Active with jobs around the world Fast and easy Ecospeed ...

Active with jobs around the world Fast and easy Ecospeed ...

Active with jobs around the world Fast and easy Ecospeed ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>the</strong>re was quite some mechanical<br />

damage all <strong>the</strong> way through <strong>the</strong><br />

coating, down to <strong>the</strong> steel, resulting<br />

in hull corrosion.” He compares this<br />

to an <strong>Ecospeed</strong> hull coating coming<br />

in for drydocking. “You see that <strong>the</strong><br />

damage is so limited on an <strong>Ecospeed</strong><br />

hull coating that it can easily be<br />

seen, which makes it easier to repair<br />

<strong>and</strong> to maintain. During <strong>the</strong> recent<br />

drydocking of a large, <strong>Ecospeed</strong><br />

coated cruise vessel which had run<br />

aground, resulting in <strong>the</strong> buckling of<br />

some 40 meters of bottom plate, only<br />

a very limited number of scratches<br />

down to <strong>the</strong> substrate were observed.<br />

On 90% of <strong>the</strong> 40 m² affected,<br />

<strong>Ecospeed</strong> only showed superficial<br />

scratches <strong>and</strong> still adhered perfectly<br />

to <strong>the</strong> steel. The high adhesion of <strong>the</strong><br />

<strong>Ecospeed</strong> coating to <strong>the</strong> steel actually<br />

also helps to reduce any undercreep<br />

corrosion, which <strong>with</strong> <strong>the</strong> traditional<br />

coating systems is responsible for<br />

<strong>the</strong> exponential expansion of <strong>the</strong><br />

coating damage.”<br />

The amount of time many ships<br />

spend in drydock is directly related<br />

to (re)painting <strong>the</strong> underwater hull.<br />

When repainting <strong>the</strong> underwater hull<br />

can be taken out of <strong>the</strong> equation for<br />

<strong>the</strong> choice of location <strong>and</strong> season for<br />

drydocking, <strong>the</strong>n <strong>the</strong> story becomes a<br />

lot easier for superintendents, for <strong>the</strong><br />

shipyards, for everybody involved.<br />

Easy <strong>and</strong> environmentally<br />

friendly fouling removal<br />

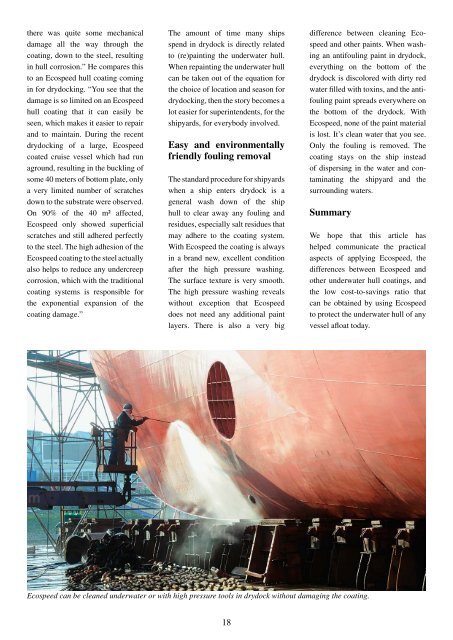

The st<strong>and</strong>ard procedure for shipyards<br />

when a ship enters drydock is a<br />

general wash down of <strong>the</strong> ship<br />

hull to clear away any fouling <strong>and</strong><br />

residues, especially salt residues that<br />

may adhere to <strong>the</strong> coating system.<br />

With <strong>Ecospeed</strong> <strong>the</strong> coating is always<br />

in a br<strong>and</strong> new, excellent condition<br />

after <strong>the</strong> high pressure washing.<br />

The surface texture is very smooth.<br />

The high pressure washing reveals<br />

<strong>with</strong>out exception that <strong>Ecospeed</strong><br />

does not need any additional paint<br />

layers. There is also a very big<br />

18<br />

difference between cleaning <strong>Ecospeed</strong><br />

<strong>and</strong> o<strong>the</strong>r paints. When washing<br />

an antifouling paint in drydock,<br />

everything on <strong>the</strong> bottom of <strong>the</strong><br />

drydock is discolored <strong>with</strong> dirty red<br />

water filled <strong>with</strong> toxins, <strong>and</strong> <strong>the</strong> antifouling<br />

paint spreads everywhere on<br />

<strong>the</strong> bottom of <strong>the</strong> drydock. With<br />

<strong>Ecospeed</strong>, none of <strong>the</strong> paint material<br />

is lost. It’s clean water that you see.<br />

Only <strong>the</strong> fouling is removed. The<br />

coating stays on <strong>the</strong> ship instead<br />

of dispersing in <strong>the</strong> water <strong>and</strong> contaminating<br />

<strong>the</strong> shipyard <strong>and</strong> <strong>the</strong><br />

surrounding waters.<br />

Summary<br />

We hope that this article has<br />

helped communicate <strong>the</strong> practical<br />

aspects of applying <strong>Ecospeed</strong>, <strong>the</strong><br />

differences between <strong>Ecospeed</strong> <strong>and</strong><br />

o<strong>the</strong>r underwater hull coatings, <strong>and</strong><br />

<strong>the</strong> low cost-to-savings ratio that<br />

can be obtained by using <strong>Ecospeed</strong><br />

to protect <strong>the</strong> underwater hull of any<br />

vessel afloat today.<br />

<strong>Ecospeed</strong> can be cleaned underwater or <strong>with</strong> high pressure tools in drydock <strong>with</strong>out damaging <strong>the</strong> coating.