Diesel - Hydraulic Clamshell Grab Type DHS-B 8,0m³

Diesel - Hydraulic Clamshell Grab Type DHS-B 8,0m³

Diesel - Hydraulic Clamshell Grab Type DHS-B 8,0m³

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

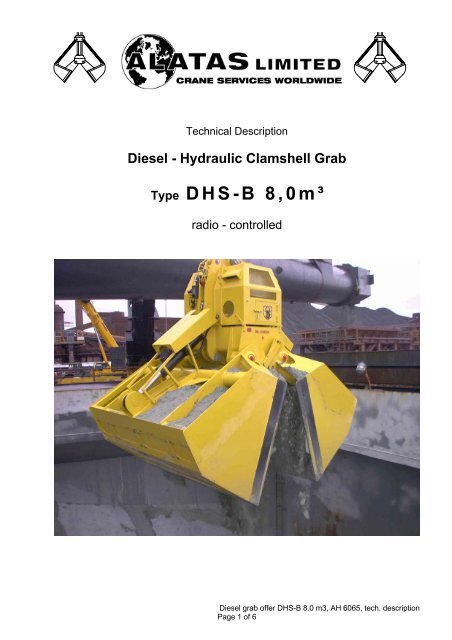

Technical Description<br />

<strong>Diesel</strong> - <strong>Hydraulic</strong> <strong>Clamshell</strong> <strong>Grab</strong><br />

<strong>Type</strong> <strong>DHS</strong>-B 8,0m³<br />

radio - controlled<br />

<strong>Diesel</strong> grab offer <strong>DHS</strong>-B 8.0 m3, AH 6065, tech. description<br />

Page 1 of 6

Page 2 of 6

General<br />

The below described radio - controlled <strong>Diesel</strong> - hydraulic clamshell grab is a modern<br />

an robust high - performance bulk - handling machine.<br />

The grab consists mainly of the following components:<br />

1. Centre <strong>Grab</strong> Section with<br />

- <strong>Diesel</strong> engine and flanged - on variable axial hydraulic piston pump<br />

- <strong>Hydraulic</strong> - tank with integrated fuel - tank<br />

- Double - arm vertical support with mounted cross member and chain support<br />

- the radio - control receiver unit with connected electric controls motor electric<br />

and battery<br />

- the two hinged covers for the complete drive<br />

- the bearing points for the two working cylinders<br />

- the four bearings for the clamshell bolts at the bottom side<br />

2. Two double - acting hydraulic cylinders with cover<br />

3. <strong>Clamshell</strong>s with<br />

- sealed joint bearings in the clamshell - turning points<br />

- the bearings for the working cylinders<br />

- the lateral working cylinder protection in the centre of the clamshell, what is the<br />

slide - way for the working cylinder - cover at the same time<br />

After being hooked into the crane the grab is ready for operation.<br />

The functions:<br />

- <strong>Diesel</strong> engine " Start "<br />

- <strong>Diesel</strong> engine " Stop "<br />

- <strong>Grab</strong> " Open "<br />

- <strong>Grab</strong> " Close "<br />

are radio - controlled by the crane driver via the mobile transmitter in the crane cabin.<br />

The control of the grab can also be done by a man near the ship’s hatch if the grab is outside<br />

of the crane driver’s range of view.<br />

The max. transmitting range is approx. 200 m.<br />

The compact construction design in combination with a suitable arrangement of all components<br />

and the optimised grab kinematics are resulting in:<br />

- a suitable course of the grab closing forces (especially at the end of the closing<br />

process high closing forces are ensured)<br />

- an wide grabbing distance between the shells<br />

Additionally there is a good filling of the grab due to the suitable shell shape and grab<br />

curves.<br />

Page 3 of 6

A high utilisation of the crane’s lifting capacity and therefore an optimised load turn -<br />

over is guaranteed due to the minimised dead weight of the grab in combination with the<br />

designed grab volume and load capacity.<br />

The mechanical stability is guaranteed by a homogeneous construction, ample dimensioned<br />

components and a good welding workmanship.<br />

Centre <strong>Grab</strong> Section<br />

The centre grab section consists of a sturdy, welded steel construction made of high tensile<br />

steel quality St 52-3. It functions simultaneously as hydraulic tank with top-mounted<br />

fuel tank, support for the clamshells and bearing point for the working cylinders.<br />

The diesel - hydraulic drive unit is installed protected by foldable covers, the exhaust pipe<br />

unit is mounted at the outside.<br />

To avoid the exhaust pipe unit from the vibrations of the diesel engine a flexible pipe made<br />

of stainless steel is installed between the exhaust bend and the exhaust pipe.<br />

The fuel store is sufficient for a single - shift working day.<br />

The cross-member with shackle and chain is bolted to the vertical support arms.<br />

Drive Unit<br />

The drive unit consists of the diesel engine with directly flanged variable axial hydraulic<br />

piston pump. The complete unit is mounted onto the tank-top of the centre grab section.<br />

<strong>Diesel</strong> engine : <strong>Type</strong> KHD Deutz / Kubota<br />

Axial piston pump : Make Rexroth - Hydromatic or equal<br />

The hydraulic control valve, necessary remote control valves and remaining fittings are<br />

mounted on the top of the hydraulic - tank.<br />

Radio Control Unit<br />

<strong>Type</strong> : 4- Channel with German FTZ - Certificate<br />

The following functions are controlled via this mobile radio unit:<br />

- <strong>Diesel</strong> engine " Start "<br />

- <strong>Diesel</strong> engine " Stop "<br />

- <strong>Grab</strong> " Open "<br />

- <strong>Grab</strong> " Close "<br />

The receiver is mounted protected on the centre grab section below the foldable covers;<br />

the antenna is mounted at the outside of the centre machine unit.<br />

Page 4 of 6

<strong>Hydraulic</strong> cylinders<br />

Double - acting hydraulic cylinders with sea - water - resistant nickel - chrome - plated piston<br />

rods. The cylinders are protected against bulk a.s.o. by steel covers.<br />

<strong>Clamshell</strong>s<br />

The grab clamshells are of a welded, stiff steel construction with solid designed bearings<br />

to be connected to the main power section and to the hydraulic cylinders.<br />

A pipe of a large diameter is installed across to the clamshell upper section and both yoke<br />

plates, which are descending from the clamshell to the grab arm bearing point.<br />

This thick walled pipe is additionally stiffening the clamshell - side plates and provides a<br />

high constructive twist resistance.<br />

The bottom- and side - plates are of steel quality St 52 - 3.<br />

The clamshell bearings are arranged rearwards, in order to enable the grab gripping into<br />

the areas underneath the top wing tanks of the vessel. The knives are a massive construction<br />

of highly wear resistant steel type HARDOX400 (or similar quality). For an additional<br />

price standard type clamshell - teeth (choice of owner) are available.<br />

Bolts<br />

- Bolt clamshell - cylinder and case : X20Cr13<br />

- Bolt clamshell - case : 42CrMo4<br />

Bearings<br />

<strong>Clamshell</strong> connection to main power section and cylinders:<br />

Sealed joint bearings with additional sealing<br />

Lubrication<br />

Each bearing point is provided with an individual lubrication bore, witch ensures that all<br />

bearing points can be checked with regard to proper grease passing.<br />

Lubrication nipples: countersunk mounted high pressure nipples of DIN - type 71 412<br />

General remark<br />

All components are easily accessible and dismountable. Screws, axles, supports a.s.o. are<br />

DIN - standard type as far as possible.<br />

Connecting parts made from stainless steel (A4).<br />

Coatings<br />

Sandblasted SA 2,5<br />

First coat : Primer<br />

Top coat : synthetic resign vanish<br />

Colours : yellow RAL 1004<br />

Page 5 of 6

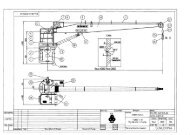

1 9 0<br />

50<br />

0<br />

5<br />

7<br />

0<br />

1<br />

3<br />

property<br />

wingis<br />

dra<br />

This<br />

Orts<br />

F<br />

S<br />

Ing<br />

of<br />

duplicated<br />

copied<br />

be<br />

not<br />

shal<br />

It<br />

parties<br />

outside<br />

to<br />

mited<br />

sub<br />

or<br />

consent<br />

writen<br />

our<br />

without<br />

DATE:<br />

CONTR:<br />

REF. :<br />

G<br />

G<br />

T<br />

S a f e wor ki ng Load ( SWL) = 32 t<br />

P r üf l ast ( Test l oad) = 59 t<br />

CONSTR. / DRAW.:<br />

STAND. CONTR.::<br />

TRACED:<br />

APPROVED:<br />

CALC.:<br />

SCALE:<br />

0 9.0 4 . 9 8 Krebs 1/5<br />

PROJ. METH.:<br />

O R T S G m b H M a s c h i n enfabrik<br />

D 2 3 6 1 1 S e r e e t z<br />

Phone: 0451 / 398850 F a x : 392374<br />

RREPL. FOR:<br />

REPL. BY:<br />

Aufhängung<br />

(Suspension) 31105769<br />

Page 6 of 6