screen cleaners - Landustrie

screen cleaners - Landustrie

screen cleaners - Landustrie

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

S C R E E N<br />

C L E A N E R S

S C R E E N<br />

C L E A N E R S<br />

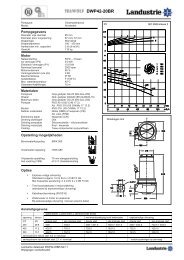

CONSTRUCTION<br />

Both types, R66 and R71, have the same basic<br />

construction and can be supplied with the same<br />

special features, such as:<br />

Narrower or wider grab<br />

Larger working depth: up to 30 meter<br />

Two-speed motor for both hoisting and<br />

travelling<br />

Stainless steel execution<br />

MÜNSTER SCREEN CLEANERS<br />

In the last 35 years <strong>Landustrie</strong> Sneek BV has<br />

acquired about 30 % of the world-wide market in<br />

the field of Münster type <strong>screen</strong> <strong>cleaners</strong>.<br />

<strong>Landustrie</strong> therefore has a considerable knowhow<br />

and experience in supplying and installing<br />

<strong>screen</strong> cleaning equipment. These <strong>screen</strong><br />

<strong>cleaners</strong> are applied in many places with<br />

unwanted floating or suspended debris.<br />

APPLICATIONS<br />

The track contains one or more profile sections<br />

and is formed out of a steel plate of 10 mm, in<br />

which the carriage with the grab is mounted.<br />

The advantage of this construction is that<br />

<strong>screen</strong>s of any width and depth can be cleaned.<br />

The variable track length allows positioning of a<br />

deposit at any desirable place. In order to meet<br />

current noise level requirements, following<br />

provisions have been made:<br />

Teflon guide strips on the grab<br />

Nylon wheels to move the carriage<br />

Low-noise lifting drive<br />

Low-noise hydraulic pump<br />

In situations where additional requirements<br />

are to be met, the carriage can be enclosed<br />

in a complete sound proof cabinet<br />

Polder drainage stations<br />

Sewage treatment plants<br />

Inlets to power- and desalination plants<br />

Storm drains<br />

Industry<br />

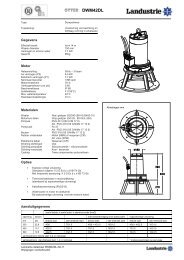

PRINCIPLE<br />

A <strong>screen</strong> is positioned in the channel. Over the<br />

<strong>screen</strong> an elevated track is placed, supported by<br />

columns or gantries. A construction, consisting of<br />

a grab connected to a carriage by cables, is<br />

running along this track. The grab is constructed<br />

in such a way that its tines fall in between the<br />

<strong>screen</strong> bars during lowering, to scrape out any<br />

jammed debris. When reaching the bottom of the<br />

<strong>screen</strong>, the grab will close hydraulically, after<br />

which the debris will be hoisted to the carriage<br />

and run along the track to the dump area.

ADVANTAGES:<br />

THE GRAB<br />

An important and unique feature of the LANDY<br />

<strong>screen</strong> cleaner is the way the grab is designed.<br />

The optimum weight distribution guarantees, that<br />

the grab will never tip over and due to the guiding<br />

strips, the grab will always clean the <strong>screen</strong> in a<br />

straight line. When encountering too much<br />

debris to handle in one haul, the grab will stay in<br />

position, close by using 2 hydraulic cylinders and<br />

grab out as much as possible, to resume its<br />

cleaning for the next cycle. No parts other then<br />

the cable drums are touching the cables so no<br />

parts are causing any unnecessary wear.<br />

This robust system ensures 100% reliability for<br />

this essential <strong>screen</strong> cleaner safety feature.<br />

The tines of the grab penetrate deeply into the<br />

bar <strong>screen</strong>, in order to make sure blockage and<br />

debris is removed from between the bars.<br />

For existing <strong>screen</strong> the grabs are adapted to the<br />

situation.<br />

CONTROLS<br />

The <strong>screen</strong> cleaner can operate fully automatically,<br />

controlled by the difference in water level<br />

across the <strong>screen</strong> detected by electronic<br />

sensors. Manual operation and operation by<br />

means of a timer is also possible.<br />

The <strong>screen</strong> will be completely cleaned from<br />

top to bottom in one cycle.<br />

The track can be equipped with curves,<br />

enabling a positioning of the deposit at any<br />

desirable place<br />

Possibility for direct dumping on truck,<br />

container or barge.<br />

Open construction and absence of<br />

intermediate transportation reduce space<br />

requirements and dirty <strong>screen</strong>ing areas.<br />

No conveyor belts required<br />

Absence of permanently submerged<br />

construction parts<br />

Insensible to icing<br />

One unit is sufficient for multi-<strong>screen</strong><br />

operation<br />

PLC control and sensors allows complete<br />

automatic operation and versatility<br />

Proximity switch secures automated<br />

functioning, no moving levers and rolls,<br />

less wear and tear<br />

Heavy weight grab of maximum compression<br />

of debris<br />

Large obstacles such as mattresses,<br />

tree-trunks and root stems can be removed<br />

One type of hydraulics for all standard<br />

products, easy replaceable<br />

The use of well known manufacturers of<br />

all moving parts, ensures a long-term supply<br />

of spare parts.<br />

Double hydraulic hose, 1 spool, protected by<br />

cable wire<br />

Less noise, wear and tear because of the use<br />

of heavy duty rubber wheels and Teflon strips<br />

The grab always remains in an upright<br />

position, in contact with the <strong>screen</strong>s. This<br />

ensures a better functioning, and a cleaner<br />

grab.<br />

The grab is designed to meet hoisting<br />

crane specifications

S C R E E N<br />

C L E A N E R S<br />

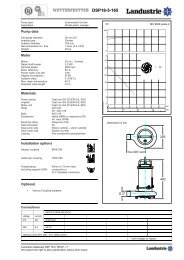

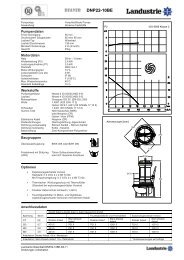

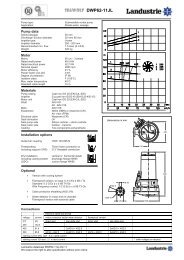

Technical details Type R 66 Type R71 Type R03<br />

Grab width standard 1860 1000 1000 mm<br />

max. up to 3000 1400 1200 mm<br />

Bar distance minimum 20 20 20 mm<br />

Weight carriage approx 920 530 450 kg<br />

Weight grab approx 620 430 290 kg<br />

Lifting weight<br />

(payload) approx 370 270 210 kg<br />

max. up to 1220 700 500 kg<br />

Working depth up to 21,00 14,70 7,70 m**<br />

Lifting motor 4,0 2,2 1,5 kW<br />

Traveling motor 1,0 0,37 0,37 kW<br />

Hydraulic motor 1,10 1,10 0,55 kW<br />

Lifting velocity approx 19,0 15,0 15,0 m/min<br />

Traveling velocity approx 30,0 30,0 20,0 m/min<br />

Hydraulic oil pressure maximal 170 170 170 bar<br />

** The working depth of the <strong>screen</strong> <strong>cleaners</strong> can be extended on request<br />

The above mentioned technical details refer to the standard execution of the<br />

mentioned types. On customer request however, we can deviate from this and<br />

design tailor made solutions for requirements not covered by the standards. All<br />

units are manufactured in accordance with EC-directive.<br />

Watertechnology<br />

<strong>Landustrie</strong> Sneek BV<br />

P.O. Box 199<br />

NL-8600 AD Sneek<br />

The Netherlands<br />

Tel. +31 515 - 48 68 88<br />

Fax +31 515 - 41 23 98<br />

e-mail info@landustrie.nl<br />

website www.landustrie.nl<br />

Office address Pieter Zeemanstraat 6, Sneek<br />

01-2013-1000 ENG.