Education - UNIMAT in der Schule

Education - UNIMAT in der Schule

Education - UNIMAT in der Schule

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Secundary_E-29.06.2011<br />

QUalIty<br />

PRODUCT<br />

The bed is a robust base that connects to the headstock and permits the<br />

carriage and tailstock to be aligned parallelly with the axis of the sp<strong>in</strong>dle.<br />

The headstock houses the ma<strong>in</strong> sp<strong>in</strong>dle, speed change mechanism and<br />

mostly gears to change the rotation speed. The headstock is required<br />

to be made as robust as possible due to the cutt<strong>in</strong>g forces <strong>in</strong>volved.The<br />

ma<strong>in</strong> sp<strong>in</strong>dle is generally hollow to allow long bars to extend through<br />

to the work area. The sp<strong>in</strong>dle runs <strong>in</strong> precisie bear<strong>in</strong>gs and is fitted with<br />

some means (thread) of attach<strong>in</strong>g work hold<strong>in</strong>g devices like chucks, collets,….<br />

This end of the sp<strong>in</strong>dle will also have an <strong>in</strong>cluded taper, usually<br />

morse, to allow the <strong>in</strong>sertion of tapers and centers.<br />

64<br />

Motor-Head stock unit<br />

Cross-Slide<br />

Chuck<br />

Longitud<strong>in</strong>al-Slide<br />

Cutt<strong>in</strong>g tool<br />

Tool hol<strong>der</strong><br />

Center<br />

Handwheel<br />

(adjustable)<br />

Tailstock<br />

Mach<strong>in</strong>e bed<br />

–<br />

P<strong>in</strong>ole<br />

In its simplest form the carriage holds the tool bit<br />

and moves it longitud<strong>in</strong>ally (turn<strong>in</strong>g) or perpendicularly<br />

(fac<strong>in</strong>g) un<strong>der</strong> the control of the operator.<br />

The operator moves the carriage manually via<br />

the handwheel or automatically by engag<strong>in</strong>g the<br />

feedscrew with the carriage feed mechanism. This<br />

provides some relief for the operator as the movement<br />

of the carriage becomes power assisted.<br />

The cross-slide sits atop the carriage and has a leadscrew that travels perpendicularly<br />

to the ma<strong>in</strong> sp<strong>in</strong>dle axis, this permits fac<strong>in</strong>g operations. This<br />

leadscrew can be engaged with the handwheel or with the feedscrew<br />

(mentioned previously) to provide automated movement to the crossslide.<br />

The compound rest (or slide) is the part of the mach<strong>in</strong>e where the tool<br />

post is mounted. It provides a smaller amount of movement along its axis<br />

via another leadscrew. The compound rest axis can be adjusted <strong>in</strong>dependently<br />

of the carriage or cross-slide. It is utilized when turn<strong>in</strong>g tapers, screw<br />

cutt<strong>in</strong>g or obta<strong>in</strong><strong>in</strong>g f<strong>in</strong>er feeds than the leadscrew normally permits.<br />

The tool bit is mounted <strong>in</strong> the toolpost which may be a two position tool<br />

post (like Unimat) or <strong>in</strong> a quick change style. The advantage of a quick<br />

change set-up is that <strong>in</strong> allowsan unlimited number of tools to be used<br />

(up to the number of hol<strong>der</strong>s available) rather than be<strong>in</strong>g limited to 1 or<br />

2 tools with the 2-position one. Interchangeable tool hol<strong>der</strong>s allow all<br />

the tools to be preset to a center height that will not change, even if the<br />

hol<strong>der</strong> is removed from the mach<strong>in</strong>e.<br />

The tailstock is a toolhol<strong>der</strong> directly mounted on the sp<strong>in</strong>dle axis, opposite<br />

the headstock. The p<strong>in</strong>ole does not rotate but does travel longitud<strong>in</strong>ally<br />

un<strong>der</strong> the action of the handwheel. The sp<strong>in</strong>dle <strong>in</strong>cludes a taper to<br />

hold drill bits, centers and other tool<strong>in</strong>g. The tailstock can be positioned<br />

along the bed and clamped <strong>in</strong> position as required. There is also provision<br />

to offset the tailstock from the sp<strong>in</strong>dles axis, this is useful for turn<strong>in</strong>g<br />

small tapers.<br />

65<br />

Lathe around 1889. Left: headstock with different gears,<br />

right: tailstock and <strong>in</strong> the middle the carriage<br />

–<br />

116<br />

Workpiece. 2 such pieces have to be processed<br />

Detail view: Detail B with the measurements<br />

of the p<strong>in</strong>s <strong>in</strong> mm<br />

Side view with measurements <strong>in</strong> mm<br />

Ready workpieces apart and put together<br />

–<br />

<strong>Education</strong><br />

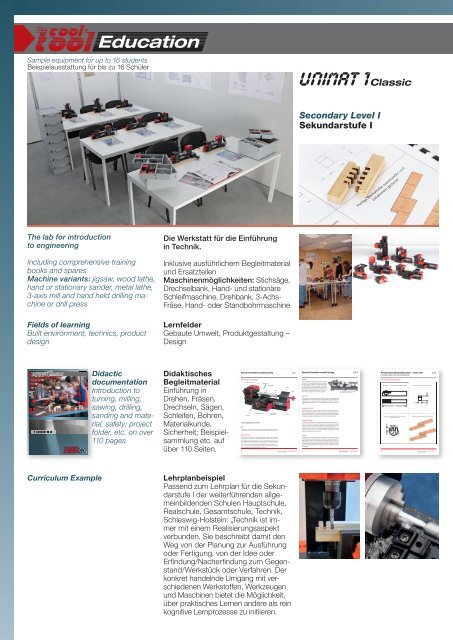

Sample equipment for up to 16 students<br />

Beispielausstattung für bis zu 16 Schüler<br />

Secondary Level I<br />

Sekundarstufe I<br />

The lab for <strong>in</strong>troduction<br />

to eng<strong>in</strong>eer<strong>in</strong>g<br />

Includ<strong>in</strong>g comprehensive tra<strong>in</strong><strong>in</strong>g<br />

books and spares<br />

Mach<strong>in</strong>e variants: jigsaw, wood lathe,<br />

hand or stationary san<strong>der</strong>, metal lathe,<br />

3-axis mill and hand held drill<strong>in</strong>g mach<strong>in</strong>e<br />

or drill press<br />

Fields of learn<strong>in</strong>g<br />

Built environment, technics, product<br />

design<br />

Die Werkstatt für die E<strong>in</strong>führung<br />

<strong>in</strong> Technik.<br />

Inklusive ausführlichem Begleitmaterial<br />

und Ersatzteilen<br />

Masch<strong>in</strong>enmöglichkeiten: Stichsäge,<br />

Drechselbank, Hand- und stationäre<br />

Schleifmasch<strong>in</strong>e, Drehbank, 3-Achs-<br />

Fräse, Hand- o<strong>der</strong> Standbohrmasch<strong>in</strong>e<br />

Lernfel<strong>der</strong><br />

Gebaute Umwelt, Produktgestaltung –<br />

Design<br />

[SEcondary lEvEl]<br />

MADE IN<br />

aUStrIa<br />

Didactic<br />

documentation<br />

Introduction to<br />

turn<strong>in</strong>g, mill<strong>in</strong>g,<br />

saw<strong>in</strong>g, drill<strong>in</strong>g,<br />

sand<strong>in</strong>g and material,<br />

safety; project<br />

fol<strong>der</strong>, etc. on over<br />

110 pages<br />

Didaktisches<br />

Begleitmaterial<br />

E<strong>in</strong>führung <strong>in</strong><br />

Drehen, Fräsen,<br />

Drechseln, Sägen,<br />

Schleifen, Bohren,<br />

Materialkunde,<br />

Sicherheit; Beispielsammlung<br />

etc. auf<br />

über 110 Seiten.<br />

general <strong>in</strong>formation on metal turn<strong>in</strong>g 2.1.1<br />

the major parts of a metal lathe<br />

the most important parts of a lathe<br />

Bed<br />

Motor-Headstock<br />

general <strong>in</strong>formation on metal turn<strong>in</strong>g 2.1.1<br />

Carriage<br />

Cross-slide<br />

Compound rest (slide)<br />

toolpost /tool hol<strong>der</strong><br />

tailstock<br />

Mill<strong>in</strong>g Project Woodwork<strong>in</strong>g Jo<strong>in</strong>ts – F<strong>in</strong>ger Jo<strong>in</strong>t 2.2.4<br />

Connect<strong>in</strong>g two pieces of wood with <strong>in</strong>terlock<strong>in</strong>g notches<br />

<strong>in</strong>structions for the project f<strong>in</strong>ger jo<strong>in</strong>t<br />

Curriculum Example<br />

Lehrplanbeispiel<br />

Passend zum Lehrplan für die Sekundarstufe<br />

I <strong>der</strong> weiterführenden allgeme<strong>in</strong>bildenden<br />

<strong>Schule</strong>n Hauptschule,<br />

Realschule, Gesamtschule, Technik,<br />

Schleswig-Holste<strong>in</strong>: „Technik ist immer<br />

mit e<strong>in</strong>em Realisierungsaspekt<br />

verbunden. Sie beschreibt damit den<br />

Weg von <strong>der</strong> Planung zur Ausführung<br />

o<strong>der</strong> Fertigung, von <strong>der</strong> Idee o<strong>der</strong><br />

Erf<strong>in</strong>dung/Nacherf<strong>in</strong>dung zum Gegenstand/Werkstück<br />

o<strong>der</strong> Verfahren. Der<br />

konkret handelnde Umgang mit verschiedenen<br />

Werkstoffen, Werkzeugen<br />

und Masch<strong>in</strong>en bietet die Möglichkeit,<br />

über praktisches Lernen an<strong>der</strong>e als re<strong>in</strong><br />

kognitive Lernprozesse zu <strong>in</strong>itiieren.