complete

complete

complete

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

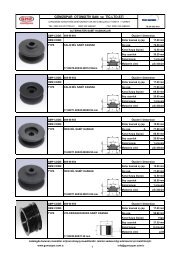

AIR SPRING MAINTENANCE AND INSTALLATION GUIDE<br />

• Control the air entrance and other connections against leaking.<br />

• Control surrounding for enough space while inflation. Usually min. 36 mm space is required for diameter<br />

increasement under high pressure.<br />

• Control periodically the suspension’s required rice height at suitable position. The measurement must<br />

be +/- 7 mm in order to avoid bottoming out or avoid occuring shocks cause by extreme expandings.<br />

• Place the air spring at high position and if necessary clean the air spring free from unknown materials<br />

with cleaning solution which should not be petrol derivatives.<br />

• Control the air spirng piston surface free from unknown material on it. Corrodes on the piston may<br />

decrease the life of the air spring. Cleaning of them is your requirement in the regular controls.<br />

• Control the shock absorbers against leaking, cracked connections, eroded bushes and extreme expandings.<br />

• Control the bolts and nuts torque applied at suitable level. Please refer to manufacturer’s manual for more<br />

specific information.<br />

• Control the weight control ventile working properly. If necessary clean or replace it with a new one.<br />

Regular maintenance of valves will save you from hundreds of Euros.<br />

• Your vehicle’s life increases and reduce your overall maintenance expense with regular controls as above<br />

mentioned.<br />

CAUTION<br />

• Please do not inflate the air spring without fixing the vehicle suspension system or any suitable structure.<br />

• The pressure should not exceed 100 psi/bar, Otherwise damages may be occured.<br />

• Working temperature is between -40’C and +70’C<br />

AIR SPRING INSTALLATION GUIDE<br />

Prior to install suspension air spring, please make sure all the necessary equipments are ready to use.<br />

Please look over to the service manual of the manufacturer in order to gain proficieny to the suspension system.<br />

If you have any doubts please contact with a specialist or suspension manufacturer or air spring<br />

manufacturer’s asistance.This prevents you losing time and protect for further damages.<br />

• While disconnecting loading adjustment ventile,control the twisted or broken connection.Replace if<br />

necessary.<br />

• Control the shock absorbers for possible replacement.There are 2 warning sign for worn shock absorber.<br />

If the shock absorber can be eassily compressed or extended then they are needed to be renewed.The shock<br />

absorbers must be hot to the touch while the vehicle is on the service if not, then they are needed to be<br />

renewed. Please do not forget regular shock absorber maintenence is the key for increasing the life of air spring.<br />

• When the air inlets are removed, it is necessary to control against cracks and other damages. Besides<br />

control the connection for loose and replace if necessary.<br />

• Sometimes failures of the air spring are clear or easily realized,sometimes failures are not realized. In<br />

case of unrealized stuation remove the air spring and correct the main problem.<br />

• When the suspension air spring is removed other suspension parts can be reached easily, therefore<br />

control the damages and worns on chasis connections,bushes and torque rods. Replace these parts if<br />

necessary.<br />

• Furthermore control the installation groove for the air spring. Remove and make sure for the any obstacles<br />

and sharp edges which will damage the new air spring.<br />

• Prior to install the new air spring clean the bead plate surface for installing.<br />

Always use new nuts for installing. Old ones may occur failures.<br />

• Control the adjustment rod working properly. Normally adjustment rod moves through intake position under<br />

load.Returning of this rod’s starting point will let the air inside the air spring. When unloading the vehicle<br />

adjustment rod will move to exhaust position. This opens the exhaust valve and let the air outside untill the<br />

rod returns starting point.