CPI - February 2011 - Working with Ductal® UHPC

CPI - February 2011 - Working with Ductal® UHPC

CPI - February 2011 - Working with Ductal® UHPC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

CONCRETE TECHNOLOGY<br />

Lafarge North America, T2W 4Y1,Calgary, Alberta, Canada<br />

<strong>Working</strong> <strong>with</strong> Ductal Ultra-High Performance Concrete<br />

Introduced to the world in the mid-90’s, Ductal ® Ultra-High-Performance Concrete (“<strong>UHPC</strong>”) has come a long way. With its unique combination<br />

of ductility, strength, durability and aesthetics, precast elements can have thinner sections and longer spans that are lighter, more grace ful<br />

and innovative (compared to conventional concrete). Highly moldable, it replicates form materials <strong>with</strong> amazing precision. Compressive<br />

strengths reach up to 200 MPa and flexural strengths up to 40 MPa, providing improved durability and impermeability against corrosion,<br />

abrasion and impact. Furthermore, it is sustainable. <strong>UHPC</strong> structures are expected to have an extended service life, resulting in less environmental<br />

impact over time.<br />

The purpose of this article is to help precasters learn about Ductal <strong>UHPC</strong> and the potential opportunities that exist through production of innovative<br />

products and solutions that compliment their existing precast products and businesses. The following article is an introduction to <strong>UHPC</strong><br />

and the first in a series of related articles that <strong>CPI</strong> will publish in future issues.<br />

Vic H. Perry, Peter J. Seibert, Lafarge,<br />

North America<br />

As one of the pioneers in Ultra-High<br />

Performance Concrete (<strong>UHPC</strong>), Lafarge<br />

worked closely <strong>with</strong> Bouygues in the early<br />

90’s to explore new possibilities in ad vanced<br />

concrete technologies. After ten years of<br />

research, they produced an innovative<br />

material <strong>with</strong> unique technological performances.<br />

The main principle of this technology<br />

is based on systematic elimination of inherent<br />

weaknesses associated <strong>with</strong> conventional<br />

concrete. The ductile behaviour of this<br />

material is a first for concrete, <strong>with</strong> the<br />

capacity to deform and support flexural<br />

and tensile loads, even after initial cra -<br />

ck ing. These performances are the result of<br />

improved micro-structural properties of the<br />

mineral matrix, especially toughness and<br />

control of the bond between the matrix and<br />

the fiber.<br />

Today, Ductal is a family of <strong>UHPC</strong> products.<br />

Two types of fibers are used to make Ductal<br />

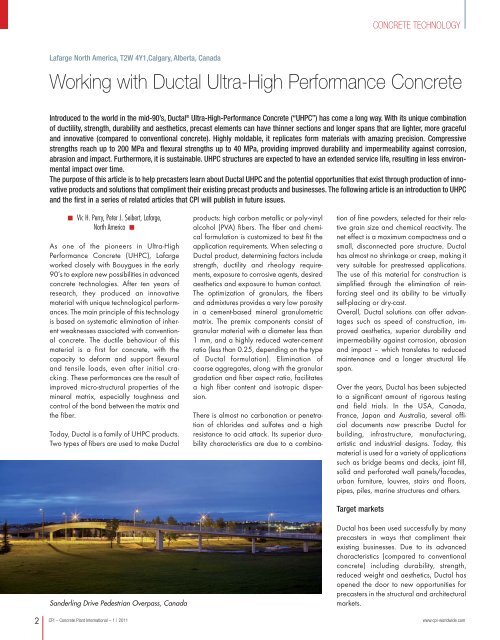

Sanderling Drive Pedestrian Overpass, Canada<br />

products: high carbon metallic or poly-vinyl<br />

alcohol (PVA) fibers. The fiber and chemical<br />

formulation is customized to best fit the<br />

application requirements. When selecting a<br />

Ductal product, determining factors include<br />

strength, ductility and rheology requirements,<br />

exposure to corrosive agents, desired<br />

aesthetics and exposure to human contact.<br />

The optimization of granulars, the fibers<br />

and admixtures provides a very low porosity<br />

in a cement-based mineral granulometric<br />

matrix. The premix components consist of<br />

granular material <strong>with</strong> a diameter less than<br />

1 mm, and a highly reduced water-cement<br />

ratio (less than 0.25, depending on the type<br />

of Ductal formulation). Elimination of<br />

coarse aggregates, along <strong>with</strong> the granular<br />

gradation and fiber aspect ratio, facilitates<br />

a high fiber content and isotropic dispersion.<br />

There is almost no carbonation or penetration<br />

of chlorides and sulfates and a high<br />

resistance to acid attack. Its superior durability<br />

characteristics are due to a combina -<br />

tion of fine powders, selected for their relative<br />

grain size and chemical reactivity. The<br />

net effect is a maximum compactness and a<br />

small, disconnected pore structure. Ductal<br />

has almost no shrinkage or creep, making it<br />

very suitable for prestressed applications.<br />

The use of this material for construction is<br />

simplified through the elimination of reinforcing<br />

steel and its ability to be virtually<br />

self-placing or dry-cast.<br />

Overall, Ductal solutions can offer advantages<br />

such as speed of construction, im -<br />

proved aesthetics, superior durability and<br />

impermeability against corrosion, abrasion<br />

and impact – which translates to reduced<br />

main tenance and a longer structural life<br />

span.<br />

Over the years, Ductal has been subjected<br />

to a significant amount of rigorous testing<br />

and field trials. In the USA, Canada,<br />

France, Japan and Australia, several offi -<br />

cial documents now prescribe Ductal for<br />

building, infrastructure, manufacturing,<br />

artis tic and industrial designs. Today, this<br />

material is used for a variety of applications<br />

such as bridge beams and decks, joint fill,<br />

solid and perforated wall panels/facades,<br />

urban furniture, louvres, stairs and floors,<br />

pipes, piles, marine structures and others.<br />

Target markets<br />

Ductal has been used successfully by many<br />

precasters in ways that compliment their<br />

existing businesses. Due to its advanced<br />

characteristics (compared to conventional<br />

concrete) including durability, strength,<br />

reduced weight and aesthetics, Ductal has<br />

opened the door to new opportunities for<br />

precasters in the structural and architectural<br />

markets.<br />

2<br />

<strong>CPI</strong> – Concrete Plant International – 1 | <strong>2011</strong><br />

www.cpi-worldwide.com