1 Troubleshooting for Sheet Extrusion - LG MMA

1 Troubleshooting for Sheet Extrusion - LG MMA

1 Troubleshooting for Sheet Extrusion - LG MMA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

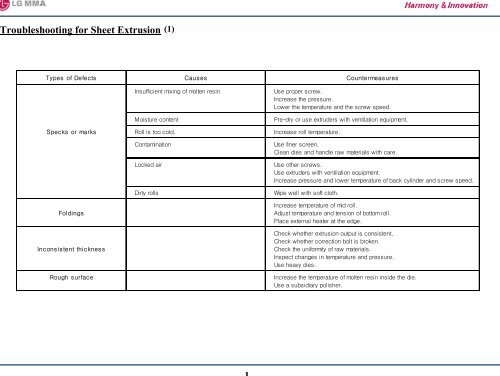

oubleshooting <strong>for</strong> <strong>Sheet</strong> <strong>Extrusion</strong> (1)<br />

Types of Defects<br />

Causes<br />

Countermeasures<br />

Insufficient mixing of molten resin<br />

Moisture content<br />

Use proper screw.<br />

Increase the pressure.<br />

Lower the temperature and the screw speed.<br />

Pre-dry or use extruders with ventilation equipment.<br />

Specks or marks Roll is too cold. Increase roll temperature.<br />

Contamination<br />

Locked air<br />

Dirty rolls<br />

Use finer screen.<br />

Clean dies and handle raw materials with care.<br />

Use other screws.<br />

Use extruders with ventilation equipment.<br />

Increase pressure and lower temperature of back cylinder and screw speed.<br />

Wipe well with soft cloth.<br />

Foldings<br />

Inconsistent thickness<br />

Rough surface<br />

Increase temperature of mid roll.<br />

Adjust temperature and tension of bottom roll.<br />

Place external heater at the edge.<br />

Check whether extrusion output is consistent.<br />

Check whether correction bolt is broken.<br />

Check the uni<strong>for</strong>mity of raw materials.<br />

Inspect changes in temperature and pressure.<br />

Use heavy dies.<br />

Increase the temperature of molten resin inside the die.<br />

Use a subsidiary polisher.

oubleshooting <strong>for</strong> <strong>Sheet</strong> <strong>Extrusion</strong> (2)<br />

Types of Defects<br />

Causes<br />

Countermeasures<br />

Die Lines<br />

Clean die lips.<br />

Streaks in the direction Moisture content Pre-dry or use extruders with ventilation equipment.<br />

of extrusion Sooted rolls Re-polish the roll surface.<br />

Streaks perpendicular to<br />

Lamination roll is too cold.<br />

Caking on rolls.<br />

Increase the temperature of lamination roll.<br />

Lower the roll temperature, the temperature of molten resin,<br />

or the temperature of blow air between sheet and roll.<br />

extraction Poor take-off unit or die. Fix take-off unit and improve die prop.<br />

Curvatures on the surface<br />

Insufficient mixing of molten resin<br />

Use other screws.<br />

Increase the extrusion pressure.<br />

Lower the screw speed.<br />

Decrease the temperature.<br />

of extrusion products Big rolling bank between roll gears. Decrease the pressure between rolls.<br />

Uni<strong>for</strong>malize thickness of sheets in the die.<br />

Increase the speed of take-off.<br />

Lamination is too hot.<br />

(Small curvatures at the edges)<br />

Lower the temperature of laminating roll.<br />

Inspect the roll surface.<br />

Clean inside the roll if possible.