JEST-M, Vol. 2, Issue 1, 2013 - MVJ College of Engineering

JEST-M, Vol. 2, Issue 1, 2013 - MVJ College of Engineering

JEST-M, Vol. 2, Issue 1, 2013 - MVJ College of Engineering

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

37 <strong>JEST</strong>-M, <strong>Vol</strong>. 2, <strong>Issue</strong> 1, <strong>2013</strong><br />

pseudorandom bit which is 1 with probability 1/2. This<br />

mechanism can mimic a probabilistic cellular automaton.<br />

VIII. CASE-STUDY- THERMO-MECHANICALLY DEFORMED<br />

COMPONENT MICROSTRUCTURE SIMULATION<br />

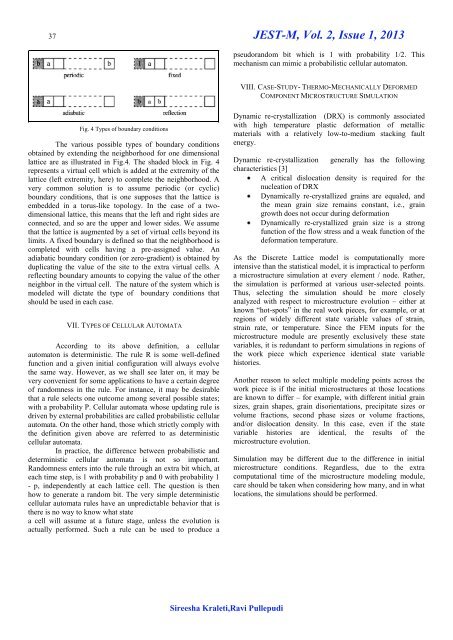

Fig. 4 Types <strong>of</strong> boundary conditions<br />

The various possible types <strong>of</strong> boundary conditions<br />

obtained by extending the neighborhood for one dimensional<br />

lattice are as illustrated in Fig.4. The shaded block in Fig. 4<br />

represents a virtual cell which is added at the extremity <strong>of</strong> the<br />

lattice (left extremity, here) to complete the neighborhood. A<br />

very common solution is to assume periodic (or cyclic)<br />

boundary conditions, that is one supposes that the lattice is<br />

embedded in a torus-like topology. In the case <strong>of</strong> a twodimensional<br />

lattice, this means that the left and right sides are<br />

connected, and so are the upper and lower sides. We assume<br />

that the lattice is augmented by a set <strong>of</strong> virtual cells beyond its<br />

limits. A fixed boundary is defined so that the neighborhood is<br />

completed with cells having a pre-assigned value. An<br />

adiabatic boundary condition (or zero-gradient) is obtained by<br />

duplicating the value <strong>of</strong> the site to the extra virtual cells. A<br />

reflecting boundary amounts to copying the value <strong>of</strong> the other<br />

neighbor in the virtual cell. The nature <strong>of</strong> the system which is<br />

modeled will dictate the type <strong>of</strong> boundary conditions that<br />

should be used in each case.<br />

VII. TYPES OF CELLULAR AUTOMATA<br />

According to its above definition, a cellular<br />

automaton is deterministic. The rule R is some well-defined<br />

function and a given initial configuration will always evolve<br />

the same way. However, as we shall see later on, it may be<br />

very convenient for some applications to have a certain degree<br />

<strong>of</strong> randomness in the rule. For instance, it may be desirable<br />

that a rule selects one outcome among several possible states;<br />

with a probability P. Cellular automata whose updating rule is<br />

driven by external probabilities are called probabilistic cellular<br />

automata. On the other hand, those which strictly comply with<br />

the definition given above are referred to as deterministic<br />

cellular automata.<br />

In practice, the difference between probabilistic and<br />

deterministic cellular automata is not so important.<br />

Randomness enters into the rule through an extra bit which, at<br />

each time step, is 1 with probability p and 0 with probability 1<br />

- p, independently at each lattice cell. The question is then<br />

how to generate a random bit. The very simple deterministic<br />

cellular automata rules have an unpredictable behavior that is<br />

there is no way to know what state<br />

a cell will assume at a future stage, unless the evolution is<br />

actually performed. Such a rule can be used to produce a<br />

Dynamic re-crystallization (DRX) is commonly associated<br />

with high temperature plastic deformation <strong>of</strong> metallic<br />

materials with a relatively low-to-medium stacking fault<br />

energy.<br />

Dynamic re-crystallization generally has the following<br />

characteristics [3]<br />

A critical dislocation density is required for the<br />

nucleation <strong>of</strong> DRX<br />

Dynamically re-crystallized grains are equaled, and<br />

the mean grain size remains constant, i.e., grain<br />

growth does not occur during deformation<br />

Dynamically re-crystallized grain size is a strong<br />

function <strong>of</strong> the flow stress and a weak function <strong>of</strong> the<br />

deformation temperature.<br />

As the Discrete Lattice model is computationally more<br />

intensive than the statistical model, it is impractical to perform<br />

a microstructure simulation at every element / node. Rather,<br />

the simulation is performed at various user-selected points.<br />

Thus, selecting the simulation should be more closely<br />

analyzed with respect to microstructure evolution – either at<br />

known “hot-spots” in the real work pieces, for example, or at<br />

regions <strong>of</strong> widely different state variable values <strong>of</strong> strain,<br />

strain rate, or temperature. Since the FEM inputs for the<br />

microstructure module are presently exclusively these state<br />

variables, it is redundant to perform simulations in regions <strong>of</strong><br />

the work piece which experience identical state variable<br />

histories.<br />

Another reason to select multiple modeling points across the<br />

work piece is if the initial microstructures at those locations<br />

are known to differ – for example, with different initial grain<br />

sizes, grain shapes, grain disorientations, precipitate sizes or<br />

volume fractions, second phase sizes or volume fractions,<br />

and/or dislocation density. In this case, even if the state<br />

variable histories are identical, the results <strong>of</strong> the<br />

microstructure evolution.<br />

Simulation may be different due to the difference in initial<br />

microstructure conditions. Regardless, due to the extra<br />

computational time <strong>of</strong> the microstructure modeling module,<br />

care should be taken when considering how many, and in what<br />

locations, the simulations should be performed.<br />

Sireesha Kraleti,Ravi Pullepudi