View Tender Document

View Tender Document

View Tender Document

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

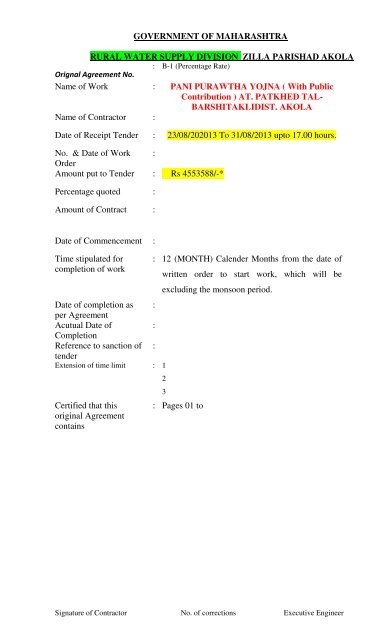

GOVERNMENT OF MAHARASHTRA<br />

RURAL WATER SUPPLY DIVISION ZILLA PARISHAD AKOLA<br />

: B-1 (Percentage Rate)<br />

<br />

Name of Work : PANI PURAWTHA YOJNA ( With Public<br />

Contribution ) AT. PATKHED TAL-<br />

BARSHITAKLIDIST. AKOLA<br />

Name of Contractor :<br />

Date of Receipt <strong>Tender</strong> : 23/08/202013 To 31/08/2013 upto 17.00 hours.<br />

No. & Date of Work :<br />

Order<br />

Amount put to <strong>Tender</strong> : Rs 4553588/-*<br />

Percentage quoted :<br />

Amount of Contract :<br />

Date of Commencement :<br />

Time stipulated for<br />

completion of work<br />

Date of completion as<br />

per Agreement<br />

Acutual Date of<br />

Completion<br />

Reference to sanction of<br />

tender<br />

Extension of time limit : 1<br />

Certified that this<br />

original Agreement<br />

contains<br />

<br />

: 12 (MONTH) Calender Months from the date of<br />

:<br />

:<br />

:<br />

written order to start work, which will be<br />

excluding the monsoon period.<br />

2<br />

3<br />

: Pages 01 to<br />

Signature of Contractor No. of corrections Executive Engineer

NAME OF WORK: -<br />

PANI PURAWTHA YOJNA ( With Public<br />

Contribution ) AT. PATKHED TAL-<br />

BARSHITAKLIDIST. AKOLA<br />

Estimated Cost put to tender Rs 4996111/-*<br />

Earnest Money Rs 45600/-*<br />

Term Deposit Receipt of Schedule Bank/<br />

Nationalised Bank/of India or Valid E.M.D.<br />

Exemption Certificate duly attested shall be uploaded at the time of submission. Total Security Deposit<br />

4% (four percent) Rs.182200/-* (50% in cash at the time of Agreement and 50% from R.A.bills ).<br />

TENDER SCHEDULE<br />

Cost of <strong>Tender</strong> Form :Rs 1000/-*<br />

Period for Downloading <strong>Tender</strong> Forms : From 23/08/2013 to 31/08/2013 at 17:01<br />

Upto at 17.00 hours.<br />

Last date and time for submitting pre- bid queries : -03/09/2013 to 06/09/2013<br />

online<br />

Date of Pre-bid meeting : ---<br />

Last date and time for online bid preparation and : Upto Date: 23/08/2013 to 02/09/2013<br />

hash submission (technical and financial)<br />

Time: 17.00 Hours<br />

Close for bidding & generate super hash<br />

: Date 02/09/2013 17.01 Hours to<br />

to 03/09/2013 Time 17.00 Hours<br />

Date and time for online bid data decryption and : Date: 06/09/2013 to 08/09/2013<br />

re-encryption (technical and commercial)<br />

Time: 17.00 Hours<br />

Receipt of bid security and tender document fees : Upto 06/09/2013 Time 17.00<br />

(in original one day before of the opening of the<br />

technical bid’s date and time )<br />

<br />

Date: 06/ 09/2013 Time 17.01 hours<br />

to 08/09/2013 Time 17.00 hours<br />

Registeration class of Contractor<br />

: Class-V and above.<br />

TO BE FILLED BY THE CONTRACTOR<br />

I/We have quoted my/our offer in percentage rate in words as well as in figures. I/We further<br />

undertake to enter into contract in regular “B-1” form in Public Works Department.<br />

Name and signature of Contractor/<br />

Power of Attorney holder<br />

With complete address.<br />

Signature of Contractor No. of corrections Executive Engineer

TENDERING PROCEDURE: -<br />

1.1 A. Blank <strong>Tender</strong> Forms.<br />

<strong>Tender</strong> Forms can be downloaded from the e-<strong>Tender</strong>ing Portal of Zilla Parishad Akola i.e.<br />

https://zp.maharashtra.etenders.in after entering the details of payment towards <strong>Tender</strong> Fees<br />

as per the <strong>Tender</strong> Schedule.<br />

1.2 B PRE-TENDER CONFERENCE: -<br />

1.2.1 Pre-tender conference open to all prospective tenderers who have downloaded tender<br />

form before the date of Pre-tender Conference, will be held on -- --Hrs. in the office of<br />

the E-<strong>Tender</strong> Section, Zilla Parishad] Akola wherein prospective <strong>Tender</strong>ers will have an<br />

opportunity to obtain clarifications regarding the work and the <strong>Tender</strong> Conditions.<br />

1.2.2 The prospective tenderers are free to ask for any additional information or clarification<br />

either in writing or orally concerning the work, and the reply to the same will be given<br />

by the Executive Engineer, in writing and this clarification referred to as Common Set<br />

of Conditions / Deviations (C.S.D.), shall form part of tender documents and which will<br />

also be common and applicable to all tenderers. The point/points if any raised in writing<br />

and/or verbally by the contractor in pre-tender conference and not finding place in<br />

C.S.D. issued after the pre- bid conference, is/are deemed rejected. In such case the<br />

provision in NIT shall prevail. No individual correspondence will be made thereafter<br />

with the contractor in this regard.<br />

1.2.3 The tender submitted by the tenderer shall be based on the clarification, additional<br />

facility offered (if any) by the Department, and this tender shall be unconditional.<br />

Conditional tenders shall be summarily REJECTED.<br />

1.2.4 All tenderers are cautioned that tenders containing any deviation from the contractual terms<br />

and conditions, specifications or other requirements and conditional tenders will be treated as<br />

non responsive. The tenderer should clearly mention in forwarding letter that his offer (in<br />

envelope No. 1& 2) does not contain any conditions, deviations from terms and conditions<br />

stipulated in the tender.<br />

1.2.5 <strong>Tender</strong>ers should have valid Class II / III / IV / IV A / V / V A Digital Signature Certificate<br />

(DSC) obtained from any Certifying Authorities. In case of requirement of DSC, interested<br />

Bidders should go to http://maharashtra.etenders.in/mah/DigitalCerti.asp and follow the<br />

procedure mentioned in the document ‘Procedure for application of Digital Certificate’.<br />

1.2.6 The <strong>Tender</strong>ers have to make a payment of Rs 1038/- online as service charges for the use of<br />

Electronic <strong>Tender</strong>ing during Online Bid Data Decryption and Re-encryption stage of the<br />

<strong>Tender</strong>.<br />

1.2.7 For any assistance on the use of Electronic <strong>Tender</strong>ing System, the Users may call the below<br />

numbers:<br />

Signature of Contractor No. of corrections Executive Engineer

Landline No. - 020 - 2531 5555 / 56<br />

Landline No. - 022 - 2661 1117 (Ext 25 / 26)<br />

Mobile No. - 91679 69601 / 04 / 14<br />

1.2.8 <strong>Tender</strong>ers should install the Mandatory Components available on the Home Page of<br />

http://maharashtra.etenders.in under the section ‘Mandatory Components’ and make the<br />

necessary Browser Settings provided under section ‘Internet Explorer Settings’<br />

1.2.9 For benefit of the <strong>Tender</strong>ers, a workshop on Electronic <strong>Tender</strong>ing System has been organised<br />

at on at . <strong>Tender</strong>ers are requested to attend the workshop for<br />

an overview of the Electronic <strong>Tender</strong>ing System and to understand the pre-requisites of<br />

participation on the Electronic <strong>Tender</strong>ing System.<br />

1.3 Guidelines to Bidders on the operations of Electronic <strong>Tender</strong>ing System of Zilla<br />

Parishad Akola on. https://zp.maharashtra.etenders.in<br />

A. Pre-requisites to participate in the <strong>Tender</strong>s processed by Zilla Parishad Akola<br />

1. Enrolment and Empanelment of Contractors on Electronic <strong>Tender</strong>ing System:<br />

The Contractors interested in participating in the <strong>Tender</strong>s of Minor Irrigation Department –<br />

processed using the Electronic <strong>Tender</strong>ing System shall be required to enrol on the Electronic<br />

<strong>Tender</strong>ing System to obtain User ID.<br />

After submission of application for enrolment on the System, the application information shall<br />

be verified by the Authorized Representative of the Service Provider. If the information is<br />

found to be complete, the enrolment submitted by the Vendor shall be approved.<br />

For participating in Limited and Restricted tenders the registered vendors have to apply for<br />

empanelment on the sub-portal of https://zp.maharashtra.etenders.in in an appropriate class of<br />

registration. The empanelment will have to be approved by the respective officer from the<br />

MID. Only empanelled vendors will be allowed to participate in such tenders.<br />

The Contractors may obtain the necessary information on the process of enrolment and<br />

empanelment either from Helpdesk Support Team or may visit the information published<br />

under the link Enrol under the section E-<strong>Tender</strong>ing Toolkit for Bidders on the Home Page of<br />

the Electronic <strong>Tender</strong>ing System.<br />

2. Obtaining a Digital Certificate:<br />

The Bid Data that is prepared online is required to be encrypted and the hash value of the Bid<br />

Data is required to be signed electronically using a Digital Certificate (Class – II or Class –<br />

III). This is required to maintain the security of the Bid Data and also to establish the identity<br />

of the Contractor transacting on the System.<br />

Signature of Contractor No. of corrections Executive Engineer

The Digital Certificates are issued by an approved Certifying Authority authorized by the<br />

Controller of Certifying Authorities of Government of India through their Authorized<br />

Representatives upon receipt of documents required to obtain a Digital Certificate.<br />

Bid data / information for a particular <strong>Tender</strong> may be submitted only using the Digital<br />

Certificate which is used to encrypt the data / information and sign the hash value during the<br />

Bid Preparation and Hash Submission stage. In case during the process of preparing and<br />

submitting a Bid for a particular <strong>Tender</strong>, the Contractor loses his/her Digital Signature<br />

Certificate (i.e. due to virus attack, hardware problem, operating system problem); he / she<br />

may not be able to submit the Bid online. Hence, the Users are advised to store his / her<br />

Digital Certificate securely and if possible, keep a backup at safe place under adequate<br />

security to be used in case of need.<br />

In case of online tendering, if the Digital Certificate issued to an Authorised User of a<br />

Partnership Firm is used for signing and submitting a bid, it will be considered equivalent to a<br />

no objection certificate / power of attorney to that User to submit the bid on behalf of the<br />

Partnership Firm. The Partnership Firm has to authorize a specific individual via an<br />

authorization certificate signed by a partner of the firm (and in case the applicant is a partner,<br />

another partner in the same form is required to authorise) to use the digital certificate as per<br />

Indian Information Technology Act, 2000.<br />

Unless the Digital Certificate is revoked, it will be assumed to represent adequate authority of<br />

the Authority User to bid on behalf of the Firm for the <strong>Tender</strong>s processed on the Electronic<br />

<strong>Tender</strong> Management System of Government of Maharashtra as per Indian Information<br />

Technology Act, 2000. The Digital Signature of this Authorized User will be binding on the<br />

Firm. It shall be the responsibility of Partners of the Firm to inform the Certifying Authority<br />

or Sub Certifying Authority, if the Authorized User changes, and apply for a fresh Digital<br />

Signature Certificate. The procedure for application of a Digital Signature Certificate will<br />

remain the same for the new Authorised User.<br />

The same procedure holds true for the Authorized Users in a Private / Public Limited<br />

Company. In this case, the Authorisation Certificate will have to be signed by the Director of<br />

the Company or the Reporting Authority of the Applicant.<br />

For information on the process of application for obtaining Digital Certificate, the Contractors<br />

may visit the section Digital Certificate on the Home Page of the Electronic <strong>Tender</strong>ing<br />

System.<br />

3. Recommended Hardware and Internet Connectivity:<br />

To operate on the Electronic <strong>Tender</strong>ing System, the Contractors are recommended to use<br />

Computer System with at least 1 GB of RAM and broadband connectivity with minimum 512<br />

kbps bandwidth.<br />

Signature of Contractor No. of corrections Executive Engineer

4. Set up of Computer System for executing the operations on the Electronic<br />

<strong>Tender</strong>ing System:<br />

To operate on the Electronic <strong>Tender</strong>ing System of Government of Maharashtra, the Computer<br />

System of the Contractors is required be set up. The Contractors are required to install<br />

Utilities available under the section Mandatory Installation Components on the Home Page of<br />

the System.<br />

The Utilities are available for download freely from the above mentioned section. The<br />

Contractors are requested to refer to the E-<strong>Tender</strong>ing Toolkit for Bidders available online on<br />

the Home Page to understand the process of setting up the System, or alternatively, contact<br />

the Helpdesk Support Team on information / guidance on the process of setting up the<br />

System.<br />

5. Payment for Service Provider Fees:<br />

In addition to the <strong>Tender</strong> <strong>Document</strong> Fees payable to MID, the Contractors will have to pay<br />

Service Providers Fees of Rs. 1,038/- through online payments gateway service available on<br />

Electronic <strong>Tender</strong>ing System. For the list of options for making online payments, the<br />

Contractors are advised to visit the link E-Payment Options under the section E-<strong>Tender</strong>ing<br />

Toolkit for Bidders on the Home Page of the Electronic <strong>Tender</strong>ing System<br />

B. Steps to be followed by Contractors to participate in the e-<strong>Tender</strong>s processed by Zilla<br />

Parishad Akola<br />

1. Preparation of online Briefcase:<br />

All Contractors enrolled on the Electronic <strong>Tender</strong>ing System of Government of Maharashtra<br />

are provided with dedicated briefcase facility to store documents / files in digital format. The<br />

Contractors can use the online briefcase to store their scanned copies of frequently used<br />

documents / files to be submitted as a part of their bid response. The Contractors are advised<br />

to store the relevant documents in the briefcase before starting the Bid Preparation and Hash<br />

Submission stage.<br />

In case, the Contractors have multiple documents under the same type (e.g. multiple Work<br />

Completion Certificates) as mentioned above, the Contractors advised to either create a single<br />

.pdf file of all the documents of same type or compress the documents in a single compressed<br />

file in .zip or .rar formats and upload the same.<br />

Signature of Contractor No. of corrections Executive Engineer

It is mandatory to upload the documents using the briefcase facility. Therefore, the<br />

Contractors are advised to keep the documents ready in the briefcase to ensure timely bid<br />

preparation.<br />

Note: Uploading of documents in the briefcase does not mean that the documents are<br />

available to , Rural Water Supply Division Zilla Parishad Akola at the time of <strong>Tender</strong><br />

Opening stage unless the documents are specifically attached to the bid during the online Bid<br />

Preparation and Hash Submission stage as well as during Decryption and Re-encryption stage.<br />

2. Online viewing of Detailed Notice Inviting <strong>Tender</strong>s:<br />

The Contractors can view the Detailed <strong>Tender</strong> Notice along with the Time Schedule<br />

(Key Dates) for all the Live <strong>Tender</strong>s released by Zilla Parishad Akola on the home page of Zilla<br />

Parishad Akola e-<strong>Tender</strong>ing Portal on https://zp.maharashtra.etenders.in under the section Recent<br />

Online <strong>Tender</strong>.<br />

3. Download of <strong>Tender</strong> <strong>Document</strong>s:<br />

The Pre-qualification / Main Bidding <strong>Document</strong>s are available for free downloading.<br />

However to participate in the online tender, the bidder must purchase the bidding documents<br />

online by filling up details of Demand Draft towards the cost of <strong>Tender</strong> Form Fee<br />

4. Online Bid Preparation and Submission of Bid Hash (Seal) of Bids:<br />

Submission of Bids will be preceded by online bid preparation and submission of the digitally<br />

signed Bid Hashes (Seals) within the <strong>Tender</strong> Time Schedule (Key Dates) published in the<br />

Detailed Notice Inviting <strong>Tender</strong>. The Bid Data is to be prepared in the templates provided by<br />

the <strong>Tender</strong>ing Authority of Executive Engineer Zilla Parishad Akola. The templates may be<br />

either form based, extensible tables and / or uploadable documents. In the form based type of<br />

templates and extensible table type of templates, the Contractors are required to enter the data<br />

and encrypt the data using the Digital Certificate.<br />

In the uploadable document type of templates, the Contractors are required to select the<br />

relevant document / compressed file (containing multiple documents) already uploaded in the<br />

briefcase.<br />

Notes:<br />

a. The Contractors upload a single document or a compressed file containing multiple<br />

documents against each unloadable option.<br />

b. The Hashes are the thumbprint of electronic data and are based on one – way<br />

algorithm. The Hashes establish the unique identity of Bid Data.<br />

c. The bid hash values are digitally signed using valid Class – II or Class – III Digital<br />

Signature of Contractor No. of corrections Executive Engineer

Certificate issued any Certifying Authority. The Contractors are required to obtain<br />

Digital Certificate in advance.<br />

d. After the hash value of bid data is generated, the Contractors cannot make any change<br />

/ addition in its bid data. The bidder may modify bids before the deadline for Bid<br />

Preparation and Hash Submission as per Time Schedule mentioned in the <strong>Tender</strong><br />

documents.<br />

e. This stage will be applicable during both, Pre-bid / Pre-qualification and Financial<br />

Bidding Processes.<br />

5. Close for Bidding (Generation of Super Hash Values):<br />

After the expiry of the cut – off time of Bid Preparation and Hash Submission stage to be<br />

completed by the Contractors has lapsed, the <strong>Tender</strong> will be closed by the <strong>Tender</strong> Authority.<br />

The <strong>Tender</strong> Authority from MID shall generate and digitally sign the Super Hash values<br />

(Seals).<br />

6. Decryption and Re-encryption of Bids (submitting the Bids online):<br />

After the time for generation of Super Hash values by the <strong>Tender</strong> Authority from M.J.P.<br />

Contractors have to make the online payment of Rs. 1,038/- towards the fees of the Service<br />

Provider.<br />

After making online payment towards Fees of Service Provider, the Contractors are required<br />

to decrypt their bid data using their Digital Certificate and immediately re-encrypt their bid<br />

data using the Public Key of the <strong>Tender</strong>ing Authority. The Public Key of the <strong>Tender</strong>ing<br />

Authority is attached to the <strong>Tender</strong> during the Close for Bidding stage.<br />

Note: The details of the Processing Fees shall be verified and matched during the Technical<br />

Opening stage.<br />

At this time, the Contractors are also required to upload the files for which they generated the<br />

Hash values during the Bid Preparation and Hash Submission stage.<br />

The Bid Data and <strong>Document</strong>s of only those Contractors who have submitted their Bid Hashes<br />

(Seals) within the stipulated time (as per the <strong>Tender</strong> Time Schedule), will be available for<br />

decryption and re-encryption and to upload the relevant documents from Briefcase. A<br />

Contractor who has not submitted his Bid Preparation and Hash Submission stage within the<br />

stipulated time will not be allowed to decrypt / re-encrypt the Bid data / submit documents<br />

during the stage of Decryption and Re-encryption of Bids (submitting the Bids online).<br />

7. Shortlisting of Contractors for Financial Bidding Process:<br />

Signature of Contractor No. of corrections Executive Engineer

The <strong>Tender</strong>ing Authority will first open the Technical Bid documents of all Contractors and<br />

after scrutinizing these documents will shortlist the Contractors who are eligible for Financial<br />

Bidding Process. The shortlisted Contractors will be intimated by email.<br />

8. Opening of the Financial Bids:<br />

The Contractors may remain present in the Office of the <strong>Tender</strong> Opening Authority at the<br />

time of opening of Financial Bids. However, the results of the Financial Bids of all<br />

Contractors shall be available on the MID e-<strong>Tender</strong>ing Portal immediately after the<br />

completion of opening process.<br />

9. <strong>Tender</strong> Schedule (Key Dates):<br />

The Contractors are strictly advised to follow the Dates and Times allocated to each stage<br />

under the column “Contractor Stage” as indicated in the Time Schedule in the Detailed<br />

<strong>Tender</strong> Notice for the <strong>Tender</strong>. All the online activities are time tracked and the Electronic<br />

<strong>Tender</strong>ing System enforces time-locks that ensure that no activity or transaction can take<br />

place outside the Start and End Dates and Time of the stage as defined in the <strong>Tender</strong><br />

Schedule.<br />

At the sole discretion of the <strong>Tender</strong> Authority, the time schedule of the <strong>Tender</strong> stages may be<br />

extended<br />

A) Works<br />

1.4 ENVELOPE No. 1: (<strong>Document</strong>s)<br />

The first envelope “Envelope No. 1” shall contain the following documents:<br />

1.4.1 Scanned copy of Demand .Draft of Rs.45600/-* issued from any Scheduled Bank and duly<br />

endorsed in the name of Chief Accounts & Finance officer. Finance Depatment Zilla<br />

Parishad Akola, or valid certificate of exemption from payment of earnest money if<br />

applicable (true copy attested by Gazetted Officer to be Submitted as per the tender<br />

Schedule).<br />

1.4.2 Scanned copy of Valid certificate as a Registered Contractor with the<br />

Government of Maharashtra in appropriate class (attested by Gazetted Officer).<br />

1.4.3 Scanned copy of valid VAT registration certificate from Maharashtra State Sale<br />

Tax Department duly attested by Gazetted Officer (Maharashtra Value<br />

Added Tax Act 2005)<br />

1.4.4 Scanned copy of list of Machinery and plants immediately available with the tenderer for use<br />

on this work and list of machinery proposed to be utilized on this work.<br />

1.4.5 Scanned copy of proof of appointment of employees<br />

1.4.6 Scanned copy of details of work done during last three years with the value of work<br />

unfinished<br />

1.4.7 Noterised Joint Venture if applicable<br />

1.4.8 Scanned copy of certified Attested copy of Registered Partnership Deed / Memorandum of Article<br />

of Association, as the case may be if the tenderer is a partnership firm or joint venture company if<br />

applicable. The Certificate shall be attested Gazetted Officer<br />

1.4.9 Power of Attorney on behalf of firm issued in the name of persons authorised to sign<br />

agreements, bill, etc. and collect cheques from department for the work done. Gazetted<br />

Signature of Contractor No. of corrections Executive Engineer

Officer Even though the bidders meet the above qualifying criteria, they are subjected to be<br />

disqualified if they have made misleading or false representation in the forms statement and<br />

attachments submitted as proof of the qualification requirements and / or record of post performance<br />

such as abandoning the works, not properly completing the contract, in ordinate delays in completion<br />

litigation history or financial failures etc.<br />

1.5 ENVELOPE No. 2 TENDER (FINANCIAL BID)<br />

The second envelope “Envelope No. 2” shall contain only the main tender including<br />

the Common Set of Conditions / Deviation issued by the Department after the pretender<br />

Conference. A tender submitted without this would be considered as invalid.<br />

The <strong>Tender</strong>er should quote his offer duly signed in terms of percentage of estimated rates at<br />

the appropriate place of tender documents to be submitted only in Envelope No. 2 He should<br />

not quote his offer any where directly or indirectly in Envelope No. 1. The contractor shall<br />

quote for the work as per details given in the main tender and also based on the detailed set of<br />

conditions issued / Additional stipulations made by the Department as informed to him by a<br />

letter from Chief Engineer / Superintending Engineer after Pre-<strong>Tender</strong> Conference. His tender<br />

shall be unconditional.<br />

1.6 SUBMISSION OF TENDER: -<br />

Refer to Section ‘Guidelines to Bidders on the operations of Electronic <strong>Tender</strong>ing System of Rural<br />

Water Supply Division / Public Works Department’ for details.<br />

1.7 OPENING OF TENDERS:<br />

On the date, specified in the <strong>Tender</strong> Schedule, following procedure will be adopted for<br />

opening of the <strong>Tender</strong>.<br />

(A) ENVELOPE No. 1 :- ( <strong>Document</strong>s )<br />

First of all Envelope No. 1 of the tender will be opened online to verify its contents as per<br />

requirements. If the various documents contained in this envelope do not meet the<br />

requirements of the Department, a note will be recorded accordingly by the tender opening<br />

authority and the said tenderers Envelope No. 2 will not be considered for further action and<br />

the same will be recorded.<br />

The decision of the tender opening authority in this regard will be final and binding on the<br />

contractors.<br />

(B) ENVELOPE No. 2: (Financial Bid)<br />

a)This envelope shall be opened online immediately after opening of Envelope No. 1, only if<br />

contents of Envelope No. 1 are found to be acceptable to the Department. The tendered rates<br />

in Schedule ‘B’ or percentage above/below the estimated rates shall then be read out. in the<br />

presence of bidders who remain present at the time of opening of Envelope No. 2.<br />

1.8 EARNEST MONEY :<br />

(i)Earnest money of minimum Rs 45600/- to be attached with the tender should be in the form of<br />

challan showing deposit of cash in to the treasury / bank or Term deposit receipt for period of one year<br />

issued by the Scheduled Bank duly endorsed in the name of Chief Accounts & Finance officer.<br />

Finance Depatment Zilla Parishad Akola,<br />

(ii)Attested copy of earnest money exemption certificate will be accepted in lieu Earnest<br />

Money Deposit from the Registered Contractors of Maharashtra State only.<br />

Earnest Money in the form of cheques or any other form except above will not be accepted.<br />

(iii)The amount will be refunded to the unsuccessful tenderers on deciding about the<br />

acceptance or otherwise of the tender. In case of successful tenderer, it will be refunded on<br />

his paying initial Security Deposit and completing the tender documents in form B-1.<br />

(iv) In case of Joint Venture Earnest money Exemption certificate in individual Capacity will<br />

not be accepted. Earnest money, Security Deposit, additional security deposit etc. in the<br />

form of T.D.R/F.D.R issued in the name of Joint Venture Company drawn by scheduled<br />

Signature of Contractor No. of corrections Executive Engineer

ank having branches in Maharashtra and endorsed, in the name of Chief Accounts &<br />

Finance Oficer,Zilla Parishad, Akola for the period of one year will be considered<br />

1.9 A SECURITY DEPOSIT:<br />

The successful tenderer whose tender is accepted will have to pay Rs.182200/-*towards the<br />

Security Deposit Rs.91100/-* is to be deposited in cash or bank guarantee of scheduled<br />

bank, F.D.R. of the scheduled bank / National Saving Certificate duly pledged in the name of<br />

the Executive Engineer Rural Water Supply Division Zilla Parishad,Akola, towards the<br />

initial Security Deposit, valid within the time limit prescribed in clause 1 of B-1 Form,<br />

agreement till completion of defect liabilities period failing which his earnest money will be<br />

forfeited to Government.(iii) In addition to the above, an amount of Rs. 91100/-* will be<br />

deducted from the running bills at 2 % of value of the gross bill towards balance security<br />

deposit. This is a compulsory deduction.<br />

1.9. B. Condition for payment of additional security deposit, if offer quoted by the tenderer is<br />

lesser than 15% below the cost put to tender.<br />

The contractor shall deposit an additional security deposit along with the security deposit as<br />

per clause 1.9 within 10 days of acceptance of tender in the form of Bank guarantee, when the<br />

below percentage quoted is more than 15% of cost put to tender.<br />

The amount of security deposit shall be worked out as per following formula.<br />

Additional Security Deposit = Rs. [% rate quoted by the contractor -15] x 50/100 x<br />

100<br />

Cost put tender (i.e. Rs. 4553588/-)<br />

If the contractor does not deposit this additional security deposit (if applicable) within<br />

stipulated time then his earnest money deposit will be forfeited and his tender will not be<br />

considered for acceptance.<br />

This additional security deposit shall be extendable up to expiry of valid extensions if<br />

any and it shall be refunded along with the final bill, after satisfactory completion of<br />

work.<br />

1.10 ISSUE OF FORMS:<br />

Information regarding contract as well as blank tender forms can be downloaded from the<br />

e<strong>Tender</strong>ing website upon providing the details of the payment of cost as detailed in the N.I.T.<br />

1.11 TIME LIMIT:<br />

The work is to be completed within time limit as specified in the N.I.T. which shall be<br />

reckoned from the date of written order for commencing the work and shall be inclusive<br />

of monsoon period.<br />

1.12 TENDER RATE:<br />

No alteration in the form of tender and the schedule of tender and no additions in the scope of<br />

special stipulations will be permitted. Rates quoted for the tender shall be taken as applicable<br />

for all leads and lifts.<br />

1.13 TENDER UNITS:<br />

The tenderers should particularly note the units mentioned in the Schedule “B” on which the<br />

rates are based. No change in the units shall be allowed. In the case of difference between the<br />

rates written in figures and in words, the correct rate will be the one, which is lower of the<br />

two.<br />

1.14 CORRECTION:<br />

No corrections shall be made in the tender documents. Any corrections that are to be made<br />

shall be made by crossing the incorrect portion and writing the correct portions above with the<br />

initials of tenderer.<br />

1.15 TENDER’S ACCEPTANCE :<br />

Acceptance of tender will rest with Jal Vyavstapan Samitee , Z.P.Akola who reserves the<br />

right to reject any or all tenders without assigning any reason therefor. The tenderer<br />

whose tender is accepted will have to enter in to a regular B-1 agreement within 10 days<br />

of being notified to do so. In case of failure on the part of <strong>Tender</strong>er to sign the<br />

agreement within the stipulated time, the earnest money paid by him shall stand<br />

Signature of Contractor No. of corrections Executive Engineer

forfeited to the Government and the offer of the tenderer shall be considered as<br />

withdrawn by him.<br />

1.16 CONDITIONAL TENDER :<br />

The tenders who do not fulfil the condition of the notification and the general rules and<br />

directions for the guidance of contractor in the agreement form or are incomplete in any<br />

respect are likely to be rejected without assigning any reason therefore.<br />

1.17(a) The <strong>Tender</strong>ers shall be presumed to have carefully examined the drawings, conditions and<br />

specifications of the work and have fully acquainted themselves with all details of the site, the<br />

conditions of rock and its joints, pattern, river, weather characteristics, labour conditions and<br />

in general with all the necessary information and data pertaining to the work, prior to<br />

tendering for the work.<br />

1.17(b) The data whatsoever supplied by the Department along with the tender documents are meant<br />

to serve only as guide for the tenderers while tendering and the Department accepts no<br />

responsibility whatsoever either for the accuracy of data or for their comprehensiveness.<br />

1.17(c) The quarries for extraction of metal, murum etc. provided in the sanctioned estimate are as per<br />

survey conducted by the Department. The Contractor should however examine these quarries<br />

and see whether full quantity of materials required for execution of the work strictly as per<br />

specification are available in these source before quoting the rates. In case the materials are<br />

not available due to reasons whatsoever, the contractor will have to bring the materials from<br />

any other source with no extra cost to Government. The rates quoted, should therefore be for<br />

all leads and lifts from wherever the materials are brought at site of work and inclusive of<br />

royalty to be paid to the Revenue Department by the Contractor.<br />

POWER OF ATTORNEY:<br />

If the tenderers are a firm or company, they should in their forwarding letter mention<br />

the names of all the partners together with the name of the person who holds the power<br />

of Attorney, authorizing him to conduct all transactions on behalf of the body, along with<br />

the tender.<br />

1.19 The tenderer may, in the forwarding letter, mention any points are may wish to make clear but<br />

the right is reserved to reject the same or the whole of the tender if the same becomes<br />

conditional tender thereby.<br />

1.20 The contractor or the firms tendering for the work shall inform the Department if they appoint<br />

their authorized Agent on the work.<br />

1.21 No foreign exchange will be released by the Department for the purchase of plants and<br />

machinery for the work by the Contractor.<br />

1.22 Any dues arising out of contract will be recovered from the contractor as arrears of Land<br />

Revenue, if not paid amicably. Moreover, recovery of Government dues from the Contractors<br />

will be affected from the payment due to the Contractor from any other Government works<br />

under execution with them.<br />

1.23 All pages of tender documents, conditions, specifications, correction slips etc. shall be<br />

initialled by the tenderer. The tender should bear full signature of the tenderer, or his<br />

authorized power of Attorney holder in case of a firm.<br />

1.24 The Income Tax at 2.30 % including surcharge or percentage in force from time to time or at<br />

the rate as intimated by the competent Income Tax authority shall be deducted from bill<br />

amount whether measured bill, advance payment or secured advance.<br />

1.25 The successful tenderer will be required to produce, to the satisfaction of the specified<br />

concerned authority a valid concurrent license issued in his favour under the provisions of the<br />

Contract Labour (Regulation and Abolition) Act 1970 for starting the work. On failure to do<br />

so, the acceptance of the tender shall be liable to be withdrawn and also liable for forfeiture of<br />

the earnest money.<br />

1.26 The tenderer shall submit the list of apprentices engaged by the Contractor under Apprentice<br />

Act.<br />

1.27 Cess @ 1% (One percent) shall be deducted at source from every bill of the<br />

Contractor by the Executive Engineer Under “ Building and Other Construction for<br />

workers Welfare Cess Act 1996<br />

1.28 VALIDITY PERIOD :<br />

Signature of Contractor No. of corrections Executive Engineer

The offer shall remain open for acceptance for minimum period of 120 days from the Date of<br />

opening of Envelope No. 2 (Financial Bid) and thereafter until it is withdrawn by the<br />

contractor by notice in writing duly addressed to the authority opening the tender and sent by<br />

Registered Post Acknowledgment due.<br />

<br />

<br />

(Affidavit)<br />

<br />

<br />

<br />

! "#$% & * <br />

'(&)*Envelope No.1+,%-&<br />

. / / &) *+ -0"#. 0 & 12 &) *<br />

%-+ 0 1$ . "# & &3456 1 <br />

-& )<br />

<br />

<br />

<br />

-"# <br />

Signature of Contractor No. of corrections Executive Engineer

FOR OFFICIAL USE<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

PANI PURAWTHA YOJNA ( With Public Contribution ) AT.<br />

PATKHED TAL-BARSHITAKLIDIST. AKOLA<br />

TENDER DOCUMENT<br />

Rural Water Supply Division ZILLA PARISHAD, AKOLA.<br />

Signature of Contractor No. of corrections Executive Engineer

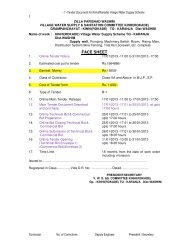

GOVERNMENT OF MAHARASHTRA<br />

RURAL WATER SUPPLY DIVISION ZILLA PARISHAD, AKOLA<br />

Name of Circle : MAHARASHTRA JEEVAN PRADHIKARAN CIRCLE<br />

AKOLA<br />

Name of Division :<br />

Name of Work<br />

Estimated cost put to<br />

<strong>Tender</strong> :<br />

:<br />

RURAL WATER SUPPLY DIVISION<br />

ZILLA PARISHAD, AKOLA<br />

PANI PURAWTHA YOJNA ( With Public<br />

Contribution ) AT. PATKHED TAL-<br />

BARSHITAKLIDIST. AKOLA<br />

Rs. 4553588/-*<br />

<strong>Tender</strong> Amount : Rs.1000/-<br />

Security Deposit : Rs.91100/-<br />

Name of the contractor<br />

and address<br />

:<br />

Percentage above/below :<br />

Date of work order :<br />

Stipulated time of<br />

completion<br />

<strong>Tender</strong> accepted under<br />

No.<br />

: 12 months Excluding Mansoon Period .<br />

: Date<br />

Signature of Contractor No. of corrections Executive Engineer

INDEX<br />

NAME OF WORK :- PANI PURAWTHA YOJNA ( With Public Contribution )<br />

AT. PATKHED TAL-BARSHITAKLIDIST. AKOLA<br />

Sr.No.<br />

Contents<br />

Page Number<br />

From To<br />

1 <strong>Tender</strong> Schedule, Revised <strong>Tender</strong> Schedule 1 2<br />

2 Invitation of <strong>Tender</strong> a) Press Notice b) Detailed <strong>Tender</strong> Notice 3 21<br />

3 B1 <strong>Tender</strong> Form 22 26<br />

4 APPENDIX “A” Form of one year Term Deposit Receipt 27 27<br />

5 APPENDIX “B” Bank Guarantee 28 30<br />

6 Conditions of Contract 31 56<br />

7 Schedule "A" 57 57<br />

8 Schedule "B" 58 61<br />

9 Construction Programme 62 62<br />

10 Special Conditions of Contract 63 87<br />

11 General Specification Index 88 88<br />

12 General Specification 89 165<br />

Signature of Contractor No. of corrections Executive Engineer

1<br />

<br />

<br />

<br />

!"<br />

<br />

<br />

! "# " $ %& ''( "'( )*+<br />

,''(,'(,")*<br />

Main Portal : http://maharashtra.etenders.in<br />

Portal : http://wsd.maharashtra.etenders.in #$ %&'( )* %&+ #$ *<br />

,* -* !&./01&.$)$123%&'()*<br />

<br />

)**<br />

/<br />

4/<br />

<br />

!" !" #$%&&'&(()*+<br />

<br />

<br />

<br />

<br />

/$/0)53<br />

<br />

<br />

<br />

Signature of Contractor No. of corrections Executive Engineer

2<br />

<br />

B-l FORM (Percentage Rates)<br />

TENDER PAPERS FOR<br />

NAME OF WORK:- PANI PURAWTHA YOJNA ( With Public Contribution<br />

) AT. PATKHED TAL-BARSHITAKLIDIST. AKOLA<br />

1) NAME OF CONTRACTOR Shri / M/s. : _____________________________<br />

__________________________________________<br />

2) LAST DATE SUBMISSION OF TENDER : upto 03/09/2013 To 06/09/2013 17.00 hrs.<br />

3) DATE OF OPENING OF TENDER : 06/09/2013 To 08/09/2013 (If possible)<br />

4) COST OF TENDER FORM : Rs. 1000/-<br />

5) NAME OF TENDER ACCEPTING : Rural Water Supply Division<br />

AUTHORITY<br />

Zilla Parishad Akola<br />

<br />

6) AMOUNT OF CONTRACT : Rs. ___________________ i.e. _____________<br />

_______________________ % below / above.<br />

7) DATE OF WORK ORDER : / / 2013<br />

Vide T.O. No. _______________ / AB / TC.<br />

8) DATE OF COMPLETION : Date : __________________________________<br />

i.e. upto. ________________________________<br />

________________________________________<br />

________________________________________<br />

9) EXTENSION OF TIME LIMIT, : ________________________________________<br />

IF ANY<br />

________________________________________<br />

________________________________________<br />

Signature of Contractor No. of corrections Executive Engineer

3<br />

<br />

<br />

NAME OF WORK:- PANI PURAWTHA YOJNA ( With Public Contribution<br />

) AT. PATKHED TAL-BARSHITAKLIDIST. AKOLA<br />

Estimated cost put to tender . : 4996111/-<br />

Earnest Money :- In Shape of Term Deposit Rs. : 45600/-*<br />

(Term Deposit Scanned Receipt for a period of one year issued by any Schedule Bank<br />

should be attached to the tender at the time of submission.)<br />

Security Deposit: 2%: Rs. 91100/-*<br />

Balance from R.A. Bills: 2% Rs. 91100/-*<br />

<strong>Tender</strong> Period: Forty Eight ( 18) Calendar months from the date of written order to start the<br />

Work.<br />

CONTENTS OF FORM From To<br />

Form B-l Sheet __________________ ________________<br />

Schedule ‘A’ Sheet __________________ ________________<br />

Schedule ‘B’ Sheet __________________ ________________<br />

Appendices Sheet __________________ ________________<br />

General Conditions of Contract Sheet __________________ ________________<br />

Special Conditions of Contract Sheet __________________ ________________<br />

General Specifications Sheet __________________ ________________<br />

Drawings Nos. ___________________ ________________<br />

Above To be filled in by the contractor<br />

I/We have quoted my /our rates in words as well as in figures. I/We further undertake<br />

to enter into Contract in regular ‘B-1’ Form with<br />

Signature of Contractor No. of corrections Executive Engineer

4<br />

<br />

Sealed Percentage rate tenders in B-1 form are invited from the contractors registered<br />

with M.J.P. Government of Maharashtra Class V and Above only in the form of e-<strong>Tender</strong> for<br />

the work as detailed below.<br />

a. Name of work : PANI PURAWTHA YOJNA ( With Public<br />

Contribution ) AT. PATKHED TAL-BARSHITAKLIDIST. AKOLA<br />

b. Estimated cost : Rs. 4996111/-<br />

c. Earnest Money : Rs. 45600/-*<br />

d. Security Deposit : Rs. 182200/-*<br />

e. Time Limit : Eighteen (12) Calendar months Excluding monsoon period.<br />

f. Date and issue of Blank tender forms : 23.08.2013 to 31.08.2013 ( 17.01 to 17.00 Hrs)<br />

g. Date and place of Pre-Bid Conference : -<br />

h. Last date and time of receipt of tenders : Up to 17.00 Hrs. on 31/08/2013<br />

1 The blank forms of Bid Capacity documents are available on the e-<strong>Tender</strong>ing website of<br />

Govt. of Maharashtra “http:// zp.maharashtra.etenders.in.” The aspiring Bidders will have to<br />

download Pre-qualification form, from the website mentioned above.<br />

Before purchasing of bidders shall deposit process fees Rs.1000/- (Rupees One<br />

Thousand only) in the Cash.<br />

Bidders shall upload the scanned copy of Bank DD along with documents. The<br />

Application should be uploaded with the photocopies of documents attested by Gazzetted Officer<br />

such as Works Deptt.zp akola Registration Certificate Registration Certificate, VAT Registration<br />

Certificate, PAN Card, PTR and PTE Registration Certificate, EPF Registration Certificate,<br />

before 23.08..2013 upto 17.00 hours. The bidder has to fill in online format and upload<br />

information regarding qualification online.<br />

2 Blank <strong>Tender</strong> forms can be downloaded by Qualified bidders only from the<br />

department’s portal http://zp.maharashtra.etenders.in & payment of Rs. 1000/-(Rs.one.Thousand<br />

only) ) in the form of Demand Draft in the name of Chief Accounts & Finance Oficer,Zilla<br />

Parishad, Akola. and the scanned copy of DD of such amount should be uploaded, failing which<br />

the envelope No. 2 of the bidder will not be opened.<br />

Payment by Cash or Cheque as well as application by Post, Courier or RPAD will not be<br />

accepted.<br />

3 Each tender shall be accompanied by earnest money in the form of term deposit<br />

receipt for the period of one year issued by a Scheduled / Nationalised Bank in the<br />

prescribed form drawn in favour of Chief Accounts & Finance Oficer,Zilla Parishad, Akola.<br />

The contractor should submit the scanned copy of term deposit receipt along with the <strong>Tender</strong><br />

document at the time of online submission of the <strong>Tender</strong> <strong>Document</strong>. The original term<br />

deposit receipt should be submitted in the office of Etender Section, Zilla Parishad Akola<br />

before the last date of online submission of the <strong>Tender</strong> <strong>Document</strong>. Neither cheque nor cash<br />

nor bank guarantee will be accepted towards payment of earnest money.<br />

4 <strong>Tender</strong>s should be submitted online up to 17.00 hrs on 03/09/13 and will be opened<br />

Zilla Parishad, Akola on the same day, if possible. The offer will remain valid for a period of<br />

120 days from the date of opening of the tender and there after until it is withdrawn in writing<br />

by the tenderer.<br />

5. Right is reserved to reject any item of the tender or a tender or all the tenders without<br />

assigning any reason there for decision for acceptance or rejection will rest with the<br />

competent authority.<br />

6. The site of work is village DABKI TAL- Akola , District – Akola.<br />

7. The tenderers are requested to read carefully all the tender instructions mentioned in<br />

while submitting their tenders online in two envelope system. They should also be very<br />

Signature of Contractor No. of corrections Executive Engineer

5<br />

careful regarding the documents to be submitted in the envelopes. Non observance of these<br />

things may result in rejecting the tender.<br />

Signature of Contractor No. of corrections Executive Engineer

6<br />

DETAILED TENDER NOTICE<br />

1.0 Sealed Percentage rate tenders in B-1 form are invited from the contractors registered<br />

with Works Deptt.Zilla Parishad of Government of Maharashtra Class V and Above.<br />

only in the form of e-<strong>Tender</strong> for the work of PANI PURAWTHA YOJNA (<br />

With Public Contribution ) AT. PATKHED TAL-BARSHITAKLIDIST.<br />

AKOLA<br />

1.Estimated Cost (Approximately)<br />

Rs. 4996111/- Lakhs<br />

2. Earnest Money Rs. 45600/-*<br />

3. Security Deposit Rs. 91100/-*<br />

4. Time Limit 12 Month<br />

(Excluding monsoon)<br />

5. Date of online issue of 23/08/13 to<br />

<strong>Document</strong>s.<br />

31/0813 (17.00 hrs.)<br />

6. Date of online receipt of upto 31/08/13 (up to 17.00 hrs.)<br />

<strong>Document</strong>s.<br />

7. Date of online issue of Blank 23.08.2013(10.01 hrs) to<br />

<strong>Tender</strong> forms.<br />

31.08.2013(17.00 hrs.)<br />

8. Last date of online receipt of 31/08/13 (17.00hrs)<br />

<strong>Tender</strong> forms<br />

1.2 The blank tender forms can be downloaded by the qualified contractor only from the<br />

website of Govt. of Maharashtra shttp://maharashtra.etenders.in “<strong>Tender</strong> Purchase”.<br />

While submitting the duly filled <strong>Tender</strong> <strong>Document</strong>s the Bidder is required to Deposit<br />

<strong>Tender</strong> Fee amount Rs.1000/- (Rs. one.Thousand only) only in the form of Demand<br />

Draft in the name of Chief Accounts & Finance Oficer,Zilla Parishad, Akola and the<br />

scanned copy DD of such amount should be uploaded, failing which the envelope No. 2 of<br />

the bidder will not be opened.<br />

1.3 ---------------<br />

Signature of Contractor No. of corrections Executive Engineer

7<br />

1.4 Each tender shall be accompanied by scanned copy of earnest money in the form of a<br />

receipt of DD. Either cheque nor cash nor bank guarantee will be NOT accepted<br />

towards payment of earnest money. The original DD issued by a<br />

Nationalised/scheduled Bank should be submitted in the office of Etender<br />

section,,Zilla Parishad, Akola before the last date of online submission of the <strong>Tender</strong><br />

<strong>Document</strong>.<br />

1.5 <strong>Tender</strong>s should be submitted online from 03/09/2013(17.01 hrs) to 06/09/13 (17.00<br />

hrs) and will be opened by the Authorised Commitee on the same day if possible. The<br />

offer will remain valid for a period of 120 days, from the date of opening of tender and<br />

there after until it is withdrawn in writing by the tenderer.<br />

1.6 The right is reserved to reject any item of the tender, or a tender, or all the tenders,<br />

without assigning any reason therefore. Decision for acceptance or rejection rests with<br />

the Chief Engineer, M.I. (L.S.) Pune. & Authourised Committee of etender opened.<br />

1.7 The latest Income Tax documents (PAN Card and Balance Sheet from Chartered<br />

Accountant and Filed IT Returns, Details of Receipt & Payments) and valid<br />

contractor’s Registration Certificate,Valid VAT Registration Certificate in form<br />

II(Rule-4 (i) under Rule 1984) along with clearance Certificate, Registration and<br />

Clearance Certificate as per the provision in labour /employees provident fund, labour<br />

licence. Scanned copies of all Originals will have to be submitted with qualification /<br />

blank tender form; otherwise qualification/tender forms will be rejected. The<br />

contractor’s who successfully qualify in qualification evaluation can participate in the<br />

further process of tendering.<br />

1.8 ------<br />

1.9 PANI PURAWTHA YOJNA ( With Public Contribution ) AT. PATKHED<br />

TAL-BARSHITAKLIDIST. AKOLA<br />

1.10 Conditional <strong>Tender</strong>s will not be accepted.<br />

1.11 A) Prior to the issue of Blank tender form for the work, the general experience,<br />

machinery details, Bid capacity of the interested contractor will be evaluated and<br />

determined on the basis of the necessary and requisite information submitted by them<br />

in the prescribed document. Only those contractors who successfully qualify in<br />

evaluation will be eligible to tender for the work and blank tender form will be issued<br />

to them only.<br />

The blank forms of Bid Capacity documents are available on the e-<strong>Tender</strong>ing<br />

website of Govt. of Maharashtra “https://maharashtra.etenders.in.” The aspiring Bidders<br />

will have to download form, from the website mentioned above. Before purchasing the<br />

duly filled documents bidders shall deposit process fees Rs.1000/- (Rupees one.Thousand<br />

only) in the form of Demand Draft in the name of Chief Accounts & Finance Oficer,Zilla<br />

Parishad, Akola .<br />

Payment by Cash or Cheque as well as application by Post, Courier or RPAD will<br />

not be accepted.<br />

C) 50% of the each type of machinery required for the work as listed in para 3.37 of<br />

prequalification shall be owned by the contractor in his name and documentary<br />

evidence in the form of scanned copy of original document should be produced for the<br />

same and for the rest 50% of machinery the details of sources of availability from<br />

where the machinery planned to be procured shall be given along with<br />

M.O.U. with the Party Supplying such machinery along with Supply guarantee on<br />

Rs.100/- Bond paper.<br />

Signature of Contractor No. of corrections Executive Engineer

8<br />

2. INSTRUCTIONS AND NOTES FOR THE GUIDNCE OF TENDERERS<br />

2.1 The tenderer shall be presumed to have carefully examined all documents, forms<br />

statement, special conditions schedules, drawings, general conditions and specifications<br />

of contract and to have fully acquainted themselves with all the details of site labour<br />

conditions and in general with all necessary information and date etc. pertaining to and<br />

needed for the work till completion of the work.<br />

2.2 The tenders should see in particular the quarry sites and satisfy themselves about the<br />

quality and quantities of the materials available as the rates quoted will be inclusive of<br />

all leads and lifts involved in bringing the materials from the quarry areas. All necessary<br />

testing of materials shall be carried out by the Contractor at his own cost to confirm their<br />

suitability before the materials will be permitted to be used. No claim in respect of<br />

additional leads and lifts and private quarry charges of any kind will be entertained. Any<br />

lead shown on any map or at any page of this document should not be taken into<br />

consideration and no claim on account of this will be entertained.<br />

3 ROYALTIES :<br />

3.1 All quarry fees, royalties, octroi dues and ground rent for stacking materials, if any,<br />

shall be paid by the contractor. All fees, etc. including royalties, are included in the<br />

rates submitted in the <strong>Tender</strong>.<br />

3.2 The amount of royalty included in the items of schedule 'B', the amount of royalty is to<br />

be paid by the contractor in advance before any material handling. If, contractor fails to<br />

pay, the amount of royalty shall be deducted from RA Bill as per the prevailing rates and<br />

will be released only after producing the documentary evidence of payment of royalty<br />

charges paid to concerned Revenue Authority. If contractor fails to produce the<br />

documentary evidence of payment of royalty charges, the amount of royalty deducted<br />

from RA Bill shall be directly paid to the concerned Revenue Authority. If any penalties<br />

are imposed by the Revenue Authority the same shall be borne by the contractor.<br />

4. PREFERENCE :<br />

Preference will be given to those contractors who have previous experience of such type<br />

of large works and who have necessary machinery with them who qualify through the<br />

Qualification evaluation.<br />

5. TIME LIMIT :<br />

The work is to be completed within Forty Twelve (12) calendar months including<br />

monsoon from date of written Work Order to commence the work.<br />

6. CONDITIONAL TENDERS :<br />

i) Conditional tenders will not be considered for acceptance<br />

ii) The tenderers are requested to read carefully all the instructions mentioned in para<br />

(8B) while submitting their tenders in e-tendering system in two envelope system .<br />

They should also be very careful regarding the documents to be submitted. Non<br />

observance of these things may result in rejection of the tender.<br />

<strong>Tender</strong>s which do not fulfill any of the conditions of notification and general rules<br />

and directions for the guidance of the contractors on page 1 of agreements form<br />

(printed B-1 form) or are incomplete in any respect are liable to be rejected<br />

without assigning any reason thereof.<br />

7. TENDER QUOTING<br />

a) The tenderer should quote percentage below or above both in words and figures.<br />

While online submission of the <strong>Tender</strong>, no alteration in the form of the tender and in<br />

the schedule of quantities and no addition in the form of special stipulation will be<br />

permitted. No change in the units shall be allowed. The rates quoted in <strong>Tender</strong> shall<br />

be taken as applying to all conditions of weather and the rates quoted will be inclusive<br />

of all taxes if any.<br />

Signature of Contractor No. of corrections Executive Engineer

9<br />

b) <strong>Tender</strong>ed percentage below or above shall be written at the appropriate place in<br />

English both in words and figures. In case the percentage expressed in words differs<br />

from that expressed in figures, the lowest of the two will be taken as correct.<br />

c) Neither erasures nor over- writings shall be made in the price schedule and in general in<br />

the tendered documents. Every correction shall be made by crossing the pen across<br />

the incorrect or unrequired portion and writing the correct or required portion above.<br />

All corrections shall bear the dated initials of the tenderer.<br />

d) All pages of the tender documents, conditions, specifications and drawings, etc. shall<br />

be signed by the tenderer with his digital signature.<br />

e) The tender shall contain the name, residence and place of business of person/ persons<br />

submitting the tender.<br />

f) <strong>Tender</strong> by partnership firm shall furnish the full name(s) of all authorized<br />

representative on behalf of each partner followed by the name and designation of the<br />

person signing. An attested copy of the partnership deed shall be furnished along with<br />

the tender. <strong>Tender</strong> by companies shall be signed with the legal name of the company<br />

and signed by the person authorized to sign it in the matter.<br />

h) Whenever, whether in the submission of tender or later in other matters the signatures<br />

are made by one person on behalf of a company or partnership, the tenderer shall<br />

supply an attested copy of the power of attorney.<br />

i) Witnesses and sureties shall be the persons of status and probity and their names,<br />

occupations and address shall be stated below their signatures. All signatures shall be<br />

dated.<br />

8. TENDERING PROCEDURE :<br />

A) BLANK TENDER FORMS :<br />

Blank <strong>Tender</strong> forms can be downloaded from the website as stipulated in the <strong>Tender</strong><br />

notice./ corrigendum.<br />

B) PRE-TENDER CONFERENCE :--------<br />

a) TECHNICAL ENVELOPE (T1) :<br />

The first envelope, named as “Envelope T1”, shall contain scanned copies of original<br />

documents of the following .<br />

1. DD of any Scheduled/Nationalised Bank for the amount of earnest money or certificate<br />

of exemption for payment of earnst money, if applicable, duly attested by gazzetted<br />

officer.<br />

2. Certificates of Registration of the Contractor with WD may be applicable.<br />

3. VAT registration certificate in respect of sale by transfer of property in goods involved<br />

in the executions of a work contract under the provision of rule 58 of Maharashtra added<br />

tax Act 2005 should be submitted in original or certified copy.<br />

4. Certificate of registration under clause (5) Sub-clause (1) of Maharashtra State Professional<br />

tax rules 1975 should be submitted in original or certified copy.<br />

5 Income tax Certificate : Attached copy of acknowledgement of Income Tax latest return<br />

or audit balance sheet with profit and loss account certified by C.A. valid upto date of<br />

submission of tender or N.O.C. from Income Tax Department<br />

6. Government of Maharashtra Irrigation Department Circular No. Misc. 1098/212/98<br />

Mantralaya Mumbai Dt. 19 .1.1999. “The Contractor’s firm is required to get themselves<br />

registered under provision labour general provident fund act “and accordingly it is<br />

required to produce necessary certificate duly attested towards the deposit in the labour<br />

G .P. F. Account from the competent authority.<br />

Signature of Contractor No. of corrections Executive Engineer

10<br />

7. Deed of Partnership or Articles of Association and Memorandum of Association for<br />

Limited Company.<br />

8. ---------<br />

9. The pages of all the <strong>Tender</strong> <strong>Document</strong>s must be digitally signed by the Bidder<br />

and the marking of digital signature must be seen on each page. Otherwise<br />

the tender will not be considered for further activities.<br />

b) COMMERCIAL ENVELOPE (C1) – TENDER<br />

The second envelope named as “Envelope C1” shall contain only the main <strong>Tender</strong><br />

including the common set of conditions / stipulations issued by the Department after the<br />

pre-<strong>Tender</strong> conference. A <strong>Tender</strong> submitted online without this will be considered as<br />

invalid.<br />

The <strong>Tender</strong>er should quote his offer on Schedule “B” of the <strong>Tender</strong> as a percentage of<br />

estimated rates at the appropriate place in the <strong>Tender</strong> documents and enclose in Envelope C1.<br />

The <strong>Tender</strong>er should not quote his offer anywhere directly or indirectly in Envelope T1. The<br />

contractor shall quote for the work as per details given in this main tender and also based on<br />

the detailed set of conditions issued /additional stipulation made by the department. This<br />

<strong>Tender</strong> shall be unconditional.<br />

c) SUBMISSION OF TENDER :<br />

The two Envelopes T l and C1, shall be submitted online by uploading:<br />

.<br />

The date and time for receipt of envelope containing <strong>Tender</strong> shall strictly apply in all<br />

cases. The <strong>Tender</strong>er should ensure that their <strong>Tender</strong> is properly uploaded & submitted<br />

before the stipulated expiry date and time. No delay on account of any cause will be<br />

entertained for the late receipt of the <strong>Tender</strong>. A <strong>Tender</strong> offered or received after the<br />

date and time is over, will either not be accepted or if inadvertently accepted, will not<br />

be opened.<br />

d) OPENING OF TENDERS :<br />

On the date specified in the tender notice following procedure will be adopted for<br />

opening of the tender.<br />

TECHNICAL ENVELOPE (T1) :<br />

Envelope Tl of all the <strong>Tender</strong>ers will be opened first to verify that its contents are as<br />

per requirements. If the various documents contained in this envelope do not meet the<br />

requirements of the Department, a note will be recorded accordingly by the <strong>Tender</strong> opening<br />

authority and the said <strong>Tender</strong>’s Envelope C1 will not be considered for further action and the<br />

same will be recorded.<br />

COMMERCIALENVELOPE (C1) :<br />

This envelope shall be opened immediately after opening of Envelope T1, only if the<br />

contents of Envelope Tl are found to be acceptable to the Department. The percentage above<br />

or below the estimated rates shall then be read out.<br />

10. The tenders will be opened on 05.06.2013 (at 17.01 hours) to 07.06.2013 (at 18.00 hrs.)<br />

if possible in presence of the tenderers or their authorized agents, who may choose to be<br />

present.<br />

Signature of Contractor No. of corrections Executive Engineer

11<br />

11. THE TENDER WILL BE LIABLE TO BE REJECTED OUTRIGHT IF WHILE<br />

SUBMITTING :<br />

1) The tenderer proposes any alterations in the work specified in the tender or in the<br />

time allowed for carrying out the work or any other condition.<br />

2) Any of the pages of the tender are removed or replaced<br />

3) The percentage above or below are not clearly mentioned both in figures and words<br />

in the tender documents.<br />

4) The <strong>Tender</strong>er, or in the case of a partnership firm, each partner thereof, does not sign<br />

or the signature/s is / are not attested by a witness on B-1 <strong>Tender</strong> Form of the tender<br />

in the space provided for the purpose (or provisions of paragraph 14.( d) are not<br />

complied with). In case of tender by companies, it should be signed by the legal name<br />

of the company and signed by the person authorized to sign to tender documents in<br />

the matter.<br />

5) Any erasures are made in the tender.<br />

6) All corrections and additions or pasted slips are not signed by the tenderer.<br />

12. EARNEST MONEY / SECURITY DEPOSIT :<br />

i) a) A sum of Rs.45600/-* on account of earnest money should be in form of DD<br />

issued by a Scheduled / Nationalised Bank, in favour of Chief Accounts &<br />

Finance Oficer,Zilla Parishad, Akola the contractor should draw demand draft<br />

of the same amount from scheduled / Nationalised bank and submit scanned<br />

copy of demand draft along with <strong>Tender</strong> document at the time of online<br />

submission of the <strong>Tender</strong>. The original D D should be submitted with<br />

documents to the Etender Section, Zilla Parishad, Akola before the last date<br />

of submission of <strong>Tender</strong>.<br />

b) Earnest Money in the form of cash or cheque will not be accepted.<br />

ii) ----<br />

iii<br />

In lieu of cash deposit mentioned above in Para (ii) Government Security, gold<br />

bonds, guarantee bonds from a Scheduled Bank in the form acceptable to<br />

Government, National Savings certificates, National Defense Saving<br />

Certificates, for the value for which they can be encashed at the time of<br />

presentation as security deposit, Port Trust bonds, Municipal debentures, scripts<br />

of rural debentures issued by the Mumbai State Co-operative Land Mortgage<br />

Bank Limited, standing in the name of the <strong>Tender</strong>er shall be accepted, if<br />

pledged as a Security Deposit in the name of Executive Engineer Rural<br />

Water Supply Division Zilla Parishad, Akola. Guarantee bonds of scheduled<br />

bank in the form acceptable to government shall be accepted, for a period equal<br />

to the time limit plus the period of defects liability (Clause 20 of B-1 tender<br />

form). The balance, amounts of security deposit of Rs. 91100/-* shall be<br />

recovered by 2% deduction from running account bills.<br />

12.1 ADDITIONAL SECURITY DEPOSIT :<br />

If the tenderer quotes rate less than 15% below or greater than 15% above, then the<br />

contractors has to furnish the additional security deposit before communication of acceptance<br />

of tender at the percentage by which the contractor has quoted less than 15% or more than<br />

15%. For example, if the contractors quoted rate is 25% below, the contractors has to furnish<br />

an additional security deposit procedure mentioned above (25-15)/100 x 15 = 2.75% of the<br />

estimated cost in the form of same guarantee which will be released at the time of payment of<br />

final bill. In either case, if the additional security deposit is not furnished as per requirement<br />

the Earnest Money will be forfeited (As per Govt. Circular (Marathi) Misc. 1097<br />

(105/97)/M.P. Dated : 22/5/1998). If there is an addition of work due to Extra Item, deviation<br />

Signature of Contractor No. of corrections Executive Engineer

12<br />

in tendered quantities beyond 125%, additional security deposit on extra cost beyond tender<br />

cost shall be recovered at the rate of 4% through the Running Account Bill.<br />

13. ACCEPTANCE OF THE TENDER :-<br />

Acceptance of the tender will rest with the Supdtt. Engineer, MJP Circle Akola /<br />

Executive Engr R.W.S. Dn. Z. P.Akola who reserves the right to reject any item of the<br />

tender, or a <strong>Tender</strong> or all <strong>Tender</strong>s without assigning any reasons thereof. The person /persons<br />

whose <strong>Tender</strong> may be accepted shall have to pay the cash security deposit and enter into<br />

regular B-l agreement within ten days of being notified to do so (which period may be<br />

extended by the Superintending Engineer MJP Circle Akola up to 15 days if he thinks it<br />

fit to do so), and shall abide by all rules & regulations embodied therein. In the event of the<br />

failure of the <strong>Tender</strong>er to sign the agreement within the stipulated time, the earnest money<br />

paid by him shall stand forfeited to Government and the acceptance of the tender shall be<br />

considered as withdrawn. In the case of contractors who are exempted from paying the<br />

earnest money and who fail to pay the security deposit & sign the agreement in the stipulated<br />

time, the fixed amount deposited by them as per the rule governing registration of contractors,<br />

shall stand forfeited to Government. The facility of not paying earnest money extended to<br />

such contractors shall also stand withdrawn from the date on which they fail to comply with<br />

the requirements and their registration is also liable to be cancelled.<br />

The offer shall remain open for acceptance for a minimum period of 90 (Ninety) days<br />

from the date fixed for opening the same and there after until it is withdrawn by the<br />

contractor by notice in writing duly addressed to the authority opening the <strong>Tender</strong> and sent by<br />

registered post acknowledgment due or otherwise delivered at the office of such authority and<br />

also subject to other conditions shown in Memorandum of Agreement printed .<br />

14. The right is reserved to revise or amend the tender documents prior to the last date<br />

notified for the issue of tenders. Such revisions or amendments or extensions shall be<br />

communicated to all concerned in the form of addenda or by notice in the press as may be<br />

considered suitable.<br />

15. Should some items of work are being executed departmentally, the quantities that<br />

would be executed during the period between the issue of tender notice and fixation of<br />

agency will be deducted from the quantities in the tender. The tenderer should take<br />

cognizance of this fact and no claims would be tenable on a account of such reduction in the<br />

quantities. [Vide Govt. Letter No. 1076/ 1181/666 (E) 17 dated 08/06/76.]<br />

16. The successful tenderer should produce to the satisfaction of the competent authority<br />

accepting the <strong>Tender</strong> a valid and concurrent license issued in his favor under the provisions of<br />

the contract labour ( Regulation and Abolition) Act .1970 and the Maharashtra contract<br />

labour (Regulation and Abolition) Rule 1971 before starting the work. On failure to do so, the<br />

acceptance of the <strong>Tender</strong> will be liable to be withdrawn and also the earnest money will be<br />

forfeited to the Government.<br />

17. In the case of possibility of excess execution of the quantities of several items the<br />

necessary proposals are to be submitted to the competent authority for approval before<br />

execution of work and the decision of the competent authority being binding on the<br />

contractor. (As per Government of Maharashtra, Irrigation Department, circular No. Misc.<br />

1997 (S97) MPCP Mantralaya Mumbai Dt. 22.5.98.)<br />

18. The Contractor is bound to submit his yearly work (month wise) program regarding<br />

item-wise quantities, amounts and other details regarding it, month-wise which will be<br />

finalised by the Executive Engineer, before the issue of the Work Order and the same will be<br />

revived at the beginning of the financial year as per availability of the funds. The work<br />

schedule may be periodically revised by the Executive Engineer, only if found necessary due<br />

to circumstances beyond the control of the Contractor.<br />

Signature of Contractor No. of corrections Executive Engineer

13<br />

B - 1 TENDER FORM<br />

RURAL WATER SUPPLY DIVISION ZILLA PARISHAD AKOLA<br />

Percentage Rate <strong>Tender</strong> and Contract for MJP CSR<br />

GENERAL RULES AND DIRECTIONS FOR THE GUIDANCE OF CONTRACTORS<br />

1. All work proposed to be executed by Contract shall be notified in a form of Invitation to<br />

<strong>Tender</strong>, pasted on a board hung up in the office of the Executive Engineer and signed by<br />

the Executive Engineer.<br />

This form will state the work to be carried out as well as the date for submitting and<br />

opening <strong>Tender</strong>s, and the time allowed for carrying out the work; also the amount of<br />

earnest money to be deposited with the <strong>Tender</strong>er and the amount of security deposit to<br />

be deposited by the successful <strong>Tender</strong> and the percentage, if any, to be deducted from<br />

bills. It will also state whether a refund of quarry fees, royalties, octroi dues and ground<br />

rents will be granted. Copies of the specifications designs and drawing and estimated<br />

rates, scheduled rates, and any other documents required in connection with the work<br />

which will be signed by the Executive Engineer for the purpose of identification shall<br />

also be open for inspection by Contractors at the office of the Executive Engineer,<br />

RURAL WATER SUPPLY DIVISION Zilla Parishad, Akola during office hours.<br />

Where the works are proposed to be executed according to the specifications recommended<br />

by a Contractor and approved by a competent authority on behalf of the<br />

Government of Maharashatra such specification with designs and drawing shall form<br />

part of the accepted <strong>Tender</strong>.<br />

2. In the event of the <strong>Tender</strong> being submitted by a firm, it must be signed by each partner<br />

there of and in the event of the absence of any partner, it shall be signed on his behalf by<br />