(A2LA Cert. No. 0887.01) 04/26/2002 Page 1 of 6 ... - Tinius Olsen

(A2LA Cert. No. 0887.01) 04/26/2002 Page 1 of 6 ... - Tinius Olsen

(A2LA Cert. No. 0887.01) 04/26/2002 Page 1 of 6 ... - Tinius Olsen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

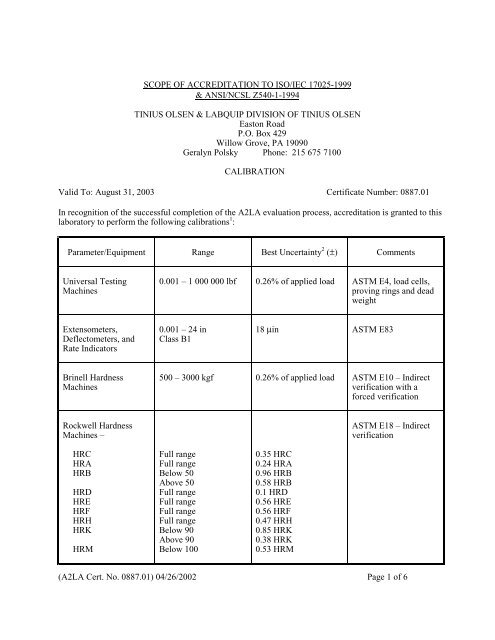

SCOPE OF ACCREDITATION TO ISO/IEC 17025-1999<br />

& ANSI/NCSL Z540-1-1994<br />

TINIUS OLSEN & LABQUIP DIVISION OF TINIUS OLSEN<br />

Easton Road<br />

P.O. Box 429<br />

Willow Grove, PA 19090<br />

Geralyn Polsky Phone: 215 675 7100<br />

CALIBRATION<br />

Valid To: August 31, 2003 <strong>Cert</strong>ificate Number: <strong>0887.01</strong><br />

In recognition <strong>of</strong> the successful completion <strong>of</strong> the <strong>A2LA</strong> evaluation process, accreditation is granted to this<br />

laboratory to perform the following calibrations 1 :<br />

Parameter/Equipment Range Best Uncertainty 2 (±) Comments<br />

Universal Testing<br />

Machines<br />

0.001 – 1 000 000 lbf 0.<strong>26</strong>% <strong>of</strong> applied load ASTM E4, load cells,<br />

proving rings and dead<br />

weight<br />

Extensometers,<br />

Deflectometers, and<br />

Rate Indicators<br />

0.001 – 24 in<br />

Class B1<br />

18 µin ASTM E83<br />

Brinell Hardness<br />

Machines<br />

500 – 3000 kgf 0.<strong>26</strong>% <strong>of</strong> applied load ASTM E10 – Indirect<br />

verification with a<br />

forced verification<br />

Rockwell Hardness<br />

Machines –<br />

ASTM E18 – Indirect<br />

verification<br />

HRC<br />

HRA<br />

HRB<br />

HRD<br />

HRE<br />

HRF<br />

HRH<br />

HRK<br />

HRM<br />

Full range<br />

Full range<br />

Below 50<br />

Above 50<br />

Full range<br />

Full range<br />

Full range<br />

Full range<br />

Below 90<br />

Above 90<br />

Below 100<br />

0.35 HRC<br />

0.24 HRA<br />

0.96 HRB<br />

0.58 HRB<br />

0.1 HRD<br />

0.56 HRE<br />

0.56 HRF<br />

0.47 HRH<br />

0.85 HRK<br />

0.38 HRK<br />

0.53 HRM<br />

(<strong>A2LA</strong> <strong>Cert</strong>. <strong>No</strong>. <strong>0887.01</strong>) <strong>04</strong>/<strong>26</strong>/<strong>2002</strong> <strong>Page</strong> 1 <strong>of</strong> 6

Parameter/Equipment Range Best Uncertainty (±) Comments<br />

Rockwell Hardness<br />

Machines – (cont)<br />

ASTM E18 – Indirect<br />

verification<br />

HRM<br />

HRR<br />

HR15N<br />

HR30N<br />

HR45N<br />

HR15T<br />

HR30T<br />

HR45T<br />

Above 100<br />

Below 120<br />

Above 120<br />

Below 75<br />

Above 75<br />

Full range<br />

Below 50<br />

Above 50<br />

Below 75<br />

Above 75<br />

Full range<br />

Full range<br />

0.43 HRM<br />

0.29 HRR<br />

0.21 HRR<br />

0.34 HR15N<br />

0.24 HR15N<br />

0.27 HR30N<br />

0.58 HR45N<br />

0.14 HR45N<br />

0.35 HR15T<br />

0.29 HR15T<br />

0.73 HR30T<br />

0.48 HR45T<br />

Microhardness<br />

Machines –<br />

ASTM E384 – Indirect<br />

method<br />

Vickers<br />

100 gf<br />

200 gf<br />

300 gf<br />

500 gf<br />

1000 gf<br />

10 kgf<br />

12 HV<br />

13 HV<br />

13 HV<br />

9 HV<br />

8 HV<br />

8 HV<br />

Knoop<br />

100 gf<br />

200 gf<br />

300 gf<br />

500 gf<br />

1000 gf<br />

14 HK<br />

10 HK<br />

10 HK<br />

12 HK<br />

12 HK<br />

Impact Testing<br />

Machines –<br />

Level<br />

Timing<br />

Pendulum Length<br />

Vertical Fall<br />

Shaft Play<br />

Free Hang<br />

Weight<br />

Height Difference<br />

Izod Striker Centered<br />

Any plastic impact<br />

testing machine that<br />

conforms with ASTM<br />

D256, ISO 179 or 180<br />

92T<br />

66 Impact<br />

60µin/in<br />

0.<strong>26</strong> sec<br />

0.008 in<br />

0.007 in<br />

80 µin<br />

0.008 in<br />

0.64%<br />

0.002 in<br />

0.003 in<br />

0.006 in<br />

ASTM D256, and ISO<br />

179, 180<br />

(<strong>A2LA</strong> <strong>Cert</strong>. <strong>No</strong>. <strong>0887.01</strong>) <strong>04</strong>/<strong>26</strong>/<strong>2002</strong> <strong>Page</strong> 2 <strong>of</strong> 6

Parameter/Equipment Range Best Uncertainty (±) Comments<br />

Impact Testing<br />

Machines – (cont)<br />

Izod Height Gage<br />

Charpy Go/<strong>No</strong> Go Gage<br />

ASTM<br />

ISO<br />

Radius Gage<br />

TMI Replicate<br />

Any plastic impact<br />

testing machine that<br />

conforms with ASTM<br />

D256, ISO 179 or 180<br />

0.00<strong>04</strong> in<br />

0.0016 in<br />

0.0032 in<br />

0.0020 in<br />

0.0003 in<br />

ASTM D256, and ISO<br />

179, 180<br />

Distance between<br />

Anvils<br />

Striker Centered on<br />

Anvils<br />

Striking Bit Parallel to<br />

Anvils<br />

Levels<br />

Free Swing Zero<br />

11 Free Swing Friction<br />

Striker and Anvil<br />

Replicate<br />

Any metal impact<br />

testing machine that<br />

conforms with ASTM<br />

E23<br />

0.0002 in<br />

0.0012 in<br />

0.00012 in/in<br />

60 µin/in<br />

0.14 ft-lb<br />

0.4 ft-lb<br />

0.0003 in<br />

ASTM E23<br />

Specimen Alignment <strong>of</strong><br />

Universal Testing<br />

Machines<br />

2.8% bending ASTM E1012<br />

Extrusion<br />

Plastometers –<br />

Bore Measurement<br />

Piston Rod Diameter<br />

Piston Foot Diameter<br />

Piston Foot and Orifice<br />

Length<br />

Weight<br />

Height <strong>of</strong> Switch<br />

Switch Calibration<br />

Temperature<br />

Level<br />

Timer<br />

Go Gage<br />

<strong>No</strong>Go Gage<br />

up to 300° C<br />

300°C to 400° C<br />

0.00016 in<br />

0.0008 in<br />

0.0002 in<br />

0.0014 in<br />

0.22%<br />

0.0028 in<br />

0.00<strong>04</strong> in<br />

0.06° C<br />

0.24° C<br />

0.00<strong>04</strong> in/in<br />

0.19 seconds<br />

12 µin<br />

18 µin<br />

ASTM D1238 and ISO<br />

1133<br />

(<strong>A2LA</strong> <strong>Cert</strong>. <strong>No</strong>. <strong>0887.01</strong>) <strong>04</strong>/<strong>26</strong>/<strong>2002</strong> <strong>Page</strong> 3 <strong>of</strong> 6

Parameter/Equipment Range Best Uncertainty (±) Comments<br />

Heat Deflection Testing<br />

Machines –<br />

ASTM D648 and ISO<br />

75<br />

Support Spacing<br />

Standard Support<br />

Radius<br />

HDUL Load Radius<br />

Vicat Needle<br />

LVDT Readings<br />

Dial Indicator<br />

Resolution<br />

Weight<br />

Temperature Up to 300°C<br />

0.008 in<br />

0.0016 in<br />

0.0014 in<br />

0.00018 in<br />

18µin<br />

0.00002 in<br />

0.23%<br />

0.06°C<br />

Vicat Testing<br />

Machines –<br />

ASTM D1525 and ISO<br />

306<br />

Support Spacing<br />

Standard Support Radius<br />

HDUL Load Radius<br />

Vicat Needle<br />

LVDT Readings<br />

Dial Indicator Resolution<br />

Weight<br />

Temperature Up to 300°C<br />

0.008 in<br />

0.0016 in<br />

0.0014 in<br />

0.00018 in<br />

18µin<br />

0.00002 in<br />

0.23%<br />

0.06°C<br />

Bending Moment<br />

Machines 3 –<br />

ASTM D747<br />

Degrees Motion<br />

Stopwatch<br />

Span<br />

Weight<br />

Standard Shim<br />

0.20°<br />

0.19 seconds<br />

0.01 in<br />

0.20%<br />

0.2 in-lb<br />

<strong>Olsen</strong> Cal 60<br />

0.0050 – 1 in 12 µin <strong>Olsen</strong> procedure 0700<br />

Calibrator 3<br />

Extensometer<br />

Dial Indicator 3 0.0010 – 5 in 20 µin <strong>Olsen</strong> procedure 0740<br />

(<strong>A2LA</strong> <strong>Cert</strong>. <strong>No</strong>. <strong>0887.01</strong>) <strong>04</strong>/<strong>26</strong>/<strong>2002</strong> <strong>Page</strong> 4 <strong>of</strong> 6

Parameter/Equipment Range Best Uncertainty (±) Comments<br />

Plastic Impact<br />

Specimen <strong>No</strong>tcher &<br />

Plastic Impact <strong>No</strong>tches<br />

Specimen 3 –<br />

<strong>Olsen</strong> procedures 8100<br />

and 0730<br />

Main Spindle Shaft<br />

Motion<br />

<strong>No</strong>tch Verification<br />

Device<br />

<strong>No</strong>tch Angle<br />

<strong>No</strong>tch Radius<br />

Thickness under the<br />

<strong>No</strong>tch<br />

0.00008 in<br />

20 µin<br />

0.08°<br />

0.0003 in<br />

0.00<strong>04</strong> in<br />

Displacement<br />

Verification on<br />

Universal Testing<br />

Machine<br />

0.01 – 40 in 0.0014 in Crosshead position<br />

<strong>Olsen</strong> procedure 2500<br />

Rate Verification –<br />

<strong>Olsen</strong> procedure 2700<br />

Load<br />

Strain<br />

Position<br />

Crosshead Speed<br />

0.001 – 1 000 000 lb/min<br />

0.001 – 40 in/min<br />

0.001 – 40 in/min<br />

0.001 – 40 in/min<br />

0.<strong>26</strong>%<br />

18 µin<br />

0.0014 in<br />

0.0014 in<br />

Durometer Hardness<br />

Tester –<br />

A, B, C, D, DO, O, &<br />

OO<br />

ASTM D2240 and<br />

<strong>Olsen</strong> procedure 0830<br />

Tip Pr<strong>of</strong>ile<br />

Durometer Scale<br />

Durometer Force<br />

0.0003 in<br />

0.00014 in<br />

0.3 gf<br />

Mass<br />

5 g – 25 kg<br />

0.01 – 50 lb<br />

0.5 – 2 g or<br />

0.001 – 0.005 lbf<br />

0.05%<br />

0.05%<br />

0.02%<br />

ASTM E74, NIST<br />

Technical <strong>No</strong>te 577 and<br />

<strong>Olsen</strong> procedure 0800<br />

Weighing Scale<br />

1 mg – 6 kg<br />

1 – 25 000 g<br />

0.008%<br />

0.05%<br />

<strong>Olsen</strong> procedure 1500<br />

or <strong>Olsen</strong> procedure<br />

0770<br />

(<strong>A2LA</strong> <strong>Cert</strong>. <strong>No</strong>. <strong>0887.01</strong>) <strong>04</strong>/<strong>26</strong>/<strong>2002</strong> <strong>Page</strong> 5 <strong>of</strong> 6

Parameter/Equipment Range Best Uncertainty (±) Comments<br />

Temperature 0°C to 300°C<br />

300°C to 400°C<br />

0.06°C<br />

0.24°C<br />

RTD w/indicator<br />

system<br />

Dimension – Measuring<br />

using CAL 60,<br />

Micrometer, Caliper or<br />

Scales<br />

0 – 1 in<br />

0 – 1 in<br />

0 – 6 in<br />

0 – 24 in<br />

18 µin<br />

0.0014 in<br />

0.008 in<br />

0.010 in<br />

CAL 60<br />

Micrometer<br />

Caliper<br />

Scales<br />

Dimension 3 –<br />

Measuring using Gage<br />

Blocks or Optical<br />

Comparator<br />

0 – 6 in 20 µin Gage blocks and<br />

comparator<br />

_______________________<br />

1 This laboratory <strong>of</strong>fers commercial calibration services provided by <strong>Tinius</strong> <strong>Olsen</strong> and the Labquip<br />

Division <strong>of</strong> <strong>Tinius</strong> <strong>Olsen</strong> Calibration technicans at the address noted above, the Minooka, IL location and<br />

those provided at client sites. Please note that accredited certificates may be issued from the Labquip<br />

Division located in Minooka, IL.<br />

2 Best Uncertainties represent expanded uncertainties using a coverage factor <strong>of</strong> k=2 which provides a<br />

level <strong>of</strong> confidence <strong>of</strong> approximately 95%.<br />

3 Calibration for this parameter is performed at the Willow Grove, PA location only.<br />

(<strong>A2LA</strong> <strong>Cert</strong>. <strong>No</strong>. <strong>0887.01</strong>) <strong>04</strong>/<strong>26</strong>/<strong>2002</strong> <strong>Page</strong> 6 <strong>of</strong> 6