Production Data 83 - Nostalgic British Cars

Production Data 83 - Nostalgic British Cars

Production Data 83 - Nostalgic British Cars

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Technical Tips On Wire Wheels 125<br />

Slight sideways run-out (or ‘out of true’) with wire wheels is therefore not significant: a couple of hard<br />

corners will soon re-arrange the wheel spokes anyway. Vertical ‘run out’ should not be permitted, ever.<br />

By far the most common cause of wire wheel ’wobbles’ is an incorrect method employed in balancing.<br />

A simple spirit level balancer is the thing to seek out. Under no circumstances should balancing be<br />

attempted on the now common dynamic machine without the use of the special sprung cones shown in<br />

the illustration, because, although the wheel locates correctly on its inner coned surface, these machines<br />

‘try’ and locate onto the inside of the wire wheels outer flange - which is NOT a true machined surface.<br />

This incorrect technique appears as terrific sideways run-out and the balancing ‘specialist’ always<br />

blames the wheel. Now you know the truth.<br />

It is always best to check the wire wheel by clamping it onto a front hub, using the correct knock-on nut<br />

BEFORE fitting the tyre.<br />

Spin the wheel on the hub & check sideways or vertical run-out as shown in the illustration, and observe<br />

or measure the run-out. + or – 1 /16" is not a problem, even +/- 1 /8" is barely detectable on the road.<br />

So You Think You’ve Got Wobbly Wire Wheels?<br />

(By Pete Cox)<br />

Back in the good old days when Pete Buckles and myself were just young lads, we were able to buy<br />

virtually direct from Dunlop, so the wire wheels were inexpensive. These <strong>British</strong> made wheels were sold<br />

mostly to the TR Register members at insanely low prices. 4.5" x 60 spoke wire wheels went out at<br />

£4.10.0d!, with no VAT to pay and we still made a pound on each wheel!<br />

The low prices enabled me to indulge in experiments: if they didn’t work (or fit), offending wheels would<br />

always be ‘sold on’ and a couple of ‘bob’ profit could still be made.<br />

So my TR2, an attractive beast wearing glistening Midnight Blue paint work and not so glistening (but<br />

by then typical), rusty quarter panels, finalised it’s development with the unusual combination of 6"<br />

Cobra wheels at the front and, 5.5" TR6 wheels at the rear. This was because the TR2 was always<br />

enthusiastically driven and the growing pile of Lockheed half shafts finally stopped growing the day a<br />

second hand TR4 rear axle was installed, its extra width requiring the above wheel combination to<br />

balance its cornering habits.<br />

Now, wire wheels are built to flex (or bend) and<br />

this was brought shockingly home to me on one<br />

occasion when Pete Buckles visited me in<br />

Birmingham (remember Clapgate Lane?). We<br />

were off to visit a supplier (who incidentally, still<br />

stamps out trunnion blanks for Moss). Pete’s TR3<br />

followed my TR2 down an interestingly twisty<br />

road which I happened to know particularly well,<br />

and, after exiting a seriously exciting corner I<br />

looked in the mirror to check on the progress of<br />

our illustrious leader, and was horrified to see his<br />

car in a lurid slide (he maintained it was under<br />

control) with its outside front wheel keeling over<br />

at a crazy angle, almost 6° off vertical.<br />

This memory has remained vivid ever since, and<br />

is one explanation why Moss Europe (formerly<br />

Cox & Buckles) do not sell second hand or<br />

reconditioned wire wheels.<br />

If it is assumed that both hub & rim of a<br />

wire wheel are in good condition, it may<br />

be worth having the wheel re-spoked<br />

‘as necessary’ and then trued up by a<br />

competent re-builder. The wheel will<br />

probably need shot blasting and stove<br />

enamelling which will bring the cost to<br />

near to (or possibly over) the price of a<br />

new wheel. Remember also that you<br />

have got a used, worn wheel, not a nice<br />

new one. Bear in mind then, that the<br />

wheel is capable of being flexed by 4"<br />

(i.e., the hub is fixed and the top of the<br />

wheel is 4" further out than the bottom),<br />

while it is rotating at speed on the road,<br />

and it is then supposed to return to the<br />

original shape.<br />

So the conclusion is summarised as follows<br />

Our new wire wheels are built and assembled to the highest standards<br />

When your wheel/tyre fitter says they are no good, there is a very, very strong chance that he is not using<br />

the equipment in a fashion which is appropriate for wire wheels. The above tips will allow you to check<br />

the ‘truth’ of the wire wheel, whether the wheel is new or used.<br />

It’s a sad truth wire wheels have a bad reputation that they don’t deserve, but the people who give them<br />

a bad reputation, actually deserve it themselves. We have total confidence in the Dunlop product we sell.<br />

Pete Cox<br />

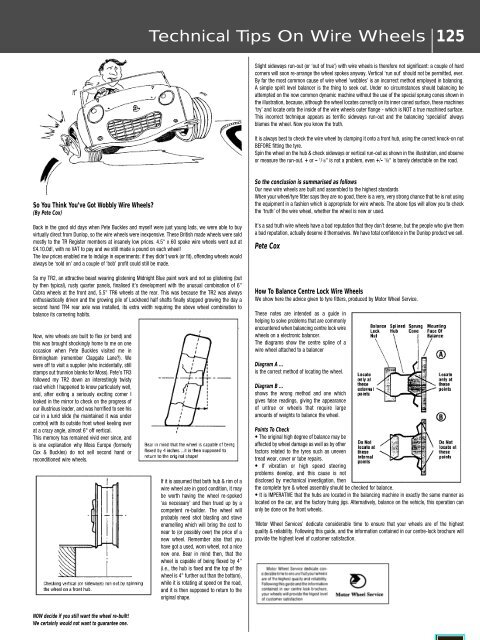

How To Balance Centre Lock Wire Wheels<br />

We show here the advice given to tyre fitters, produced by Motor Wheel Service.<br />

These notes are intended as a guide in<br />

helping to solve problems that are commonly<br />

encountered when balancing centre lock wire<br />

wheels on a electronic balancer.<br />

The diagrams show the centre spline of a<br />

wire wheel attached to a balancer<br />

Diagram A ...<br />

is the correct method of locating the wheel.<br />

Diagram B ...<br />

shows the wrong method and one which<br />

gives false readings, giving the appearance<br />

of untrue or wheels that require large<br />

amounts of weights to balance the wheel.<br />

Points To Check<br />

• The original high degree of balance may be<br />

affected by wheel damage as well as by other<br />

factors related to the tyres such as uneven<br />

tread wear, cover or tube repairs.<br />

• If vibration or high speed steering<br />

problems develop, and this cause is not<br />

disclosed by mechanical investigation, then<br />

the complete tyre & wheel assembly should be checked for balance.<br />

• It is IMPERATIVE that the hubs are located in the balancing machine in exactly the same manner as<br />

located on the car, and the factory truing jigs. Alternatively, balance on the vehicle, this operation can<br />

only be done on the front wheels.<br />

‘Motor Wheel Services’ dedicate considerable time to ensure that your wheels are of the highest<br />

quality & reliability. Following this guide, and the information contained in our centre-lock brochure will<br />

provide the highest level of customer satisfaction.<br />

NOW decide if you still want the wheel re-built!<br />

We certainly would not want to guarantee one.