DINSE ECO.flow: Save GAS! ...the ECOnomic way! - Dinse-gmbh.com

DINSE ECO.flow: Save GAS! ...the ECOnomic way! - Dinse-gmbh.com

DINSE ECO.flow: Save GAS! ...the ECOnomic way! - Dinse-gmbh.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Press Information<br />

<strong>DINSE</strong> <strong>ECO</strong>.<strong>flow</strong>: <strong>Save</strong> <strong>GAS</strong>!<br />

...<strong>the</strong> <strong>ECO</strong>nomic <strong>way</strong>!<br />

Hamburg – <strong>DINSE</strong> have al<strong>way</strong>s searched for <strong>way</strong>s to handle <strong>the</strong> shield gas that is being<br />

used during <strong>the</strong> welding process in an economical <strong>way</strong>. All <strong>DINSE</strong> welding torches have a<br />

separate shield gas hose in <strong>the</strong> torch set which feeds <strong>the</strong> gas directly to <strong>the</strong> head.<br />

This significantly reduces needless gas loss. <strong>DINSE</strong> did fur<strong>the</strong>r developments and now<br />

presents <strong>the</strong> gas pressure regulator <strong>ECO</strong>.<strong>flow</strong> which not only minimises gas consumption<br />

but also ensures a high quality welding seam due to <strong>the</strong> constant stream of shield gas and<br />

a better gas coverage.<br />

<strong>ECO</strong>.<strong>flow</strong> is a multistage gas pressure regulator with a <strong>flow</strong> meter that reduces <strong>the</strong> initial<br />

surge of gas at <strong>the</strong> start of welding. The reduction of up to 50% of <strong>the</strong> gas <strong>flow</strong> saves<br />

significantly on <strong>the</strong> consumable cost of <strong>the</strong> welding process. Additionally <strong>the</strong> quality of <strong>the</strong><br />

welding seam is improved.<br />

When welding with conventional gas controllers due to <strong>the</strong> back pressure <strong>the</strong>re is a huge<br />

loss of gas directly after opening <strong>the</strong> valve. The <strong>ECO</strong>.<strong>flow</strong> reduces this pressure and<br />

guarantees a consistent and correct gas <strong>flow</strong>.<br />

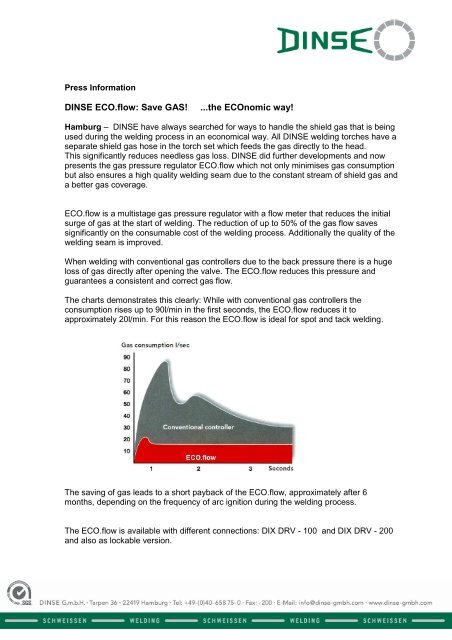

The charts demonstrates this clearly: While with conventional gas controllers <strong>the</strong><br />

consumption rises up to 90l/min in <strong>the</strong> first seconds, <strong>the</strong> <strong>ECO</strong>.<strong>flow</strong> reduces it to<br />

approximately 20l/min. For this reason <strong>the</strong> <strong>ECO</strong>.<strong>flow</strong> is ideal for spot and tack welding.<br />

The saving of gas leads to a short payback of <strong>the</strong> <strong>ECO</strong>.<strong>flow</strong>, approximately after 6<br />

months, depending on <strong>the</strong> frequency of arc ignition during <strong>the</strong> welding process.<br />

The <strong>ECO</strong>.<strong>flow</strong> is available with different connections: DIX DRV - 100 and DIX DRV - 200<br />

and also as lockable version.

The <strong>com</strong>pany founded in Hamburg by Wilhelm <strong>Dinse</strong> in 1954 is today one of <strong>the</strong> leading<br />

<strong>com</strong>panies for welding and brazing systems in Europe. <strong>DINSE</strong> systems are used in <strong>the</strong> automotive<br />

and general vehicle industry, aircraft construction, agricultural engineering, in <strong>the</strong> construction of<br />

machines, plants and structural steel works, as well as in traditional shipbuilding. In addition to<br />

traditional manual welding systems, <strong>DINSE</strong> has developed automatic and robotic welding devices<br />

for many years. Based on standard <strong>com</strong>ponents, <strong>DINSE</strong> systematically builds different system<br />

solutions. <strong>DINSE</strong> has users with technologically exacting demands in all areas of application, be it<br />

MIG/MAG, TIG, PLASMA or LASER welding and brazing.<br />

www.dinse-<strong>gmbh</strong>.<strong>com</strong><br />

More information can be obtained from:<br />

<strong>DINSE</strong> G.m.b.H.<br />

Saskia Schmidt<br />

tel.: +49 – (0)40 - 658 75-245<br />

fax: +49 – (0)40 - 658 75-200<br />

e-mail: schmidt@dinse-<strong>gmbh</strong>.<strong>com</strong><br />

gas pressure regulator <strong>DINSE</strong> <strong>ECO</strong>.<strong>flow</strong> DIX DRV - 100<br />

Photo: <strong>DINSE</strong> G.m.b.H., Hamburg