RailLok⢠Weldable Clip General Specifications - Gantrex

RailLok⢠Weldable Clip General Specifications - Gantrex

RailLok⢠Weldable Clip General Specifications - Gantrex

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

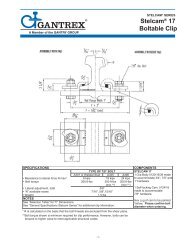

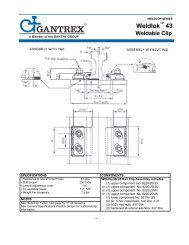

RailLok TM Series<br />

WELDABLE CLIP<br />

<strong>General</strong> Specification<br />

This general specification describes the revolutionary, patent pending RailLok TM series of weldable rail clips which<br />

incorporate a “double wedge design” feature and bolts with a “square shank base”.<br />

It is an evolution of the GANTREX ® crane rail soft-mounting system which consists of a range of redesigned weldable<br />

crane rail clips and steel reinforced rubber pads to address today’s unique problems. Individual data sheets on the<br />

various GANTREX ® clips and pad profiles provide details of the unique characteristics and geometry of each product.<br />

GENERAL CHARACTERISTICS<br />

All RailLok TM series clips are specifically designed for the mounting of crane rails, with or without pad.<br />

A full range of weldable clips is available to the designer, offering both cost efficiency and the very best technical<br />

solution for the installation.<br />

All RailLok TM clips consist of two interacting components which allow easy lateral rail adjustment and, once correctly<br />

installed, are self-locking and self-tightening. A controlled vertical force is applied to the rail foot through a synthetic<br />

rubber “nose” which is vulcanize-bonded to the clip upper component.<br />

The new “double wedge design” clip feature allows more efficient and rapid installation, as the upper component,<br />

by design, keeps a tight contact with the rail foot as the bolts are torqued and the nose compresses. Locating the<br />

rail by “hammering” is no longer required. In addition, impact wrenches can be used to accelerate the installation<br />

process because of the newly-designed screw type bolt with a “square shank base”.<br />

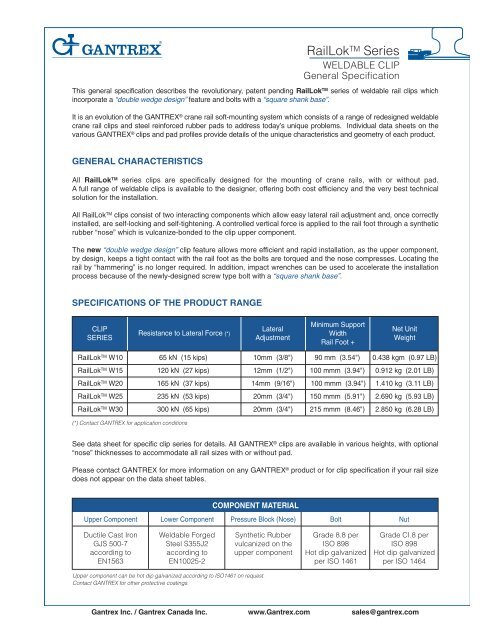

SPECIFICATIONS OF THE PRODUCT RANGE<br />

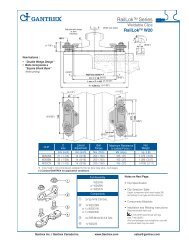

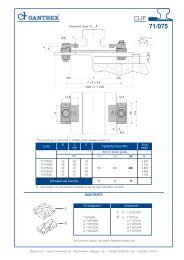

CLIP<br />

SERIES<br />

Resistance to Lateral Force (*)<br />

Lateral<br />

Adjustment<br />

Minimum Support<br />

Width<br />

Rail Foot +<br />

Net Unit<br />

Weight<br />

RailLok TM W10 65 kN (15 kips) 10mm (3/8") 90 mm (3.54") 0.438 kgm (0.97 LB)<br />

RailLok TM W15 120 kN (27 kips) 12mm (1/2") 100 mmm (3.94") 0.912 kg (2.01 LB)<br />

RailLok TM W20 165 kN (37 kips) 14mm (9/16") 100 mmm (3.94") 1.410 kg (3.11 LB)<br />

RailLok TM W25 235 kN (53 kips) 20mm (3/4") 150 mmm (5.91") 2.690 kg (5.93 LB)<br />

RailLok TM W30 300 kN (65 kips) 20mm (3/4") 215 mmm (8.46") 2.850 kg (6.28 LB)<br />

(*) Contact GANTREX for application conditions<br />

See data sheet for specific clip series for details. All GANTREX ® clips are available in various heights, with optional<br />

“nose” thicknesses to accommodate all rail sizes with or without pad.<br />

Please contact GANTREX for more information on any GANTREX ® product or for clip specification if your rail size<br />

does not appear on the data sheet tables.<br />

COMPONENT MATERIAL<br />

Upper Component Lower Component Pressure Block (Nose) Bolt Nut<br />

Ductile Cast Iron<br />

GJS 500-7<br />

according to<br />

EN1563<br />

<strong>Weldable</strong> Forged<br />

Steel S355J2<br />

according to<br />

EN10025-2<br />

Synthetic Rubber<br />

vulcanized on the<br />

upper component<br />

Grade 8.8 per<br />

ISO 898<br />

Hot dip galvanized<br />

per ISO 1461<br />

Grade CI.8 per<br />

ISO 898<br />

Hot dip galvanized<br />

per ISO 1464<br />

Upper component can be hot dip galvanized according to ISO1461 on request.<br />

Contact GANTREX for other protective coatings.<br />

<strong>Gantrex</strong> Inc. / <strong>Gantrex</strong> Canada Inc. www.<strong>Gantrex</strong>.com sales@gantrex.com

TECHNICAL ADVANTAGES OF THE NEW RailLok TM CLIPS<br />

New Features<br />

RailLok TM Series<br />

WELDABLE CLIP<br />

<strong>General</strong> Specification<br />

• Contact between the clip upper component and rail is enhanced during bolt tightening and nose compression<br />

because of the “double wedge design”.<br />

• Does not require hammering of the clip to contact rail.<br />

• Use of impact wrench speeds up the installation process.<br />

• Larger lateral rail adjustments.<br />

• Higher resistance to lateral loads using lighter components.<br />

• Compact design for use with narrower supports and to avoid guide roller interference.<br />

All old features have been maintained<br />

• Simple and positive lateral rail adjustment of up to 20 mm (3/4") depending on type of clip.<br />

• Self-locking and self-tightening features through wedging action.<br />

• Higher resistance to lateral loads through careful selection of clip component materials.<br />

• Controlled vertical force applied to rail through synthetic rubber “nose”:<br />

• Minimized crane runway maintenance and down time.<br />

CLIP SELECTION<br />

The following information must be available in order to select the correct GANTREX ® clip for your installation :<br />

• Rail designation (e.g. 175 CR, A 120).<br />

• Thickness of pad or wear plate under the rail.<br />

• Maximum side thrust per wheel.<br />

• Support width, namely girder top flange or soleplate.<br />

• Lateral adjustment required.<br />

• Vertical clearance tolerances where guide rollers are used.<br />

Please consult GANTREX on any questions regarding selection.<br />

INSTALLATION INSTRUCTIONS<br />

See data sheet on specific clip for product details.<br />

Refer to “Installation and Suggested Weld Instructions” for detailed information on use.<br />

A standard option on all GANTREX ® clips is protection against corrosion in the form of electro or hot-dip galvanizing.<br />

The lower component is first welded to the plate or girder before the entire system is galvanized. The clip bolt<br />

assemblies come standard as hot dip galvanized.<br />

If painting is required, please consult GANTREX before using mineral-based solvents, as they may adversely<br />

affect the coefficient of friction between components.<br />

Do not use cleaning fluids or protective coatings which contain ketones or similar chemicals, as they may seriously<br />

damage the rubber nose.<br />

We reserve the right to discontinue or change specifications or design at any time without prior notice<br />

and without incurring any obligation whatsoever.<br />

To Reach Your Nearest <strong>Gantrex</strong> Office:<br />

In USA Call: 1 (800) 242-6873 • In Canada Call: 1 (800) 884-5960<br />

Visit Our Web Site: www.<strong>Gantrex</strong>.com or email: sales@gantrex.com<br />

July 2012