Product catalogue: Automatic control and heat ... - Polna S.A.

Product catalogue: Automatic control and heat ... - Polna S.A.

Product catalogue: Automatic control and heat ... - Polna S.A.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

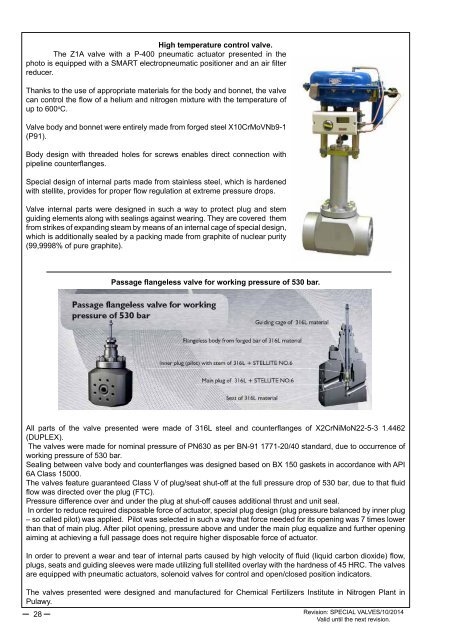

High temperature <strong>control</strong> valve.<br />

The Z1A valve with a P-400 pneumatic actuator presented in the<br />

photo is equipped with a SMART electropneumatic positioner <strong>and</strong> an air filter<br />

reducer.<br />

Thanks to the use of appropriate materials for the body <strong>and</strong> bonnet, the valve<br />

can <strong>control</strong> the flow of a helium <strong>and</strong> nitrogen mixture with the temperature of<br />

up to 600 o C.<br />

Valve body <strong>and</strong> bonnet were entirely made from forged steel X10CrMoVNb9-1<br />

(P91).<br />

Body design with threaded holes for screws enables direct connection with<br />

pipeline counterflanges.<br />

Special design of internal parts made from stainless steel, which is hardened<br />

with stellite, provides for proper flow regulation at extreme pressure drops.<br />

Valve internal parts were designed in such a way to protect plug <strong>and</strong> stem<br />

guiding elements along with sealings against wearing. They are covered them<br />

from strikes of exp<strong>and</strong>ing steam by means of an internal cage of special design,<br />

which is additionally sealed by a packing made from graphite of nuclear purity<br />

(99,9998% of pure graphite).<br />

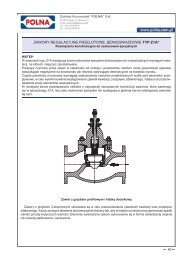

Passage flangeless valve for working pressure of 530 bar.<br />

All parts of the valve presented were made of 316L steel <strong>and</strong> counterflanges of X2CrNiMoN22-5-3 1.4462<br />

(DUPLEX).<br />

The valves were made for nominal pressure of PN630 as per BN-91 1771-20/40 st<strong>and</strong>ard, due to occurrence of<br />

working pressure of 530 bar.<br />

Sealing between valve body <strong>and</strong> counterflanges was designed based on BX 150 gaskets in accordance with API<br />

6A Class 15000.<br />

The valves feature guaranteed Class V of plug/seat shut-off at the full pressure drop of 530 bar, due to that fluid<br />

flow was directed over the plug (FTC).<br />

Pressure difference over <strong>and</strong> under the plug at shut-off causes additional thrust <strong>and</strong> unit seal.<br />

In order to reduce required disposable force of actuator, special plug design (plug pressure balanced by inner plug<br />

– so called pilot) was applied. Pilot was selected in such a way that force needed for its opening was 7 times lower<br />

than that of main plug. After pilot opening, pressure above <strong>and</strong> under the main plug equalize <strong>and</strong> further opening<br />

aiming at achieving a full passage does not require higher disposable force of actuator.<br />

In order to prevent a wear <strong>and</strong> tear of internal parts caused by high velocity of fluid (liquid carbon dioxide) flow,<br />

plugs, seats <strong>and</strong> guiding sleeves were made utilizing full stellited overlay with the hardness of 45 HRC. The valves<br />

are equipped with pneumatic actuators, solenoid valves for <strong>control</strong> <strong>and</strong> open/closed position indicators.<br />

The valves presented were designed <strong>and</strong> manufactured for Chemical Fertilizers Institute in Nitrogen Plant in<br />

Pulawy.<br />

28 Revision: SPECIAL VALVES/10/2014<br />

Valid until the next revision.