Improving Safety and Security with Automation MOC

Improving Safety and Security with Automation MOC

Improving Safety and Security with Automation MOC

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Technology<br />

<strong>Improving</strong> <strong>Safety</strong> <strong>and</strong><br />

<strong>Security</strong> <strong>with</strong> <strong>Automation</strong> <strong>MOC</strong><br />

Continuous improvement in pipeline operations is dependent on frequent automation parameter<br />

changes, but these are often excluded from Management Of Change (<strong>MOC</strong>). This article will<br />

explore how process safety can be maintained pipelines by including multi-vendor automation<br />

systems in a rigorous <strong>MOC</strong> process.<br />

In 1931, Herbert William Heinrich who was the<br />

Assistant Superintendent of the Engineering<br />

<strong>and</strong> Inspection Division of Travelers Insurance<br />

Company wrote a revolutionary book entitled<br />

Industrial Accident Prevention, A Scientific Approach.<br />

His research became the basis for the theory of<br />

“Behavior-based safety”Behavior-Based <strong>Safety</strong>, which<br />

seeks to minimize accidents by eliminating at-risk<br />

behaviors in the workplace.<br />

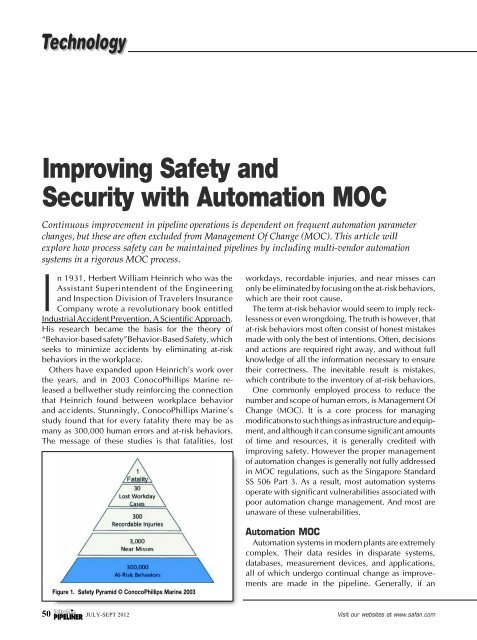

Others have exp<strong>and</strong>ed upon Heinrich’s work over<br />

the years, <strong>and</strong> in 2003 ConocoPhillips Marine released<br />

a bellwether study reinforcing the connection<br />

that Heinrich found between workplace behavior<br />

<strong>and</strong> accidents. Stunningly, ConocoPhillips Marine’s<br />

study found that for every fatality there may be as<br />

many as 300,000 human errors <strong>and</strong> at-risk behaviors.<br />

The message of these studies is that fatalities, lost<br />

Figure 1. <strong>Safety</strong> Pyramid © ConocoPhillips Marine 2003<br />

workdays, recordable injuries, <strong>and</strong> near misses can<br />

only be eliminated by focusing on the at-risk behaviors,<br />

which are their root cause.<br />

The term at-risk behavior would seem to imply recklessness<br />

or even wrongdoing. The truth is however, that<br />

at-risk behaviors most often consist of honest mistakes<br />

made <strong>with</strong> only the best of intentions. Often, decisions<br />

<strong>and</strong> actions are required right away, <strong>and</strong> <strong>with</strong>out full<br />

knowledge of all the information necessary to ensure<br />

their correctness. The inevitable result is mistakes,<br />

which contribute to the inventory of at-risk behaviors.<br />

One commonly employed process to reduce the<br />

number <strong>and</strong> scope of human errors, is Management Of<br />

Change (<strong>MOC</strong>). It is a core process for managing<br />

modifications to such things as infrastructure <strong>and</strong> equipment,<br />

<strong>and</strong> although it can consume significant amounts<br />

of time <strong>and</strong> resources, it is generally credited <strong>with</strong><br />

improving safety. However the proper management<br />

of automation changes is generally not fully addressed<br />

in <strong>MOC</strong> regulations, such as the Singapore St<strong>and</strong>ard<br />

SS 506 Part 3. As a result, most automation systems<br />

operate <strong>with</strong> significant vulnerabilities associated <strong>with</strong><br />

poor automation change management. And most are<br />

unaware of these vulnerabilities.<br />

<strong>Automation</strong> <strong>MOC</strong><br />

<strong>Automation</strong> systems in modern plants are extremely<br />

complex. Their data resides in disparate systems,<br />

databases, measurement devices, <strong>and</strong> applications,<br />

all of which undergo continual change as improvements<br />

are made in the pipeline. Generally, if an<br />

50 JULY-SEPT 2012 Visit our websites at www.safan.com

automation change affects a drawing or other entity<br />

currently under change control, then an <strong>MOC</strong> case<br />

is initiated. Otherwise, robust change management<br />

most likely does not occur. As automation systems<br />

directly control the process, the wrong modifications<br />

to them could have a tremendous negative impact<br />

upon safety, economics, environmental compliance,<br />

<strong>and</strong> reliability. (It should be noted that certain types<br />

of routine parameter modifications, which are core<br />

to daily process operations, such as changes to<br />

setpoints, control modes, <strong>and</strong> manual outputs, must<br />

necessarily be an exception to the <strong>MOC</strong> process.)<br />

Undocumented <strong>and</strong> unapproved changes to automation<br />

systems have been identified as contributing<br />

factors to a number of recent industry incidents<br />

<strong>and</strong> accidents. And, <strong>with</strong> the advent of new viruses<br />

that can affect the interaction of control systems<br />

<strong>with</strong> the process, ensuring that every automation<br />

configuration change is detected <strong>and</strong> then reconciled<br />

<strong>with</strong> an approved management of change<br />

(<strong>MOC</strong>) case in a timely manner has become a<br />

crucial element of control system security.<br />

A major complaint concerning the traditional <strong>MOC</strong><br />

process is the great consumption of time <strong>and</strong> resources<br />

necessary to be compliant <strong>with</strong> regulations.<br />

This is a considerable impediment to the full adoption<br />

of <strong>MOC</strong> for automation, in that the process<br />

takes more time <strong>and</strong> energy to implement than the<br />

time required to make the actual automation changes,<br />

<strong>and</strong> so seems excessive by comparison. The ratio of<br />

work to benefits is perceived to be skewed heavily<br />

toward work <strong>and</strong> away from benefits, <strong>and</strong> so <strong>MOC</strong><br />

for these types of changes is often excluded from the<br />

work process.<br />

An incident caused by unmanaged automation<br />

change recently occurred at a petroleum refinery<br />

(this could easily be translated to a pipeline) operated<br />

by one of PAS’ clients. A specific process<br />

measurement was oscillating into <strong>and</strong> out of the<br />

alarm state, creating a nuisance for the process<br />

operators. It was noted that the measurement excursions<br />

past the alarm trip point were both small in<br />

amplitude <strong>and</strong> duration, so the operating supervisor<br />

raised the high alarm trip point in order to eliminate<br />

the nuisance. However, unknown to him, the new<br />

level at which he set the alarm was above the safety<br />

shutdown trip point. A short time later, the unit<br />

unexpectedly shut down.<br />

It is possible that a traditional <strong>MOC</strong> process could<br />

have prevented this incident through its regimen of<br />

peer reviews, approvals, <strong>and</strong> pre-startup safety reviews.<br />

However, routine automation changes occur<br />

so frequently that the sheer volume of <strong>MOC</strong> cases<br />

would quickly overwhelm staff. In a scenario, such<br />

as the one above, the amount of <strong>MOC</strong>-related work<br />

is so much greater than the effort to simply type in<br />

the new parameter, that traditional <strong>MOC</strong> would<br />

simply not be practical.<br />

So this situation presents a dilemma. To ensure<br />

that only safe <strong>and</strong> appropriate modifications are<br />

made to configurations, each change, whether to<br />

the actual configuration or to the underlying computing<br />

infrastructure, must be under strict <strong>MOC</strong><br />

control. However, the traditional <strong>MOC</strong> process is<br />

untenable for general use <strong>with</strong> automation. A shorter,<br />

more streamlined, <strong>MOC</strong> process that evaluates,<br />

approves <strong>and</strong> tracks all changes, but does not entail<br />

more effort than the modification itself is clearly<br />

needed for most parameter-only automation configuration<br />

modifications.<br />

But, since most automation configuration changes<br />

are parametric in nature, <strong>and</strong> can easily be changed,<br />

how can we be certain that all modifications were<br />

made under <strong>MOC</strong> control? How can we be assured<br />

that an unapproved, <strong>and</strong> potentially dangerous<br />

modification has not slipped into our systems? One<br />

possible answer is if the automation databases were<br />

continually monitored for changes <strong>and</strong> compared to<br />

already approved <strong>MOC</strong> cases to determine if those<br />

changes were actually authorized. In this scenario,<br />

any changes that do not reconcile <strong>with</strong> a specific<br />

<strong>MOC</strong> case, would therefore be considered unapproved<br />

<strong>and</strong> thus require investigation.<br />

Integrity Software <strong>and</strong> Intelligent <strong>MOC</strong><br />

Integrity Software from PAS does exactly that. First,<br />

it imports the entire automation configuration database<br />

at regular intervals <strong>and</strong> compares it to the<br />

database image taken during the last import. It then<br />

tracks <strong>and</strong> reports on all changes made between<br />

import intervals. While most automation system manufacturers<br />

are able to track changes <strong>with</strong>in their own<br />

JULY-SEPT 2012 51

systems, Integrity software does so across system<br />

boundaries, <strong>and</strong> is therefore able to track signal<br />

genealogy throughout integrated systems. A common<br />

example of a signal crossing the boundaries of<br />

interoperable systems is a safety transmitter that is<br />

connected to a <strong>Safety</strong> Instrumented System (SIS),<br />

which passes the measured value to a Distributed<br />

Control System (DCS) for display, which in turn<br />

passes it to a process historian for archiving. Integrity<br />

software provides this signal mapping <strong>and</strong><br />

change tracking for over 50 different automation<br />

systems as well as their Microsoft Windows©- based<br />

underlying architecture.<br />

An optional application for Integrity Software,<br />

i<strong>MOC</strong> provides the next necessary aspect of the<br />

automation <strong>MOC</strong> solution. It<br />

is an intelligent management<br />

of change application designed<br />

specifically to address<br />

the special needs of automation.<br />

i<strong>MOC</strong> provides robust<br />

management of change capabilities<br />

that are easy to engineer<br />

<strong>and</strong> use, but more<br />

importantly reconcile the<br />

changes detected by the Integrity<br />

Change Tracker <strong>with</strong><br />

the specific <strong>MOC</strong> cases that<br />

authorized them. This capability<br />

ensures that all unapproved<br />

automation changes<br />

are identified to system administrators,<br />

<strong>and</strong> reports of unreconciled changes<br />

are automatically generated.<br />

Simplified <strong>MOC</strong><br />

As discussed above, the traditional <strong>MOC</strong> process is<br />

impractical for most automation modifications. In<br />

situations where an automation change does not also<br />

involve modifications of equipment, drawings, procedures<br />

or other items under change control, PAS suggests<br />

a special classification of the <strong>MOC</strong> process that<br />

is initiated, approved <strong>and</strong> closed out by the automation<br />

professional that actually makes the change. This<br />

process would employ a simple checklist form that<br />

would describe the change, include the necessary<br />

approvals, <strong>and</strong> be electronically signed by the person<br />

making the change. It is assigned a tracking number<br />

<strong>and</strong> saved as an <strong>MOC</strong> case by the i<strong>MOC</strong> software,<br />

<strong>and</strong> then on the next import of the configuration<br />

database by the Integrity Software, the modifications<br />

are reconciled <strong>with</strong> the <strong>MOC</strong> case that authorized<br />

them (Figure 2). A report of all unreconciled modifications<br />

is generated so that unauthorized changes are<br />

immediately identified <strong>and</strong> communicated to the responsible<br />

parties. Those unreconciled changes may<br />

then be either accepted as they are or a new <strong>MOC</strong> case<br />

may then be created to authorize changing them back<br />

to an acceptable state. With minimal effort, this process<br />

ensures that no unauthorized changes remain in<br />

the automation systems.<br />

Figure 2. Reconciliation of Modifications to a Specific <strong>MOC</strong> Case<br />

Clearly this simplified <strong>MOC</strong> process is not appropriate<br />

for all <strong>MOC</strong> classifications, so the i<strong>MOC</strong> Workflow<br />

Builder provides the ability to develop different templates<br />

for various types of workflows. For example,<br />

there is a class of automation modifications that affect<br />

drawings, procedures <strong>and</strong> other items, <strong>and</strong> therefore<br />

requires a longer, more complicated workflow. These<br />

other variations in workflow templates are then associated<br />

<strong>with</strong> the appropriate work classifications, <strong>and</strong><br />

are selectable from a menu as <strong>MOC</strong> cases are initiated.<br />

Figure 3 is an example of one of these longer<br />

workflow templates under construction in the i<strong>MOC</strong><br />

Workflow Builder. The <strong>MOC</strong> workflow is composed of<br />

elements called states <strong>and</strong> transitions. States are repre-<br />

52 JULY-SEPT 2012 Visit our websites at www.safan.com

y automatically identifying <strong>and</strong><br />

cross-referencing all configuration<br />

linkages <strong>and</strong> places where<br />

an automation parameter is used.<br />

This feature significantly speeds<br />

preparation of RFCs by reducing<br />

the time spent researching the<br />

scope of the change, <strong>and</strong> also<br />

ensures that no critical use of the<br />

parameter under change is omitted<br />

from the process.<br />

Figure 3. An <strong>MOC</strong> Workflow under Construction<br />

sented by the rounded rectangular boxes, while transitions<br />

are represented by the arrows. Each state may<br />

have a checklist associated <strong>with</strong> it that comprises<br />

various user-selected elements such as checkboxes,<br />

data-entry fields, attachment boxes for attaching documents,<br />

expression boxes for calculations <strong>and</strong> electronic<br />

signature boxes for recording approvals <strong>and</strong><br />

completions. Transitions contain the logic that either<br />

moves the case to the next state or routes it to an<br />

alternate path.<br />

Engineers spend a substantial amount of time acquiring<br />

approvals in order to initiate cases, move them to<br />

the next phase, or close them out. Integrity i<strong>MOC</strong><br />

reduces time spent gathering approvals by using Web<br />

2.0 technology to “push” them to the approvers. Userdefined<br />

approval logic may be applied so that for<br />

example, if a primary approver is unavailable, a secondary<br />

approver would automatically receive the approval<br />

request. And, if the approvers don’t respond in<br />

a timely manner, i<strong>MOC</strong> reminds them that they have<br />

an outst<strong>and</strong>ing approval task. These features provide a<br />

significant reduction in time spent on non-value-added<br />

activities associated <strong>with</strong> the <strong>MOC</strong> process.<br />

i<strong>MOC</strong> software also helps reduce engineering time<br />

spent on preparing initial Requests For Change (RFC)<br />

Conclusion<br />

While <strong>MOC</strong> is a core process<br />

in process industry plants around<br />

the world, the amount of effort<br />

required to implement it for typical<br />

automation changes is so disproportionate<br />

to the changes<br />

themselves that is not always applied.<br />

This practice leaves infrastructure<br />

vulnerable to unapproved, undocumented,<br />

<strong>and</strong> potentially even malicious changes made to their<br />

automation systems. Only through a program of rigorous<br />

<strong>MOC</strong> that reconciles automation changes to<br />

the <strong>MOC</strong> cases that authorized them, can unapproved<br />

or undocumented changes be eliminated as a<br />

cause of incidents. The Integrity <strong>and</strong> i<strong>MOC</strong> applications<br />

from PAS work in harmony to provide rigorous<br />

<strong>MOC</strong> that reconciles automation changes <strong>with</strong> minimal<br />

effort, <strong>and</strong> thus improve the safety <strong>and</strong> security of<br />

your process automation.<br />

PP<br />

This publication thanks Mr. Chris<br />

Lyden, President of PAS for providing<br />

this article. Prior to PAS, Mr.<br />

Lyden spent 26 years at Honeywell<br />

<strong>and</strong> held several executive positions<br />

including Vice-President of Sales for Honeywell<br />

HiSpec Solutions <strong>and</strong> Vice-President, General<br />

Manager. In addition, Mr. Lyden worked at<br />

Invensys Process Systems as Vice President of<br />

Global Marketing where he served on the leadership<br />

team which helped restore the company<br />

to financial health.<br />

JULY-SEPT 2012 53