PLA LOOK - IKV-Kolloquium

PLA LOOK - IKV-Kolloquium

PLA LOOK - IKV-Kolloquium

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

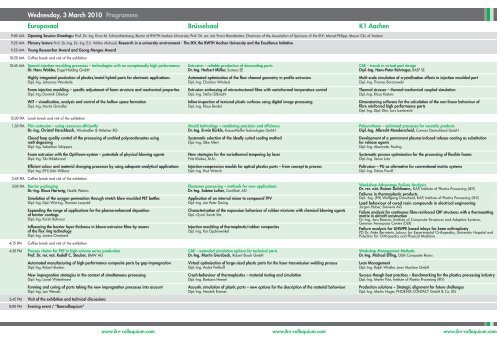

Wednesday, 3 March 2010 Programme<br />

Europasaal Brüsselsaal K1 Aachen<br />

9:00 AM Opening Session Greetings: Prof. Dr.-Ing. Ernst M. Schmachtenberg, Rector of RWTH Aachen University; Prof. Dr. rer. nat. Franz Brandstetter, Chairman of the Association of Sponsors of the <strong>IKV</strong>; Marcel Philipp, Mayor City of Aachen<br />

9:20 AM Plenary lecture Prof. Dr.-Ing. Dr.-Ing. E.h. Walter Michaeli, Research in a university environment - The <strong>IKV</strong>, the RWTH Aachen University and the Excellence Initiative<br />

9:50 AM Young Researcher Award and Georg Menges Award<br />

10:20 AM Coffee break and visit of the exhibition<br />

10:45 AM Special injection moulding processes – technologies with an exceptionally high performance Extrusion – reliable production of demanding parts CAE – trends in virtual part design<br />

Dr. Hans Wobbe, Engel Holding GmbH Dr.-Ing. Herbert Müller, Surteco SE Dipl.-Ing. Hans-Peter Behringer, BASF SE<br />

Highly integrated production of plastics/metal hybrid parts for electronic applications Automated optimisation of the flow channel geometry in profile extrusion Multi-scale simulation of crystallisation effects in injection moulded part<br />

Dipl.-Ing. Johannes Wunderle Dipl.-Ing. Christian Windeck Dipl.-Ing. Thomas Baranowski<br />

Foam injection moulding – specific adjustment of foam structure and mechanical properties Extrusion embossing of microstructured films with variothermal temperature control Thermal stresses – thermal-mechanical coupled simulation<br />

Dipl.-Ing. Dominik Obeloer Dipl.-Ing. Stefan Eilbracht Dipl.-Ing. Klaus Küsters<br />

WIT – visualisation, analysis and control of the hollow space formation Inline-inspection of textured plastic surfaces using digital image processing Dimensioning software for the calculation of the non-linear behaviour of<br />

Dipl.-Ing. Moritz Gründler<br />

12:00 PM Lunch break and visit of the exhibition<br />

Dipl.-Ing. Klaus Berdel fibre reinforced high performance parts<br />

Dipl.-Ing. Dipl.-Kfm. Lars Lambrecht<br />

1:30 PM Film extrusion – using resources efficiently Mould technology – combining precision and efficiency Polyurethane – optimised processes for versatile products<br />

Dr.-Ing. Christof Herschbach, Windmöller & Hölscher KG Dr.-Ing. Erwin Bürkle, KraussMaffei Technologies GmbH Dipl.-Ing. Albrecht Manderscheid, Cannon Deutschland GmbH<br />

Closed loop quality control of the processing of undried polycondensates using Systematic selection of the ideally suited cooling method Development of a permanent plasma-induced release coating as substitution<br />

melt degassing Dipl.-Ing. Silke Allert for release agents<br />

Dipl.-Ing. Sebastian Schippers Dipl.-Ing. Alexander Pauling<br />

Foam extrusion with the OptiFoam-system – potentials of physical blowing agents New strategies for the variothermal tempering by laser Systematic process optimisation for the processing of flexible foams<br />

Dipl.-Ing. Tilo Hildebrand Fritz Klaiber, M.Sc. Dipl.-Ing. Simon Latz<br />

Efficient colour and material changing processes by using adequate analytical applications Injection-compression moulds for optical plastics parts – from concept to process Pultrusion – PU as alternative for conventional matrix systems<br />

Dipl.-Ing. (FH) Udo Wilkens Dipl.-Ing. Paul Walach Dipl.-Ing. Tobias Preuß<br />

2:45 PM Coffee break and visit of the exhibition<br />

3:00 PM Barrier packaging<br />

Dr.-Ing. Klaus Hartwig, Nestlé Waters<br />

Simulation of the oxygen permeation through stretch blow moulded PET bottles<br />

Elastomer processing – methods for new applications<br />

Dr.-Ing. Sabine Luther, ContiTech AG<br />

Application of an internal mixer to compound TPV<br />

Workshop Advantage Failure Failure Analysis Analysis<br />

Dr.<br />

Dr. rer.<br />

rer.<br />

nat<br />

nat.<br />

Rainer<br />

Rainer<br />

Dahlmann,<br />

Dahlmann,<br />

KAP,<br />

KAP,<br />

Institute<br />

Institute<br />

of Plastics<br />

of Plastics<br />

Processing<br />

Processing (<strong>IKV</strong>)<br />

Failures in thermoplastic products<br />

Dipl.-Ing. Failures in (FH) thermoplastic Wolfgang Dorscheid, products KAP, Institute of Plastics Processing (<strong>IKV</strong>)<br />

Dipl.-Ing. Dipl.-Wirt.Ing. Thorsten Leopold<br />

Expanding the range of applications for the plasma-enhanced deposition<br />

of barrier coatings<br />

Dipl.-Ing. Karim Bahroun<br />

Influencing the barrier layer thickness in blown-extrusion films by means<br />

of the flex ring technology<br />

Dipl.-Ing. Janina Overbeck<br />

Dipl.-Ing. Jan Peter Dering<br />

Characterisation of the expansion behaviour of rubber mixtures with chemical blowing agents<br />

Dipl.-Gyml. Sarah Sitz<br />

Injection moulding of thermoplastic/rubber composites<br />

Dipl.-Ing. Kai Opdenwinkel<br />

Load Dipl.-Ing. behaviour (FH) Wolfgang of cured Dorscheid, resin compounds KAP, Institute in of electrical Plastics Processing engineering (<strong>IKV</strong>)<br />

Jürgen Huber, Siemens AG<br />

Failure<br />

Load behaviour<br />

analysis for<br />

of cured<br />

continuous<br />

resin<br />

fibre-reinforced<br />

compounds in electrical<br />

CRP structures<br />

engineering<br />

with a thermosetting<br />

matrix Jürgen Huber, in aircraft Siemens construction AG<br />

Dr.-Ing. Jens Baaran, Institute of Composite Structures and Adaptive Systems,<br />

German Aerospace Center (DLR)<br />

Failure<br />

Failure analysis<br />

analysis<br />

for<br />

for<br />

continuous<br />

UHWPE based<br />

fibre-reinforced<br />

inlays for knee<br />

CRP struct-<br />

arthroplasty<br />

PD ures Dr. with Anke a thermosetting Bernstein, Labour matrix for Experimental in aircraft construction Orthopedics, University Hospital and<br />

Polyclinic Dr.-Ing. Jens for Baaran, Orthopedics Institute and of Physical Composite Medicine<br />

Structures and<br />

4:15 PM Coffee break and visit of the exhibition<br />

4:30 PM Process chains for FRP in high-volume series production CAE – extended simulation options for technical parts Workshop Management Methods<br />

Prof. Dr. rer. nat. Rudolf C. Stauber, BMW AG Dr.-Ing. Martin Giersbeck, Robert Bosch GmbH Dr.-Ing. Michael Effing, DSM Composite Resins<br />

Automated manufacturing of high-performance composite parts by gap-impregnation Virtual optimisation of large-sized plastic parts for the laser transmission welding process Lean Management<br />

Dipl.-Ing. Robert Bastian Dipl.-Ing. André Potthoff Dipl.-Ing. Ralph Winkler, Lean Machine GmbH<br />

New impregnation strategies in the context of simultaneous processing Crash-behaviour of thermoplastics – material testing and simulation Success though best practices – Benchmarking for the plastics processing industry<br />

Dipl.-Ing. Lionel Winkelmann Dipl.-Ing. Barbara Heesel Dipl.-Ing. Martin Pütz, Institute of Plastics Processing (<strong>IKV</strong>)<br />

Forming and curing of parts taking the new impregnation processes into account Acoustic simulation of plastic parts – new options for the description of the material behaviour Production solutions – Strategic alignment for future challenges<br />

Dipl.-Ing. Jan Wessels Dipl.-Ing. Hendrik Kremer Dipl.-Ing. Martin Hager, PHOENIX CONTACT GmbH & Co. KG<br />

5:45 PM Visit of the exhibition and technical discussions<br />

8:00 PM Evening event / "Beercolloquium"<br />

www.ikv-colloquium.com<br />

www.ikv-colloquium.com<br />

www.ikv-colloquium.com

Thursday, 4 March 2010 Programme<br />

Europasaal Brüsselsaal K1 Aachen<br />

9:00 AM Plenary lecture Prof. Dr.-Ing. Ullrich Masberg, Rubber engineering and simulation<br />

9:30 AM Coffee break and visit of the exhibition<br />

9:45 AM Plastics surfaces – optics, haptics and functionality Processing long and continuous-fibre reinforced thermoplastics Workshop Medical Engineering<br />

Dr.-Ing. Oliver Becker, Johnson Controls Interiors GmbH & Co. KG Dr.-Ing. Christian Obermann, Bond-Laminates GmbH Dr.-Ing. Gösta Pretel, Gerresheimer Wilden GmbH<br />

SMC parts for automotive exterior applications – using simulation to accomplish 3D-fibre-spraying – complex preforms with local adjustable Challenges in medical engineering: Development, regulatory requirements,<br />

class A surfaces mechanical properties documentation<br />

Dipl.-Ing. Christoph Kremer Dipl.-Ing. Marco Pöhler Dr. Heinrich Prinz, CellMed GmbH<br />

Metal decorated plastic parts – in-mould decoration and in-mould forming in one step Double-diaphragm-forming for technical thermoplastic matrices Biocompatibility: in-vitro tests in the development and certification<br />

Dipl.-Ing. Roland Mäsing Dipl.-Ing. Roman Schöldgen Dr.-Ing. Ute Müller, BMP Laboratory for Medical Material Testing GmbH<br />

Superhydrophobic plastic surfaces – primary forming and functionalising in one step Liquid composite moulding with in-situ polymerising CBT for large parts Experience in the setting up of medical companies in Germany<br />

Fritz Klaiber, M.Sc. Dipl.-Ing. Lionel Winkelmann Alfred A. Bulitz, Gira Giersiepen GmbH & Co. KG, Elektroinstallationssysteme<br />

11:00 AM Coffee break and visit of the exhibition<br />

11:30 AM Material-tailored production strategies for precision parts Compounds – selective adjustment and use of properties Workshop Tyres for the Future<br />

Prof. Dr.-Ing. Christian Drummer, LKT, University Erlangen-Nuremberg Dr. rer. nat. Günter Beyer, Kabelwerk Eupen AG Prof. Dr.-Ing. Ullrich Masberg, Institute of Plastics Processing (<strong>IKV</strong>)<br />

Micro hybrid technology – minimising deformations in overmoulding of flexible inserts Production of plastic-clay-masterbatches The future of tyre development<br />

Dipl.-Ing. Thomas Kamps Dipl.-Ing. Florian Puch Dr. Bernd Löwenhaupt, Goodyear Dunlop Tires Germany GmbH<br />

Ultrasonic welding of hybrid systems in microtechnology Dispersing clay in anionically produced polyamide Mixing technology in reflection of future tyre technology<br />

Dipl.-Ing. Mathias Weber Dipl.-Ing. Bernd Rothe Dipl.-Ing. (FH) Bernd Lanius, Michelin Reifenwerke AG & Co. KGaA<br />

Eliminating disturbances in the injection moulding process by pvT-based online control 2-component injection moulding of parts with integrated conductors made of Future production technologies in tyre manufacturing<br />

Dipl.-Ing. Andreas Schreiber thermoplastic/metal-compounds Dr. Jörg Nohl, Continental AG<br />

Dipl.-Ing. Jan Fragner<br />

12:45 PM Lunch break and visit of the exhibition<br />

2:15 PM Visits to the Institute<br />

5:45 PM Estimated end of the 25th International Plastics Technology Colloquium 2010<br />

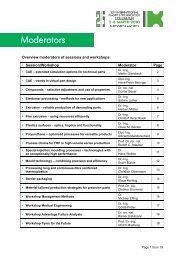

Moderators<br />

We are looking forward to welcoming the<br />

following moderators of the sessions and<br />

workshops to Aachen.<br />

Dr.-Ing. Oliver Becker<br />

Director Advanced Manufacturing<br />

Engineering<br />

Johnson Controls GmbH<br />

Dipl.-Ing. Hans-Peter Beringer<br />

Head of Business Management<br />

Automotive BASF SE<br />

Dr. rer. nat. Günter Beyer<br />

Head of Department<br />

Chem.-phys. Laboratories<br />

Kabelwerk Eupen AG<br />

Dr.-Ing. Erwin Bürkle<br />

Research and Development<br />

Processengineering<br />

KraussMaffei Technologies GmbH<br />

Dr. rer. nat Rainer Dahlmann<br />

Centre for Analysis and Testing<br />

of Plastics (KAP),<br />

Institute of Plastics Processing (<strong>IKV</strong>)<br />

Prof. Dr.-Ing. Dietmar Drummer<br />

Chair of Polymer Technology<br />

University of Erlangen-Nürnberg<br />

Dr.-Ing. Michael Effing<br />

President<br />

DSM Composite Resins AG<br />

Dr.-Ing. Martin Giersbeck<br />

Vice President Research and<br />

Advance Engineering Plastics Technology<br />

Robert Bosch GmbH<br />

Dr.-Ing. Klaus Hartwig<br />

Head of Product Technology Center<br />

Nestlé Waters<br />

Dr.-Ing. Christof Herschbach<br />

Head of Business Development &<br />

Marketing<br />

Windmöller & Hölscher KG<br />

Dr.-Ing. Sabine Luther<br />

Head of Engineering<br />

ContiTech AG<br />

Dipl.-Ing. Albrecht Manderscheid<br />

CEO<br />

Cannon Deutschland GmbH<br />

Please bear in mind that the programme is subject to change.<br />

Many thanks for your understanding.<br />

Prof. Dr.-Ing. Ullrich Masberg<br />

Area of research rubber technology<br />

Institute of Plastics Processing (<strong>IKV</strong>)<br />

Dr.-Ing. Herbert Müller<br />

Member of the Board of Management<br />

SURTECO SE<br />

Dr.-Ing. Christian Obermann<br />

Technical Director<br />

Bond-Laminates GmbH<br />

Dr.-Ing. Gösta Pretel<br />

Director Technical Competence Center<br />

Gerresheimer Wilden GmbH<br />

Prof. Dr. rer. nat. Rudolf C. Stauber<br />

Head of Department of Operational<br />

Stability and Materials<br />

BMW AG<br />

Dr. Hans Wobbe<br />

CTO<br />

Engel Holding GmbH<br />

www.ikv-colloquium.com www.ikv-colloquium.com www.ikv-colloquium.com