Perfect cleaning of flat glass, solar glass, foils Combi Sword Brushes ...

Perfect cleaning of flat glass, solar glass, foils Combi Sword Brushes ...

Perfect cleaning of flat glass, solar glass, foils Combi Sword Brushes ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

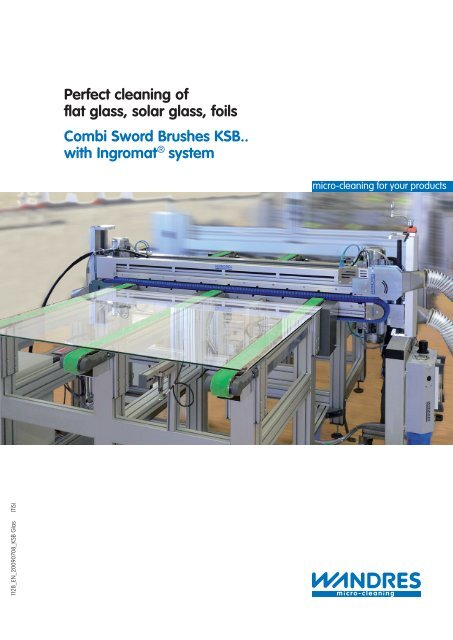

<strong>Perfect</strong> <strong>cleaning</strong> <strong>of</strong><br />

<strong>flat</strong> <strong>glass</strong>, <strong>solar</strong> <strong>glass</strong>, <strong>foils</strong><br />

<strong>Combi</strong> <strong>Sword</strong> <strong>Brushes</strong> KSB..<br />

with Ingromat ® system<br />

micro-<strong>cleaning</strong> for your products<br />

1128_EN_20090708_KSB Glas (TiS)

<strong>Combi</strong> <strong>Sword</strong> <strong>Brushes</strong> ®<br />

Cleaning after stacking<br />

For subsequent production processes, it is<br />

very important to remove dust, fibres and<br />

tiny particles gently and effectively from<br />

the <strong>glass</strong> surfaces.<br />

<strong>Combi</strong> <strong>Sword</strong> <strong>Brushes</strong> KSB..<br />

clean delicate surfaces from both sides.<br />

Cleaning after cutting<br />

Cutting and breaking <strong>glass</strong> plates<br />

produces <strong>glass</strong> chips and fine dust<br />

particles that hamper the production<br />

process.<br />

<strong>Combi</strong> <strong>Sword</strong> <strong>Brushes</strong> KSB..<br />

remove <strong>glass</strong> chips and dust particles<br />

even from sharp-edged <strong>glass</strong> plates.<br />

Cleaning after seaming<br />

Large <strong>glass</strong> plates are contaminated<br />

with dust and tiny particles after the<br />

edge processing.<br />

4 <strong>Sword</strong> <strong>Brushes</strong> BIP..<br />

provide an effective <strong>cleaning</strong> result near<br />

the edges <strong>of</strong> the plates.<br />

Wandres Ingromat ® system<br />

1. In the travel direction <strong>of</strong> the linear<br />

brushes, the Ingromat sprayer<br />

delivers a thin film <strong>of</strong> Ingromat liquid<br />

(anti-static agent, here shown in green)<br />

to the tips <strong>of</strong> the linear brushes.<br />

2. The micro-moistened brushes move<br />

transversally to the transport direction.<br />

They bind the particles to the brush<br />

filaments and transport them effectively<br />

towards the suction system.<br />

3. At the deflection, the brush filaments are<br />

cleaned mechanically and with a jet <strong>of</strong><br />

compressed air.

<strong>Combi</strong> <strong>Sword</strong> <strong>Brushes</strong> ®<br />

Cleaning before washing<br />

machines<br />

Particles from parting agents at the<br />

upper and lower surface <strong>of</strong> the <strong>glass</strong><br />

pollute the filters <strong>of</strong> washing machines.<br />

<strong>Combi</strong> <strong>Sword</strong> <strong>Brushes</strong> KSB..<br />

remove particles effectively.<br />

Maintenance efforts at the washing<br />

machines can be reduced drastically.<br />

Cleaning <strong>of</strong> transport rollers<br />

Contaminated transport conveyors or rollers<br />

spread dust and particles all over the place.<br />

<strong>Sword</strong> <strong>Brushes</strong> BIP…<br />

are easily integrated into existing conveyor<br />

systems. With clean transport conveyors or<br />

rollers, you will avoid indentations caused<br />

by dirt particles or <strong>glass</strong> chips.<br />

Cleaning before printing<br />

Clean <strong>glass</strong> surfaces are an important<br />

precondition for subsequent processes<br />

such as printing or finishing.<br />

<strong>Combi</strong> <strong>Sword</strong> <strong>Brushes</strong> KSB..<br />

provide ultrapure product surfaces.<br />

Drive motor<br />

Self-<strong>cleaning</strong> nozzle<br />

Sprayer<br />

Roto-rack<br />

Linear brush<br />

Pressure buffer<br />

Suction<br />

Self-<strong>cleaning</strong><br />

nozzle<br />

Cross section <strong>of</strong> cover to<br />

show all components inside

Double-sided <strong>cleaning</strong> before<br />

converting<br />

Cleaning <strong>of</strong> bent surfaces<br />

The lower surface <strong>of</strong> a <strong>glass</strong> plate is<br />

cleaned twice.<br />

Wandres GmbH micro-<strong>cleaning</strong><br />

D-79256 Buchenbach, Dorfstr. 12<br />

Germany<br />

Tel. + 49 (0)7661-93 30-0, Fax -93 30-30<br />

sales@wandres.com<br />

www.wandres.com<br />

Wandres Corporation<br />

USA-Ann Arbor, MI 48108<br />

719 W. Ellsworth Rd., Ste. 7<br />

Tel. +1 734-2149903, Fax -2149906<br />

sales@wandresusa.com