Hinges & Fittings for side hung Windows and Doors

Hinges & Fittings for side hung Windows and Doors

Hinges & Fittings for side hung Windows and Doors

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

5<br />

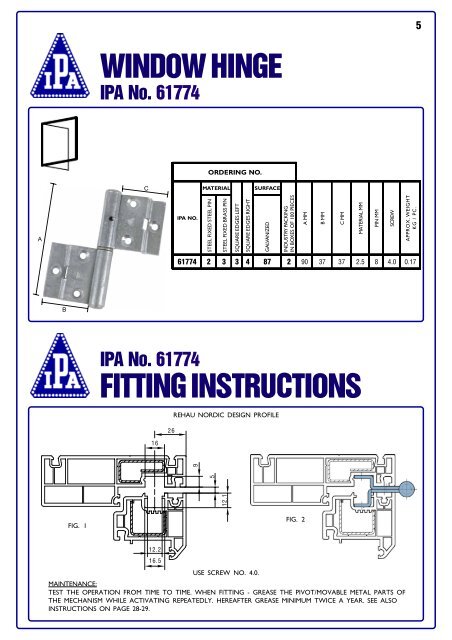

WINDOW HINGE<br />

IPA No. 61774<br />

ORDERING NO.<br />

C<br />

MATERIAL<br />

SURFACE<br />

A<br />

IPA NO.<br />

STEEL FIXED STEEL PIN<br />

STEEL FIXED BRASS PIN<br />

SQUARE EDGES LEFT<br />

SQUARE EDGES RIGHT<br />

GALVANIZED<br />

INDUSTRY PACKING<br />

IN BOXES OF 100 PIECES<br />

A MM<br />

B MM<br />

C MM<br />

MATERIAL MM<br />

PIN MM<br />

SCREW<br />

APPROX. WEIGHT<br />

KG / PC.<br />

61774 2 3 3 4 87 2 90 37 37 2.5 8 4.0 0.17<br />

B<br />

IPA No. 61774<br />

FITTING INSTRUCTIONS<br />

16<br />

26<br />

REHAU NORDIC DESIGN PROFILE<br />

12.1<br />

5<br />

9<br />

FIG. 1<br />

FIG. 2<br />

12.2<br />

16.5<br />

USE SCREW NO. 4.0.<br />

MAINTENANCE:<br />

TEST THE OPERATION FROM TIME TO TIME. WHEN FITTING - GREASE THE PIVOT/MOVABLE METAL PARTS OF<br />

THE MECHANISM WHILE ACTIVATING REPEATEDLY. HEREAFTER GREASE MINIMUM TWICE A YEAR. SEE ALSO<br />

INSTRUCTIONS ON PAGE 28-29.

6<br />

DOOR HINGE<br />

IPA No. 61798<br />

C<br />

ORDERING NO.<br />

MATERIAL<br />

SURFACE<br />

A<br />

IPA NO.<br />

STEEL FIXED STEEL PIN<br />

STEEL FIXED BRASS PIN<br />

SQUARE EDGES LEFT<br />

SQUARE EDGES RIGHT<br />

GALVANIZED<br />

INDUSTRY PACKING<br />

IN BOXES OF 50 PIECES<br />

61798 2 3 3 4 87 2 120 58 42.5 4.0 9.5 5.0 0.45<br />

A MM<br />

B MM<br />

C MM<br />

MATERIAL MM<br />

PIN MM<br />

SCREW<br />

APPROX. WEIGHT<br />

KG / PC.<br />

B<br />

IPA No. 61798<br />

FITTING INSTRUCTIONS<br />

16<br />

REHAU NORDIC DESIGN PROFILE<br />

26<br />

12.1<br />

5<br />

9<br />

FIG. 1 FIG. 2<br />

12.2<br />

16.5<br />

USE SCREW NO. 5.0.<br />

MAINTENANCE:<br />

TEST THE OPERATION FROM TIME TO TIME. WHEN FITTING - GREASE THE PIVOT/MOVABLE METAL PARTS OF<br />

THE MECHANISM WHILE ACTIVATING REPEATEDLY. HEREAFTER GREASE MINIMUM TWICE A YEAR. SEE ALSO<br />

INSTRUCTIONS ON PAGE 28-29.

7<br />

ADJUSTABLE DOOR HINGE<br />

IPA No. 60798<br />

ORDERING NO.<br />

MATERIAL<br />

SURFACE<br />

IPA NO.<br />

STEEL FIXED STEEL PIN<br />

SQUARE EDGES LEFT<br />

SQUARE EDGES RIGHT<br />

GALVANIZED<br />

INDUSTRY PACKING<br />

IN BOXES OF 50 PIECES<br />

A MM<br />

B MM<br />

C MM<br />

MATERIAL MM<br />

PIN MM<br />

SCREW<br />

APPROX. WEIGHT<br />

KG / PC.<br />

60798 2 3 4 87 2 120 58 2.5 4 9.5 5.0 0.49<br />

■<br />

ADJUSTABLE HORISONTALLY AND VERTICALLY<br />

C<br />

A<br />

B<br />

RIGHT

8<br />

IPA No. 60798<br />

FITTING INSTRUCTIONS<br />

UPPER HINGE PART<br />

REHAU NORDIC DESIGN PROFILE<br />

LOWER HINGE PART<br />

16<br />

26<br />

5<br />

9<br />

FIG. 1<br />

12.1<br />

ADJUSTMENT PLATE<br />

FITTING:<br />

1. MOUNT THE ADJUSTMENT PLATE IN THE GROOVE OF<br />

THE DOOR IN THE MIDDLE OF WHERE THE LOWER<br />

HINGE PART IS BEING MOUNTED.<br />

2. PLACE HINGE SO THAT THE LOWER HINGE PART IS<br />

OVER THE ADJUSTMENT PLATE AND FASTEN IT. THE<br />

ADJUSTMENT SCREWS SHOULD BE LOOSENED.<br />

12.2<br />

16.5<br />

FIG. 2<br />

ADJUSTMENT:<br />

VERTICALLY:<br />

ADJUST TO WANTED POSITION ON<br />

THE LARGE SCREW AT THE BOTTOM<br />

OF THE HINGE - ±3 MM.<br />

HORIZONTALLY: LOOSEN THE MOUNTING SCREWS<br />

AND ADJUST TO WANTED POSITION.<br />

FASTEN THE MOUNTING SCREWS.<br />

MAINTENANCE:<br />

TEST THE OPERATION FROM TIME TO TIME. WHEN<br />

FITTING - GREASE THE PIVOT/MOVABLE METAL PARTS OF<br />

THE MECHANISM WHILE ACTIVATING REPEATEDLY.<br />

HEREAFTER GREASE MINIMUM TWICE A YEAR. SEE ALSO<br />

INSTRUCTIONS ON PAGE 28-29.

SIDE SWING WINDOW 90 0<br />

WITH FRICTION<br />

IPA No. 62795<br />

9<br />

ORDERING NO.<br />

MATERIAL<br />

SURFACE<br />

IPA NO.<br />

STEEL<br />

LEFT<br />

RIGHT<br />

ELECTROPLATED<br />

STANDARDPACKING<br />

IN BOXES OF 5 SETS<br />

A MM<br />

B MM<br />

C MM<br />

SCREW<br />

APPROX. WEIGHT<br />

KG / SET<br />

62795 1 7 8 21 1 23 29.5 325 4.0 0.50<br />

■<br />

ADJUSTABLE FRICTION<br />

■<br />

CONVENIENT FOR CLEANING<br />

A<br />

B<br />

■<br />

SWINGS 90°<br />

■<br />

OPENS CLEAR FROM CURTAINS<br />

AND WINDOW FRAME<br />

■<br />

MAX. VENTILATION<br />

■<br />

CONCEALED FITTINGS<br />

■<br />

ANODIZED ALUMINIUM RAILS<br />

C<br />

TOP FITTING<br />

BOTTOM FITTING<br />

1 SET<br />

RIGHT HAND<br />

FIRE-ESCAPE OPENING:<br />

500 MM FROM SASH HEIGHT 726 MM

10<br />

IPA No. 62795<br />

FITTING INSTRUCTIONS<br />

REHAU NORDIC DESIGN PROFILE<br />

16<br />

2.5<br />

5<br />

9<br />

16.5<br />

FIG. 2<br />

HORIZONTAL PLAN<br />

HINGE SIDE<br />

FITTING SHOWN ON FRAME CILL<br />

RIGHT HAND ILLUSTRATION<br />

IPA NO. 62795<br />

MAX. SASH WEIGHT KGS 40<br />

FIG. 1<br />

VERTICAL PLAN<br />

MIN. SASH WIDTH 315<br />

MAX. SASH WIDTH 820<br />

SCREW 4,0<br />

FIG. 3<br />

FITTING:<br />

1. THE FITTING SHOULD BE POSITIONED IN THE GROOVES AT HEAD AND CILL OF FRAME AND<br />

SCREWED ON (FIGURE 1 AND 2)<br />

2. NOW PUSH THE WINDOW SASH INTO POSITION BY SASH SLOTS AND FASTEN THE SCREWS.<br />

3. THE FRICTION CAN NOW BE ADJUSTED ON THE TOP FITTING. IF A LARGER OPENING IS WANTED<br />

THEN JUST MOVE THE ADJUSTABLE STOP FITTING IN THE TOP FRAME ALUMINIUM RAIL.<br />

MAINTENANCE:<br />

THE FITTINGS ARE NOT TO BE PAINTED. TEST THE OPERATION FROM TIME TO TIME. WHEN FITTING -<br />

LUBRICATE THE PIVOT/MOVABLE METAL PARTS OF THE MECHANISM WHILE ACTIVATING REPEATEDLY.<br />

HEREAFTER LUBRICATE MINIMUM TWICE A YEAR. DO NOT LUBRICATE THE ALUMINIUM RAILS. SEE ALSO<br />

INSTRUCTIONS ON PAGE 28-29.

SIDE SWING WINDOW 90 0<br />

WITH FRICTION<br />

IPA NO. 62796-97 - adjustable<br />

11<br />

ORDERING NO.<br />

B<br />

A<br />

IPA NO.<br />

MATERIAL<br />

STEEL<br />

LEFT<br />

RIGHT<br />

SURFACE<br />

ELECTROPLATED<br />

STANDARD PACKING<br />

IN BOXES OF 5 SETS<br />

62796 1 7 8 21 1 17 23 247 4,0 0.36<br />

62797 1 7 8 21 1 17 23 377 4.0 0.56<br />

A MM<br />

B MM<br />

C MM<br />

SCREW<br />

WEIGHT APPROX.<br />

KG / SET<br />

■<br />

■<br />

■<br />

■<br />

■<br />

■<br />

■<br />

ADJUSTABLE FRICTION<br />

CONVENIENT FOR CLEANING<br />

SWINGS 90°<br />

OPENS CLEAR FROM CURTAINS<br />

AND WINDOW FRAME<br />

MAX. VENTILATION<br />

CONCEALED FITTINGS<br />

ANODIZED ALUMINIUM RAILS<br />

C<br />

TOP FITTING<br />

BOTTOM FITTING<br />

FIRE-ESCAPE OPENING IPA NR. 62796:<br />

500 MM FROM SASH HEIGHT 706 MM<br />

1 SET<br />

RIGHT<br />

FIRE-ESCAPE OPENING IPA NR. 62797:<br />

500 MM FROM SASH HEIGHT 750 MM<br />

600 MM FROM SASH HEIGHT 855 MM

12<br />

IPA NO. 62796-97<br />

FITTING INSTRUCTIONS<br />

16<br />

REHAU NORDIC DESIGN PROFILE<br />

ECCENTRIC SCREW<br />

FITTING SHOWN ON TOP<br />

FRAME CILL - RIGHT HAND<br />

ILLUSTRATION<br />

2.5<br />

5<br />

9<br />

ADJUSTMENT PLATE<br />

MARK<br />

HINGE SIDE<br />

16.5<br />

FIG. 2<br />

HORIZONTAL PLAN<br />

FITTING SHOWN<br />

ON BOTTOM FRAME<br />

CILL - RIGHT HAND<br />

ILLUSTRATION<br />

HINGE SIDE<br />

FITTING:<br />

FIG. 1<br />

VERTICAL PLAN<br />

IPA NO. 62796 62797<br />

MAX. SASH WEIGHT KGS 30 40<br />

MIN. SASH WIDTH 240 370<br />

MAX. SASH WIDTH 750 835<br />

SCREW 4.0 4.0<br />

FIG. 3<br />

1. THE FITTING SHOULD BE POSITIONED IN THE GROOVES AT HEAD AND CILL OF FRAME AND<br />

SCREWED ON (FIGURE 1 AND 2)<br />

2. NOW PUSH THE WINDOW SASH INTO POSITION BY SASH SLOTS AND FASTEN THE SCREWS.<br />

3. THE FRICTION CAN NOW BE ADJUSTED ON THE TOP FITTING. IF A LARGER OPENING IS WANTED<br />

THEN JUST MOVE THE ADJUSTABLE STOP FITTING IN THE TOP FRAME ALUMINIUM RAIL.<br />

4. THE SASH CAN BE ADJUSTED ±1.5 MM SIDEWAYS. BEFORE ANY ADJUSTMENT THE MOUNTING SCREW IN THE<br />

ADJUSTMENT PLATE IN THE TOP OF THE FRAME HAVE TO BE LOOSENED. THEN ADJUST BY USING A TORX-20<br />

KEY TO TURN THE ECCENTRIC SCREW. BY DELIVERY THE MARK ON THE ECCENTRIC SCREW IS IN A 90 0<br />

POSITION COMPARED TO THE FITTING, WHICH INDICATING THE 0-POSITION. THE ECCENTRIC SCREW CAN BE<br />

TURNED 90 0 TO EACH SIDE, WHICH GIVES THE MAXIMUM ADJUSTMENT OF 1½ MM. AFTER THE ADJUSTMENT<br />

THE MOUNTINGSCREW IN THE ADJUSTMENT PLATE IS FASTENED.<br />

MAINTENANCE:<br />

THE FITTINGS ARE NOT TO BE PAINTED. TEST THE OPERATION FROM TIME TO TIME. WHEN FITTING - LUBRICATE<br />

THE PIVOT/MOVABLE METAL PARTS OF THE MECHANISM WHILE ACTIVATING REPEATEDLY. HEREAFTER LUBRICATE<br />

MINIMUM TWICE A YEAR. DO NOT LUBRICATE THE ALUMINIUM RAILS. SEE ALSO INSTRUCTIONS ON PAGE 28-29.