LEED Materials Documentation Submittal Cover Sheet_Lucketts.pdf

LEED Materials Documentation Submittal Cover Sheet_Lucketts.pdf

LEED Materials Documentation Submittal Cover Sheet_Lucketts.pdf

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

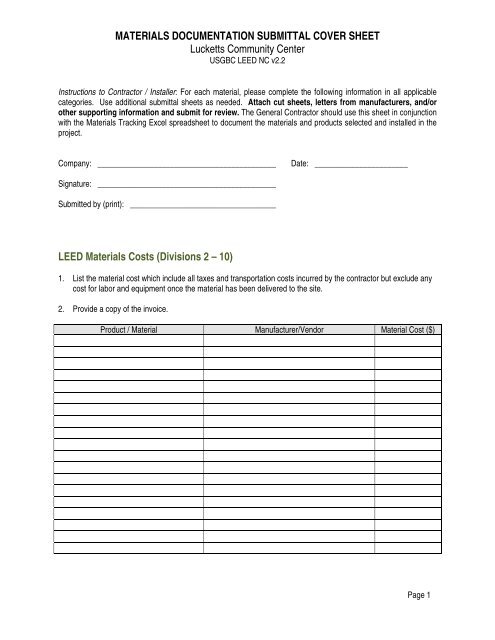

MATERIALS DOCUMENTATION SUBMITTAL COVER SHEET<br />

<strong>Lucketts</strong> Community Center<br />

USGBC <strong>LEED</strong> NC v2.2<br />

Instructions to Contractor / Installer: For each material, please complete the following information in all applicable<br />

categories. Use additional submittal sheets as needed. Attach cut sheets, letters from manufacturers, and/or<br />

other supporting information and submit for review. The General Contractor should use this sheet in conjunction<br />

with the <strong>Materials</strong> Tracking Excel spreadsheet to document the materials and products selected and installed in the<br />

project.<br />

Company: ____________________________________________<br />

Date: _______________________<br />

Signature: ____________________________________________<br />

Submitted by (print): ____________________________________<br />

<strong>LEED</strong> <strong>Materials</strong> Costs (Divisions 2 – 10)<br />

1. List the material cost which include all taxes and transportation costs incurred by the contractor but exclude any<br />

cost for labor and equipment once the material has been delivered to the site.<br />

2. Provide a copy of the invoice.<br />

Product / Material Manufacturer/Vendor Material Cost ($)<br />

Page 1

MATERIALS DOCUMENTATION SUBMITTAL COVER SHEET<br />

<strong>Lucketts</strong> Community Center<br />

USGBC <strong>LEED</strong> NC v2.2<br />

<strong>LEED</strong> MR credit 3: <strong>Materials</strong> Reuse (Divisions 2 – 10)<br />

List all material / product that have been salvaged, refurbished or reused on this project.<br />

Salvaged Material<br />

Onor<br />

Off-<br />

Site<br />

Modification made to the On-site <strong>Materials</strong> or<br />

Source of Off-Site Salvaged <strong>Materials</strong><br />

Replacement<br />

Value ($)<br />

<br />

I confirm that appropriate backup documentation has been provided (check box).<br />

Page 2

MATERIALS DOCUMENTATION SUBMITTAL COVER SHEET<br />

<strong>Lucketts</strong> Community Center<br />

USGBC <strong>LEED</strong> NC v2.2<br />

<strong>LEED</strong> MR credit 4: Recycled Content (Divisions 2 – 10)<br />

Does the material / product contain postconsumer or preconsumer content?<br />

Yes / No<br />

For product composed of multiple materials, calculate assembly recycled content using the percents by weight of the<br />

post-consumer recycled content and the pre-consumer recycled content in the assembly.<br />

Components<br />

Weight (lbs)<br />

Postconsumer<br />

Preconsumer<br />

% Weight (lbs) % Weight (lbs)<br />

<br />

I confirm that appropriate backup documentation has been provided (check box).<br />

<strong>LEED</strong> MR credit 5: Regional <strong>Materials</strong> (Divisions 2 – 10)<br />

Are the materials and products extracted, harvested or recovered as well as manufactured within 500 miles?<br />

If a portion of the material qualified for regional materials, list only that portion and associated cost satisfying the<br />

credit requirement.<br />

For assemblies or products manufactured within the 500-mile radius but containing only some components that also<br />

were extracted within the 500-mile radius, use multiple lines. Base the proportionality of such products’ cost on the<br />

weight of their various components.<br />

Product<br />

Manufacturer<br />

Distance between<br />

Project &<br />

Extraction/Harvest<br />

(miles)<br />

Product<br />

Cost ($)<br />

Value Qualifying as<br />

Regional ($)<br />

<br />

I confirm that appropriate backup documentation has been provided (check box).<br />

Page 3

MATERIALS DOCUMENTATION SUBMITTAL COVER SHEET<br />

<strong>Lucketts</strong> Community Center<br />

USGBC <strong>LEED</strong> NC v2.2<br />

<strong>LEED</strong> MR credit 6: Rapidly Renewable <strong>Materials</strong> (Divisions 2 – 10)<br />

Are the materials or products made from plants that are typically harvested within 10-year or shorter cycle?<br />

For assembly rapidly renewable content, the fraction of the assembly that is considered rapidly renewable is<br />

determined by weight. That fraction is then applied to the material cost to determine the renewable value.<br />

Product Company Product ($)<br />

%<br />

Renewable<br />

Renewable<br />

Value ($)<br />

<br />

I confirm that appropriate backup documentation has been provided (check box).<br />

<strong>LEED</strong> MR credit 7: FSC Certified Wood (Divisions 2 – 10)<br />

Are the new wood-based products and materials certified in accordance with Forest Stewardship Council (FSC)<br />

principles and criteria?<br />

Only for materials permanently installed in the project.<br />

In the case of an assembly, only the percentage of FSC-certified wood can be applied toward the credit. Determine<br />

the amount of new wood as a percent of the total weight, volume or cost and the amount of FSC-certified wood as a<br />

percent of the total weight, volume or cost.<br />

Wood Product<br />

Vendor<br />

Material<br />

Value ($)<br />

Percent<br />

Wood<br />

(by<br />

weight)<br />

Value of<br />

Wood ($)<br />

Percent<br />

Certified<br />

Wood<br />

(by<br />

weight)<br />

Value of<br />

Certified<br />

Wood<br />

($)<br />

FSC chain-ofcustody<br />

certificate<br />

number<br />

<br />

I confirm that appropriate backup documentation has been provided (check box).<br />

Page 4

MATERIALS DOCUMENTATION SUBMITTAL COVER SHEET<br />

<strong>Lucketts</strong> Community Center<br />

USGBC <strong>LEED</strong> NC v2.2<br />

<strong>LEED</strong> EQ credit 4.1: Low-Emitting <strong>Materials</strong> - Adhesives and Sealants<br />

Do the adhesives and sealants (inside of weatherproofing system and applied on-site) comply with the <strong>LEED</strong> NC<br />

v2.2 VOC limits?<br />

Adhesives, sealants and sealant primers comply with South Coast Air Quality Management District (SCAQMD) Rule<br />

#1168. Aerosol Adhesives comply with Green Seal Standard for Commercial Adhesives GS-36.<br />

Product<br />

Manufacturer<br />

VOC<br />

Content<br />

(g/L less<br />

water)<br />

VOC Limit<br />

(SCAQMD Rule<br />

1168 or Green Seal<br />

GS-36)<br />

<br />

I confirm that appropriate backup documentation has been provided (check box).<br />

<strong>LEED</strong> EQ credit 4.2: Low-Emitting <strong>Materials</strong> - Paints and Coatings<br />

Do the paints and coatings comply with the <strong>LEED</strong> NC v2.1 VOC limits?<br />

Architectural paints, coatings and primers comply with Green Seal Standard GS-11. Anti-corrosive and anti-rust<br />

paints complied with Green Seal Standard GC-03. Clear wood finishes, floor coatings, stains, sealers, and shellacs<br />

comply with South Coast Air Quality Management District (SCAQMD) Rule 1113.<br />

Product<br />

Manufacturer<br />

VOC<br />

Content<br />

(g/L less<br />

water)<br />

VOC Limit<br />

(SCAQMD Rule<br />

1113 or Green Seal<br />

GS-11 or GS-03)<br />

<br />

I confirm that appropriate backup documentation has been provided (check box).<br />

Page 5

MATERIALS DOCUMENTATION SUBMITTAL COVER SHEET<br />

<strong>Lucketts</strong> Community Center<br />

USGBC <strong>LEED</strong> NC v2.2<br />

<strong>LEED</strong> EQ credit 4.3: Low-Emitting <strong>Materials</strong> – Carpet Systems<br />

1. Does the carpet meet the Carpet and Rug Institute’s Green Label Plus requirements? Yes / No<br />

2. Does the cushion meet the Carpet and Rug Institute’s Green requirements? Yes / No<br />

3. Do carpet adhesives have less than 50 g/L VOC? Yes / No<br />

Product Name<br />

Manufacturer<br />

<br />

I confirm that appropriate backup documentation has been provided (check box).<br />

<strong>LEED</strong> EQ credit 4.4: Low-Emitting <strong>Materials</strong> - Composite Wood and Agrifiber Products<br />

1. Does the composite wood and agrifiber product contain any added urea formaldehyde resins?<br />

2. Does the laminate adhesive use to fabricate on-site and shop-applied composite wood and agrifiber assemblies<br />

contain any added urea formaldehyde resins?<br />

Composite wood and agrifiger products are defined as: particleboard, medium density fiberboard (MDF), plywood,<br />

wheatboard, strawboard, panel substrates and door cores.<br />

Product/Manufacturer<br />

Yes or No?<br />

<br />

I confirm that appropriate backup documentation has been provided (check box).<br />

Page 6