Digest Eng 07-D2 - korloy

Digest Eng 07-D2 - korloy

Digest Eng 07-D2 - korloy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

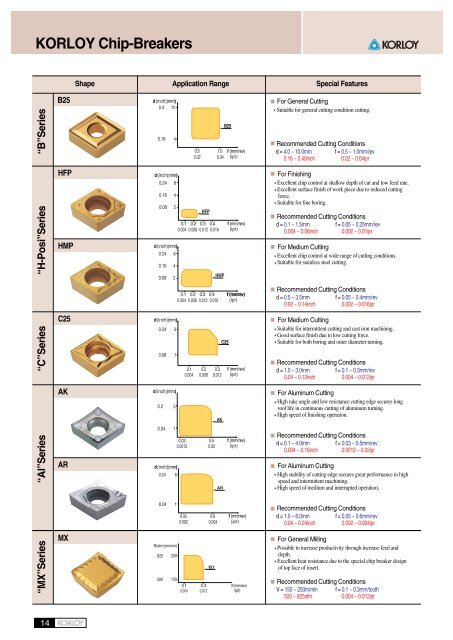

KORLOY Chip-Breakers<br />

Shape Application Range Special Features<br />

“H-Posi”Series “B”Series<br />

B25<br />

HFP<br />

HMP<br />

For General Cutting<br />

Suitable for general cutting condition cutting.<br />

Recommended Cutting Conditions<br />

d = 4.0 ~ 10.0mm f = 0.5 ~ 1.0mm/rev<br />

0.16 ~ 0.40inch 0.02 ~ 0.04ipr<br />

For Finishing<br />

Excellent chip control at shallow depth of cut and low feed rate.<br />

Excellent surface finish of work piece due to reduced cutting<br />

force.<br />

Suitable for fine boring.<br />

Recommended Cutting Conditions<br />

d = 0.1 ~ 1.5mm<br />

f = 0.05 ~ 0.25mm/rev<br />

0.004 ~ 0.06inch 0.002 ~ 0.01ipr<br />

For Medium Cutting<br />

Excellent chip control at wide range of cutting conditions.<br />

Suitable for stainless steel cutting.<br />

“C”Series<br />

C25<br />

AK<br />

Recommended Cutting Conditions<br />

d = 0.5 ~ 3.5mm<br />

f = 0.05 ~ 0.4mm/rev<br />

0.02 ~ 0.14inch 0.002 ~ 0.016ipr<br />

For Medium Cutting<br />

Suitable for intermittent cutting and cast iron machining.<br />

Good surface finish due to low cutting force.<br />

Suitable for both boring and outer diameter turning.<br />

Recommended Cutting Conditions<br />

d = 1.0 ~ 3.0mm<br />

f = 0.1 ~ 0.3mm/rev<br />

0.04 ~ 0.12inch 0.004 ~ 0.012ipr<br />

For Aluminum Cutting<br />

High rake angle and low resistance cutting edge secures long<br />

tool life in continuous cutting of aluminum turning.<br />

High speed of finishing operation.<br />

“Al”Series<br />

AR<br />

Recommended Cutting Conditions<br />

d = 0.1 ~ 4.0mm<br />

f = 0.03 ~ 0.5mm/rev<br />

0.004 ~ 0.16inch 0.0012 ~ 0.02ipr<br />

For Aluminum Cutting<br />

High stability of cutting edge secures great performance in high<br />

speed and intermittent machining.<br />

High speed of medium and interrupted operation.<br />

“MX”Series<br />

MX<br />

Recommended Cutting Conditions<br />

d = 1.0 ~ 6.0mm<br />

f = 0.05 ~ 0.6mm/rev<br />

0.04 ~ 0.24inch 0.002 ~ 0.024ipr<br />

For General Milling<br />

Possible to increase productivity through increase feed and<br />

depth.<br />

Excellent heat resistance due to the special chip breaker design<br />

of top face of insert.<br />

Recommended Cutting Conditions<br />

V = 150 ~ 250m/min f = 0.1 ~ 0.3mm/tooth<br />

500 ~ 825sfm 0.004 ~ 0.012ipt<br />

14