2012 Haas Lathe Brochure - Haas Automation, Inc.

2012 Haas Lathe Brochure - Haas Automation, Inc.

2012 Haas Lathe Brochure - Haas Automation, Inc.

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

THE FOUNDATION FOR SUCCESS<br />

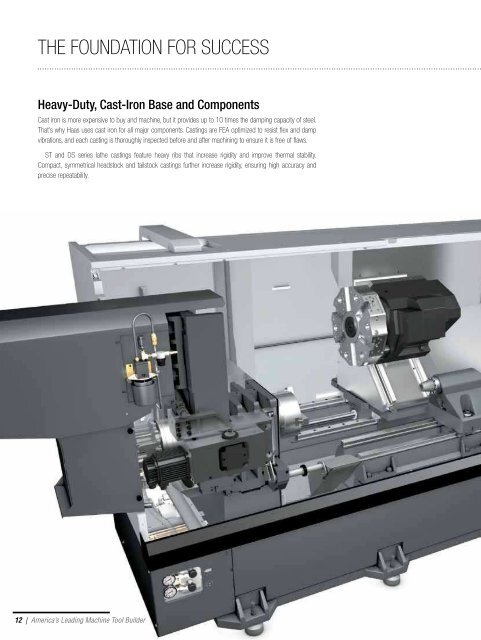

Heavy-Duty, Cast-Iron Base and Components<br />

Cast iron is more expensive to buy and machine, but it provides up to 10 times the damping capacity of steel.<br />

That’s why <strong>Haas</strong> uses cast iron for all major components. Castings are FEA optimized to resist flex and damp<br />

vibrations, and each casting is thoroughly inspected before and after machining to ensure it is free of flaws.<br />

ST and DS series lathe castings feature heavy ribs that increase rigidity and improve thermal stability.<br />

Compact, symmetrical headstock and tailstock castings further increase rigidity, ensuring high accuracy and<br />

precise repeatability.<br />

Cutting-Edge Design Tools Make it Possible<br />

At <strong>Haas</strong>, we’ve learned that it’s less about the total mass of the machine’s structure<br />

that gives the best results, and more about exactly where the mass is positioned.<br />

By utilizing the most modern, cutting-edge design and analysis tools, our engineers<br />

have put the mass exactly where it’s needed to provide a rock-solid base that<br />

absorbs vibration and harmonics, while providing smooth surface finishes and great<br />

repeatibility. For the <strong>Haas</strong> ST/DS series turning centers, all structural components<br />

were optimized using finite element analysis (FEA) to produce the most rigid designs<br />

and superior cutting.<br />

Single Setup, Top-Down Machining<br />

<strong>Haas</strong> ST/DS series base castings are machined in a single setup, using top-down<br />

machining on <strong>Haas</strong> VS-3 vertical machining centers. Each casting’s spindle head<br />

mount, Z-axis rails, and tailstock mounts are machined in a single setup, which<br />

provides higher accuracies and smoother production. Our ability to precisely<br />

machine all critical features of each casting eliminates alignment errors in final<br />

assembly. High-accuracy, in-process inspection guarantees that every machined<br />

casting meets our stringent quality standards.<br />

12 | America’s Leading Machine Tool Builder<br />

<strong>Haas</strong> <strong>Automation</strong>, <strong>Inc</strong>. 800-331-6746 www.<strong>Haas</strong>CNC.com | 13