CENTADISC®-C - centasweden.se

CENTADISC®-C - centasweden.se

CENTADISC®-C - centasweden.se

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

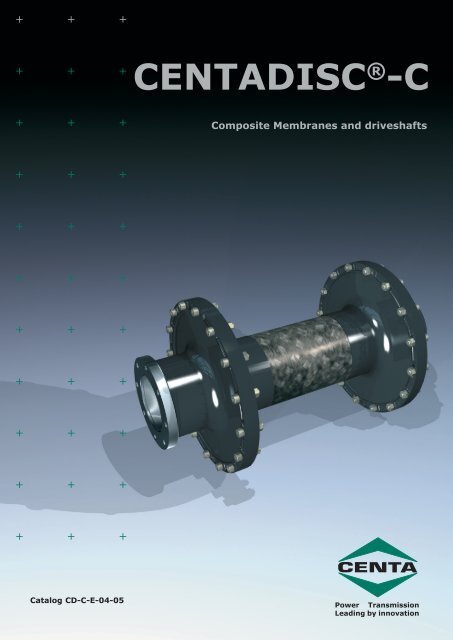

CENTADISC ® -C<br />

Composite Membranes and driveshafts<br />

Catalog CD-C-E-04-05<br />

Power Transmission<br />

Leading by innovation

Couplings and drive shafts made from diver<strong>se</strong><br />

fiber-reinforced plastics (e.g. CENTAFLEX<br />

<strong>se</strong>ries K and X) have been designed, developed<br />

and produced by CENTA Antriebe for<br />

decades.<br />

Numerous fiber-reinforced drive shafts with<br />

ratings up to 23000 kW and torques up to<br />

700000 Nm have successfully been applied.<br />

Especially within the performance range of up<br />

to 16 kNm there is demand for lightweight,<br />

reasonable, elastic drive shafts for fast ferries<br />

and fast craft of any kind.<br />

Therefore CENTA Antriebe has developed for<br />

this range a <strong>se</strong>ries of lightweight, fiber-reinforced<br />

membranes, namely CENTADISC-C,<br />

which add up to especially lightweight elastic<br />

drive shafts when being combined with GFK<br />

(glass fiber) or CFK (carbon fiber) tubes.<br />

Components:<br />

Membranes as injection moulding parts made from high<br />

grade, tough plastics. Type „F“ without and Type „G“ with<br />

glass fibre.<br />

Tubes made from GFK or CFK, according to requirements.<br />

CFK-tubes are less in weight and offer a higher critical<br />

speed, thus allow to bridge even larger gaps without supporting<br />

bearings.<br />

Length according to requirements and technical facilities.<br />

Connecting flanges or hubs<br />

Steel, stainless steel or aluminium, connecting dimensions<br />

according to requirements.<br />

Connections:<br />

Membranes with moulded in aluminium tube, which is<br />

bonded to the tube or end fittings. Membranes arranged<br />

in pairs and linked together by screws.<br />

Characteristics and advantages<br />

• Robust, lightweight, torsional stiff, corrosion resistant,<br />

sound absorbing and dampening for vibrations.<br />

• Any kind of displacement (axial, radial and angular) is<br />

accepted without wear within the tolerable limits.<br />

• Adaptable concerning length and connecting flanges or<br />

hubs.<br />

• The middle part can be removed radially without displacing<br />

the units. The load capacity and reliability under<br />

maximum misalignment and nominal torque has been<br />

proven by detailed tests with more than 10x10 6 load<br />

changes.<br />

• Design is patented.<br />

Typical areas of application:<br />

In ship propulsion between engine and gear or water jet<br />

(in combination with a torsional flexible coupling) and between<br />

gear and water jet; cooling towers, water pumps.<br />

<strong>se</strong>ries with<br />

hub<br />

<strong>se</strong>ries with flange<br />

long or short<br />

CD-C-2<br />

CENTA Power Transmission leading by innovation

Technical data<br />

Dimensions<br />

<strong>se</strong>ries with<br />

short flange<br />

<strong>se</strong>ries with hub<br />

<strong>se</strong>ries with long flange<br />

Size<br />

Nominal<br />

Torque<br />

Max. Angular<br />

Misalignment**<br />

Max. Axial<br />

Misalignment<br />

D 1<br />

D 2<br />

=D 3<br />

D 4<br />

L 1<br />

L 2<br />

L 3<br />

L 4<br />

D 5<br />

D 6<br />

N d 6<br />

D 7<br />

B<br />

max. ± 0,1 H7<br />

transient continuous transient contiunous<br />

[kNm] max [°] max [°] max [mm] max [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]<br />

CD-C1F 2 4 2,64<br />

CD-C1G 3 2 1,32<br />

± 4 2,64 350 153 90 165 121 179 127 180 155,5 8 M 14 110 19<br />

CD-C2F 4 4 2,64<br />

CD-C2G 6 2 1,32<br />

CD-C3F 8 4 2,64<br />

CD-C3G 12 2 1,32<br />

CD-C4F 12,5 4 2,64<br />

CD-C4G 20 2 1,32<br />

± 5 3,30 450 212 135 169 110 169 138 212 155,5 8 M 14 110 14<br />

± 6 3,96 540 266 170 222 148 222 166 266 218 8 M 18 140 23<br />

± 7 4,62 600 312 200 231 147 231 188 312 245 8 M 20 175 20<br />

Dimension L* is produced according customers requirements. It can reach a maximum of 6 m, is nevertheless dependant upon speed. We are at your<br />

<strong>se</strong>rvice for consultation. The dimensions of the connecting flanges (D 5<br />

, D 6<br />

, D 7<br />

, D 8<br />

) comply with our company standards. Deviating tailored flanges are<br />

possible. Each side of the universal joint shaft can either be equipped with hubs or connecting flanges. The flanges are available with dimension L 2<br />

in<br />

short version or with dimension L 3<br />

in long version. The materials available for hubs and flanges are steel, aluminium or titanium.<br />

** Maximum angular misalignment each side, meaning per membrane <strong>se</strong>t.<br />

We re<strong>se</strong>rve the right to amend any dimensions or detail specified or illustrated in this publication without notice and<br />

without incurring any obligation to provide such modification to such couplings previously delivered. Plea<strong>se</strong> ask for an<br />

application drawing and current data before making a detailed coupling <strong>se</strong>lection.<br />

We would like to draw your attention to the need of preventing accidents or injury. No safety guards are included in<br />

our supply.<br />

Copyright to this technical document is held by CENTA Antriebe Kirschey GmbH.<br />

CD-C-3<br />

CENTA Power Transmission leading by innovation

CENTA Flexible shafts for marine and industry<br />

CENTAFLEX <strong>se</strong>ries A, G, GZ or GS<br />

Torsionally soft, the<strong>se</strong> economic flexible shafts u<strong>se</strong> the outstanding<br />

CENTAFLEX A <strong>se</strong>ries elements, which compensate for<br />

axial, radial and angular misalignment. Suitable for all kinds of<br />

applications. Continuous angular deflection of up to 2 degrees,<br />

per element, is possible.<br />

Torque range up to 14 kNm.<br />

CENTALINK<br />

Torsionally stiff but capable of compensating for substantial<br />

misalignments of all kinds while dampening transmitted noi<strong>se</strong>.<br />

Proven over the years in many applications in shaft lines of<br />

up to 25 m in length, e.g. windturbines, pump <strong>se</strong>ts and ship<br />

propulsion.<br />

Torque range up to 300 kNm.<br />

CENTADISC-M<br />

Ba<strong>se</strong>d on the proven and patented steel membrane design of<br />

the CENTAX <strong>se</strong>ries M coupling, and compensating for all kinds<br />

of misalignment. Lengths up to 10 m. Using intermediate<br />

bearings and additional membranes any length of shaft can<br />

be provided.<br />

Torque range up to 500 kNm and more.<br />

Shaft material<br />

All flexible shafts can be manufactured using tubes from steel<br />

(or other conventional metals) or composites. CENTA has been<br />

in the forefront of composite shaft technology since 1996,<br />

delivering complete flexible shafts for fast ferries, naval and<br />

super luxury yachts, crui<strong>se</strong> ships and pump <strong>se</strong>ts.<br />

CENTA system engineering<br />

CENTA engineers complete shaft systems including couplings,<br />

clutches, bearings and bulk head <strong>se</strong>als, having carried out the<br />

necessary torsional vibration and critical speed calculations.<br />

Complete flexible shaft systems up to 25m length and capable<br />

of transmitting 600 kNm torque have been provided for fast ferries<br />

with aluminium hulls.<br />

CENTA shaft systems, especially tho<strong>se</strong> manufactured from<br />

composites connected by membranes provide light weight<br />

installations able to flex in all directions in order to avoid dangerous<br />

reaction forces from misalignments, thermal growth,<br />

distortion and movement of the hull or frame.<br />

Suitable designs to connect die<strong>se</strong>l engines with gear units and<br />

gear units with water jets, azimuthing propellors and any other<br />

kind of driven units are available.<br />

Ship propulsion<br />

Typical arrangement of CENTA<br />

couplings and Carbon Fibre shafts.<br />

The first <strong>se</strong>ction behind the engines<br />

also compri<strong>se</strong>s 2 CENTAX torsional<br />

couplings each that tune the torsional<br />

vibrations of the system.<br />

Postfach 11 25 ∙ D-42755 Haan<br />

Telefon: +49-(0)21 29-912-0<br />

e-mail: centa@centa.de<br />

Bergische Stras<strong>se</strong> 7<br />

Fax: +49-(0)21 29-27 90<br />

http://www.centa.de