trimethoxyethoxyvinylsilane GPS Safety Summary - Evonik ...

trimethoxyethoxyvinylsilane GPS Safety Summary - Evonik ...

trimethoxyethoxyvinylsilane GPS Safety Summary - Evonik ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Exposure<br />

Human / Environment<br />

There is no exposure to humans from Trimethoxyethoxyvinylsilane via the<br />

environment, as the substance is highly reactive and, thus, immediately<br />

hydrolyzes. Manufacturing occurs under controlled conditions, with releases<br />

to air and waste water according to the existing legal and regional<br />

permissions. Releases to the environment during use and handling are<br />

limited by use of appropriate measures as mentioned in the <strong>Safety</strong> Data<br />

Sheet and described under Risk Management Recommendations. Due to the<br />

reactive nature of Trimethoxyethoxyvinylsilane when in contact with water, or<br />

indeed with silanols, under the conditions used to prepare silicone polymers<br />

and resins, it can be assumed that they are completely consumed in the<br />

hydrolysis/condensation process,<br />

In those cases where Trimethoxyethoxyvinylsilane in sealants is used in<br />

professional applications, the Silane has invariably hydrolyzed and<br />

condensed to form Siloxane oligomers and polymers and there is no<br />

exposure from the end product.<br />

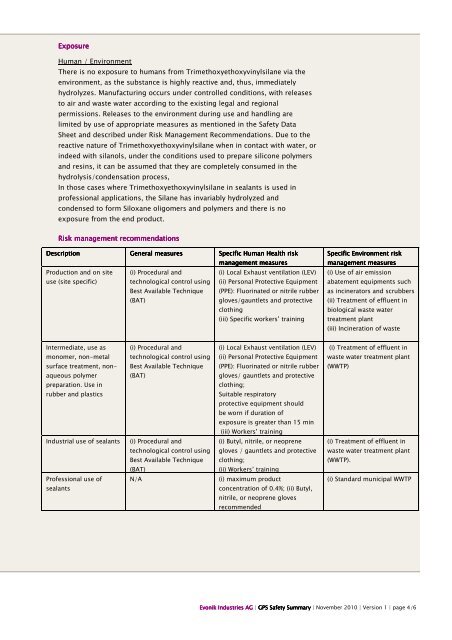

Risk management recommendations<br />

Description<br />

General measures<br />

Specific Human Health risk<br />

management measures<br />

Specific Environment risk<br />

management measures<br />

Production and on site<br />

(i) Procedural and<br />

(i) Local Exhaust ventilation (LEV)<br />

(i) Use of air emission<br />

use (site specific)<br />

technological control using<br />

(ii) Personal Protective Equipment<br />

abatement equipments such<br />

Best Available Technique<br />

(PPE): Fluorinated or nitrile rubber<br />

as incinerators and scrubbers<br />

(BAT)<br />

gloves/gauntlets and protective<br />

(ii) Treatment of effluent in<br />

clothing<br />

biological waste water<br />

(iii) Specific workers’ training<br />

treatment plant<br />

(iii) Incineration of waste<br />

Intermediate, use as<br />

(i) Procedural and<br />

(i) Local Exhaust ventilation (LEV)<br />

(i) Treatment of effluent in<br />

monomer, non-metal<br />

technological control using<br />

(ii) Personal Protective Equipment<br />

waste water treatment plant<br />

surface treatment, non-<br />

Best Available Technique<br />

(PPE): Fluorinated or nitrile rubber<br />

(WWTP)<br />

aqueous polymer<br />

(BAT)<br />

gloves/ gauntlets and protective<br />

preparation. Use in<br />

clothing;<br />

rubber and plastics<br />

Suitable respiratory<br />

protective equipment should<br />

be worn if duration of<br />

exposure is greater than 15 min<br />

(iii) Workers’ training<br />

Industrial use of sealants<br />

(i) Procedural and<br />

(i) Butyl, nitrile, or neoprene<br />

(i) Treatment of effluent in<br />

technological control using<br />

gloves / gauntlets and protective<br />

waste water treatment plant<br />

Best Available Technique<br />

clothing;<br />

(WWTP).<br />

(BAT)<br />

(ii) Workers’ training<br />

Professional use of<br />

N/A<br />

(i) maximum product<br />

(i) Standard municipal WWTP<br />

sealants<br />

concentration of 0.4%; (ii) Butyl,<br />

nitrile, or neoprene gloves<br />

recommended<br />

<strong>Evonik</strong> Industries I<br />

AG | <strong>GPS</strong> <strong>Safety</strong> <strong>Summary</strong> | November 2010 | Version 1 | page 4/6