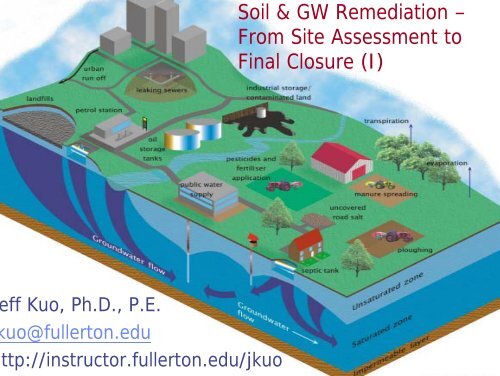

Soil & GW Remediation â From Site Assessment to Final Closure (I)

Soil & GW Remediation â From Site Assessment to Final Closure (I)

Soil & GW Remediation â From Site Assessment to Final Closure (I)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Soil</strong> & <strong>GW</strong> <strong>Remediation</strong> –<br />

<strong>From</strong> <strong>Site</strong> <strong>Assessment</strong> <strong>to</strong><br />

<strong>Final</strong> <strong>Closure</strong> (I)<br />

ff Kuo, Ph.D., P.E.<br />

uo@fuller<strong>to</strong>n.edu<br />

ttp://instruc<strong>to</strong>r.fuller<strong>to</strong>n.edu/jkuo<br />

1

Content<br />

UST removal procedure<br />

Remedial investigation<br />

Groundwater and soil sampling<br />

Characterization of vadoze zone<br />

Characterization of groundwater<br />

movement<br />

Mass partition in different phases<br />

Fate & transport of contaminants<br />

Aquifer res<strong>to</strong>ration<br />

2

3<br />

Content…<br />

<strong>Soil</strong> remediation<br />

technologies<br />

<strong>GW</strong> remediation<br />

technologies<br />

Treatment of VOC-laden<br />

air<br />

Selection of remedial<br />

technologies<br />

<strong>Final</strong> closure<br />

Modeling

UST Removal Procedure<br />

His<strong>to</strong>rical record<br />

Pre-drilling<br />

Permitting<br />

• Fire department<br />

• Local environmental agency<br />

• Air quality management districts<br />

Dig-alert<br />

Sampling locations<br />

• EPA methods (EPA 8015, EPA 8020, EPA 418.1,….)<br />

• Certified labs<br />

Additional excavation<br />

Separation of contaminated soils<br />

4

Remedial<br />

Investigation<br />

What chemicals are present?<br />

Where, on the site, are these chemicals located?<br />

His<strong>to</strong>rical records<br />

• What industrial activities occurred at the <strong>Site</strong>?<br />

• What chemicals were used at the <strong>Site</strong>?<br />

• Where were they used?<br />

• Were chemicals s<strong>to</strong>red in tanks? Where? Are<br />

they still in the tanks?<br />

How much of these chemicals were released?<br />

• Records?<br />

• Recollection of employees?<br />

5

Common Remedial<br />

Investigation (RI)<br />

Activities<br />

Removal of contamination source(s) such as<br />

leaky USTs<br />

Installation of soil borings (Boring?)<br />

Installation of groundwater moni<strong>to</strong>ring wells<br />

<strong>Soil</strong> sample collection and analysis<br />

Groundwater sample collection and analysis<br />

Aquifer testing<br />

6

Data Collected from RI<br />

Types of contaminants present in soil and gw<br />

Concentrations of contaminants in the collected<br />

samples<br />

Vertical and areal extents of contaminant plumes in<br />

soil and gw<br />

Vertical and areal extents of free-floating product or<br />

the DNAPLs<br />

<strong>Soil</strong> characteristics including the types of soil,<br />

density, moisture content, etc.<br />

Groundwater elevations<br />

Drawdown data collected from aquifer tests<br />

7

Groundwater and <strong>Soil</strong> Sampling<br />

8

<strong>Soil</strong> Gas Survey<br />

9

<strong>Soil</strong> Gas Survey<br />

Good remote sensing <strong>to</strong>ol for locating VOCs<br />

Also used <strong>to</strong> defined gw plume.<br />

For sandy formation, it may over-estimate the<br />

problem.<br />

Inexpensive and fast.<br />

10

General Considerations<br />

Types of Moni<strong>to</strong>ring<br />

Sampling Pro<strong>to</strong>col<br />

Types of Samples<br />

Sampling Location<br />

Sampling Frequency<br />

Sampling Size, Bottles, Preservation<br />

11

Types of Moni<strong>to</strong>ring/Sampling<br />

Detection Moni<strong>to</strong>ring<br />

• presence of contamination condition<br />

• existing drinking water wells?<br />

<strong>Assessment</strong> Moni<strong>to</strong>ring<br />

• extent and magnitude of contamination<br />

Evaluation Moni<strong>to</strong>ring<br />

• data for remediation system design<br />

Performance Moni<strong>to</strong>ring<br />

• evaluation of remediation effort<br />

12

Sampling Pro<strong>to</strong>col<br />

Objectives<br />

• Property transfer<br />

• Environmental liability (establish baseline for<br />

insurance/mortgage, clean-up)<br />

Locations, frequencies, types, methods, H&S<br />

Information needed for design a sampling plan<br />

• site his<strong>to</strong>ry (spill, operation, disposal practices)<br />

• site geology and hydrogeology<br />

Good documentation (always)<br />

Leave room for evolutionary development<br />

• collect more, analyze less<br />

13

Types of Samples<br />

QA/QC are important concerns!<br />

Field Blank (p. 90 EPA manual)<br />

• DI water from lab → field → sample vial→ lab<br />

• Used <strong>to</strong> determine the limit of detection<br />

Rinse/Cleaning Blank<br />

• contaminated from previous sample?<br />

Duplicate Samples<br />

• collected as back-up<br />

• soil samples are commonly duplicated.<br />

Replicate Samples<br />

• sub-samples of the same sample<br />

• labeled separately <strong>to</strong> estimate lab precision<br />

14

Types of Samples<br />

Split Samples<br />

QA/QC are important concerns!<br />

• split in half in the field <strong>to</strong> two labs or<br />

regula<strong>to</strong>ry agency<br />

Spiked Samples<br />

• spiked w/a reference standard in the lab<br />

• estimate recovery and matrix interference<br />

Labora<strong>to</strong>ry Blank<br />

• DI water analyzed <strong>to</strong> determine lab<br />

contamination<br />

Standard Reference Samples<br />

• detect instrument calibration error or analytical<br />

15

16<br />

Types of Samples ….<br />

Travel Blank<br />

Grab Sample vs. Composite Sample<br />

• cost saving?<br />

• field or lab? depth or area?<br />

• time-weighted or volume/mass-weighted?<br />

• be careful about VOCs<br />

QA/QC are important concerns

Locations & Number<br />

of Samples<br />

Statistically based sampling plans<br />

• Number of samples determined statistically.<br />

• Location of samples determined by selecting<br />

n sample points from m potential points at<br />

random.<br />

Judgmentally based sampling plans<br />

• need some knowledge (soil gas survey,<br />

surface geophysical technique, Hydropunch)<br />

17

Locations & Number<br />

of Samples…<br />

Use US EPA’s Data Quality Objective Process<br />

• Used by USEPA <strong>to</strong> ensure consistent national<br />

approach <strong>to</strong> environmental sampling.<br />

• Systematic, rational approach <strong>to</strong> determine<br />

when, where, and how <strong>to</strong> collect samples or<br />

measurements.<br />

18

Locations & Number of Samples ...<br />

Kuo’s suggestions/approach<br />

Start from the center of source (if known)<br />

Go outward for a specific distance<br />

Another distance, if contaminated<br />

Cut back half-way, if not contaminated<br />

Vadose zone: every 5 <strong>to</strong> 10 ft<br />

At the property line?<br />

19

Sampling Frequency<br />

Quarterly (most of time is OK) for <strong>GW</strong> sampling<br />

• survey all wells quarterly, part of them<br />

monthly<br />

Intermittent or slug source<br />

• need more frequent sampling<br />

20

Sampling Size, Containers, and<br />

Preservation Method<br />

Large enough <strong>to</strong> be representative & for analysis<br />

Bottles (EPA Table 9-14, p. 147)<br />

• plastics (Teflon?)<br />

• glass (transparent or amber)<br />

• head-space free (40-ml VOA vial)<br />

• metal<br />

Preservation Method<br />

Chain of Cus<strong>to</strong>dy<br />

Holding Time<br />

On-site Measurement<br />

21

23<br />

adose Zone Sampling –<br />

nalyte selection<br />

Target Compounds<br />

Subsurface<br />

Chemistry<br />

• CEC<br />

Microbial<br />

Geology<br />

• grain size<br />

distribution<br />

• porosity, K

Vadose Zone Sampling –<br />

Surface sampling<br />

Hand Sampling (surface) –<br />

scoops<br />

Hand Sampling (subsurface)<br />

• Hand Augers<br />

• Limited sample depth<br />

Direct Push Samplers<br />

• <strong>From</strong> greater depths<br />

• Allow stratified sampling.<br />

• Hydraulic hammer<br />

24

Vadose Zone Sampling –<br />

On-site analysis<br />

25<br />

No direct reading instruments yet for contaminants<br />

at needed low level detection limits.<br />

On-site methods may be used in some cases.<br />

Few methods approved by USEPA.<br />

Limited <strong>to</strong> specific contaminants.<br />

On-site mobile lab.<br />

Use PID (pho<strong>to</strong>-ionization detec<strong>to</strong>r), FID (flameionization<br />

detec<strong>to</strong>r), OVA (organic vapor analyzer),<br />

LEL (lower explosive limit) for screening.

26<br />

adose Zone Sampling –<br />

rilling<br />

Auger<br />

• Minimal damages <strong>to</strong> aquifer<br />

• No drilling fluid required<br />

• Flight acts as temporary<br />

casing<br />

• Good for unconsolidated<br />

deposits<br />

• Limited <strong>to</strong> 150 ft in depth<br />

Rotary<br />

Cable Tool

Vadose Zone Sampling –<br />

Standard penetration test<br />

A 2" dia, 18" length split core sampler is used in the<br />

Standard Penetration Test (ASTM-D-1586-84), <strong>to</strong><br />

measure soil resistance <strong>to</strong> core penetration.<br />

This test consists of driving the core sampler in<strong>to</strong><br />

the soil by dropping a 140-lb hammer 30” in<br />

repetitive blows. Using an 18" sampler, the number<br />

of blows for three successive 6" penetration<br />

increments are counted.<br />

The number of blows corresponding <strong>to</strong> the first 6"<br />

increment is discarded, while the blows for the<br />

remaining two increments are combined and<br />

reported as the number of blows per foot. 27

Standard penetration test<br />

28

29<br />

Amount of Cuttings from <strong>Soil</strong> Boring<br />

1: Determine the diameter of the boring, d b.<br />

2: Determine the depth of the boring, h.<br />

3: Calculate the volume of the cutting using the<br />

following formula:<br />

Volume of cuttings<br />

π 2<br />

= ∑ ( db<br />

)( h)( fluffy fac<strong>to</strong>r)<br />

4

Groundwater Moni<strong>to</strong>ring - Objectives<br />

Groundwater level<br />

Groundwater quality<br />

• Target Compounds<br />

• DO, pH, conductance<br />

• Dissolved gas<br />

• Fe, Mn, carbonates<br />

• If TCE, then DCE, vinyl chloride<br />

Presence of free-floating product<br />

Aquifer testing<br />

Extraction of groundwater<br />

30

Groundwater<br />

Wells - Design<br />

31<br />

Location<br />

No. of wells<br />

Diameter, Depth<br />

Perforation<br />

• interval, size, method<br />

Packing materials<br />

Permit<br />

Drilling method<br />

H & S

Groundwater Wells -<br />

Construction Materials<br />

Main Considerations<br />

• Compatibility<br />

• Cost<br />

• Handling<br />

• Strength<br />

Choices (EPA Table 4-3, p. 44)<br />

• PVC, PTFE, PP, PE<br />

• Steel, SS<br />

Flexible Joints<br />

32

Groundwater Wells - Sampling<br />

Wells need <strong>to</strong> be developed after installation<br />

Well inspection<br />

Purging<br />

• Remove stagnant water<br />

• 3-5 pore volumes (well casing + filter pack)<br />

• May want <strong>to</strong> minimize purge water<br />

• Moni<strong>to</strong>r pH, conductivity, and temperature - until<br />

stabilized.<br />

• EPA Figure 9-9 and Table 9-8.<br />

Sample collection<br />

Field blanks/rinse blanks<br />

S<strong>to</strong>rage and transport<br />

33

34<br />

<strong>GW</strong> Sampling - Containers<br />

Head space free<br />

Minimize aeration and air contact<br />

Dedicated for each well<br />

No or little adsorption<br />

Teflon, PP, PE: good<br />

PVC, Tygon, silicon rubber - NG

<strong>GW</strong> Sampling - Devices<br />

Bailers<br />

• art, in-line measurement of<br />

pH …. is impossible<br />

• Not good for purging<br />

(homogenize well volume<br />

only)<br />

Bladder Pumps<br />

• cylinder w/ an internal bladder<br />

that compress and expanded<br />

by a gas.<br />

• precise and pulseless flow.<br />

Submersible Pumps<br />

• deep well with high volume,<br />

poor accuracy<br />

35

<strong>GW</strong> Sampling - Hydropunch<br />

The Hydropunch is pushed <strong>to</strong> the<br />

desired depth and the push pipes<br />

are retracted, exposing the<br />

Hydropunch screen <strong>to</strong> the<br />

groundwater.<br />

The groundwater enters and is<br />

allowed <strong>to</strong> come <strong>to</strong> equilibrium,<br />

which generally takes less than 15<br />

<strong>to</strong> 20 minutes.<br />

One-time deal – no permanent well<br />

installation.<br />

36

Well Volumes for<br />

Groundwater<br />

Sampling<br />

Well volume = volume of the groundwater<br />

enclosed inside the well casing + volume of the<br />

groundwater in the pore space of the packing.<br />

π 2 π 2 2<br />

Well volume = [ dc ] h+ [ ( d −d ) h]<br />

φ<br />

4 4<br />

b c<br />

37

38<br />

Well Volumes for <strong>GW</strong><br />

Sampling - Example<br />

The water depth inside one of the four<br />

moni<strong>to</strong>ring wells was measured <strong>to</strong> be 14.5’.<br />

Three well volumes need <strong>to</strong> be purged out<br />

before sampling. Calculate the amount of<br />

purge water and also the number of 55-gallon<br />

drums needed <strong>to</strong> s<strong>to</strong>re the water. Assume<br />

the porosity of the well packing <strong>to</strong> be 0.40.

Well Volumes for <strong>GW</strong> Sampling - Example<br />

π 2 π 2 2<br />

Well volume = [ dc ] h+ [ ( d −d ) h]<br />

φ<br />

4 4<br />

b c<br />

) Well volume = (π/4)(4/12) 2<br />

(14.5) + (π/4)[(10/12) 2 -<br />

(4/12) 2 ](14.5)(0.4) = 13.92 ft 3<br />

) 3 well volumes =<br />

(3)(13.92)=41.8 ft 3 = 313<br />

gallons<br />

) Number of 55-gallon drums<br />

needed= (41.8 ft 3 )(7.48<br />

gal/ft 3 ) ÷ (55 gallon/drum) =<br />

5.7 drums<br />

39

Chemical Compounds of Concern<br />

40

41<br />

Chemical Compounds of Concern<br />

Common examples of chlorinated solvents

Chemical Compounds of Concern<br />

42<br />

Common examples of aromatics<br />

trachlorodibenzo-p-dioxin

43<br />

Chemical Compounds of Concern<br />

Others

Vadose Zone ….<br />

Contaminants may be present in<br />

• Vadose zone<br />

• vapors in the void<br />

• free product in the void<br />

• dissolved in soil moisture<br />

• adsorbed on<strong>to</strong> the soil matrix<br />

• floating on <strong>to</strong>p of the capillary fringe (for LNAPLs)<br />

• Groundwater<br />

• dissolved in the groundwater<br />

• adsorbed on<strong>to</strong> the aquifer material<br />

• sitting on <strong>to</strong>p of the bedrock (for DNAPLs)<br />

44

Mass & volume of soil excavated<br />

during tank removal<br />

Mass & volume of contaminated soil<br />

left in thevadosezone<br />

Mass of contaminants in the vadose<br />

zone<br />

Mass & volume of the free-floating<br />

product<br />

Volume of contaminated groundwater<br />

Mass of contaminants in the aquifer<br />

<strong>GW</strong> flow gradient and direction<br />

Hydraulic conductivity of the aquifer<br />

45<br />

Common Engineering<br />

Calculation Related <strong>to</strong> RI

Mass-concentration<br />

Relationship (ppm)<br />

Liquid: 1 ppm = 1/1,000,000 ~ 1 mg/L<br />

1% by wt. = 10,000 ppm<br />

Solid: 1 ppm = 1 mg/kg =1,000 ppb<br />

Air: ppmV<br />

1ppmV =<br />

MW 224 .<br />

[ mg/ m ] at 0 C<br />

MW<br />

=<br />

2405 . mg m<br />

3<br />

[ / ] at<br />

o<br />

20 C<br />

MW<br />

=<br />

245 . mg m<br />

3<br />

[ / ] at<br />

o<br />

25 C<br />

3<br />

o<br />

6<br />

1ppmV −<br />

= × 10<br />

359<br />

3<br />

[ lb/ ft ]<br />

o<br />

at 32 F<br />

MW<br />

−6 = × 10<br />

385<br />

3<br />

[ lb/ ft ]<br />

o<br />

at 68 F<br />

MW<br />

−6 = × 10<br />

392<br />

3<br />

[ lb/ ft ]<br />

o<br />

at 77 F<br />

46

47<br />

Mass-concentration<br />

Relationship ….<br />

Mass of contaminant in liquid =<br />

(liquid volume)(liquid concentration)<br />

= (V l<br />

)(C)<br />

Mass of contaminant in soil = (X)(M s<br />

)<br />

= (X)[(V s<br />

)(ρ b<br />

)]<br />

Mass of contaminant in air =<br />

(air volume)(concentration in mass/vol)<br />

= (V a<br />

)(G)

Mass-concentration Relationship (Example)<br />

Which of the following media contains the largest<br />

amount of xylene (show your calculations)?<br />

(a) 1 million gallons of water containing 10 ppm of<br />

xylene<br />

(b) 100 cubic yards of soil (bulk density = 1.8<br />

g/cm 3 ) with 10 ppm of xylene<br />

(c) An empty warehouse (200' x 50' x 20') with 10<br />

ppmV xylene in air.<br />

48

Mass-concentration Relationship (Example)<br />

(a) Mass of contaminant in liquid = (V)(C)<br />

= (1,000,000 gallon)(3.785 L/gallon)(10 mg/L) = 3.79 x 10 7 mg<br />

(b) Mass of contaminant in soil = (X)[(V s )(ρ b )]<br />

= [(100 yd 3 )(27 ft 3 /yd 3 )(30.48cm/ft) 3 ][(1.8g/cm 3 )(kg/1000g)](10<br />

mg/kg) = 1.37 x 10 6 mg<br />

(c) Molecular weight of xylene [C 6 H 4 (CH 3 ) 2 ] = 106 g/mole<br />

10 ppmV = (10)(MW of xylene/24.05) mg/m 3 = (10)(106/24.05)<br />

mg/m 3 = 44.07 mg/m 3<br />

Mass of contaminant in air = (V)(G)<br />

= [(200 x 50 x 20 ft 3 )(0.3048m/ft) 3 ](44.07 mg/m 3 ) = 2.5x10 5 mg<br />

49

ass & Volume of <strong>Soil</strong><br />

om a Tank Pit<br />

xample)<br />

Step 1: Measure the dimensions of the<br />

tank pit.<br />

Step 2: Calculate the volume of the tank<br />

pit from the measured dimensions.<br />

Step 3: Determine the number and<br />

volumes of the USTs removed.<br />

Step 4: Subtract the <strong>to</strong>tal volume of the<br />

USTs from volume of the tank pit.<br />

Step 5: Multiply the value from Step #4<br />

50

Mass & Volume of<br />

<strong>Soil</strong> from a Tank Pit<br />

(Example)<br />

(Example) Two 5,000-gallon USTs and one<br />

4,000-gallon UST were removed. The<br />

excavation resulted in a tank pit of 50’ x 24’ x<br />

18’. The excavated soil was s<strong>to</strong>ckpiled on-site.<br />

The bulk density of soil in-situ (before<br />

excavation) = 1.8 g/cm 3 and bulk density of soil<br />

in the s<strong>to</strong>ckpiles is 1.64 g/cm 3 .<br />

Estimate the mass and volume of the excavated<br />

soil.<br />

51

Mass & Volume of <strong>Soil</strong> from<br />

a Tank Pit (Example)<br />

Volume of the tank pit = (50’)(24’)(18’) = 21,600 ft 3 .<br />

Total volume of the USTs = (2)(5,000) + (1)(4,000)<br />

= 14,000 gallons<br />

= (14,000 gallon)(ft 3 /7.48 gallon) = 1,872 ft 3 .<br />

Volume of soil in the tank pit before removal =<br />

(volume of tank pit) - (volume of USTs)<br />

= 21,600 - 1,872 = 18,728 ft 3 .<br />

Volume of soil excavated (in the s<strong>to</strong>ckpile)<br />

= (volume of soil in the tank pit) x (fluffy fac<strong>to</strong>r)<br />

= (18,728)(1.10) = 20,600 ft 3<br />

= (20,600 ft 3 )[yd 3 /27 ft 3 ]= 763 yd 3 .<br />

52

Mass & Volume of <strong>Soil</strong><br />

from a Tank Pit<br />

(Example)<br />

Mass of soil excavated = (volume of the soil in the<br />

tank pit)(bulk density of soil in-situ)<br />

= (volume of the soil in the s<strong>to</strong>ckpile)(bulk density<br />

of soil in the s<strong>to</strong>ckpile)<br />

<strong>Soil</strong> density in situ =<br />

(1.8 g/cm 3 )[(62.4lb/ft 3 )/(1g/cm 3 )]= 112 lb/ft 3 .<br />

<strong>Soil</strong> density in s<strong>to</strong>ckpiles =<br />

(1.64)(62.4) = 102 lb/ft 3 .<br />

Mass of soil excavated = (18,728 ft 3 )(112 lb/ft 3 ) =<br />

2,098,000 lb = 1,049 <strong>to</strong>ns<br />

= (20,600 ft 3 )(102 lb/ft 3 ) = 2,101,000 lb = 1,051<br />

53

Volume of <strong>Soil</strong> in the Vadose<br />

Zone (Example)<br />

1. Determine area of the plume at each sampling depth, A i .<br />

2. Determine the thickness interval for each area, h i.<br />

3. Determine the volume of the contaminated soil, V s , using:<br />

4. Determine the mass of the contaminated soil, M s , by<br />

multiplying V s by the density of soil.<br />

V = ∑ A i<br />

h<br />

(Example) After the USTs were removed, five soil borings were<br />

installed., the area of the plume was determined as follow:<br />

Depth (ft bgs) Area of the plume (ft 2 )<br />

15 0<br />

20 350<br />

25 420<br />

30 560<br />

35 810<br />

40 0<br />

54<br />

i

olume of <strong>Soil</strong> in the<br />

adose Zone (Example)<br />

V = ∑ A i<br />

h<br />

i<br />

i<br />

Thickness interval for each area is the same at 5 ft.<br />

Volume of the contaminated soil<br />

= (5)(350) + (5)(420) + (5)(560) + (5)(810)<br />

= 10,700 ft 3 = 396 yd 3, or<br />

= (22.5-17.5)(350) + (27.5 - 22.5)(420) + (32.5 -<br />

27.5)(560) + (37.5 -32.5)(810) = 10,700 ft 3<br />

Mass of the contaminated soil<br />

3 3<br />

55

Capillary Fringe<br />

Capillary fringe (or capillary zone) is a<br />

zone immediately above the water<br />

table of unconfined aquifers.<br />

It extends from the <strong>to</strong>p of the water<br />

table due <strong>to</strong> the capillary rise of water.<br />

The capillary fringe often creates complications in site<br />

remediation projects.<br />

If the water table fluctuates, the capillary fringe will<br />

move upward or downward with the water table.<br />

If free-floating product exists, the fluctuation of the<br />

water table will cause the free product moving away<br />

56

57<br />

Capillary Rise<br />

Height of capillary rise<br />

is a function of diameter<br />

of capillary tube<br />

h c1<br />

h c2<br />

h c3<br />

h c4

Capillary Fringe …..<br />

The height of capillary fringe at a site strongly<br />

depends on its subsurface geology.<br />

For pure water at 20 o C in a clean glass tube, the<br />

height of capillary rise can be approximated by<br />

the following equation:<br />

h<br />

c = 0153 .<br />

r<br />

where h c<br />

is the height of capillary rise in cm, and<br />

r is the radius of the capillary tube in cm. This<br />

formula can be used <strong>to</strong> estimate the height of<br />

the capillary fringe.<br />

58

Mass/Volume of Free-Floating Product<br />

It is now well-known that the thickness of free<br />

product found in the formation (the actual thickness)<br />

is much smaller than that floating on <strong>to</strong>p of the<br />

water in a moni<strong>to</strong>ring well (the apparent thickness).<br />

t = t( 1 − S ) − h<br />

g g a<br />

Ballestero et al. (1994):<br />

• t g = actual (formation) free product thickness<br />

t = apparent (wellbore) product thickness<br />

S g = specific gravity of free product<br />

h a = distance from bot<strong>to</strong>m of the free product <strong>to</strong> the<br />

water table. If no further data for h a are available,<br />

average wetting capillary rise can be used as h a .<br />

59

Thickness of<br />

Free-Floating<br />

Product<br />

(Example) A recent survey of a <strong>GW</strong> moni<strong>to</strong>ring well<br />

showed a 75-in thick layer of gasoline floating on <strong>to</strong>p<br />

of the water. The density of gasoline is 0.8 g/cm 3<br />

and the thickness of the capillary fringe above the<br />

water table is one foot. Estimate the actual thickness<br />

of the free-floating product in the formation.<br />

Actual free product thickness<br />

= (75)(1 - 0.8) - 12 = 3 inches<br />

60

Mass/Volume of Free-<br />

Floating Product<br />

Step 1: Determine the areal extent of the free-floating<br />

product.<br />

Step 2: Determine the true thickness of the freefloating<br />

product.<br />

Step 3: Determine the volume of the free-floating<br />

product by multiplying the area with the true<br />

thickness and the porosity of the formation.<br />

Step 4: Determine the mass of the free-floating<br />

product by multiplying the volume with its density.<br />

61

Mass/Volume of Free-<br />

Floating Product<br />

(Example) Recent groundwater moni<strong>to</strong>ring results<br />

at a contaminated site indicate the areal extent of<br />

the free-floating product is approximately a<br />

rectangular shape of 50 ft by 40 ft.<br />

The true thicknesses of the free-floating product in<br />

the four moni<strong>to</strong>ring wells inside the plume are 2,<br />

2.6, 2.8, and 3 ft, respectively.<br />

The porosity of the subsurface is 0.35.<br />

Estimate the mass and volume of the free-floating<br />

product present at the site. Assume the specific<br />

62

Mass/Volume of Free-Floating Product<br />

(a) The areal extent of the free-floating product = (50')(40') =<br />

2,000 ft 2<br />

(b)The average thickness of the free-floating product<br />

= (2 + 2.6 + 2.8 + 3)/4 = 2.6 ft<br />

(c)The volume of the free-floating product<br />

= (area)(thickness)(porosity of the formation)<br />

= (2,000 ft 2 )(2.6 ft)(0.35) = 1,820 ft 3<br />

= (1,820 ft 3 )(7.48 gal/ft 3 ) = 13,610 gallon<br />

(d) Mass of the free-floating product<br />

= (volume of the free-floating product)(density of the freefloating<br />

product)<br />

= (1,820 ft 3 ){0.8 g/cm 3 )[62.4 lb/ft 3 /(1 g/cm 3 )]}= 90,854 lb<br />

= 41,300 kg.<br />

63

Mass of<br />

Contaminants<br />

Present in<br />

Different Phases<br />

A NAPL enters subsurface, it may end up in 4 phases.<br />

• leave the free product and enter the air void.<br />

• dissolve in the liquid.<br />

• adsorb on<strong>to</strong> the soil grains.<br />

Concentrations in the void, in the soil moisture, and<br />

on the soil grains are interrelated and affected greatly<br />

by the presence or absence of the free product.<br />

Partition of the contaminants in these four phases has<br />

a great impact on the fate and transport of the<br />

64

Mass of Contaminants<br />

Present in Different<br />

Phases…..<br />

Understanding this partition is needed <strong>to</strong> implement<br />

cost-effective alternatives for cleanup.<br />

Here, we will discuss:<br />

• vapor concentration resulting from the presence<br />

of free-product in the pores<br />

• relationship between the concentration in the<br />

liquid and that in the air<br />

• relationship between the concentration in the<br />

liquid and that on the soil<br />

• relationship among the liquid, vapor and solid<br />

concentrations<br />

65

Equilibrium between Free<br />

Product and Vapor<br />

For an ideal liquid mixture, the<br />

vapor-liquid equilibrium follows<br />

Raoult's law as:<br />

P = ( P )( x )<br />

A<br />

vap<br />

• P A<br />

= partial pressure of A in the<br />

vapor phase<br />

• P vap = vapor pressure of A as a<br />

pure liquid<br />

• x A<br />

= mole fraction of A in the<br />

liquid phase<br />

A<br />

66

Equilibrium between<br />

Free Product & Vapor ...<br />

P = ( P )( x )<br />

A<br />

vap<br />

A<br />

The partial pressure is the pressure that a compound<br />

would exert if all other gases were not present.<br />

This is equivalent <strong>to</strong> the mole fraction of the<br />

compound in the gas phase multiplied by the entire<br />

pressure of the gas.<br />

Raoult's law holds only for ideal solutions. In dilute<br />

aqueous solutions commonly found in environmental<br />

applications, Henry's law applies.<br />

67

Equilibrium between<br />

Free Product & Vapor ...<br />

Benzene leaked in<strong>to</strong> a vadose zone. Estimate<br />

the maximum benzene concentration (in ppmV)<br />

in the pore space. T = 25 o C.<br />

• Vapor pressure = 95 mm-Hg at 25 o C=<br />

0.125 atm.<br />

• Partial pressure of benzene in the pore space<br />

is 0.125 atm (125,000 x 10 -6 atm), which is<br />

equivalent <strong>to</strong> 125,000 ppmV.<br />

68

69<br />

Equilibrium between Free Product &<br />

Vapor ...<br />

Discussion: The 125,000 ppmV is the vapor<br />

concentration in equilibrium with the pure benzene<br />

liquid. The equilibrium can occur in a confined<br />

space or a stagnant phase.<br />

If the medium is not <strong>to</strong>tally confined, the vapor<br />

tends <strong>to</strong> move away from the source and creates a<br />

concentration gradient (the vapor concentration<br />

decreases with the distance from the free liquid).<br />

However, in the vicinity of the free product the<br />

vapor concentration would be at or near this<br />

equilibrium value.

Liquid-Vapor Equilibrium<br />

Henry's law is used <strong>to</strong> describe the<br />

equilibrium relationship between the<br />

liquid and vapor concentrations.<br />

At equilibrium, the partial pressure<br />

of a gas above a liquid is<br />

proportional <strong>to</strong> the concentration of<br />

the chemical in the liquid.<br />

P A<br />

= H A<br />

C A<br />

• P A<br />

= partial pressure of A in the<br />

gas phase<br />

• H A<br />

= Henry's constant of A<br />

• C A<br />

= conc. of A in the liquid<br />

70

Liquid-Vapor<br />

Equilibrium…..<br />

Henry's law can also be expressed as:<br />

G = HC<br />

• C = concentration in the liquid phase<br />

• G = concentration in the gas phase.<br />

The units of the Henry's law constant (or Henry's<br />

constant) reported in the literature vary considerably<br />

The units commonly encountered are: atm/mole<br />

fraction, atm/M, M/atm, atm/(mg/L), and<br />

dimensionless.<br />

71

72<br />

Liquid-Vapor Equilibrium…..<br />

Henry's Constant Conversion Table (from Kuo & Cordery, 1988)<br />

Desired unit for Henry's constant<br />

Conversion equation<br />

atm/M, or atm L/mole<br />

H = H * RT<br />

atm m 3 /mole<br />

H = H * RT/1,000<br />

M/atm<br />

H = 1/(H * RT)<br />

atm/(mole fraction in liquid), or atm<br />

H = (H * RT)[1,000γ/W]<br />

(mole fraction in vapor)/(mole fraction in liquid)<br />

H = (H * RT)[1,000γ/W]/P<br />

Note: H * = Henry's constant in dimensionless form<br />

γ = specific gravity of the solution (1 for dilute solution)<br />

W = equivalent molecular weight of solution (18 for dilute aqueous solution)<br />

R = 0.082 atm/(K)(M)<br />

T = system temperature in Kelvin<br />

P = system pressure in atm (usually =1 atm)<br />

M = solution molarity in (g mol/L)

Liquid-Vapor Equilibrium…..<br />

Henry's constant of any given compound varies with<br />

T. The Henry’s constant is practically the ratio of the<br />

vapor pressure divided by solubility.<br />

H = vapor pressure<br />

solubility<br />

The higher the vapor pressure the larger the Henry’s<br />

constant is. The lower the solubility, the higher<br />

Henry’s constant will be. For most organics, the<br />

vapor pressure increases and the solubility decreases<br />

with temperature.<br />

73

74<br />

Liquid-Vapor Equilibrium…..<br />

(Example) Henry's constant for benzene in water<br />

at 25 o C is 5.55 atm/M. Convert this value <strong>to</strong><br />

dimensionless units and also <strong>to</strong> units of atm.<br />

H = H * RT = 5.55 = H * (0.082)(273 +25)<br />

• H * = 0.227 (dimensionless)<br />

H = (H * RT)[1,000γ/W]<br />

• H=(0.227)(0.082)(273+25)][(1,000)(1)/(18)]<br />

= 308 atm

Liquid-Vapor Equilibrium…..<br />

(Example) The subsurface of a site is contaminated with<br />

tetrachloroethylene (PCE). Recent soil vapor survey<br />

indicates that the vapor contained 1,250 ppmV PCE.<br />

Estimate the PCE concentration in the soil moisture.<br />

Assume the subsurface temperature <strong>to</strong> be 20 o C.<br />

H = H * RT = 25.9 = H * (0.082)(273 +20)<br />

• H * = 1.08 (dimensionless)<br />

Convert ppmV <strong>to</strong> mg/m 3<br />

• 1,250 ppmV = (1,250)[(165.8/24.05)] mg/m 3<br />

• = 8,620 mg/m 3 = 8.62 mg/L<br />

G = HC = 8.62 mg/L = (1.08)C<br />

75

Solid-Liquid Equilibrium<br />

Adsorption is the process in which a component<br />

moves from liquid/gas phase <strong>to</strong> solid phase<br />

across the interfacial boundary.<br />

• adsorbent (e.g., vadose zone soil, aquifer<br />

matrix, and activated carbon)<br />

• adsorbate (e.g., the contaminant)<br />

• solvent (e.g., soil moisture and groundwater)<br />

Adsorption is an important mechanism governing<br />

the contaminant’s fate and transport in an<br />

environmental medium.<br />

76

Solid-Liquid Equilibrium….<br />

For a system where solid phase and liquid phase<br />

coexist, an adsorption isotherm describes the<br />

equilibrium relationship between the liquid and<br />

solid phases. The “isotherm” indicates that the<br />

relationship is for a constant temperature.<br />

Two most popular isotherms are the Langmuir<br />

isotherm and the Freundlich isotherm. Both<br />

were derived in early 1900s. The Langmuir<br />

isotherm has a theoretical basis, while the<br />

Freundlich is a semi-empirical relationship.<br />

77

Solid-Liquid Equilibrium….<br />

Langmuir isotherm:<br />

X<br />

=<br />

X<br />

max 1+<br />

KC<br />

KC<br />

• X = sorbed concentration, C = liquid<br />

concentration, K = equilibrium<br />

constant, and X max<br />

= the maximum<br />

adsorbed concentration.<br />

Freundlich isotherm:<br />

1/<br />

X = KC n<br />

• Both K and 1/n are empirical<br />

constants.<br />

78

Solid-Liquid Equilibrium….<br />

Both isotherms are non-linear. Incorporating<br />

them in<strong>to</strong> the mass balance equation will make<br />

the computer simulation harder or more timeconsuming.<br />

Fortunately, it was found that in many<br />

environmental applications, the linear form of<br />

the Freundlich isotherm applies. It is called the<br />

linear adsorption isotherm, since 1/n =1, thus<br />

X = KC<br />

79

Solid-Liquid<br />

Equilibrium….<br />

For soil-water systems, the linear adsorption isotherm<br />

is often written as:<br />

X = K p<br />

C; or K p<br />

= X/C<br />

• where K p<br />

is called the partition coefficient that<br />

measures the tendency of a chemical <strong>to</strong> be<br />

adsorbed by soil or sediment from a liquid phase<br />

and describes how the chemical compound<br />

distributes (partitions) itself between the two media.<br />

Henry’s constant, which was discussed earlier, can<br />

be viewed as the vapor-liquid partition coefficient.<br />

80

Solid-Liquid Equilibrium….<br />

For a given organic chemical compound, the partition<br />

coefficient is not the same for every soil.<br />

It was found that K p<br />

increases as the fraction of<br />

organic carbon, f oc<br />

, increases in soil, thus<br />

K p<br />

=f oc<br />

K oc<br />

The organic carbon partition coefficient, K oc<br />

, can be<br />

considered as the partition coefficient for the organic<br />

compound in<strong>to</strong> a hypothetical pure organic carbon<br />

phase. For soil which is not 100% organics, the<br />

81

82<br />

Solid-Liquid Equilibrium….<br />

K oc<br />

is actually a theoretical parameter. Research<br />

has been conducted <strong>to</strong> relate them <strong>to</strong> more<br />

commonly available chemical properties such as<br />

solubility in water (S w<br />

) and the octanol-water<br />

partition coefficient.<br />

K ow<br />

is a dimensionless constant:<br />

Coctanol<br />

K ow =<br />

C<br />

• C octanol<br />

= conc. of an organic compound in octanol<br />

• C water<br />

water<br />

= conc. of the organic compound in water

Solid-Liquid Equilibrium….<br />

K ow<br />

indicates how an organic compound will<br />

partition between an organic phase and water.<br />

Values of K ow<br />

range widely, from 10 -3 <strong>to</strong> 10 7 .<br />

Organic chemicals with low K ow<br />

values are<br />

hydrophilic and have low soil adsorption. Many<br />

equations exist between K oc<br />

and K ow<br />

(or S w<br />

)<br />

The following is also commonly used:<br />

K oc<br />

= 0.63 K ow<br />

83

Solid-Liquid Equilibrium….<br />

(Example) The aquifer is contaminated with PCE. A<br />

groundwater sample contains 200 ppb of PCE.<br />

Estimate the PCE concentration adsorbed on the<br />

aquifer material, which contains 1% of organic<br />

carbon. Assume the adsorption follows a linear<br />

model.<br />

(a) Log K ow<br />

= 2.6 => K ow<br />

= 398<br />

(b) K oc<br />

=0.63K ow<br />

=0.63(398)=251 mL/g=251 L/kg<br />

(c) K p<br />

=f oc<br />

K oc<br />

=(1%)(251)=2.51 mL/g=2.51 L/kg<br />

(d) X = K p<br />

C = (2.51 L/kg)(0.2 mg/L) = 0.50 mg/kg<br />

84

Solid-Liquid-Vapor Equilibrium<br />

The soil moisture in the vadose zone is in contact with<br />

both soil grains and air in the void, and the<br />

contaminant in each phase can travel <strong>to</strong> the other<br />

phases. The concentration in the liquid, for example,<br />

is affected by the concentrations in the other phases<br />

(i.e., soil, vapor, and free product).<br />

These concentrations are related by the equilibrium<br />

equations. If the system is at equilibrium and the<br />

concentration of one phase is known, the<br />

concentrations at other phases can be estimated.<br />

Although in real applications, the equilibrium condition<br />

does not always exist, the estimate serves as a good<br />

starting point or as the range of the real values.<br />

85

Partition of Contaminants<br />

in Different Phases<br />

M<br />

V<br />

t<br />

= [( φ ) + ( ρ ) K + ( φ ) H ] C<br />

w b p a<br />

K<br />

w b p<br />

= [ ( φ ) ( ρ )<br />

+ +<br />

H H<br />

( φ )] G<br />

a<br />

w<br />

H<br />

= [ ( φ ) + ρb<br />

+ ( φa<br />

) ]<br />

K<br />

K<br />

p<br />

P<br />

X<br />

where M t<br />

/V can be viewed as the average mass<br />

concentration of the plume.<br />

86

Partition of Contaminants<br />

in Different Phases…..<br />

(Example) A new technician collected a<br />

groundwater sample. He filled only half of the 40-<br />

mL sample vial. The benzene concentration in the<br />

collected groundwater was analyzed <strong>to</strong> be 5 mg/L.<br />

Determine:<br />

(1) benzene concentration of benzene in the head<br />

space before the vial was opened,<br />

(2) percentage of <strong>to</strong>tal benzene mass in the<br />

aqueous phase of the closed vial, and<br />

(3) true benzene concentration, if head-space free<br />

sample is collected.<br />

87

88<br />

Partition of Contaminants<br />

in Different Phases…..<br />

Basis: 1-liter container<br />

(1) Concentration of benzene in the head space<br />

= H x C l<br />

= (0.22)(5) = 1.1 mg/L = 340 ppmV.<br />

(2) Mass of benzene in liquid = (5)(0.5) = 2.5 mg<br />

Mass of benzene in the head space = (1.1)(0.5)<br />

= 0.55 mg<br />

Total mass of benzene = 2.5 + 0.55 = 3.05 mg<br />

% of <strong>to</strong>tal benzene in liquid = 2.5/3.05 = 82%.<br />

(3) The actual liquid concentration should be<br />

= (3.05)/(0.5) = 6.1 mg/L

Partition of Contaminants<br />

in Different Phases…..<br />

(Example) The aquifer underneath a site is<br />

contaminated with PCE. The aquifer porosity is 0.4<br />

and the bulk density of the aquifer material is 1.8<br />

g/cm 3 . A groundwater sample contains 200 ppb of PCE.<br />

Assuming a linear adsorption model, estimate:<br />

(1) the PCE concentration adsorbed on the aquifer<br />

material, (f oc<br />

= 0.01), and<br />

(2) the partition of PCE in the two phases, i.e.,<br />

89

Partition of<br />

Contaminants<br />

in Different<br />

Phases…..<br />

(a) PCE concentration adsorbed on<strong>to</strong> the solid has<br />

been determined as 0.50 mg/kg.<br />

(b) Basis: 1-liter aquifer formation<br />

Mass of PCE in the liquid phase<br />

= (C)[(V)(φ)] = (0.2)[(1)(0.4)] = 0.08 mg<br />

Mass of PCE adsorbed on the solid<br />

90

91<br />

Partition of Contaminants<br />

in Different Phases…..<br />

Total mass of PCE = mass in liquid + mass on<br />

the solid<br />

= 0.08 + 0.9 = 0.98 mg<br />

Percentage of <strong>to</strong>tal PCE mass in the aqueous<br />

phase<br />

= 0.08/0.98 = 8.2%.<br />

Discussion: 91.8% of <strong>to</strong>tal PCE is adsorbed on<strong>to</strong><br />

the aquifer materials. This partially explains<br />

why the clean-up of aquifer takes a long time<br />

using the pump-and-treat method

Groundwater<br />

Movement<br />

Why do we have <strong>to</strong> know?<br />

Advection is the primary transport mechanisms<br />

of contaminants.<br />

How far does it go? - <strong>Site</strong> <strong>Assessment</strong><br />

How fast can we remove it? - <strong>Remediation</strong><br />

Where is it from?<br />

Where is it going?<br />

92

Darcy’s Law<br />

Q = -KA (∆h/dL)<br />

v<br />

Q<br />

= = −<br />

A<br />

K dh<br />

dl<br />

93

Calculating Gradient from Well Data<br />

Graphical method<br />

42 m<br />

45 m<br />

40 m<br />

39 m<br />

40 m<br />

45 m<br />

49 m<br />

Linear interpolation between well points<br />

94

Darcy Velocity vs.<br />

Seepage Velocity<br />

Does this Darcy velocity represent the<br />

groundwater flow velocity?<br />

The Darcy velocity in Darcy’s equation assumes<br />

the flow occurs through the entire cross-section<br />

of the porous medium.<br />

The actual fluid velocity through the porous<br />

medium would be larger than the Darcy velocity.<br />

This flow velocity is often called the seepage<br />

velocity or the interstitial velocity.<br />

Q<br />

vs = =<br />

φ A<br />

v<br />

φ<br />

95

Hydraulic Conductivity vs.<br />

Intrinsic Permeability<br />

The intrinsic permeability of a soil core sample is<br />

1 Darcy. What is the hydraulic conductivity of<br />

this soil for water at 25 o C?<br />

• density of water (25 o C) = 0.99703 g/cm 3<br />

• viscosity of water (25 o C) = 0.00890 g/s•cm<br />

K<br />

=<br />

kρg<br />

µ<br />

=<br />

(9.87 × 10<br />

−9<br />

2<br />

cm )(0.99703g/<br />

cm<br />

0.00890g/<br />

s • cm<br />

3<br />

)(980cm/<br />

s<br />

2<br />

)<br />

= 1.09×<br />

10<br />

−3<br />

cm/<br />

s<br />

=<br />

(1.09×<br />

10<br />

−3<br />

)(2.12×<br />

10<br />

4<br />

)<br />

=<br />

23.0gpd<br />

/<br />

ft<br />

2<br />

96

Methods of Determining K<br />

Labora<strong>to</strong>ry Tests<br />

• Sieve Analysis<br />

• Constant Head Permeameter<br />

• Falling-Head Permeameter<br />

Aquifer Tests<br />

• Pumping Test<br />

• Slug Test<br />

97

Constant Head Permeameter<br />

Used for sands,<br />

noncohesive sediment<br />

Cylindrical chamber <strong>to</strong><br />

hold sample<br />

Maintain a constant head<br />

Water moves through<br />

sample at constant rate<br />

Measure Q (volume/ time)<br />

Q = -KA (∆ h/L)<br />

Rearrange<br />

K = QL/A(-∆h)<br />

98

Falling Head Permeameter<br />

Continuity: flow in = flow out<br />

K =<br />

d<br />

d<br />

2<br />

t<br />

2<br />

c<br />

L<br />

t<br />

h<br />

ln(<br />

h<br />

o<br />

)<br />

K = hydraulic conductivity<br />

L = sample length<br />

h 0<br />

= initial head in falling tube<br />

h = final head in falling tube<br />

t = time<br />

d t<br />

= diameter of falling head tube<br />

d c<br />

= diameter of chamber<br />

99

Aquifer Tests<br />

T<br />

S<br />

K<br />

Usually involve pumping a well at a constant rate (stress<br />

the aquifer) for several hours <strong>to</strong> several days and<br />

measuring water levels in nearby observation wells<br />

located at different distances from the pumping well.<br />

100

Water Wells<br />

<strong>GW</strong> Moni<strong>to</strong>ring Wells<br />

101

Pumping Test<br />

One pumping well<br />

Several moni<strong>to</strong>ring wells<br />

Expensive and time consuming<br />

Cover a large area<br />

Water disposal?<br />

Interference<br />

Get flow rate and contaminant concentrations<br />

102

Steady State Analysis<br />

for Confined System<br />

T = transmissivity (L<br />

r 2 /T)<br />

Q<br />

T =<br />

2<br />

2π(h 2<br />

–h 1<br />

) ln ( r ) Q = pumping rate (L 3 /T)<br />

1<br />

h 1<br />

= head at distance r 1<br />

(L)<br />

h 2<br />

= head at distance r 2<br />

(L)<br />

rouble is steady-state can take a long time time <strong>to</strong> reach,<br />

and cannot give us information regarding s<strong>to</strong>rage! 103

K = hydraulic conductivity (L/T)<br />

Q = pumping rate (L 3 /T)<br />

b 1<br />

= saturated thickness at distance r 1<br />

(L)<br />

b = saturated thickness at distance r (L)<br />

104<br />

Steady State<br />

Analysis<br />

for Unconfined<br />

System<br />

K =<br />

r 2<br />

r 1<br />

Q<br />

π(b 22<br />

–b 12<br />

) ln ( )

105<br />

Slug Tests<br />

Quick and cheap: “instantaneously” raising or lowering<br />

the water level in a well and by dropping a long object<br />

in<strong>to</strong> the well <strong>to</strong> displace the water moni<strong>to</strong>ring the<br />

recovery of the water level<br />

Localized<br />

No information on Q and C<br />

Initial condition t = 0 t = t 1 t = t 2 t = t 3

106<br />

Perched Aquifer<br />

Lens is “Perched” Above Unconfined System<br />

Lens of Low Permeability Material<br />

in Unsaturated Zone

Retardation Fac<strong>to</strong>r<br />

for Plume Migration in Groundwater<br />

Physical, chemical, and biological processes in<br />

the subsurface that can affect the fate and<br />

transport of contaminants.<br />

The processes include:<br />

• biotic degradation<br />

• abiotic degradation<br />

• dissolution<br />

• ionization<br />

• volatilization<br />

• adsorption.<br />

107

108<br />

Retardation Fac<strong>to</strong>r<br />

for Plume Migration in Groundwater…..<br />

For transport of dissolved plume in groundwater,<br />

adsorption of contaminants is probably the most<br />

important and most studied mechanism for<br />

removal of contaminants from the groundwater.<br />

If adsorption is the primary removal mechanism<br />

in the subsurface, the reaction term in advectiondispersion<br />

equation can then be written as<br />

(ρ b<br />

/φ)∂S/∂t, where ρ b<br />

= dry bulk density of soil<br />

(or the aquifer matrix), φ = porosity, t = time,<br />

and S = contaminant concentration on soil.

109<br />

∂ C<br />

∂ C ∂ C<br />

= D − v ±<br />

∂ x<br />

Retardation Fac<strong>to</strong>r<br />

∂ t<br />

2<br />

∂ x<br />

for Plume Migration in Groundwater…...<br />

Assume a linear adsorption isotherm (e.g., S =<br />

K p<br />

C), thus<br />

∂ S<br />

= K p<br />

∂ C<br />

2<br />

RXN<br />

∂ S<br />

∂ t<br />

∂ S ∂ C<br />

= ( )( )<br />

∂ C ∂ t<br />

=<br />

K<br />

p<br />

∂ C<br />

∂ t<br />

∂ C<br />

∂ t<br />

ρ b ∂ C ρ bK<br />

p ∂ C ∂ C<br />

+ ( ) K p = (1 + ) = D −<br />

φ ∂ t φ ∂ t<br />

2<br />

∂ x<br />

2<br />

v<br />

∂ C<br />

∂ x

110<br />

∂ C<br />

Retardation Fac<strong>to</strong>r<br />

∂ t<br />

2<br />

∂ x<br />

for Plume Migration in Groundwater…...<br />

2<br />

∂ C ∂ C<br />

= D − v ±<br />

∂ x<br />

RXN<br />

∂ C<br />

∂ t<br />

ρ b ∂ C ρ bK<br />

p ∂ C ∂ C<br />

+ ( ) K p = (1 + ) = D −<br />

φ ∂ t φ ∂ t<br />

2<br />

∂ x<br />

Divide both sides by (1 + ρ b<br />

K p<br />

/φ):<br />

2<br />

v<br />

∂ C<br />

∂ x<br />

∂ C<br />

∂ t<br />

2<br />

D ∂ C<br />

= −<br />

R 2<br />

∂ x<br />

v ∂ C<br />

R ∂ x<br />

where<br />

R<br />

= 1 +<br />

ρ<br />

b<br />

K<br />

φ<br />

p

Retardation Fac<strong>to</strong>r<br />

for Plume Migration in Groundwater…...<br />

R<br />

= 1 +<br />

ρ<br />

b<br />

K<br />

φ<br />

p<br />

R = retardation fac<strong>to</strong>r (dimensionless) and ≥ 1.<br />

R reduces the impact of dispersion and migration<br />

velocity by a fac<strong>to</strong>r of R.<br />

All of the mathematical solutions that are used <strong>to</strong><br />

solve the transport of inert tracers can be used for<br />

the contaminants, if the groundwater velocity and<br />

the dispersion coefficient are divided by R.<br />

<strong>From</strong> the definition of R, one can tell that R is a<br />

function of ρ b<br />

, φ, and K p<br />

.<br />

For a given aquifer, ρ b<br />

and φ would be the same<br />

for different contaminants. Consequently, the<br />

greater the partition coefficient, the greater the R.<br />

111

Effect of the distribution coefficient on contaminant<br />

retardation during transport in a shallow groundwater.<br />

112

Retardation Fac<strong>to</strong>r<br />

for Plume Migration in Groundwater…...<br />

The groundwater underneath a landfill is<br />

contaminated with benzene, and pyrene.<br />

Estimate the R: φ = 0.40; ρ b<br />

= 1.8 g/cm 3; f oc<br />

=<br />

0.015; K oc<br />

= 0.63 K ow<br />

(a) Log(K ow<br />

) = 2.13 for benzene K ow<br />

= 135<br />

Log(K ow<br />

) = 4.88 for pyrene K ow<br />

= 75,900<br />

(b) K oc<br />

= (0.63)(135) = 85 (for benzene)<br />

K oc<br />

= (0.63)(75,900) = 47,800 (for pyrene)<br />

(c) K p<br />

= (0.015)(85) = 1.275 (for benzene)<br />

K p<br />

= (0.015)(47,800) = 717 (for pyrene)<br />

113

114<br />

Retardation Fac<strong>to</strong>r<br />

for Plume Migration in Groundwater…...<br />

(d) benzene:<br />

R<br />

ρbK<br />

p (.)(. 18 1275)<br />

= 1+ = 1+ =<br />

φ<br />

04 .<br />

674 .<br />

R<br />

pyrene:<br />

ρ bK<br />

p ( 18 . )( 717)<br />

= 1+ = 1+ =<br />

φ<br />

04 .<br />

3227 ,

Migration Speed of the Dissolved Plume<br />

The retardation fac<strong>to</strong>r relates the plume<br />

migration velocity <strong>to</strong> the groundwater seepage<br />

velocity as:<br />

R<br />

V s<br />

Vs<br />

= or Vp<br />

=<br />

V<br />

R<br />

p<br />

Where V s<br />

is the groundwater seepage velocity and<br />

V p<br />

is the velocity of the dissolved plume.<br />

When the value of R is equal <strong>to</strong> unity (for inert<br />

compounds), the compound will move at the<br />

same speed as the groundwater flow without any<br />

"retardation”.<br />

When R = 2, for example, the contaminant will<br />

115

Migration Speed of the Dissolved Plume…..<br />

(Example) The groundwater underneath a landfill<br />

is contaminated with benzene and pyrene. A<br />

recent groundwater moni<strong>to</strong>ring in September<br />

1997 indicated that benzene has traveled 50m<br />

down-gradient; while pyrene was not detected in<br />

the down-gradient well.<br />

Time when benzene first entered the aquifer?<br />

φ = 0.40; K = 30 m/day;i = 0.01<br />

ρ b<br />

= 1.8 g/cm 3 ;f oc<br />

= 0.015<br />

116

R<br />

V s<br />

Vs<br />

= or Vp<br />

=<br />

V<br />

R<br />

Migration Speed of the Dissolved Plume…..<br />

p<br />

(a) Darcy velocity: v = ki = (30)(0.01) = 0.3 m/d<br />

(b) <strong>GW</strong> velocity (or the seepage velocity)<br />

v s<br />

= v/φ = (0.3)/(0.4) = 0.75 m/d<br />

(c) Migration speeds of the plumes:<br />

v p<br />

= (0.75)/(6.74) = 0.111 m/d (for benzene)<br />

v p<br />

= (0.75)/(3227) = 0.0002 m/d (for pyrene)<br />

(d) Time for benzene <strong>to</strong> travel 50 meters:<br />

t = (50 m)/(40.6 m/yr) = 1.23 yr<br />

Benzene entered the gw in June of 1996.<br />

117

Migration<br />

Speed of the<br />

Dissolved<br />

Plume…..<br />

Discussion:<br />

The estimate is the time when the benzene<br />

entered the aquifer. The information given is not<br />

sufficient <strong>to</strong> estimate the time the leachates<br />

leaked through the landfill liner.<br />

The migration of pyrene is extremely small, 0.08<br />

m/yr, therefore, it was not detected in the<br />

downstream moni<strong>to</strong>ring wells. Most, if not all, of<br />

the pyrene compounds will be adsorbed on<strong>to</strong> the<br />

118

Migration Speed of<br />

the Dissolved<br />

Plume…..<br />

The estimates are rough, because lots of fac<strong>to</strong>rs may<br />

affect the accuracy of the estimates.<br />

Fac<strong>to</strong>rs include uncertainty of the hydraulic conductivity<br />

porosity, i, K ow<br />

,f oc<br />

, etc.<br />

Neighborhood pumping will affect the natural<br />

groundwater gradient and, consequently, the migration<br />

of the plume.<br />

Other subsurface reactions such as oxidation and<br />

biodegradation may also have large impacts on the fate<br />

119