Development of Micro Alloyed Structural Steels - Steelworld

Development of Micro Alloyed Structural Steels - Steelworld

Development of Micro Alloyed Structural Steels - Steelworld

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Technology<br />

<strong>Development</strong> <strong>of</strong> <strong>Micro</strong> <strong>Alloyed</strong><br />

<strong>Structural</strong> <strong>Steels</strong> in<br />

Secondary Steel Sector<br />

- R. K. Bagchi, Director, NISST<br />

Introduction<br />

Plain carbon mild steels with varying<br />

carbon contents were used for any<br />

common constructional job. With<br />

Thermo Mechanical Treatment (TMT)<br />

process, it became possible to attain<br />

higher strength values. Yield strength<br />

values <strong>of</strong> common mild steels are 37-47<br />

kgmm-2, whereas that for TMT steels is<br />

55-65 kgmm-2. This improvement in<br />

YS values shall be responsible in<br />

tonnage saving <strong>of</strong> constructional<br />

materials. But in turn may be <strong>of</strong>fset by<br />

high cost <strong>of</strong> TMT plant and<br />

accessories. Moreover, TMT process<br />

is applicable to round sections only. It<br />

is also difficult to obtain desired<br />

microstructure <strong>of</strong> ribbed bars to<br />

designate those as proper TMT bars. A<br />

reasonable percentage <strong>of</strong> tonnage TMT<br />

steel bars are available in the market<br />

which fall into this category.<br />

<strong>Micro</strong> alloying was adopted to<br />

produce structural steels at lower cost<br />

and <strong>of</strong> consistent quality in secondary<br />

steel sector comprising <strong>of</strong> induction<br />

furnaces and re-rolling units.<br />

Strength Specific Cost (SSC)<br />

Strength specific cost can be<br />

considered to be an important factor for<br />

selection or development <strong>of</strong> a material.<br />

It can be expressed in terms <strong>of</strong> total<br />

cost incurred per tonne <strong>of</strong> finished<br />

product to raise per unit strength (UTS)<br />

<strong>of</strong> a material from a base value. Total<br />

cost incurred may include all direct and<br />

indirect cost components.<br />

48<br />

November 2012

Technology<br />

The base UTS value for 12mm dia mild<br />

steel structural ribbed bar is around 41<br />

kgmm-2. 12mm dia TMT bars having<br />

acceptable metallurgical quality<br />

presents a value <strong>of</strong> 65kgmm-2. If an<br />

amount <strong>of</strong> Rs 'X' is to be incurred per<br />

ton to produce the TMT bars, then SSC<br />

would be X/(65-41) or X/24. A lower<br />

value <strong>of</strong> SSC is desirable when two<br />

materials are to be compared.<br />

Experimental-Methodology<br />

<strong>Micro</strong> alloyed steels have been<br />

developed through induction melting<br />

furnace and controlled rolling route to<br />

r e p l a c e T M T b a r s u s e d f o r<br />

construction purposes.<br />

An induction furnace was selected<br />

for making steel ingots and a re-rolling<br />

mill was chosen for rolling the ingots to<br />

1 2 m m d i a r i b b e d b a r s . F o r<br />

investigation, a base chemistry was<br />

selected to have:<br />

%C %Si %Mn %S %P %Cr %Ni %Mo %Cu<br />

Min. .20 .25 .80 – -- ---------- traces ------------<br />

Max. .25 .35 1.00 .04 .04<br />

%Vanadium and %Niobium were<br />

both varied. Nitrogen content was<br />

aimed at 150ppm in some heats. Total<br />

12 heats were cast. Melting was done<br />

in a 500 kg (converted to 250 kg)<br />

induction melting furnace, 3½” x 4½”<br />

sized pencil ingots were cast and rolled<br />

to 12mm dia ribbed bars. 3 different<br />

sets <strong>of</strong> cooling parameters <strong>of</strong> rolled<br />

products were adopted.<br />

One set was made with full water<br />

quenching, as applied in TMT<br />

production (WQ). One large set was<br />

made with out water cooling. It was air<br />

cooled on cooling bed. One bar from<br />

each heat <strong>of</strong> this set was twisted after<br />

cooling [CTD(AC)] and rest was kept<br />

as it is (AC). The third set was again<br />

water cooled, but with much less water<br />

as compared to the first set (WC), as<br />

shown in Table 1:<br />

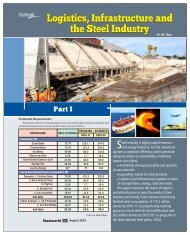

Set<br />

A<br />

B<br />

C<br />

D<br />

Heat No<br />

1-12<br />

1-12<br />

1-12<br />

1-12<br />

TABLE-1 : FOUR DIFFERENT SETS OF TRIAL<br />

Designate<br />

Post Rolling Treatment<br />

WQ<br />

AC<br />

CTD(AC)<br />

WC<br />

Results and Discussion<br />

Samples were taken from each stage <strong>of</strong><br />

production. One test piece was cast<br />

from each heat, it was normalized and<br />

tested for chemical analysis through<br />

d i r e c t r e a d i n g s p e c t r o m e t e r ,<br />

metallographic studies like micro<br />

structure, grain size and inclusion<br />

rating, hardness in BHN, mechanical<br />

tests like UTS, YS, %El and bendrebend<br />

tests were carried out. Tests<br />

pieces were cut from each heat <strong>of</strong> 4<br />

sets <strong>of</strong> rolled products and each set<br />

was tested for micro structure,<br />

hardness. UTS, YS and %El. The<br />

results have been presented in tabular<br />

form in Table-2 for inclusion rating and<br />

Table-3 through Table-8 for<br />

Mechanical tests.<br />

Inclusion Rating<br />

In all the heats, levels <strong>of</strong> inclusion<br />

types A, B & C were very good. Mixed<br />

oxides were high in almost all the heats.<br />

It is possible that some <strong>of</strong> these<br />

particles could be seen in SEM analysis<br />

and might have affected strength and<br />

ductility values.<br />

During steel melting, although<br />

measures were taken to reduce<br />

i n c l u s i o n l e v e l s , s o m e m o r e<br />

precautions are needed to reduce the<br />

level <strong>of</strong> mixed oxides in steels. It is<br />

important to control both indigenous<br />

and exogenous inclusions to improve<br />

mechanical properties. These are<br />

possible with little care in steel melting<br />

and casting.<br />

Mechanical Properties<br />

Results <strong>of</strong> mechanical tests have<br />

been presented below, from Table 3-<br />

Table-8.<br />

In unalloyed steel, AC resulted<br />

Water quenching as in TMT<br />

Normal air cooling in cooling bed<br />

Normal air cooling and CTD (cold twisted deformed)<br />

Water cooling with 50% lesser water as compared to set A<br />

(The treatment designations would be used later in the report e.g. Heat No.1, set A with<br />

water quench as 1AWQ and so on)<br />

almost equal or better strength and<br />

ductility as compared to WQ but were<br />

lower than WC. In the cases <strong>of</strong> V<br />

combinations, though strength values<br />

under AC were lower (2-13) than those<br />

under WQ, ductility values were better<br />

in AC. Here again, UTS values were<br />

higher under WC than those obtained<br />

under WQ and AC. Though %<br />

Elongation values were lower under<br />

WC than under WQ and AC, % RA values<br />

were more.<br />

Strength went down with increasing<br />

vanadium percentages, under almost all<br />

cooling conditions. But %E values were<br />

the lowest with WC and were higher<br />

under AC conditions, with the highest<br />

value obtained with V4. Vanadium<br />

produces strengthening effect through<br />

precipitation hardening and only AC<br />

enhances strength without sacrificing<br />

the ductility.<br />

When V+N combinations were<br />

used, similar trend as with was<br />

followed. All the WC samples<br />

developed LC. No appreciable<br />

improvement observed with N<br />

additions. %E values decreased with<br />

more %V under AC and WQ. Under WQ<br />

and WC, values <strong>of</strong> %E and %RA were<br />

lower than obtained under AC. Faster<br />

cooling enhanced strength values but<br />

reduced the ductility. Nb combinations<br />

also presented high strength and<br />

ductility values almost comparable to<br />

vanadium combinations. Different<br />

cooling conditions did not appreciably<br />

changed the UTS values but faster<br />

cooling rates resulted in marked<br />

reduction in ductility.<br />

50<br />

November 2012

Technology<br />

Code<br />

P<br />

V2<br />

V4<br />

V6<br />

V2N<br />

V4N<br />

V6N<br />

Nb2<br />

Nb4<br />

Nb6<br />

30V4N<br />

30VNb4N<br />

Code<br />

P<br />

V2<br />

V4<br />

V6<br />

V2N<br />

V4N<br />

V6N<br />

Nb2<br />

Nb4<br />

Nb6<br />

30VN<br />

30VNbN<br />

Code<br />

P<br />

V2<br />

V4<br />

V6<br />

V2N<br />

V4N<br />

V6N<br />

Nb2<br />

Nb4<br />

Nb6<br />

30V4N<br />

30VNb4N<br />

TABLE-2 : INCLUSION RATING OF TRIAL HEATS<br />

Inclusion Rating (Thin/Thick)<br />

Sulphide (a) Alumina (b) Silicate (c) Mixed oxides (d)<br />

0.5/0.5<br />

1/0.5<br />

1/0.5<br />

0.5/0.5<br />

Test Piece<br />

(NOR)<br />

180<br />

200<br />

153<br />

200<br />

195<br />

190<br />

195<br />

172<br />

200<br />

210<br />

216<br />

190<br />

Water<br />

Quench (WQ)<br />

200<br />

234<br />

253<br />

234<br />

226<br />

234<br />

226<br />

253<br />

264<br />

226<br />

258<br />

264<br />

TABLE-3 : HARDNESS, (BHN) VALUES OF TRIAL HEATS<br />

12 mm Dia Rolled Products<br />

Air<br />

CTD (AC)<br />

Cooled (AC)<br />

210<br />

226<br />

237<br />

210<br />

222<br />

237<br />

216<br />

258<br />

222<br />

253<br />

258<br />

253<br />

286<br />

271<br />

286<br />

279<br />

253<br />

247<br />

237<br />

253<br />

286<br />

247<br />

294<br />

286<br />

TABLE - 4 : UTS, KGMM-2 VALUES OF TRIAL HEATS<br />

Test Piece Water<br />

Air<br />

CTD (AC)<br />

(NOR) Quench (WQ) Cooled (AC)<br />

63<br />

67<br />

54<br />

51<br />

65<br />

59<br />

61<br />

62<br />

58<br />

54<br />

50<br />

68<br />

70<br />

81<br />

83<br />

74<br />

78<br />

83<br />

77<br />

72<br />

86<br />

75<br />

83<br />

87<br />

69<br />

79<br />

70<br />

61<br />

73<br />

75<br />

65<br />

75<br />

78<br />

65<br />

81<br />

76<br />

80<br />

86<br />

82<br />

82<br />

84<br />

84<br />

94<br />

78<br />

87<br />

68<br />

88<br />

90<br />

2/1<br />

2/1.5<br />

2.5/1.5<br />

1/0.5<br />

2/0.5<br />

1/-<br />

1/-<br />

0.5/-<br />

1/-<br />

1/-<br />

1.5/-<br />

0.5/-<br />

0.5/-<br />

0.5/-<br />

-/-<br />

1/-<br />

-/-<br />

1/-<br />

-/-<br />

-/-<br />

1/-<br />

0.5/-<br />

-/-<br />

-/-<br />

-/-<br />

-/-<br />

-/-<br />

0.5/-<br />

0.5/-<br />

-/-<br />

0.5/-<br />

0.5/-<br />

-/-<br />

-/-<br />

-/-<br />

0.5/-<br />

-/-<br />

2/-<br />

2/-<br />

2.5/-<br />

1.5/-<br />

2/-<br />

1.5/-<br />

1/-<br />

Water<br />

Cooled (WC)<br />

237<br />

286<br />

271<br />

237<br />

231<br />

301<br />

231<br />

247<br />

258<br />

258<br />

264<br />

258<br />

Water<br />

Cooled (WC)<br />

79<br />

89<br />

83<br />

72<br />

85<br />

83<br />

85<br />

75<br />

84<br />

73<br />

82<br />

88<br />

There was no appreciable change<br />

with V+Nb+N combination having<br />

0.28%C. All the samples (other than<br />

with V4) under CTD(AC) developed LC<br />

and resulted mostly low %El and %RA<br />

values, though the UTS values were<br />

above 80 kgmm-2. CTD resulted in<br />

raising dislocation density level <strong>of</strong><br />

already stresses rolled products.<br />

Best combination <strong>of</strong> strength and<br />

ductility values were obtained with V2<br />

(UTS: 79, YS: 59, %El : 23 & % RA :<br />

59) and Nb2 (UTS : 75, YS : 61, %El : 23<br />

& %RA : 66) Typical values obtained<br />

with 12mm2 TMT <strong>of</strong> SAIL/RINL, were<br />

UTS : 65, YS : 56, %El : 25 & %RA : 45.<br />

Summary <strong>of</strong> all the results have<br />

been presented in Table-9.<br />

Strength Specific Cost (SSC)<br />

Commonly, a typical 12 mm dia<br />

TMT bar <strong>of</strong> SAIL/RINL has a UTS value<br />

<strong>of</strong> 60 kgmm-2 and that <strong>of</strong> an ordinary<br />

mild steel ribbed bar is around 40<br />

kgmm-2. Assuming the similar quality<br />

<strong>of</strong> TMT bar is produced in the<br />

secondary steel sector w i t h a n<br />

annual production <strong>of</strong> 12,000 MT, total<br />

cost <strong>of</strong> the TMT plant and accessories<br />

as Rs 1.5 crores, IRR <strong>of</strong> 18% and an<br />

expected pay back period <strong>of</strong> 5 yrs, the<br />

SSC may be calculated as Rs 17.50.<br />

In case <strong>of</strong> micro alloyed steels<br />

with low %V/Nb, expected UTS level<br />

shall be around 75 kgmm-2. As far as<br />

the cost factor is concerned,<br />

requirement <strong>of</strong> vanadium shall be less<br />

than niobium, because in steel scrap,<br />

usually little vanadium comes as<br />

residual, but not niobium. Additional<br />

cost <strong>of</strong> micro alloyed steels with low<br />

vanadium(V2) shall be around Rs<br />

200.00. In this case, the SSC may be<br />

calculated as Rs 5.72 only, which is<br />

about 2.5 times less.<br />

Moreover, if due considerations are<br />

given and applied in the design<br />

calculations for constructional<br />

activities, then there will be more<br />

savings <strong>of</strong> constructional materials for<br />

the users <strong>of</strong> micro alloyed steels than <strong>of</strong><br />

TMT bars.<br />

Savings can be even more in case <strong>of</strong><br />

other sections <strong>of</strong> constructional<br />

materials, because in those cases, the<br />

difference in UTS shall be more (from<br />

45 kgmm-2 to 79 kgmm-2) as the TMT<br />

process can not be applied to the<br />

51<br />

November 2012

Technology<br />

Code<br />

P<br />

V2<br />

V4<br />

V6<br />

V2N<br />

V4N<br />

V6N<br />

Nb2<br />

Nb4<br />

Nb6<br />

30V4N<br />

30VNb4N<br />

Code<br />

P<br />

V2<br />

V4<br />

V6<br />

V2N<br />

V4N<br />

V6N<br />

Nb2<br />

Nb4<br />

Nb6<br />

30V4N<br />

30VNb4N<br />

-2<br />

TABLE-5: YS, KGMM VALUES OF TRIAL HEATS<br />

Test Piece<br />

(NOR)<br />

40<br />

43<br />

44<br />

35<br />

43<br />

46<br />

60<br />

40<br />

39<br />

36<br />

47<br />

47<br />

Water<br />

Quench (WQ)<br />

51<br />

63<br />

73<br />

64<br />

65<br />

68<br />

68<br />

49<br />

76<br />

64<br />

70<br />

74<br />

12 mm Dia Rolled Products<br />

Air<br />

CTD (AC)<br />

Cooled (AC)<br />

49<br />

59<br />

55<br />

48<br />

57<br />

59<br />

51<br />

61<br />

61<br />

50<br />

67<br />

61<br />

64<br />

83<br />

62<br />

64<br />

-LC<br />

-LC<br />

-LC<br />

60 LC<br />

-LC<br />

-LC<br />

TABLE - 6 : %ELONGATION VALUES OF TRIAL HEATS<br />

12 mm Dia Rolled Products<br />

Test Piece<br />

(NOR)<br />

30<br />

20<br />

27<br />

27<br />

19<br />

11<br />

9<br />

25<br />

24<br />

21<br />

7<br />

18<br />

Water<br />

Quench (WQ)<br />

23<br />

24<br />

16<br />

20<br />

24<br />

20<br />

15<br />

21<br />

15<br />

25<br />

20<br />

18<br />

Air<br />

Cooled (AC)<br />

25<br />

23<br />

28<br />

24<br />

24<br />

25<br />

20<br />

23<br />

20<br />

22<br />

17<br />

24<br />

66<br />

68<br />

CTD (AC)<br />

20<br />

20<br />

17<br />

19<br />

19<br />

18<br />

17<br />

10<br />

17<br />

20<br />

18<br />

20<br />

Water<br />

Cooled (WC)<br />

63<br />

80<br />

67<br />

60<br />

69 LC<br />

72 LC<br />

74 LC<br />

63<br />

74 LC<br />

63<br />

65 LC<br />

71 LC<br />

Water<br />

Cooled (WC)<br />

25<br />

18<br />

18<br />

20<br />

19<br />

20<br />

18<br />

19<br />

20<br />

19<br />

20<br />

16<br />

Code<br />

P<br />

V2<br />

V4<br />

V6<br />

V2N<br />

V4N<br />

V6N<br />

Nb2<br />

Nb4<br />

Nb6<br />

30V4N<br />

30VNb4N<br />

TABLE - 7 : %REDUCTION IN AREA VALUES OF TRIAL HEATS<br />

12 mm Dia Rolled Products<br />

Test Piece<br />

(NOR)<br />

52<br />

53<br />

63<br />

30<br />

50<br />

17<br />

23<br />

48<br />

34<br />

29<br />

5<br />

13<br />

Water<br />

Quench (WQ)<br />

57<br />

46<br />

51<br />

54<br />

56<br />

64<br />

55<br />

33<br />

51<br />

54<br />

54<br />

39<br />

Air<br />

Cooled (AC)<br />

61<br />

59<br />

57<br />

59<br />

54<br />

61<br />

65<br />

66<br />

63<br />

60<br />

56<br />

54<br />

CTD (AC)<br />

26<br />

38<br />

44<br />

58<br />

58<br />

51<br />

18<br />

37<br />

32<br />

60<br />

47<br />

45<br />

Water<br />

Cooled (WC)<br />

66<br />

55<br />

64<br />

70<br />

49<br />

51<br />

58<br />

67<br />

58<br />

62<br />

65<br />

53<br />

52<br />

November 2012

Technology<br />

Code<br />

P<br />

V2<br />

V4<br />

V6<br />

V2N<br />

V4N<br />

V6N<br />

Nb2<br />

Nb4<br />

Nb6<br />

30VN<br />

30VNbN<br />

Code<br />

P<br />

V2<br />

V4<br />

V6<br />

V2N<br />

V4N<br />

V6N<br />

Nb2<br />

Nb4<br />

Nb6<br />

30V4N<br />

30VNb4N<br />

TABLE - 8 : BEND-RE-BEND TEST RESULTS OF TRIAL HEATS<br />

12 mm Dia Rolled Products<br />

Test Piece<br />

(NOR)<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

Water<br />

Quench (WQ)<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

Air<br />

Cooled (AC)<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

NC<br />

CTD (AC)<br />

LC<br />

LC<br />

LC<br />

NC<br />

NC<br />

LC<br />

LC<br />

LC<br />

NC<br />

NC<br />

LC<br />

LC<br />

Water<br />

Cooled (WC)<br />

TABLE - 9 : SUMMARY OF RESULTS<br />

Test Piece<br />

(Normalised)<br />

<strong>Micro</strong> Structure Rolled Product, Mech. Props<br />

VF(P) GS WQ AC WC WQ AC CTD WC<br />

25 5-6 B FP FP Nor Nor<br />

High<br />

40<br />

20<br />

25<br />

25<br />

55<br />

40<br />

40<br />

40<br />

30<br />

58<br />

50<br />

5<br />

6<br />

5-6<br />

5-6<br />

4-5<br />

4-5<br />

7<br />

5-6<br />

6-7<br />

6-7<br />

6<br />

B<br />

B<br />

B<br />

B<br />

B<br />

B<br />

B<br />

B<br />

B<br />

B<br />

B<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

FP<br />

High<br />

High<br />

Low<br />

Low<br />

High<br />

Poor<br />

Low<br />

V High<br />

Poor<br />

High<br />

Low<br />

High<br />

Nor<br />

Poor<br />

Nor<br />

Nor<br />

Low<br />

Nor<br />

High<br />

Poor<br />

V High<br />

Nor<br />

HIGH<br />

&<br />

BRITTLE<br />

LC<br />

NC<br />

NC<br />

LC<br />

NC<br />

NC<br />

NC<br />

LC<br />

NC<br />

LC<br />

LC<br />

NC<br />

LC<br />

Nor<br />

VHigh<br />

Nor<br />

High<br />

High<br />

Low<br />

Nor<br />

Low<br />

Low<br />

Poor<br />

Nor<br />

sections other than rounds and<br />

squares.<br />

References<br />

L. F. Porter & P. E. Repass “The<br />

Evolution <strong>of</strong> HSLA <strong>Steels</strong>”. Journal <strong>of</strong><br />

Metals, April 1982 pp 14.<br />

E. E. Flecher, “A Review <strong>of</strong> the<br />

Status, Selection and Physical<br />

Metallurgy <strong>of</strong> High-Strength Lowalloy<br />

<strong>Steels</strong>”, Metals and Ceramics<br />

Information Centre Report, MCIC 78-<br />

89, March 1979.<br />

B, Motgi, A. K. Chakraborty & R. L.<br />

Kumar, “<strong>Micro</strong> alloyed <strong>Steels</strong>:<br />

M e t a l l u r g i c a l P r i n c i p l e s a n d<br />

Applications”, Industrial Product<br />

Finder, September 1996, pp 329.<br />

Jitender Patel & Shunichi<br />

Hashimoto, Review Article on “Niobium<br />

for the Steel Industry”, Vol. 5 No. 6,<br />

December 2002, pp 20.<br />

Bhatnagar, Oatar, Guha,.<br />

Chattopadhyaya & Sinha, “High<br />

Strength Low Alloy <strong>Structural</strong> <strong>Steels</strong>,<br />

NML Technical Journal, Vol. 19 No.1<br />

February 1977, pp 17.<br />

V. P. Agarwal & B. Mohapatra, “<br />

Experiences in the Production <strong>of</strong><br />

Controlled Rolled HSLA plates at<br />

Rourkela Steel Plant”.<br />

F. B. Pickering, “High Strength<br />

Low-Alloy <strong>Steels</strong>, a Decade <strong>of</strong><br />

Progress”, <strong>Micro</strong> alloying 75<br />

Proceedings, 1976 pp 3-24.<br />

S. Horejs, V. Smid, V. Navral, T.<br />

Prnka and R. Halbrstatove, “Possible<br />

Method <strong>of</strong> Melting V+N based Rebar<br />

Steel”, Wire Industry, May 1984, pp<br />

405-408.<br />

“Columbium Treated Mild-Carbon<br />

Steel,” Mechanical Engg. 81, January<br />

1959, p 53.<br />

W. B. Morrison, “Effect <strong>of</strong> Grain<br />

Size on Stress Strain Relationships in<br />

Low Carbon Steel”. ASM Transaction<br />

quarterly, 59, 1966, pp 824-846.<br />

J. Heslop and N. J. Petch,”<br />

Dislocation Locking and Fracture <strong>of</strong> á-<br />

Iron”. Philosophic Magazine, 2, 1957,<br />

pp 649-658.<br />

L. J. Cuddy, “<strong>Micro</strong>structures<br />

Developed During Thermo Mechanical<br />

Treatment <strong>of</strong> HSLA <strong>Steels</strong>”. Met<br />

Transaction, 12A, July 1981.<br />

53<br />

November 2012