Pipe Ramming in the Thin Air: BTrenchless Goes Large Diameter

Pipe Ramming in the Thin Air: BTrenchless Goes Large Diameter

Pipe Ramming in the Thin Air: BTrenchless Goes Large Diameter

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

I N N O V A T O R S<br />

IN TRENCHLESS<br />

ON LOCATION PIPE RAMMING GRUNDORAM TAURUS<br />

<strong>Pipe</strong> <strong>Ramm<strong>in</strong>g</strong> <strong>in</strong> <strong>the</strong> Th<strong>in</strong> <strong>Air</strong>:<br />

<strong>BTrenchless</strong> <strong>Goes</strong> <strong>Large</strong> <strong>Diameter</strong><br />

Pneumatic pipe ramm<strong>in</strong>g cont<strong>in</strong>ues to prove that it is one<br />

of <strong>the</strong> most versatile and effective trenchless methods.<br />

With much of <strong>the</strong> attention be<strong>in</strong>g placed on pipe<br />

ramm<strong>in</strong>g’s effectiveness for assist<strong>in</strong>g directional drill<strong>in</strong>g<br />

operations, it is easy to overlook pipe ramm<strong>in</strong>g <strong>in</strong> its<br />

more traditional role of cas<strong>in</strong>g <strong>in</strong>stallation. <strong>BTrenchless</strong><br />

(a division of BT Construction), Henderson, Colo.<br />

recently showed just how effective pipe ramm<strong>in</strong>g can<br />

be for large diameter cas<strong>in</strong>g work.<br />

Accord<strong>in</strong>g to Mark Wellensiek, <strong>BTrenchless</strong> Bor<strong>in</strong>g<br />

General Super<strong>in</strong>tendent, <strong>the</strong> company has progressed<br />

from smaller diameter pipe rams to tackl<strong>in</strong>g large<br />

diameter projects. He said, “We’ve done about six<br />

pipe rams so far. We started with 24-<strong>in</strong>ch and 30-<strong>in</strong>ch<br />

diameter cas<strong>in</strong>gs, <strong>the</strong>n completed several 42-<strong>in</strong>ch<br />

diameters and worked our way up to this 84-<strong>in</strong>ch ram.”<br />

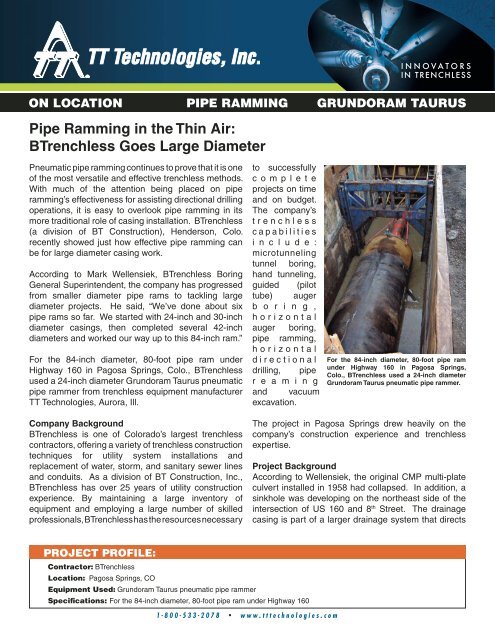

For <strong>the</strong> 84-<strong>in</strong>ch diameter, 80-foot pipe ram under<br />

Highway 160 <strong>in</strong> Pagosa Spr<strong>in</strong>gs, Colo., <strong>BTrenchless</strong><br />

used a 24-<strong>in</strong>ch diameter Grundoram Taurus pneumatic<br />

pipe rammer from trenchless equipment manufacturer<br />

TT Technologies, Aurora, Ill.<br />

to successfully<br />

c o m p l e t e<br />

projects on time<br />

and on budget.<br />

The company’s<br />

t r e n c h l e s s<br />

c a p a b i l i t i e s<br />

i n c l u d e :<br />

microtunnel<strong>in</strong>g<br />

tunnel bor<strong>in</strong>g,<br />

hand tunnel<strong>in</strong>g,<br />

guided (pilot<br />

tube) auger<br />

b o r i n g ,<br />

h o r i z o n t a l<br />

auger bor<strong>in</strong>g,<br />

pipe ramm<strong>in</strong>g,<br />

h o r i z o n t a l<br />

d i r e c t i o n a l<br />

drill<strong>in</strong>g, pipe<br />

r e a m i n g<br />

and vacuum<br />

excavation.<br />

For <strong>the</strong> 84-<strong>in</strong>ch diameter, 80-foot pipe ram<br />

under Highway 160 <strong>in</strong> Pagosa Spr<strong>in</strong>gs,<br />

Colo., <strong>BTrenchless</strong> used a 24-<strong>in</strong>ch diameter<br />

Grundoram Taurus pneumatic pipe rammer.<br />

Company Background<br />

<strong>BTrenchless</strong> is one of Colorado’s largest trenchless<br />

contractors, offer<strong>in</strong>g a variety of trenchless construction<br />

techniques for utility system <strong>in</strong>stallations and<br />

replacement of water, storm, and sanitary sewer l<strong>in</strong>es<br />

and conduits. As a division of BT Construction, Inc.,<br />

<strong>BTrenchless</strong> has over 25 years of utility construction<br />

experience. By ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g a large <strong>in</strong>ventory of<br />

equipment and employ<strong>in</strong>g a large number of skilled<br />

professionals, <strong>BTrenchless</strong> has <strong>the</strong> resources necessary<br />

The project <strong>in</strong> Pagosa Spr<strong>in</strong>gs drew heavily on <strong>the</strong><br />

company’s construction experience and trenchless<br />

expertise.<br />

Project Background<br />

Accord<strong>in</strong>g to Wellensiek, <strong>the</strong> orig<strong>in</strong>al CMP multi-plate<br />

culvert <strong>in</strong>stalled <strong>in</strong> 1958 had collapsed. In addition, a<br />

s<strong>in</strong>khole was develop<strong>in</strong>g on <strong>the</strong> nor<strong>the</strong>ast side of <strong>the</strong><br />

<strong>in</strong>tersection of US 160 and 8 th Street. The dra<strong>in</strong>age<br />

cas<strong>in</strong>g is part of a larger dra<strong>in</strong>age system that directs<br />

PROJECT PROFILE:<br />

Contractor: <strong>BTrenchless</strong><br />

Location: Pagosa Spr<strong>in</strong>gs, CO<br />

Equipment Used: Grundoram Taurus pneumatic pipe rammer<br />

Specifications: For <strong>the</strong> 84-<strong>in</strong>ch diameter, 80-foot pipe ram under Highway 160<br />

1 - 8 0 0 - 5 3 3 - 2 0 7 8 • w w w . t t t e c h n o l o g i e s . c o m

un-off from <strong>the</strong> San Juan Mounta<strong>in</strong> Range, through<br />

town of Pagosa Spr<strong>in</strong>gs and <strong>in</strong>to <strong>the</strong> San Juan River.<br />

Cont<strong>in</strong>uous flow through <strong>the</strong> culvert has made <strong>the</strong><br />

s<strong>in</strong>khole a significant problem. The edge of <strong>the</strong> s<strong>in</strong>khole<br />

was only 25 feet from <strong>the</strong> north shoulder of west bound<br />

US 160 and <strong>the</strong> portion of <strong>the</strong> exist<strong>in</strong>g culvert under<br />

Highway 160 was so deteriorated that <strong>the</strong> Colorado<br />

Dept. of Transportation (CDOT) determ<strong>in</strong>ed that <strong>the</strong><br />

pipe needed to be replaced.<br />

with repeated percussive blows. A cutt<strong>in</strong>g shoe is often<br />

welded to <strong>the</strong> front of <strong>the</strong> lead cas<strong>in</strong>g to help reduce<br />

friction and cut through <strong>the</strong> soil. Bentonite or polymer<br />

lubrication can also be used to help reduce friction<br />

dur<strong>in</strong>g ramm<strong>in</strong>g operations. <strong>Ramm<strong>in</strong>g</strong> tools, <strong>in</strong> general,<br />

are capable of <strong>in</strong>stall<strong>in</strong>g 4- through 147-<strong>in</strong>ch diameter<br />

pipe and steel cas<strong>in</strong>gs.<br />

<strong>Ramm<strong>in</strong>g</strong> can be used for horizontal, vertical, and even<br />

angled applications. It is often used under roads, like<br />

<strong>the</strong> Pagosa project, and rail l<strong>in</strong>es because it displaces<br />

<strong>the</strong> soil without creat<strong>in</strong>g voids or slumps.<br />

Accord<strong>in</strong>g to TT Technologies pipe ramm<strong>in</strong>g specialist<br />

Rick Melv<strong>in</strong> that is a key benefit of pipe ramm<strong>in</strong>g. He<br />

said, “Some <strong>in</strong>stallation methods can jeopardize <strong>the</strong><br />

<strong>in</strong>tegrity of roads or rail l<strong>in</strong>es because <strong>the</strong>y remove soil<br />

from underneath to allow for <strong>the</strong> new pipe <strong>in</strong>stallation.<br />

<strong>Pipe</strong> ramm<strong>in</strong>g’s ability to <strong>in</strong>stall various sized cas<strong>in</strong>gs<br />

without putt<strong>in</strong>g <strong>the</strong> topside structures <strong>in</strong> danger makes<br />

it a very attractive option. Also pipe ramm<strong>in</strong>g works <strong>in</strong><br />

difficult soil conditions. Boulders and rocks, as large as<br />

<strong>the</strong> cas<strong>in</strong>g itself, can be swallowed up as <strong>the</strong> cas<strong>in</strong>g<br />

moves through <strong>the</strong> soil and can be removed after <strong>the</strong><br />

<strong>in</strong>stallation is complete.”<br />

Dur<strong>in</strong>g <strong>the</strong> pipe ramm<strong>in</strong>g process, a pneumatic hammer is attached to<br />

<strong>the</strong> rear of <strong>the</strong> cas<strong>in</strong>g or pipe.<br />

Wellensiek said, “As <strong>the</strong> ma<strong>in</strong> artery between Pagosa<br />

Spr<strong>in</strong>gs and Durango, Colo, Highway160 is a very busy<br />

two lane highway and CDOT did not want to impact<br />

traffic by open cutt<strong>in</strong>g <strong>the</strong> highway to <strong>in</strong>stall a new<br />

culvert. Open cutt<strong>in</strong>g was really never an option. We<br />

would have had to perform that type of work late at<br />

night when traffic levels were as low as possible.”<br />

Ultimately, plans were drawn up to ram an 84-<strong>in</strong>ch<br />

diameter steel cas<strong>in</strong>g over <strong>the</strong> deteriorat<strong>in</strong>g 60-<strong>in</strong>ch<br />

CMP culvert and encase it. The exist<strong>in</strong>g CMP would<br />

<strong>the</strong>n be removed from <strong>the</strong> steel cas<strong>in</strong>g and a new 60-<br />

<strong>in</strong>ch RCP l<strong>in</strong>e <strong>in</strong>stalled. The <strong>BTrenchless</strong> crew would<br />

face many challenges <strong>in</strong> order to make that happen.<br />

<strong>Pipe</strong> <strong>Ramm<strong>in</strong>g</strong> 101<br />

Dur<strong>in</strong>g <strong>the</strong> pipe ramm<strong>in</strong>g process, a pneumatic<br />

hammer is attached to <strong>the</strong> rear of <strong>the</strong> cas<strong>in</strong>g or pipe.<br />

The ramm<strong>in</strong>g tool, which consists of a piston with<strong>in</strong> a<br />

cas<strong>in</strong>g, drives <strong>the</strong> pipe or cas<strong>in</strong>g through <strong>the</strong> ground<br />

An entire length of pipe can be <strong>in</strong>stalled at once or,<br />

for longer runs, one section at a time can be <strong>in</strong>stalled.<br />

In that case, <strong>the</strong> ramm<strong>in</strong>g tool is removed after each<br />

section is <strong>in</strong> place and a new section is welded on to <strong>the</strong><br />

end of <strong>the</strong> newly <strong>in</strong>stalled section. The ramm<strong>in</strong>g tool is<br />

connected to <strong>the</strong> new section and ramm<strong>in</strong>g cont<strong>in</strong>ues.<br />

Several methods can be used to remove spoil from <strong>the</strong><br />

cas<strong>in</strong>g <strong>in</strong>clud<strong>in</strong>g compressed air, water, an augur<strong>in</strong>g<br />

system or o<strong>the</strong>r types of earthmov<strong>in</strong>g equipment.<br />

High and Not So Dry<br />

One of <strong>the</strong> first challenges Wellensiek and <strong>the</strong><br />

<strong>BTrenchless</strong> crew faced was elevation. Wellensiek said,<br />

“Pagosa Spr<strong>in</strong>gs sits at an elevation of 7,100 feet above<br />

sea level. That has a direct impact on <strong>the</strong> capacity of<br />

your air compressor system.”<br />

Ano<strong>the</strong>r difficult aspect of <strong>the</strong> project was ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g<br />

dra<strong>in</strong>age flow through <strong>the</strong> exist<strong>in</strong>g culvert while<br />

ramm<strong>in</strong>g. Wellensiek said, “At times <strong>the</strong>re was really<br />

low flow. Twice dur<strong>in</strong>g this project we were completely<br />

flooded out because of ra<strong>in</strong> and <strong>the</strong>re was no way to<br />

handle that amount of water. So basically we stopped,<br />

and got out of <strong>the</strong> way. There was noth<strong>in</strong>g else we<br />

could do.”<br />

On <strong>the</strong> Job<br />

<strong>BTrenchless</strong> crews excavated a ramm<strong>in</strong>g pit on <strong>the</strong><br />

1 - 8 0 0 - 5 3 3 - 2 0 7 8 • w w w . t t t e c h n o l o g i e s . c o m

south side of <strong>the</strong> road and prepared a ramm<strong>in</strong>g pad<br />

by layer<strong>in</strong>g approximately 18 <strong>in</strong>ches of <strong>in</strong>ch-and-a-half<br />

rock <strong>in</strong> <strong>the</strong> bottom of <strong>the</strong> pit. Once complete crews<br />

assembled <strong>the</strong> 60-<strong>in</strong>ch jack and bor<strong>in</strong>g mach<strong>in</strong>e. The<br />

rails of <strong>the</strong> mach<strong>in</strong>e were used to support and guide <strong>the</strong><br />

new 84-<strong>in</strong>ch cas<strong>in</strong>g dur<strong>in</strong>g <strong>the</strong> pipe ramm<strong>in</strong>g process.<br />

Once <strong>the</strong> cas<strong>in</strong>g was placed <strong>in</strong> position, crews made<br />

<strong>the</strong> connection between <strong>the</strong> 84-<strong>in</strong>ch cas<strong>in</strong>g and <strong>the</strong> 24-<br />

<strong>in</strong>ch pie rammer. Melv<strong>in</strong> expla<strong>in</strong>ed, “The connection<br />

between <strong>the</strong> tool and <strong>the</strong> cas<strong>in</strong>g is made through a<br />

tapered ram cone and 84-<strong>in</strong>ch cotter segments. This<br />

configuration ensures that <strong>the</strong> maximum driv<strong>in</strong>g force<br />

is transferred to <strong>the</strong> pipe. In <strong>the</strong> past, ramm<strong>in</strong>g a cas<strong>in</strong>g<br />

of this diameter would have required a fabricated<br />

ramm<strong>in</strong>g adapter, but as <strong>the</strong> demand for larger and<br />

large diameter ramm<strong>in</strong>g equipment has <strong>in</strong>creased, we<br />

(TT Technologies) now offer standard ramm<strong>in</strong>g gear for<br />

cas<strong>in</strong>g diameters as large as 96 <strong>in</strong>ches. This saves<br />

time and money for <strong>the</strong> contractor.”<br />

Accord<strong>in</strong>g to Wellensiek, remov<strong>in</strong>g <strong>the</strong> exist<strong>in</strong>g CMP<br />

pipe was a challenge once <strong>the</strong> ramm<strong>in</strong>g was complete.<br />

He said, “When <strong>the</strong> new cas<strong>in</strong>g was hammered over<br />

an exist<strong>in</strong>g pipe we encountered some 30-<strong>in</strong>ch m<strong>in</strong>us<br />

rock dur<strong>in</strong>g <strong>the</strong> process. These rocks were pushed<br />

<strong>in</strong>to <strong>the</strong> exist<strong>in</strong>g CMP. In addition, as <strong>the</strong> cas<strong>in</strong>g was<br />

hammered, <strong>the</strong> ground was compressed around <strong>the</strong><br />

exist<strong>in</strong>g CMP multi plate. We needed use an acetylene<br />

torch to cut <strong>the</strong> CMP <strong>in</strong>to 10-foot sections. Then, we<br />

pulled out those sections with <strong>the</strong> bor<strong>in</strong>g mach<strong>in</strong>e.”<br />

After <strong>the</strong> old CMP pipe was removed and all <strong>the</strong> spoil<br />

cleaned out, <strong>the</strong> new 60-<strong>in</strong>ch RCP culvert was jacked<br />

<strong>in</strong>to place. Fly ash was used to fill <strong>the</strong> annular between<br />

<strong>the</strong> new 60-<strong>in</strong>ch pipe and <strong>the</strong> 84-<strong>in</strong>ch cas<strong>in</strong>g.<br />

Wellensiek was impressed with <strong>the</strong> results. He said,<br />

“I was really pleasantly surprised that that 84-<strong>in</strong>ch<br />

cas<strong>in</strong>g went across <strong>the</strong>re as quickly as it did. The real<br />

challeng<strong>in</strong>g part was ma<strong>in</strong>ta<strong>in</strong><strong>in</strong>g <strong>the</strong> water flow through<br />

<strong>the</strong>re. But now that we’ve gotten through that, we know<br />

we’d be able to do it aga<strong>in</strong>.”<br />

Melv<strong>in</strong> said, “The <strong>BTrenchless</strong> crew really did a great<br />

job on this project. It was very challeng<strong>in</strong>g from start<br />

to f<strong>in</strong>ish, but <strong>the</strong>se guys know what <strong>the</strong>y’re do<strong>in</strong>g and<br />

do it well.”<br />

Jim Schill<br />

Technical Writer<br />

Mankato, MN<br />

2020 E New York Street • Aurora, IL 60502 • 1-800-533-2078 • 1-630-851-8200 • FAX 1-630-851-8299<br />

www.tttechnologies.com • E-mail <strong>in</strong>fo@tttechnologies.com<br />

Copyright© 2007, TT Technologies, Inc.<br />

GRUNDORAM is a registered<br />

trademark of TT Technologies, Inc.<br />

Specifications subject to change at any time.