ST-101 Vibration Screening Tool - PdP Services - Providing ...

ST-101 Vibration Screening Tool - PdP Services - Providing ...

ST-101 Vibration Screening Tool - PdP Services - Providing ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

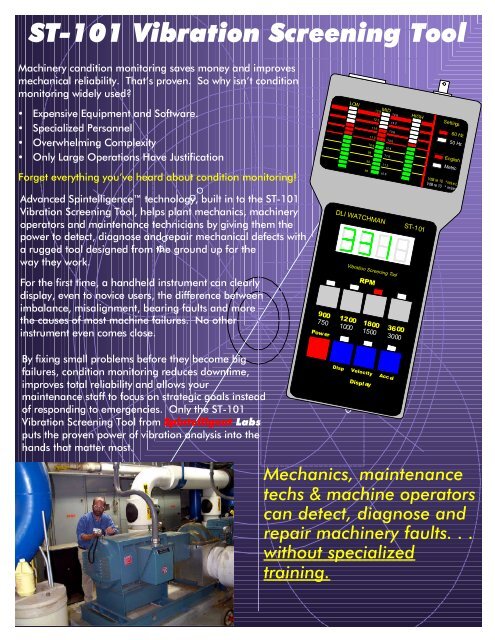

<strong>ST</strong>-<strong>101</strong> <strong>Vibration</strong> <strong>Screening</strong> <strong>Tool</strong><br />

Machinery condition monitoring saves money and improves<br />

mechanical reliability. That’s proven. So why isn’t condition<br />

monitoring widely used?<br />

• Expensive Equipment and Software.<br />

• Specialized Personnel<br />

• Overwhelming Complexity<br />

• Only Large Operations Have Justification<br />

Forget everything you’ve heard about condition monitoring!<br />

Advanced Spintelligence technology, built in to the <strong>ST</strong>-<strong>101</strong><br />

<strong>Vibration</strong> <strong>Screening</strong> <strong>Tool</strong>, helps plant mechanics, machinery<br />

operators and maintenance technicians by giving them the<br />

power to detect, diagnose and repair mechanical defects with<br />

a rugged tool designed from the ground up for the<br />

way they work.<br />

LOW MID HIGH<br />

128 148<br />

122 142<br />

86<br />

110<br />

104<br />

98<br />

92<br />

116<br />

130<br />

124<br />

118<br />

112<br />

106<br />

136<br />

DLI WATCHMAN <strong>ST</strong>-<strong>101</strong><br />

900<br />

750<br />

Pow er<br />

1200<br />

1000<br />

<strong>Vibration</strong> <strong>Screening</strong> <strong>Tool</strong><br />

Settings<br />

60 Hz<br />

50 Hz<br />

English<br />

Metric<br />

VdB re 10 - 8 m/s ec<br />

VdB re 10 - 9 m/sec<br />

For the first time, a handheld instrument can clearly<br />

display, even to novice users, the difference between<br />

imbalance, misalignment, bearing faults and more −<br />

the causes of most machine failures. No other<br />

instrument even comes close.<br />

RPM<br />

1800<br />

1500<br />

3600<br />

3000<br />

By fixing small problems before they become big<br />

failures, condition monitoring reduces downtime,<br />

improves total reliability and allows your<br />

maintenance staff to focus on strategic goals instead<br />

of responding to emergencies. Only the <strong>ST</strong>-<strong>101</strong><br />

<strong>Vibration</strong> <strong>Screening</strong> <strong>Tool</strong> from Spintelligent Labs<br />

puts the proven power of vibration analysis into the<br />

hands that matter most.<br />

Disp Velocity Acc el<br />

Displ ay<br />

Mechanics, maintenance<br />

techs & machine operators<br />

can detect, diagnose and<br />

repair machinery faults. . .<br />

without specialized<br />

training.

The <strong>ST</strong>-<strong>101</strong> is dramatically different than other types of<br />

vibration monitor equipment on the market. In a clear,<br />

simple way, a mechanic, machinery operator or other<br />

user can quickly determine the condition of a machine<br />

and, by matching up simple patterns, determine the<br />

corrective action required. No specialized training is<br />

required to effectively use the <strong>ST</strong>-<strong>101</strong>.<br />

Sample Bargraph Patterns<br />

LOW<br />

128<br />

122<br />

116<br />

110<br />

104<br />

98<br />

MID<br />

148<br />

142<br />

136<br />

130<br />

124<br />

118<br />

HIGH<br />

All Bars in Green<br />

<strong>Vibration</strong> levels are acceptable.<br />

Once you get past the bells and whistles of other low<br />

cost vibration monitoring instruments, you'll see that<br />

they tell you a single overall vibration level and provide<br />

no help diagnosing the underlying cause, or they tell<br />

you the bearings are shot, which is too late to correct<br />

the real cause of the problem before the damage is<br />

done.<br />

LOW<br />

92<br />

86<br />

128<br />

122<br />

116<br />

110<br />

104<br />

98<br />

MID<br />

112<br />

106<br />

148<br />

142<br />

136<br />

130<br />

124<br />

118<br />

HIGH<br />

Equal LOW and MID bars<br />

Red bars indicate unacceptable<br />

vibration levels. Equal LOW and<br />

MID bars indicate rotation rate<br />

vibration, caused by imbalance<br />

or misalignment depending on<br />

measurement direction<br />

Only the <strong>ST</strong>-<strong>101</strong> <strong>Vibration</strong> <strong>Screening</strong> <strong>Tool</strong> can tell you<br />

the entire story! If you have critical machinery, every<br />

mechanic should have an <strong>ST</strong>-<strong>101</strong> in his toolbox.<br />

<strong>ST</strong>-<strong>101</strong> Features<br />

Handheld <strong>Vibration</strong> Analyzer<br />

Single Accelerometer Input<br />

Patented Spintelligence Diagnostic Method (For rotating<br />

machinery)<br />

QuickTrend display for rapid trending<br />

4 Digit display of overall levels in US or ISO units<br />

Powered by 4 AA Alkaline Batteries<br />

Water resistant, high impact plastic case<br />

Supplied Accessories<br />

Industrial Accelerometer with Magnetic Mount & 10' Coiled<br />

Cable, featuring lifetime warranty & free annual calibration<br />

AA Alkaline Batteries<br />

Color Operator's Guide, Pocket Reference Card & App Notes<br />

Ballistic Nylon Carrying Case<br />

Spintellitrend Online Trending Service Subscription<br />

Optional Accessories<br />

SunFilter for viewing in direct sunlight<br />

Mounting Targets for repeatable measurements<br />

Validation Kit for full self-test of the <strong>ST</strong>-<strong>101</strong><br />

Accelerometers and termination boxes for remote locations<br />

Spintellitrend Server Appliance<br />

LOW<br />

LOW<br />

LOW<br />

92<br />

86<br />

128<br />

122<br />

116<br />

110<br />

104<br />

98<br />

92<br />

86<br />

128<br />

122<br />

116<br />

110<br />

104<br />

98<br />

92<br />

86<br />

128<br />

122<br />

116<br />

110<br />

104<br />

98<br />

92<br />

86<br />

MID<br />

MID<br />

MID<br />

112<br />

106<br />

148<br />

142<br />

136<br />

130<br />

124<br />

118<br />

112<br />

106<br />

148<br />

142<br />

136<br />

130<br />

124<br />

118<br />

112<br />

106<br />

148<br />

142<br />

136<br />

130<br />

124<br />

118<br />

112<br />

106<br />

HIGH<br />

HIGH<br />

HIGH<br />

MID bar 2 segments over LOW bar<br />

Red bars indicate unacceptable<br />

vibration levels. The bargraph<br />

pattern indicates vibration at<br />

twice rotation rate. This is<br />

usually caused by misalignment.<br />

Equal MID and HIGH bars<br />

Red bars indicate unacceptable<br />

vibration levels. The bargraph<br />

pattern indicates vibration at<br />

approximately 10 times rotation<br />

rate. This is usually caused by<br />

poor air flow through fan blades<br />

or pump impellers.<br />

HIGH bar is elevated<br />

Red bars indicate unacceptable<br />

vibration levels. The bargraph<br />

pattern indicates deteriorated<br />

rolling element bearings or<br />

possible pump cavitation on<br />

pumps.<br />

Spintelligent Labs<br />

Represented by:<br />

www.spintelligentlabs.com<br />

<strong>PdP</strong> <strong>Services</strong><br />

5317 Holden Street<br />

Charleston, SC 29418<br />

843-552-8053<br />

hugginsrl@cs.com<br />

<strong>Providing</strong> Innovative Predictive Maintenance <strong>Services</strong>

![[Machine Guard MG-4]](https://img.yumpu.com/5809653/1/184x260/machine-guard-mg-4.jpg?quality=85)