Modular Construction & Prefabrication USA - The Structural Engineer

Modular Construction & Prefabrication USA - The Structural Engineer

Modular Construction & Prefabrication USA - The Structural Engineer

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

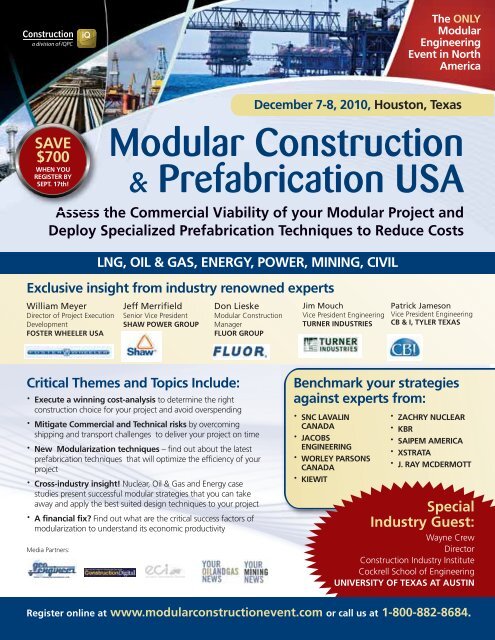

<strong>The</strong> ONLY<br />

<strong>Modular</strong><br />

<strong>Engineer</strong>ing<br />

Event in North<br />

America<br />

December 7-8, 2010, Houston, Texas<br />

SAVE<br />

$700<br />

WHEN YOU<br />

REGISTER BY<br />

SEPT. 17th!<br />

<strong>Modular</strong> <strong>Construction</strong><br />

& <strong>Prefabrication</strong> <strong>USA</strong><br />

Assess the Commercial Viability of your <strong>Modular</strong> Project and<br />

Deploy Specialized <strong>Prefabrication</strong> Techniques to Reduce Costs<br />

LNG, OIL & GAS, ENERGY, POWER, MINING, CIVIL<br />

Exclusive insight from industry renowned experts<br />

William Meyer<br />

Director of Project Execution<br />

Development<br />

FOSTER WHEELER <strong>USA</strong><br />

Jeff Merrifield<br />

Senior Vice President<br />

SHAW POWER GROUP<br />

Don Lieske<br />

<strong>Modular</strong> <strong>Construction</strong><br />

Manager<br />

FLUOR GROUP<br />

Jim Mouch<br />

Vice President <strong>Engineer</strong>ing<br />

TURNER INDUSTRIES<br />

Patrick Jameson<br />

Vice President <strong>Engineer</strong>ing<br />

CB & I, TYLER TEXAS<br />

Critical <strong>The</strong>mes and Topics Include:<br />

•<br />

Execute a winning cost-analysis to determine the right<br />

construction choice for your project and avoid overspending<br />

•<br />

Mitigate Commercial and Technical risks by overcoming<br />

shipping and transport challenges to deliver your project on time<br />

•<br />

New <strong>Modular</strong>ization techniques – find out about the latest<br />

prefabrication techniques that will optimize the efficiency of your<br />

project<br />

•<br />

Cross-industry insight! Nuclear, Oil & Gas and Energy case<br />

studies present successful modular strategies that you can take<br />

away and apply the best suited design techniques to your project<br />

•<br />

A financial fix? Find out what are the critical success factors of<br />

modularization to understand its economic productivity<br />

Media Partners:<br />

Benchmark your strategies<br />

against experts from:<br />

•<br />

SNC LAVALIN<br />

CANADA<br />

•<br />

JACOBS<br />

ENGINEERING<br />

• WORLEY PARSONS<br />

CANADA<br />

• KIEWIT<br />

•<br />

ZACHRY NUCLEAR<br />

• KBR<br />

• SAIPEM AMERICA<br />

• XSTRATA<br />

• J. RAY MCDERMOTT<br />

Special<br />

Industry Guest:<br />

Wayne Crew<br />

Director<br />

<strong>Construction</strong> Industry Institute<br />

Cockrell School of <strong>Engineer</strong>ing<br />

UNIVERSITY OF TEXAS AT AUSTIN<br />

Register online at www.modularconstructionevent.com or call us at 1-800-882-8684.

December 7-8, 2010, Houston, Texas<br />

<strong>Modular</strong> <strong>Construction</strong><br />

& <strong>Prefabrication</strong> <strong>USA</strong><br />

Assess the Commercial Viability of your <strong>Modular</strong> Project and<br />

Deploy Specialized <strong>Prefabrication</strong> Techniques to Reduce Costs<br />

Dear <strong>Engineer</strong>ing Expert,<br />

Are you equipped with the key techniques to execute an end-to-end<br />

modular project and reap the massive cost-saving benefits?<br />

Learn the best options and most practical techniques for your current projects to<br />

cut costs and optimise value, efficiency and safety by attending <strong>Construction</strong><br />

IQ’s <strong>Modular</strong> <strong>Construction</strong> & <strong>Prefabrication</strong> <strong>USA</strong> event this December in<br />

Houston, TX.<br />

We’ve researched with 70+ engineering experts to ensure that you benefit from<br />

the most relevant sessions and discussions on modular construction, and find the<br />

answers to questions and challenges that still haven’t been fully realised in<br />

modern-day construction. For this reason, we’ll be discussing the answers to<br />

critical and recurring questions, including:<br />

•<br />

When should you implement a modularization strategy?<br />

•<br />

How to apply modular to your large scale complex project?<br />

•<br />

Ways to overcome logistical challenges and control costs?<br />

Getting the complete picture on modular construction is essential to your decision<br />

making process, so that you can evaluate the commercial viability of your projects<br />

and execute the best strategy successfully. Join us to tackle these issues and<br />

discuss how an effective evaluation of your project could make you reap the<br />

benefits of the modularization.<br />

<strong>Modular</strong> <strong>Construction</strong> & <strong>Prefabrication</strong> <strong>USA</strong> will bring together the Senior Project<br />

Managers, Vice Presidents and Project Owners to share knowledge and best<br />

practice strategies with you, while highlighting the main variables that must be<br />

considered when thinking about constructing modular.<br />

Who Should Attend<br />

<strong>Modular</strong> <strong>Construction</strong> &<br />

<strong>Prefabrication</strong> <strong>USA</strong>?<br />

• Vice Presidents, <strong>Engineer</strong>ing<br />

• Project Managers<br />

• Client owners<br />

• <strong>Modular</strong> <strong>Construction</strong> Managers<br />

• Director of Project Execution<br />

Development<br />

• Heads of projects<br />

• Modulors<br />

• Specialized Consultants<br />

If your role is linked to construction in<br />

engineering, this is the must-attend<br />

meeting of the year for you!<br />

Our Guarantee to You:<br />

1. New contacts, new business<br />

– our unparalleled<br />

networking opportunities are<br />

designed to give you crucial<br />

face time with key decision<br />

makers from across the<br />

industry<br />

2. <strong>The</strong> very best business<br />

intelligence! We have<br />

carefully selected each and<br />

every member of our speaker<br />

faculty to ensure that you<br />

hear from only the thoughtleaders<br />

and pioneers in<br />

modular construction<br />

3. In-depth interactive master<br />

classes will deliver detailed<br />

insight into commercial<br />

viability, and suitability of<br />

modularisation<br />

Download free resources (past presentations, podcasts, and articles) by visiting<br />

our website at www.modularconstructionevent.com in the weeks leading up to<br />

the event.<br />

Be sure to register your seat early for this exciting event by calling us directly at<br />

1-800-882-8684 and we’ll see you December 7-8, 2010 in sunny Houston!<br />

Best regards,<br />

Sladjana Franovic<br />

Conference Director<br />

<strong>Construction</strong> IQ<br />

Don’t forget to sign up for<br />

our practical workshop when<br />

you register for the<br />

conference! Places are limited<br />

– reserve your place today!<br />

FACT!<br />

• 100% focused<br />

<strong>Modular</strong> event<br />

• 15+ Expert Speakers<br />

• 10+ Hours of<br />

Networking<br />

• Case-Study<br />

Intensive Agenda<br />

• Practical &<br />

Interactive Workshop<br />

2<br />

Register online at www.modularconstructionevent.com or call 1-800-882-8684

Conference Agenda Day One<br />

Tuesday, December 7, 2010<br />

Assess the commercial viability of your modular project and deploy specialized prefabrication techniques to reduce costs<br />

8:30 Registration & Coffee<br />

9:00 Chairman’s Welcome Address<br />

James T O’Connor<br />

Principal Researcher<br />

UNIVERSITY OF TEXAS<br />

9:15 How Do We Break through the <strong>Modular</strong>ization Glass Ceiling?<br />

•<br />

Key lessons learned from recent <strong>Modular</strong>ization success case studies<br />

•<br />

Find out what implementation strategies can help in exploiting the<br />

beneficial economics of modularization<br />

•<br />

Understand the technological advances and industry changes required<br />

to consistently complete successful modular projects<br />

•<br />

Insight into best-practices from other industries and other countries as<br />

well as the steps that are being taken by CII<br />

James T O’Connor<br />

Principal Researcher<br />

UNIVERSITY OF TEXAS<br />

10:00 <strong>The</strong> Economic Productivity Factor: Ensuring<br />

<strong>Modular</strong>ization is the Right Choice for Your Project<br />

•<br />

Module vs Stick built Cost differentials<br />

•<br />

<strong>The</strong> Foster Wheeler approach; A comparison between cost driven vs<br />

schedule driven modular and stick built projects<br />

•<br />

A planning A-Z; a complete breakdown of different factors<br />

influencing planning of modular projects<br />

William Meyer<br />

Director Project Execution Development<br />

FOSTER WHEELER <strong>USA</strong><br />

10:45 Morning Networking Break<br />

11:15 Conduct a Cost/Benefit Analysis to Determine<br />

Commercial Viability of Pre-Fabrication: Making the<br />

Best Decision for your Project<br />

•<br />

Understand the main drivers for modularization-how can this<br />

approach save your project money?<br />

•<br />

Determine suitability; Ways to go forward- How do we determine if<br />

our project is a likely candidate for modularization?<br />

•<br />

Find out how your constructability program will impact your final<br />

project costs<br />

•<br />

Understand the variables impacting the overall decision to use<br />

modularization. Insight into; labour cost, labour productivity, steel<br />

design and fabrication costs, shop Vs field assembly hours insulation<br />

and fireproofing construction costs<br />

Patrick Jameson<br />

Vice President <strong>Engineer</strong>ing<br />

CB&I, TYLER TEXAS<br />

12:00 Understand the Critical Success Factors in Using<br />

<strong>Modular</strong>ization<br />

•<br />

Learn how to control timely delivery of Material & Equipment to keep<br />

your project within the schedule<br />

•<br />

How to determine the best design choice for your project<br />

•<br />

Optimize your modularization using timely construction driven design<br />

•<br />

Learn how to reduce direct and indirect costs from both Owner & Contractor<br />

•<br />

Find out how to achieve higher productivity with reduced manpower<br />

using modularization<br />

Jim Mouch<br />

Vice President <strong>Engineer</strong>ing<br />

TURNER INDUSTRIES<br />

12:45 Networking Lunch<br />

13:45 Understand the Different Forms of Risk Associated<br />

with <strong>Modular</strong> <strong>Construction</strong>: How to Minimize your<br />

risk?<br />

•<br />

Learn best practice to mitigate risks associated with the modular<br />

construction. What are the necessary techniques that must be used<br />

from design to execution stage?<br />

•<br />

How to assess each risks ability to impact the timing and quality of<br />

your project<br />

•<br />

Evaluate the need to use modular construction: In which case to<br />

adopt this method?<br />

Bill Pender<br />

Vice President Global Project Services<br />

J. RAY MCDERMOTT<br />

14:30 Overcome the Risk When Using Overseas Fabricators<br />

and Maintain Efficacy and Efficiency<br />

•<br />

Identify the potential risks when choosing an offshore fabricator;<br />

what to look for when making the vital decision?<br />

•<br />

Develop strategic processes to combat the geographical and cultural<br />

gaps when using overseas fabricators<br />

•<br />

Learn how to establish a succinct communication plan to avoid<br />

potential risks<br />

•<br />

How to implement best practice project management methodologies<br />

to alleviate risk?<br />

Don Lieske<br />

<strong>Modular</strong> <strong>Construction</strong> Manager<br />

FLUOR <strong>USA</strong><br />

15:15 Afternoon Networking Break<br />

15:45 Getting the Right Support – How to Develop an<br />

Effective Module Execution Team with the Right<br />

Logistics Support<br />

•<br />

Understand the specific efforts and support required to develop a<br />

modular project team using an engineering team with predominate<br />

stick build experience<br />

•<br />

Early module oriented engineering and logistics support - a must for<br />

a successful project<br />

•<br />

How to mitigate the logistical challenges of moving modular<br />

constructions over land<br />

•<br />

Best-practice insight on delivering successful on-shore modular projects<br />

Michael Kluck<br />

Senior Project Manager - <strong>Engineer</strong>ing<br />

KBR<br />

16:30 Steps and Key Design Decisions for Offshore<br />

Production Modules<br />

Just confirmed!<br />

Randy Hasling, Manager of Projects will deliver best-practice<br />

insight on successful modular projects at Jacobs <strong>Engineer</strong>ing.<br />

Visit www.modularconstructionevent.com for full session details!<br />

Randy Hasling<br />

Manager of Projects<br />

JACOBS ENGINEERING<br />

17:15 End of Conference Day One<br />

3 Media Partners:

Conference Agenda Day Two<br />

Wednesday, December 8, 2010<br />

Assess the commercial viability of your modular project and deploy specialized prefabrication techniques to reduce costs<br />

08:30 Registration & Coffee<br />

09:00 Chairman’s Welcome Address<br />

James T O’Connor<br />

Principal Researcher<br />

UNIVERSITY OF TEXAS<br />

09:05 To <strong>Modular</strong>ize or not to <strong>Modular</strong>ize; Stepping through<br />

the Decision Making Process?<br />

•<br />

Find out when and why is it more beneficial to use the overseas<br />

fabrication yards. Overseas vs local fabrication yards<br />

•<br />

Learn successful methodology to execute correct pre-feasibility and<br />

feasibility study to determine if modularization is right for your project<br />

Name to be advised<br />

JACOBS ENGINEERING<br />

09:50 Develop a Winning Design Strategy that is in Harmony<br />

with the Yest of Your <strong>Modular</strong> Project<br />

•<br />

How to establish a clear design strategy during the early phases of<br />

your project<br />

•<br />

Find out how to align your design and construction teams and<br />

develop an effective process which minimizes design discrepancies<br />

during the construction phase<br />

•<br />

Manage your decision process-how your design decisions drive the<br />

overall project<br />

Paul Murray<br />

Head of Project Development<br />

SNC LAVALIN CANADA<br />

10:35 Morning Networking Break<br />

11:05 Competitive Worley Parsons Execution Strategy: High<br />

Value Project Delivery Model<br />

•<br />

How to deliver project within a schedule using HVPD model<br />

•<br />

Learn what are the main principles of HVPD model<br />

•<br />

Latest update on innovation and top advantages of using HVPD<br />

model<br />

David Johnsen<br />

<strong>Modular</strong> Manager<br />

WORLEY PARSONS CANADA<br />

11:50 <strong>Modular</strong> <strong>Construction</strong> in the Nuclear Industry from<br />

Factory Floor to You<br />

•<br />

Understand how Shaw is using modular construction methods to<br />

build the AP1000 units in China and the US and the competitive<br />

advantages this brings<br />

•<br />

Learn how Shaw’s non-nuclear modular experience can benefit the<br />

new build program and receive an update on the manufacturing<br />

facility in Lake Charles<br />

•<br />

What are the key differences concerning how modular construction<br />

will take place here in the United States and how you should prepare<br />

for this<br />

•<br />

Discover how modular construction methods affect quality control<br />

and NRC inspection activities<br />

Jeff Merrifield<br />

Senior Vice President<br />

SHAW POWER GROUP<br />

12:35 Networking Lunch<br />

13:35 <strong>The</strong> Direction of the Nuclear Plant <strong>Construction</strong> and<br />

the Effectiveness of <strong>Modular</strong>ization in this Industry<br />

•<br />

Learn about advanced design and new construction techniques in<br />

nuclear construction<br />

•<br />

Avoid the pitfalls! Insight into non-cost effective way of using<br />

modularization<br />

•<br />

Examples of effective usage of modularization on nuclear projects<br />

Mike Mosley<br />

Program Manager<br />

ZACHRY NUCLEAR<br />

14:20 Discuss the Advancement of <strong>Modular</strong> Techniques in<br />

Mining and Gas Sectors<br />

•<br />

Using modularization in new mine developments; Discussing the best<br />

practices of Kiewit<br />

•<br />

Find out how emerging technology can maximize the use of the<br />

modular techniques on your project<br />

•<br />

Examples where further advancements in the use of modular<br />

techniques can dramatically cut scheduling times and ultimately<br />

construction costs<br />

Roger Errington<br />

District Estimating Manager<br />

KIEWIT<br />

15:05 Afternoon Networking Break<br />

15:50 A Look at How the Advancements in Steel Fabrication<br />

Yards have Improved the Cost, Quality and Longevity<br />

of Steel Structures Used in <strong>Modular</strong> <strong>Construction</strong><br />

•<br />

Access is paramount: Discuss the growing number of countries with<br />

viable fabrication yards; what is the future of on and off shore<br />

fabrication yards?<br />

•<br />

Making an informed decision: What variables influence the decision<br />

on which fabrication yard to use?<br />

•<br />

Selecting the right yard for your project: what to look for and where<br />

do some projects go wrong?<br />

Jim Beaudoin<br />

<strong>Modular</strong> Manager – Koniambo Nickel Project<br />

XSTRATA<br />

16:35 End of Conference<br />

Sign up for the in-depth workshop for an interactive<br />

discussion and practical insights after the conference.<br />

See page 5 for details.<br />

4 Register online at www.modularconstructionevent.com or call 1-800-882-8684

Evening Workshop<br />

Wednesday, December 8, 2010<br />

Sign up for this Workshop and complete your learning experience<br />

with in-depth and interactive practical workshops.<br />

5:00pm-8:00pm<br />

(dinner served)<br />

Key Signs That Your Project Should Go <strong>Modular</strong><br />

Deciding to use modular techniques when faced with large construction work is a decision that requires time,<br />

skills, knowledge and expertise in modularization. Analysing the scope of your project, the challenges involved<br />

and the resources available, are all key considerations in your decision making process.<br />

This workshop will step through each component of the decision making process and ultimately help you to<br />

determine if modularization is the best method for your project and if so, by how much?<br />

Benefits of Participation:<br />

•<br />

Gain an understanding of the complex nature of the decision making processes during the study phases<br />

•<br />

Be able to determine the benefits vs risks of using the overseas fabricators in comparison to using local<br />

fabrication yards<br />

•<br />

Understand the impact that the size of the fabricated module has on the project and where the module<br />

should/could be fabricated<br />

Randy Hasling, Manager of Projects, JACOBS ENGINEERING<br />

Registration Information<br />

Package Register & Pay by Register & Pay by Standard<br />

Sept. 17, 2010 October 15, 2010 Price<br />

Conference + Workshop (Save $700) (Save $500)<br />

$1,748 $1,948 $2,448<br />

Conference Only (Save $700) (Save $500)<br />

$1,199 $1,399 $1,899<br />

Workshops $549 each $549 each $549 each<br />

Please note multiple discounts cannot be combined.<br />

A $99 processing charge will be assessed to all registrations<br />

not accompanied by credit card payment at the time of<br />

registration.<br />

MAKE CHECKS PAYABLE IN U.S. DOLLARS TO: IQPC<br />

* CT residents or people employed in the state of CT must<br />

add 6% sales tax.<br />

TEAM DISCOUNTS<br />

For information on team discounts, please contact IQPC<br />

Customer Service at enquire@iqpc.co.uk. Only one discount<br />

may be applied per registrant.<br />

Special Discounts Available: A limited number of discounts<br />

are available for the non-profit sector, government<br />

organizations and academia.<br />

Keep in Contact with Us!<br />

Details for making payment via EFT or wire transfer:<br />

JPMorgan Chase - Penton Learning Systems LLC dba IQPC: 957-097239<br />

ABA/Routing #: 021000021<br />

Reference: Please include the name of the attendee(s) and the event number:<br />

19290.001<br />

Payment Policy: Payment is due in full at the time of registration and includes<br />

lunches and refreshments. Your registration will not be confirmed until payment<br />

is received and may be subject to cancellation.<br />

For IQPC’s Cancellation, Postponement and Substitution Policy, please<br />

visit www.iqpc.com/cancellation<br />

Special Dietary Needs: If you have a dietary restriction, please contact<br />

Customer Service at enquire@iqpc.co.uk to discuss your specific needs.<br />

©2010 IQPC. All Rights Reserved. <strong>The</strong> format, design, content and arrangement<br />

of this brochure constitute a trademark of IQPC. Unauthorized reproduction will<br />

be actionable under the Lanham Act and common law principles.<br />

Follow us on Twitter: www.twitter.com/constructioniq<br />

Join the LinkedIn Group: <strong>Construction</strong> Professionals Networking and Events Group<br />

1<br />

2<br />

3<br />

4<br />

5<br />

5 Key Reasons<br />

Why <strong>Modular</strong><br />

<strong>Construction</strong> and<br />

<strong>Prefabrication</strong> Gives<br />

you the Best Value for<br />

your Marketing Spend.<br />

• Complete exposure to<br />

decision-makers who are<br />

responsible for the selection,<br />

procurement and purchasing<br />

of modular solutions<br />

• You’ll notice that the<br />

athmosphere is different from<br />

other conferences. We actually<br />

maintain a reduced vendor<br />

ratio, which creates a more<br />

intimate environment for<br />

networking and knowledge<br />

sharing.<br />

• Your clients and prospects will<br />

be attending <strong>Modular</strong><br />

<strong>Construction</strong> and<br />

<strong>Prefabrication</strong> 2010 and this is<br />

the perfect opportunity to<br />

make yours the brand and the<br />

product they remember<br />

• Extensive networking<br />

opportunities, allowing for<br />

face-to-face interaction with<br />

the heads of your target<br />

market<br />

• <strong>The</strong> perfect environment for<br />

high quality lead generation:<br />

Our delegates have already<br />

made a significant investment<br />

in attending our conference<br />

to network with key industrys<br />

advisors-make sure they meet<br />

you on the site! This is your<br />

opportunity to network with<br />

your clients and impress your<br />

competitiors’ clients<br />

<strong>Modular</strong> <strong>Construction</strong> and<br />

<strong>Prefabrication</strong> <strong>USA</strong> is not a<br />

tradeshow, there will only be a<br />

limited number of opportunities<br />

available. To secure premium<br />

exposure, contact Matthew<br />

Richardson at +44 (0)20 7368<br />

9500 or sponsorship@iqpc.co.uk.<br />

Media Partners<br />

5 Have a Question? Email us at enquire@iqpc.co.uk.

YES! Please register me for:<br />

REGISTRATION CARD<br />

<strong>Modular</strong> <strong>Construction</strong><br />

& <strong>Prefabrication</strong> <strong>USA</strong><br />

International Quality & Productivity Center<br />

535 5th Avenue, 8th Floor<br />

New York, NY 10017<br />

❑ Main Summit Only<br />

❑ Workshop<br />

See Page 5 for pricing details.<br />

Your customer registration code is:<br />

When registering, please provide the code above.<br />

Name__________________________________ Job Title ________________________<br />

Organization____________________________________________________________<br />

Approving Manager______________________________________________________<br />

Address________________________________________________________________<br />

City__________________________________State______________Zip____________<br />

Phone________________________________Fax_______________________________<br />

E-mail__________________________________________________________________<br />

❑ Please keep me informed via email about this and other related events.<br />

❑ Check enclosed for $_________ (Payable to IQPC)<br />

❑ Charge my __Amex __Visa __Mastercard __Diners Club<br />

Card #__________________________________Exp. Date___/___ CVM code ______<br />

Details for making payment via EFT or wire transfer can be found on<br />

preceding page.<br />

❑ I cannot attend, but please keep me informed of all future events.<br />

19290.001/DM/KV<br />

5 EASY WAYS TO REGISTER:<br />

1<br />

2<br />

3<br />

4<br />

5<br />

Web: www.modularconstructionevent.com<br />

Call: 1-800-882-8684<br />

Email: enquire@iqpc.co.uk<br />

Fax: 1-646-378-6025<br />

Mail: IQPC<br />

535 5th Avenue, 8th Floor,<br />

New York, NY 10017<br />

<strong>The</strong> ONLY<br />

<strong>Modular</strong><br />

<strong>Engineer</strong>ing<br />

Event in North<br />

America<br />

December 7-8, 2010, Houston, Texas<br />

SAVE<br />

$700<br />

WHEN YOU<br />

REGISTER BY<br />

SEPT. 17th!<br />

<strong>Modular</strong> <strong>Construction</strong><br />

& <strong>Prefabrication</strong> <strong>USA</strong><br />

Assess the Commercial Viability of your <strong>Modular</strong> Project and<br />

Deploy Specialized <strong>Prefabrication</strong> Techniques to Reduce Costs<br />

LNG, OIL & GAS, ENERGY, POWER, MINING, CIVIL<br />

Register online at www.modularconstructionevent.com or call us at 1-800-882-8684.