Here - Heritage Express

Here - Heritage Express

Here - Heritage Express

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3801 Project<br />

Progress Update<br />

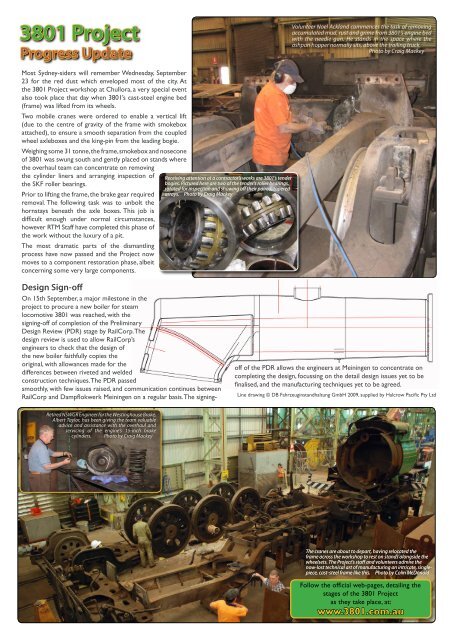

Volunteer Noel Ackland commences the task of removing<br />

accumulated mud, rust and grime from 3801’s engine bed<br />

with the needle gun. He stands in the space where the<br />

ashpan hopper normally sits, above the trailing truck.<br />

Photo by Craig Mackey<br />

Most Sydney-siders will remember Wednesday, September<br />

23 for the red dust which enveloped most of the city. At<br />

the 3801 Project workshop at Chullora, a very special event<br />

also took place that day when 3801’s cast-steel engine bed<br />

(frame) was lifted from its wheels.<br />

Two mobile cranes were ordered to enable a vertical lift<br />

(due to the centre of gravity of the frame with smokebox<br />

attached), to ensure a smooth separation from the coupled<br />

wheel axleboxes and the king-pin from the leading bogie.<br />

Weighing some 31 tonne, the frame, smokebox and nosecone<br />

of 3801 was swung south and gently placed on stands where<br />

the overhaul team can concentrate on removing<br />

the cylinder liners and arranging inspection of<br />

Receiving attention at a contractor’s works are 3801’s tender<br />

the SKF roller bearings.<br />

bogies. Pictured here are two of the tender’s roller bearings,<br />

Prior to lifting the frame, the brake gear required<br />

removal. The following task was to unbolt the<br />

hornstays beneath the axle boxes. This job is<br />

difficult enough under normal circumstances,<br />

however RTM Staff have completed this phase of<br />

the work without the luxury of a pit.<br />

The most dramatic parts of the dismantling<br />

process have now passed and the Project now<br />

moves to a component restoration phase, albeit<br />

concerning some very large components.<br />

rotated for inspection and showing off their paired, tapered<br />

arrays.<br />

Photo by Craig Mackey<br />

Design Sign-off<br />

On 15th September, a major milestone in the<br />

project to procure a new boiler for steam<br />

locomotive 3801 was reached, with the<br />

signing-off of completion of the Preliminary<br />

Design Review (PDR) stage by RailCorp. The<br />

design review is used to allow RailCorp’s<br />

engineers to check that the design of<br />

the new boiler faithfully copies the<br />

original, with allowances made for the<br />

differences between riveted and welded<br />

construction techniques. The PDR passed<br />

smoothly, with few issues raised, and communication continues between<br />

RailCorp and Dampflokwerk Meiningen on a regular basis. The signingoff<br />

of the PDR allows the engineers at Meiningen to concentrate on<br />

completing the design, focussing on the detail design issues yet to be<br />

finalised, and the manufacturing techniques yet to be agreed.<br />

Line drawing © DB Fahrzeuginstandhaltung GmbH 2009, supplied by Halcrow Pacific Pty Ltd<br />

Retired NSWGR Engineer for the Westinghouse Brake,<br />

Albert Taylor, has been giving the team valuable<br />

advice and assistance with the overhaul and<br />

servicing of the engine’s 15-inch brake<br />

cylinders. Photo by Craig Mackey<br />

The crane and truck crews join members of<br />

the 3801 Project team following the boiler’s<br />

relocation to the outside of the workshop.<br />

3801’s<br />

tender<br />

underframe<br />

and bogies<br />

viewed from<br />

the Project’s new<br />

scaffolding. Paul Gray<br />

and Matthew Lee can be<br />

seen in the background, while<br />

volunteers Frank Licastro and<br />

Tim Ball prepare the locomotive’s<br />

electrical wiring system for removal.<br />

Photo by Craig Mackey<br />

The cranes are about to depart, having relocated the<br />

frame across the workshop to rest on stands alongside the<br />

wheelsets. The Project’s staff and volunteers admire the<br />

now-lost technical art of manufacturing an intricate, singlepiece,<br />

cast-steel frame like this.<br />

Photo by Colin McDonald<br />

Follow the official web-pages, detailing the<br />

stages of the 3801 Project<br />

as they take place, at:<br />

www.3801.com.au