

no greater in volume than the façade cavity<br />

itself. That this flamboyant gesture survived<br />

the hard sums of a commercial project is a<br />

testament to the power of brand identification<br />

and the role of the double skin in realizing<br />

that ambition. Another vivid exemplar<br />

is a building on a prominent site in central<br />

Stuttgart (Figure 5). It has the shape of a<br />

teardrop with the pointed end reaching out<br />

toward a main thoroughfare. <strong>The</strong> plan becomes<br />

so narrow that fully one third of the<br />

outer glass leaf has nothing behind it except<br />

the cavity space.<br />

THE UNIVERSAL, ALL GLASS FAÇADE<br />

<strong>The</strong> RWE headquarters in Essen is a<br />

beautiful cylindrical tower that is considered<br />

by many in the field to be the most<br />

elegant of double skin façades (Figure 6). It<br />

faithfully realizes the historic imagery of<br />

Mies Van der Rohe’s project for an all glass<br />

skyscraper and strives to develop the<br />

“neutralizing wall” advocated by Le Corbusier<br />

many years ago. This building, and<br />

others like it, are driven by a renewal of<br />

modernist theory, now with the technical<br />

means available to try to realize those visions.<br />

<strong>The</strong> Essen tower is defined as a corridor<br />

façade, segmented at each floor<br />

plate. It is also a unitized, double curtain<br />

wall with cross-over ventilation between<br />

adjacent cells so that the intake and exhaust<br />

air streams are separated. <strong>The</strong><br />

façade elements demonstrate a commitment<br />

to repetitive production, although<br />

they are so precise and intricate they<br />

should in no way be referred to as economical.<br />

<strong>The</strong> cylindrical shape optimizes<br />

the surface to volume ratio, but it also<br />

makes the building indifferent as to solar<br />

orientation. This is the double skin proposed<br />

as a universal solution that can be<br />

deployed with equal enthusiasm to the<br />

north, south, east or west.<br />

<strong>The</strong>re is, in Frankfurt, a newer tower<br />

that makes an interesting comparison (Figure<br />

7). <strong>The</strong> work of Schnieder + Schumacher<br />

responds to the modernist legacy<br />

with equal intensity. Here the glass cylinder<br />

is pure, without accessory elements at<br />

the top or the base. <strong>The</strong> original concept<br />

called for buffer spaces that would ascend<br />

in a spiral similar to Norman Foster’s<br />

“Gherkin” in London (Swiss Re, 30 St.<br />

Mary Axe, 2004). In Frankfurt, the building<br />

has no major tenant to foot the bill and<br />

double skin techniques are reaching down<br />

into a speculative market that demands<br />

greater efficiency of means.<br />

As constructed, a square floor plan<br />

with a very simple glass façade is developed<br />

inside the protection of the outer<br />

cylinder. <strong>The</strong> difference between the two<br />

shapes produces four segmental buffer<br />

spaces, two in front of partitioned offices<br />

and two as “winter gardens” outside of<br />

open desk space. <strong>The</strong> cavities are segregated<br />

every four stories by a full circular<br />

floor plate. <strong>The</strong> outer leaf, executed skillfully<br />

by Gartner, has operable units in the<br />

upright triangles of the ornamental façade<br />

pattern. <strong>The</strong>se ventilate the buffer spaces<br />

on demand. <strong>The</strong> scheme is beautiful in its<br />

conception, but again indifferent to solar<br />

orientation; a triumph of theory over the<br />

realities of nature. <strong>The</strong> cylinder is once<br />

more proposed to minimize surface area,<br />

but since the building is so often in cooling<br />

mode, a concern for skin losses is a suspicious<br />

motivation.<br />

GREEN ARCHITECTURE<br />

<strong>The</strong> double skin takes a different role<br />

on the palette of architects who try to<br />

connect to nature rather than neutralize it.<br />

Exemplary of this approach is the work of<br />

Behnisch, Behnisch and Partner, with climate<br />

engineering by the well known firm,<br />

Transsolar, also of Stuttgart. This team has<br />

worked closely on a number of projects<br />

including the NORD/LB headquarters in<br />

Hannover, Germany (Figure 8). For<br />

Behnisch and Transsolar, the double skin in<br />

not a preconceived solution, but just one<br />

of many tools taken up in order of their effectiveness.<br />

In fact, the double skin may be<br />

quite far down that ranked list.<br />

At NORD/LB the first concern is connecting<br />