Inch - korloy

Inch - korloy

Inch - korloy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

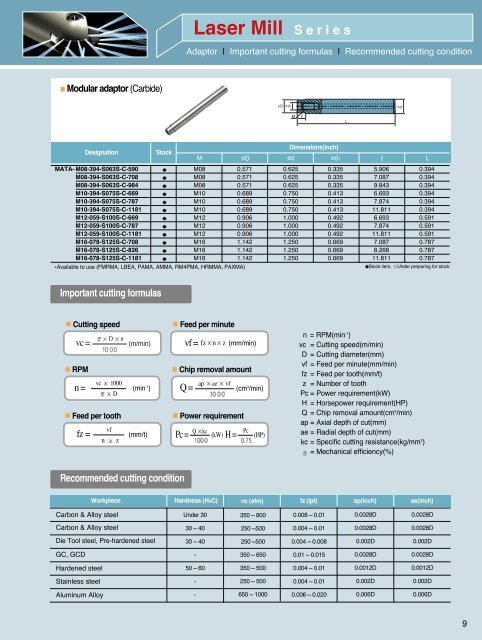

Laser Mill Series<br />

Adaptor | Important cutting formulas | Recommended cutting condition<br />

Modular adaptor (Carbide)<br />

Designation<br />

Stock<br />

Dimensions(inch)<br />

M øD ød ød1<br />

MATA- M08-394-S063S-C-590 M08 0.571 0.625 0.335 5.906 0.394<br />

M08-394-S063S-C-708 M08 0.571 0.625 0.335 7.087 0.394<br />

M08-394-S063S-C-984 M08 0.571 0.625 0.335 9.843 0.394<br />

M10-394-S075S-C-669 M10 0.689 0.750 0.413 6.693 0.394<br />

M10-394-S075S-C-787 M10 0.689 0.750 0.413 7.874 0.394<br />

M10-394-S075S-C-1181 M10 0.689 0.750 0.413 11.811 0.394<br />

M12-059-S100S-C-669 M12 0.906 1.000 0.492 6.693 0.591<br />

M12-059-S100S-C-787 M12 0.906 1.000 0.492 7.874 0.591<br />

M12-059-S100S-C-1181 M12 0.906 1.000 0.492 11.811 0.591<br />

M16-078-S125S-C-708 M16 1.142 1.250 0.669 7.087 0.787<br />

M16-078-S125S-C-826 M16 1.142 1.250 0.669 8.268 0.787<br />

M16-078-S125S-C-1181 M16 1.142 1.250 0.669 11.811 0.787<br />

Available to use (FMRMA, LBEA, PAMA, AMMA, RM4PMA, HRMMA, PAXMA)<br />

Stock item,<br />

L<br />

Under preparing for stock<br />

Important cutting formulas<br />

Cutting speed<br />

vc =<br />

RPM<br />

n =<br />

Feed per tooth<br />

fz =<br />

D n (m/min)<br />

vc 1000<br />

(min -1 )<br />

D<br />

vf<br />

(mm/t)<br />

n z<br />

Feed per minute<br />

vf = fz n z (mm/min)<br />

Chip removal amount<br />

Q = ap ae vf (cm 3 /min)<br />

Power requirement<br />

Pc = Q kc (kW) H = Pc (HP)<br />

n = RPM(min -1 )<br />

vc = Cutting speed(m/min)<br />

D = Cutting diameter(mm)<br />

vf = Feed per minute(mm/min)<br />

fz = Feed per tooth(mm/t)<br />

z = Number of tooth<br />

Pc = Power requirement(kW)<br />

H = Horsepower requirement(HP)<br />

Q = Chip removal amount(cm 3 /min)<br />

ap = Axial depth of cut(mm)<br />

ae = Radial depth of cut(mm)<br />

kc = Specific cutting resistance(kg/mm 2 )<br />

= Mechanical efficiency(%)<br />

Recommended cutting condition<br />

Workpiece<br />

Hardness (HRC) vc (sfm)<br />

fz (ipt)<br />

ap(inch) ae(inch)<br />

Carbon & Alloy steel<br />

Under 30<br />

350 ~ 800<br />

0.008 ~ 0.01<br />

0.0028D<br />

0.0028D<br />

Carbon & Alloy steel<br />

30 ~ 40<br />

250 ~500<br />

0.004 ~ 0.01<br />

0.0028D<br />

0.0028D<br />

Die Tool steel, Pre-hardened steel<br />

30 ~ 40<br />

250 ~500<br />

0.004 ~ 0.008<br />

0.002D<br />

0.002D<br />

GC, GCD<br />

-<br />

350 ~ 650<br />

0.01 ~ 0.015<br />

0.0028D<br />

0.0028D<br />

Hardened steel<br />

50 ~ 60<br />

350 ~ 500<br />

0.004 ~ 0.01<br />

0.0012D<br />

0.0012D<br />

Stainless steel<br />

-<br />

250 ~ 500<br />

0.004 ~ 0.01<br />

0.002D<br />

0.002D<br />

Aluminum Alloy<br />

-<br />

650 ~ 1000<br />

0.006 ~ 0.020<br />

0.006D<br />

0.006D<br />

9