Maximizing Profits by Optimizing Cow Comfort - ABS Global

Maximizing Profits by Optimizing Cow Comfort - ABS Global

Maximizing Profits by Optimizing Cow Comfort - ABS Global

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Maximizing</strong> <strong>Profits</strong><br />

<strong>by</strong> Amy Ryan<br />

<strong>by</strong> <strong>Optimizing</strong> <strong>Cow</strong> <strong>Comfort</strong><br />

<strong>Optimizing</strong> cow comfort is a key to profitability on any dairy, since optimal<br />

cow comfort results in higher milk production, improved herd health, and increased<br />

reproductive success. Ensuring maximal cow comfort really comes down to<br />

knowing what activities your cows are experiencing during a 24-hour period.<br />

Evaluating <strong>Cow</strong> <strong>Comfort</strong><br />

Under ideal cow comfort situations, there are six fundamental activities that<br />

make up a cow’s daily (24-hour) routine. These activities include: eating, milking,<br />

restraint for management activities, socializing, drinking, and lying down making<br />

milk. Milking and lock-up time activities are fixed amounts of time dependent<br />

upon facility design and management efficiency. The other activities (eating,<br />

drinking, socializing, and lying) are variable time activities that are dependent<br />

upon factors such as stall design, grouping, ration palatability, and bedding<br />

management. Reviewing the amount of time devoted to these activities each day,<br />

is a good indicator of whether you are optimizing cow comfort and avoiding<br />

non-productive activity like excessive time on concrete (TOC) (see Activity<br />

Charting Exercise).<br />

Eating. Studies have shown that a cow’s Dry Matter Intake (DMI) is directly<br />

correlated to her level of production. Therefore, maximizing feed intake for<br />

your cows is a main component in increased production and profitability.<br />

A good way to accomplish this is promoting good<br />

feedbunk management practices, such as frequent feed<br />

push-ups (10-15 times per day), daily cleaning of feedbunk,<br />

and managing for 2-5% weighbacks. Ideally, cows<br />

will eat 6-15 meals per day of 4-9 lbs of DMI per meal,<br />

with each of these sessions lasting 20-30 minutes. So, on<br />

a whole, that would add up to about 4.5 to 5 hours, or<br />

approximately 19%-21% of a cow’s day. The largest meals<br />

are eaten immediately after milking which necessitates<br />

that managers provide plenty of fresh ration when cows<br />

return from milking.<br />

Milking. When we discuss milking turn time, most<br />

people think it is the pen size divided <strong>by</strong> the number<br />

of cows per hour the parlor will milk. However, when<br />

monitoring milking turn time, it is important to take<br />

into account the total milking time per pen plus additional time away from the<br />

feedbunk and freestalls. Total milking turn time starts when a pen is pushed to<br />

the parlor and ends when the last cow gets back to the pen, times the number of<br />

milkings per 24 hours. Total Milking turn time should be less than 3 hours (13%)<br />

per day, regardless of how many times per day the cows are milked. An increase in<br />

this time takes away from a cow’s other activities, like eating and socializing, which<br />

can mean decreased milk production and heat expression.<br />

Lock-up. As stated above, lock-up time is essential for different reasons on a<br />

dairy (heat detection, vaccinations, A.I., examinations, etc.). Although it is an<br />

Photo 1. Ideal Freestall Use Index (FUI)<br />

important part of management, this should<br />

be a very minimal part of a cow’s day.<br />

The total time spent per day locked<br />

up or retained for management purposes<br />

should not exceed 1.5 hours (6%) per day.<br />

During long lock-up times, high producing<br />

cows may not be able to consume enough<br />

feed, even if adequate feed is available for<br />

the average producing cows. Long lock-ups<br />

may disrupt high producing cows’ usual<br />

eating habits, since they prefer to eat smaller<br />

amounts of feed more times a day. During<br />

summer heat stress, lock-up periods should<br />

occur before the heat of the day becomes<br />

significant and have shades overhead.<br />

Lying. In order to maximize milk<br />

production, a cow should spend over 12<br />

hours, or greater than 50% of her day<br />

lying in a stall, lot or pasture.<br />

According to research, the amount<br />

IN ORDER TO MAXIMIZE MILK PRODUCTION, A COW<br />

SHOULD SPEND OVER 12 HOURS, OR GREATER THAN 50%<br />

OF HER DAY LYING IN A STALL, LOT OR PASTURE.<br />

of blood flow to the udder increases<br />

dramatically, when a cow is lying down<br />

and relaxed. A good evaluation of lying<br />

time is the Freestall Use Index (FUI).<br />

FUI is determined <strong>by</strong> counting all animals<br />

within a pen that are not eating or drinking<br />

and then calculating the percent of these<br />

animals that are lying down normally.<br />

The FUI should be measured 2-3 hours

after milking time. Optimal cow comfort<br />

will result in greater than 90% Freestall<br />

Use Index, which is depicted in photo<br />

1. Additionally, at least 50% or more of<br />

lying cows, should be chewing their cud.<br />

As more and more modern dairies are going<br />

to a total confinement design, ability to lie<br />

cows down will have a big impact on cow<br />

longevity, foot health, and overall profitability.<br />

Socializing. In general, socializing<br />

refers to the amount of time that a cow<br />

spends walking around, or interacting<br />

with other animals around her. This<br />

includes grooming, exercising, licking,<br />

but most importantly, expression of heat.<br />

This aspect of a cow’s day may be largely<br />

influenced <strong>by</strong> cow health, environment,<br />

grouping, and time allowed <strong>by</strong> other<br />

activities. On average, a cow spends about<br />

1.5 hours (6%) of her day socializing.<br />

Drinking. Water consumption is a<br />

crucial component to high milk production.<br />

A typical cow should spend 1 hour or 3<br />

percent of her day consuming water.<br />

A high producing cow will drink 30-40<br />

gallons of water per day, which equals<br />

three to four pounds of water per 1 pound<br />

of milk she produces. In order to maintain<br />

this level of consumption, watertanks<br />

should be located in 2-4 sites per pen<br />

and cleaned once per day. There should<br />

be about 3 inches linear space allowed<br />

per cow or one space for 10 animals<br />

when using "hole" type water devices.<br />

<strong>Optimizing</strong> <strong>Cow</strong> Activity<br />

Evaluating your herd’s cow comfort<br />

and identifying problems is only the first<br />

step to increased profits. Finding solutions<br />

and eliminating bottlenecks is the<br />

next phase in successful cow comfort.<br />

Here are a couple different ways to keep<br />

cows off their feet and making milk.<br />

• Decreasing Milking Turn Time<br />

–<br />

This may involve improved parlor<br />

routines that result in decreased unit<br />

on time, shutting down sprinkler pens,<br />

or reducing pen sizes.<br />

• Lock-up times – Studies have shown that unless exceeding 4 hours per day, this is<br />

not a huge bottleneck on most dairies. According to research, the exception<br />

would be if animals become heat stressed while being locked. (see references)<br />

• Improve Freestall Use Index<br />

– If FUI is less than 90% on your dairy, it likely<br />

represents your largest opportunity to correct excessive TOC. Why aren’t<br />

your cows using your freestalls? The two most common reasons are lack of<br />

lunge space or bedding surfaces that are compacted or uncomfortable to lie<br />

Photo 2. Neck rail too low, or inadequate lunge space<br />

on. If using brisket boards, they need to be positioned 66-68 inches from the<br />

rear curb of the stall, placed at a 45-60 degree angle, and not be higher than<br />

4 inches above the bedding surface. Excessive cows standing half in stalls may<br />

be due to low neck rails or inadequate lunge space (see photo 2). Neck rails<br />

should be positioned, 46-48 inches above the bedding height, and should be<br />

placed 60-66 inches from the rear of the curb.<br />

• Install Rubber Belting or Mats –<br />

Many of today’s dairymen are exploring the<br />

use of rubber belting and mats in their facilities.<br />

According to Dr. Neil Michael, Director of Technical Services at <strong>ABS</strong>,<br />

rubber belting seems to work well in return and transfer lanes (photo 3),<br />

while the commercial, softer rubber mats may work better in the feeding<br />

lanes (photo 4). "I believe that rubber mats are key for high producing cows<br />

in today’s commercial dairy operations to reduce time on concrete," says,<br />

Michael. "I know this an expensive recommendation, but so are cows that<br />

can’t get to the feedbunk or have delayed conception due to lameness." He<br />

also mentions that people need to be careful when purchasing conveyor belting,<br />

because some types are harder than others, depending on age, and it’s use<br />

prior to being used in the dairy.<br />

As for commercially<br />

available rubber mats, they<br />

are an increased cost, but<br />

many dairies are choosing<br />

this avenue because they<br />

are thicker than conveyor<br />

belting, and provide more<br />

cushion and shock absorption.<br />

Tim Dewey, herd<br />

manager of Cimarron<br />

Dairy in Cimarron, Kan.,<br />

Photo 3. Rubber belting in transfer lanes

installed these rubber mats in his 8,000-cow dairy six months ago, and is<br />

extremely pleased with the results. "We put the rubber mats in half of the<br />

holding pen, in the parlor itself, in the parlor exit lanes, and in the housing<br />

pens of our freestall facility to help decrease wear and tear on our cows’<br />

feet," says Dewey. "Not only has it improved our feet condition, I believe<br />

we are seeing better conception rate, due to the increased cow comfort."<br />

Plus the mats have really paid for themselves. "Our cull rate due to foot<br />

problems has decreased 12% since we installed the mats. That alone has<br />

paid for the investment," notes Dewey.<br />

<strong>Comfort</strong>able, Profitable <strong>Cow</strong>s<br />

Ensuring cow comfort on your dairy is key to profitability, whether it’s<br />

through higher milk production or improved pregnancy production. Using<br />

fundamental activity times to assess cow comfort can help you detect problems,<br />

and then improve milking turn times, freestall use, or consider rubber matting<br />

Photo 4. Rubber mats in feeding areas<br />

in<br />

key areas of your dairy as needed. All in<br />

all, optimizing essential cow activities<br />

puts money in your pockets.<br />

http://www.vetmed.wsu.edu/courses-jmgay/PM98Student<strong>Comfort</strong>.htm<br />

Specific References:<br />

1. Cermack, J., <strong>Cow</strong> <strong>Comfort</strong> and Lameness-Design of Cubicles, Bovine Practitioner, 1998: 78-83.<br />

2. McFarland, D.F., Gamroth, M. J., and Bucklin, R., Freestall designs with cow comfort in mind. Dairy systems for the 21st century.<br />

Proceedings of the third international dairy housing conference held in Orlando, Florida, USA, 2-5 February 1994: 145-158.<br />

3. Radostits, O.M., Leslie, K.E., and Fetrow, J., Herd Health Food Animal Production Medicine, Saunders, Philadelphia, 1994: 301-330.<br />

4. Albright, J.L., Stouffer, D.K., and Coe, B.L., <strong>Cow</strong> comfort and preference in free stalls with reference to flooring and bedding, Journal of Dairy Science, 1989: 67.<br />

5. Rodenburg, J., House, H.K., Anderson, N.G., and Bucklin, R., Free stall base and bedding materials: Effect on cow comfort, Dairy systems for<br />

the 21st century. Proceedings of the third international dairy housing conference held in Orlando, Florida, USA, 2-5 February 1994: 154-164.<br />

6. Shipka, M.P., C.W. Arave. 1995. Influence of extended manger lock-up on cow behavior and production factors in dairy cattle<br />

management. J. Anim. Scie.73 (Suppl.1):310 (Abstr.)<br />

7. Arave, C.W., D. Bolinger, M.P. Shipka, J.L. Albright. 1996. Effect of extended lock-up of lactating cows on milk production, feed intake and behavior.<br />

J. Anim. Sci. 74 (Suppl. 1):43 (Abstr.)<br />

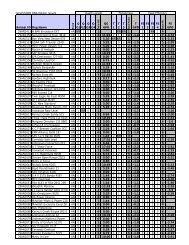

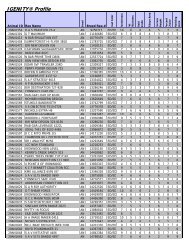

Activity Charting Exercise<br />

Dr. Neil Michael, Director of Technical<br />

Services at <strong>ABS</strong>, has developed the following<br />

spread sheet exercise to help you monitor<br />

the daily activity of your cattle. The<br />

easiest way to incorporate your data into<br />

the spreadsheet is to enter the following for<br />

your herd: dry matter intake, total turn time<br />

per day milking, lock-up time per day and<br />

the estimated free stall use. Once you have<br />

entered this information, the<br />

program can calculate your herd’s activity<br />

chart, and you can compare this to the<br />

breakdowns in an ideal herd (scenario<br />

shown above).<br />

To obtain this spreadsheet, visit the VIP Lounge in the<br />

Technical Service tab of the <strong>ABS</strong> website (www.absglobal.com).<br />

For more details on activity charting, contact your local <strong>ABS</strong><br />

Representative or call the Technical Services department at<br />

1-800-<strong>ABS</strong>-STUD today.<br />

<strong>ABS</strong> <strong>Global</strong>, Inc. • 1525 River Road • DeForest, WI 53532 •(608) 846-3721 • Fax: (608)846-6392 • www.absglobal.com