Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

A.M.T. <strong>ENGINEERS</strong> (<strong>INDIA</strong>)<br />

Basant Nagar, Kashmir Road,<br />

BATALA – 143 505.<br />

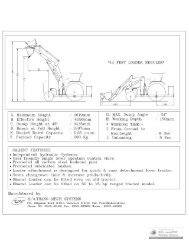

MACHINE :- PIPE THREADING MACHINE<br />

CAPACITY :- ½” to 2½” N.B. PIPE CAP.<br />

TYPE :- PILLAR TYPE (MANUAL) ( Pillar Type Vice)<br />

SPCN. NO. :- AMT – 1101<br />

GENERAL: -<br />

The Pipe Threading Machine is used for Cutting External Thread on Steel Pipe by Chasing method. HSS<br />

Tangential Chasers are used as cutters. Pipe remains stationery and Die Head rotates. BSP, BSPT, NPT,<br />

UNF, BSW, Acme Threads can be cut on this machine depending upon the type of Chasers. The Pipe<br />

Threading Machine mainly consists the following:-<br />

- Base, - HeadStock, - Saddle, - Pillar Type Clamping Vice, - Die Head.<br />

BASE: -<br />

The Base of Pipe Threading Machine is made of Cast Iron. It is Very Rigid and sturdy in construction so as<br />

to take maximum Load and absorb max. Vibrations. It is provided with four Nos. Foundation Holes of Dia<br />

M20 at four corners of the bed, a built-in Coolant Tank, Space for fitting Coolant Pump. The Head Stock is<br />

fitted on the Base.<br />

HEAD STOCK: -<br />

The Head Stock Body of Pipe Threading Machine is made of Cast Iron. It is Very rigid and sturdy in design.<br />

The Head Stock is designed for Two Nos. Spindle Speeds, provided with heavy duty Helical Gears made<br />

out of Axle Forging. The Shifting Gears slide on Splined Shafts. The Shafts are mounted on heavy duty<br />

Ball Bearings. The Input Shaft will be provided with a pulley having three grooves for C-Section V-belts.<br />

The Main Spindle is mounted on Two Anti-friction Taper Roller Bearings. The Head Stock is Oil Filled. It is<br />

provided with Oil Filling hole, Oil Drain hole and Oil Level Indicator.<br />

Two Hard Chrome Plated Pillars are fitted in the Head Stock body precisely aligned with the main Spindle<br />

axis. The Pillars are ground and finished to minimize the wear and tear.<br />

SADDLE:-<br />

The saddle made of Cast Iron, is moved on the Pillars. It is provided with Gun Metal Bushes, precisely<br />

machined and Hand Scraped to minimize wear and tear and for better and accurate movement of the<br />

saddle on the pillars. It is provided with Rack and Pinion arrangement to move the Saddle to and fro.<br />

Lubrication Points are provided wherever necessary.<br />

CLAMPING VICE: -<br />

The Pillar Type Clamping Vice made of MS rods (Hardcrome plated) and plates fitted on the Saddle. The<br />

Vice is provided with Finger Type Clamping Jaws for Clamping the Entire range of pipe size in its cap. The<br />

Pipe Clamping Jaws are fitted on two sliding blocks precisely machined, fitted in the pillar Type Vice.<br />

Movement of the sliding Blocks is made by means of a Nut & Screw arrangement, which is then fitted with<br />

a Heavy duty Handle. One Block remains Stationery while the second moves for the clamping purpose.<br />

DIE HEAD:-<br />

The Self Opening Die Head made out of Forged Steel is provided with the Machine. The Chasers<br />

areclamped in the chaser holders. A Gun Metal Ring provided on the Die Head is attached with the saddle<br />

by means of a Nut & Screw arrangement which makes the Die Head to Open (Release the pipe) after<br />

cutting a specified thread length. The Die Head can make generally R.H. BSPT, NPT threads. For making<br />

BSP, BSW, UNF, Parallel or L.H. threads, the Chaser Holders are to be changed. For these threads Spare<br />

Holders can be provided at an Extra Cost.<br />

Contd. Page – 2 -

SPCN. No. AMT- 1101 - 2 -<br />

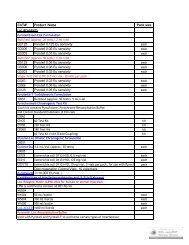

SPECIFICATIONS<br />

Min. Dia of Pipe to be Thread :- ½” N.B. Pipe<br />

Max. Dia “ “ “ “ “ :- 2½” N.B. Pipe<br />

Max. Length of thread to be cut :-200 mm<br />

Number/Range of Spindle Speeds :-Two Nos./ 110 & 212 RPM or 80 & 155(or as per your requirement)<br />

Main Motor HP/RPM :-10 / 960 RPM<br />

Approx. Wt. Of the Machine. :-1200 Kgs.<br />

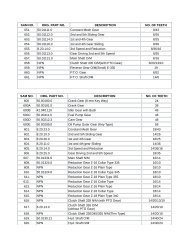

List of Standard Accessories: -<br />

Motor Pulley :- One No. Goti Handle :- One No.<br />

Allen Keys :- Two Nos. Water Collecting Tray :- One No.<br />

Clamping Jaws :- One Set. Chaser Setting Gauge :- One No.<br />

Goti :- Two Nos.<br />

Optional Accessories :-<br />

- Elec. Coolant Pump. - Lead Screw Arrangement.<br />

- Manual Pipe Stopper. - Automatic Pipe Stopper.<br />

- Electricals. - Clamping Jaws EN-31 Material.<br />

Drafted By Approved By Dated Modified<br />

Bhupinder Singh Surjit Singh 10-04-2001 20-9-2003