Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

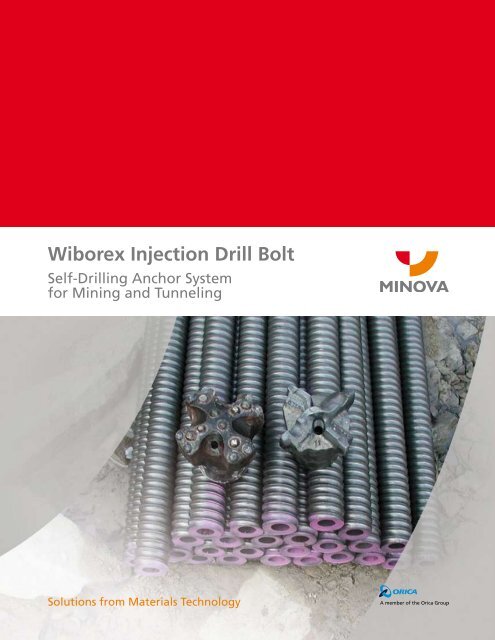

<strong>Wiborex</strong> <strong>Injection</strong> <strong>Drill</strong> <strong>Bolt</strong><br />

Self-<strong>Drill</strong>ing Anchor System<br />

for Mining and Tunneling<br />

Solutions from Materials Technology

<strong>Wiborex</strong> - <strong>Injection</strong> <strong>Drill</strong> <strong>Bolt</strong> System<br />

Application Areas<br />

<strong>Wiborex</strong> injection drill bolts are steel rods made of finegrained construction steel<br />

equipped with coarse thread that can be used as consumable drilling bar, reinforcement<br />

pipe, and injection pipe. Elongation with coupling sleeves, the ability to use<br />

different drill bits and the ability to brace with nuts and a plate is possible due to<br />

the continuous thread on the bar.<br />

The <strong>Wiborex</strong> injection bolts make it possible to drill, inject, anchor and stabilize<br />

all in one easy step with considerable time saving compared with normal bolting,<br />

boring and injection methods. <strong>Wiborex</strong> injection bolts are used as rock bolts, as<br />

pins, or as piles in mining, tunneling and specialized civil engineering. The permits<br />

of the <strong>Wiborex</strong> 30/16, 30/11, 40/16, 73/53, and 103/78 systems have been obtained.<br />

Application Areas<br />

System anchors<br />

Interception and stress relief bolting<br />

Application as bonding shields<br />

Tunnel repairs<br />

Securing of slopes and excavation pits<br />

Strata consolidation<br />

Installation against avalanches<br />

Securing of side-strips<br />

Underpinning<br />

Repairing of retaining walls

Used with Resins and Grouts<br />

<strong>Wiborex</strong> injection drill anchors are offered in different dimensions for numerous<br />

applications. <strong>Wiborex</strong> injection drill bolts are available in different corrosion<br />

protection coatings (hot-dip galvanized, Duplex, INOX).<br />

Used with resins and grouts<br />

The two-component injection resins Carbolith Thix and Carbolith Flex are<br />

especially suitable for bonding <strong>Wiborex</strong> injection drill bolts because the resins<br />

cure within just a few minutes and the bolt can be loaded in a very short time.<br />

Carbolith Thix is a rapid-hardening and rapid-curing silicate resin. It is CFC and<br />

halogen free. Carbolith Thix may be used with overhead boreholes with large<br />

diameters as well since it hardens very quickly right after mixing. Once both<br />

components have been mixed together, the resin begins hardening, becomes<br />

viscous and cannot flow even into large cracks on its own but has to be pumped<br />

in. The mixture then cures into a viscoplastic silicate resin.<br />

<strong>Wiborex</strong> injection<br />

drill bolts facilitate<br />

drilling, injecting,<br />

bolting, and stabilizing<br />

all in one easy<br />

step.<br />

Carbolith Flex is a medium setting, non-foaming two-component silicate resin. It is CFC free. Carbolith Flex<br />

also reacts in the presence of running water. Its short setting time prevents material from being flushed<br />

away by ground water movements. Once both components are mixed, the resulting viscous emulsion does<br />

not absorb any additional water and does not mix with water either. The initially liquid resin mixture<br />

quickly reaches a consistency where it no longer flows freely and then cures without further foaming.<br />

All commercially available materials can be used in connection with the anchor grout and the cements.<br />

For example, hydraulic ready-mix grout is suitable for rock anchors and injection work. The grout has to be<br />

easily handled and pumped, has to be suitable for injection, and should not have a tendency to bleed or<br />

segregate. To guarantee overhead work, the utilized grout should also be thixotropic.

<strong>Drill</strong>ing Rigs<br />

Ideally mounted pneumatic or hydraulic hammer drills are<br />

used. <strong>Wiborex</strong> injection bored piles up to 40 / 16 rotate counterclockwise;<br />

from 73 / 53 upwards they rotate clockwise.<br />

<strong>Wiborex</strong> 52 / 26 is available as counterclockwise or clockwise<br />

rotating bore pile.<br />

Stressing/grouting of the <strong>Wiborex</strong> injection drill anchors can<br />

be carried out<br />

during the drilling procedure using cement suspensions.<br />

This requires inserting a drill adapter into the flushing<br />

head.<br />

after drilling to the back of the borehole using<br />

two-component resins, anchor grout or cement.

Technical Details<br />

Unit<br />

30/16<br />

30/11<br />

40/20<br />

40/16<br />

52/26<br />

73/53<br />

103/78<br />

103/51<br />

R32/22<br />

R32/20<br />

R32/15<br />

Outer diameter<br />

[mm]<br />

[in]<br />

30<br />

1.18<br />

30<br />

1.18<br />

40<br />

1.57<br />

40<br />

1.57<br />

52<br />

2.05<br />

73<br />

2.87<br />

103<br />

4.06<br />

103<br />

4.06<br />

32<br />

1.26<br />

32<br />

1.26<br />

32<br />

1.26<br />

Effective outer<br />

diameter<br />

[mm]<br />

[in]<br />

27.2<br />

1.07<br />

26.2<br />

1.03<br />

36.4<br />

1.43<br />

37.1<br />

1.46<br />

48.8<br />

1.92<br />

69.9<br />

2.75<br />

100.4<br />

3.95<br />

98.5<br />

3.88<br />

- - -<br />

Inner diameter<br />

[mm]<br />

[in]<br />

16<br />

0.63<br />

11<br />

0.43<br />

20<br />

0.79<br />

16<br />

0.63<br />

26<br />

1.02<br />

53<br />

2.09<br />

78<br />

3.07<br />

51<br />

2.00<br />

22<br />

0.87<br />

20<br />

0.79<br />

15<br />

0.59<br />

Cross-section<br />

[mm 2 ]<br />

[in 2 ]<br />

382<br />

0.59<br />

446<br />

0.69<br />

726<br />

1.13<br />

879<br />

1.36<br />

1,337<br />

2.07<br />

1,631<br />

2.53<br />

3,146<br />

4.88<br />

5,501<br />

8.53<br />

360<br />

0.56<br />

400<br />

0.62<br />

455<br />

0.71<br />

Yield point<br />

[kN]<br />

[tons]<br />

180<br />

20.2<br />

260<br />

29.2<br />

430<br />

48.3<br />

525<br />

59.0<br />

730<br />

82.1<br />

970<br />

109.0<br />

1,570<br />

176.5<br />

2,726<br />

306.4<br />

182<br />

20.5<br />

244<br />

27.4<br />

323<br />

36.3<br />

Yield stress<br />

[N/mm 2 ]<br />

[psi x 10 3 ]<br />

470<br />

68.2<br />

580<br />

84.1<br />

590<br />

85.6<br />

590<br />

85.6<br />

550<br />

79.8<br />

590<br />

85.6<br />

500<br />

72.5<br />

500<br />

72.5<br />

500<br />

72.5<br />

630<br />

91.4<br />

730<br />

105.9<br />

Ultimate load<br />

[kN]<br />

[tons]<br />

220<br />

24.7<br />

320<br />

36.0<br />

539<br />

60.6<br />

660<br />

67.4<br />

929<br />

104.4<br />

1,160<br />

130.4<br />

1,950<br />

219.2<br />

3.460<br />

388.9<br />

221<br />

24.8<br />

291<br />

32.7<br />

363<br />

40.8<br />

Allowed<br />

shearing force<br />

[kN]<br />

[tons]<br />

58<br />

6.52<br />

88<br />

9.90<br />

138<br />

15.51<br />

164<br />

18.43<br />

240<br />

27.98<br />

329<br />

36.98<br />

535<br />

60.13<br />

599<br />

67.33<br />

- - -<br />

Weight<br />

[kg/m]<br />

[lbs/ft]<br />

3.0<br />

2.0<br />

3.3<br />

2.2<br />

5.6<br />

3.8<br />

6.9<br />

4.6<br />

10.5<br />

7.1<br />

12.8<br />

8.6<br />

24.7<br />

16.6<br />

43.2<br />

29.0<br />

2.8<br />

1.9<br />

3.2<br />

2.2<br />

3.4<br />

2.3<br />

Rotating<br />

direction<br />

left left left left<br />

left<br />

right<br />

right right right left left left<br />

Further sizes on demand.

<strong>Minova</strong> USA Inc.<br />

150 Carley Court<br />

Georgetown KY 40324 USA<br />

Phone 502 863 6800<br />

Fax 502 863 1374<br />

Email<br />

Website<br />

sales.info@minovaint.com<br />

www.minovausa.com<br />

Important Note: Warranty<br />

<strong>Minova</strong> USA Inc. warrants that its products, at the time of shipment, conform to the applicable descriptions set forth in the invoice and are free from defects<br />

in material and workmanship. NO OTHER WARRANTY, WHETHER EXPRESS, IMPLIED OR STATUTORY, INCLUDING ANY WARRANTY OF MERCHANTABI-<br />

LITY, OR FITNESS FOR A PARTICULAR PURPOSE, SHALL EXIST IN CONNECTION WITH THE SALE OR USE OF ANY MINOVA USA INC. PRODUCT, AND ALL SUCH<br />

WARRANTIES ARE HEREBY EXPRESSLY DISCLAIMED AND EXCLUDED.<br />

All claims under this warranty must be made in writing to <strong>Minova</strong> USA Inc. within 15 days after discovery of the defect, and within 90 days of the date of<br />

shipment by <strong>Minova</strong> USA Inc. of the product claimed defective. Upon timely receipt of a claim, <strong>Minova</strong> USA Inc. shall have the option either to inspect the<br />

product while in Buyer’s possession or to request Buyer to return the product to <strong>Minova</strong> USA Inc. for inspection. Claims not made as provided above and<br />

within the applicable time period will be barred. All warranties shall be null and void if the products have not been stored and used in accordance with<br />

procedures recommended by <strong>Minova</strong> USA Inc.<br />

<strong>Minova</strong> USA Inc. shall, at its option, either replace the nonconforming or defective product or refund to Buyer its purchase price. The foregoing constitutes<br />

Buyer’s sole and exclusive remedy for any breach or warranty.