autojet® antimicrobial spray systems - Spraying Systems Co.

autojet® antimicrobial spray systems - Spraying Systems Co.

autojet® antimicrobial spray systems - Spraying Systems Co.

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

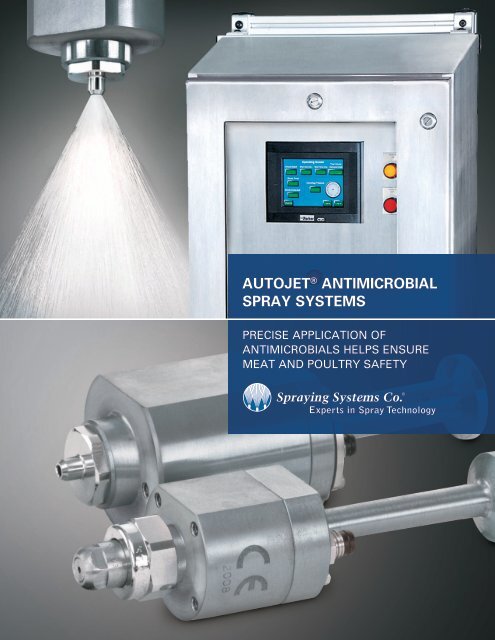

AUTOJET ® ANTIMICROBIAL<br />

SPRAY SYSTEMS<br />

PRECISE APPLICATION OF<br />

ANTIMICROBIALS HELPS ENSURE<br />

MEAT AND POULTRY SAFETY<br />

Experts in Spray Technology

ENSURE FOOD SAFETY,<br />

INCREASE PRODUCTIVITY<br />

AND REDUCE CHEMICAL USE<br />

SYSTEM OVERVIEW:<br />

Meat and poultry processors all have a common goal —<br />

to ensure the highest level of food safety possible while<br />

minimizing production costs. AutoJet ® Antimicrobial Spray<br />

<strong>Systems</strong> help processors achieve these goals by eliminating<br />

slower, more expensive post-pasteurization techniques.<br />

AutoJet Antimicrobial Spray <strong>Systems</strong> apply a predetermined<br />

volume of <strong>antimicrobial</strong> agent onto each product or into<br />

each package. An AutoJet <strong>spray</strong> controller monitors liquid<br />

pressure and flow from PulsaJet ® automatic <strong>spray</strong> nozzles<br />

to ensure the proper volume of <strong>antimicrobial</strong> is delivered to<br />

each product.<br />

Used successfully with several commercially-available<br />

topical <strong>antimicrobial</strong>s, the efficacy of this technology has<br />

been established by the USDA/ARS.<br />

The <strong>systems</strong> have a proven track record of effectively<br />

controlling pathogens including E. coli, Salmonella and<br />

Listeria monocytogenes while reducing operating costs<br />

for processors. Using this technology, some customers<br />

have eliminated the need for lactates, diacetates and other<br />

internal <strong>antimicrobial</strong>s entirely.<br />

AutoJet Antimicrobial Spray <strong>Systems</strong> can be incorporated<br />

into existing HACCP plans. An optional auto-refill/ratio panel<br />

is available to continuously monitor the fluid level in the<br />

pressure tank and trigger a refill cycle when necessary. The<br />

auto-refill/ratio panel also dilutes concentrated <strong>antimicrobial</strong><br />

to the proper ratio for application.<br />

2 <strong>spray</strong>.com | 1.800.95.SPRAY | Intl. Tel: 1.630.665.5000

BENEFITS:<br />

• Closed-loop control ensures precise application of <strong>antimicrobial</strong><br />

for consistent performance and minimal waste<br />

• Different shot sizes and timing intervals can be<br />

pre-programmed for automatic batch changes<br />

• Pressure tank is easy to assemble/disassemble and clean<br />

• Easy integration in existing product lines<br />

• Unattended operation – alarms notify workers if intervention<br />

is required<br />

• Optional auto-refill/ratio panel triggers tank refill and<br />

maintains proper <strong>antimicrobial</strong> concentration<br />

SYSTEM MODULES:<br />

Application requirements determine the actual<br />

configuration of an AutoJet ® Antimicrobial Spray System.<br />

Key components include PulsaJet ® electric <strong>spray</strong> nozzles<br />

with FDA-compliant finishes, an Allen-Bradley PLC and a<br />

pressure pot.<br />

IDEAL FOR:<br />

• Bagged whole muscle products<br />

• Hot dogs, links and formed products<br />

• Fresh meats – subprimals and trim<br />

• Packaged poultry products<br />

• Sliced meat and poultry products<br />

<strong>spray</strong>.com | 1.800.95.SPRAY | Intl. Tel: 1.630.665.5000<br />

3

Trigger sensor<br />

PulsaJet ® nozzle<br />

Antimicrobial<br />

PulsaJet nozzles<br />

Thru-beam<br />

photo-eye<br />

PulsaJet nozzles<br />

BAGGED WHOLE MUSCLE<br />

PRODUCTS AND HOT DOGS<br />

FRESH MEATS<br />

Antimicrobials are <strong>spray</strong>ed into the vacuum packages<br />

before sealing. Vacuum-sealing of the packages<br />

distributes the <strong>antimicrobial</strong> evenly around the product.<br />

The efficacy of this SLIC ® (Sprayed Lethality in <strong>Co</strong>ntainer)<br />

process has been established by the USDA/ARS.<br />

<strong>Co</strong>nveyorized meat and poultry products are <strong>spray</strong>ed<br />

with multiple PulsaJet nozzles within an enclosed<br />

<strong>spray</strong> station, typically located before injectors/<br />

tenderizers or immediately prior to packaging.<br />

4 <strong>spray</strong>.com | 1.800.95.SPRAY | Intl. Tel: 1.630.665.5000

PulsaJet nozzles<br />

Antimicrobial<br />

TUMBLERS, MIXERS AND<br />

BLENDERS<br />

SLICED PRODUCTS<br />

Meat trim pieces inside tumblers, mixers and blenders<br />

are <strong>spray</strong>ed with multiple PulsaJet ® nozzles to ensure<br />

even coating of all pieces before the grinding process.<br />

Tests have shown consistent coverage throughout<br />

ground meat packages using the AutoJet ® Antimicrobial<br />

Spray System.<br />

Integrated into the most advanced slicing <strong>systems</strong> on<br />

the market and synchronized with blade movement, high<br />

speed PulsaJet automatic <strong>spray</strong> nozzles apply precise<br />

<strong>antimicrobial</strong> doses to each sliced product prior to<br />

packaging. Additional <strong>antimicrobial</strong>s are added to each<br />

package to cover all surfaces of the stack.<br />

<strong>spray</strong>.com | 1.800.95.SPRAY | Intl. Tel: 1.630.665.5000<br />

5

RESULTS EXPERIENCED BY<br />

PROCESSORS<br />

OLD WORLD PROVISIONS: ANNUAL SAVINGS OF $300,000<br />

Old World Provisions, a meat processor specializing in whole<br />

muscle products and roll stock products, decided to use the<br />

AutoJet ® Antimicrobial Spray System to reduce the expense<br />

of the functional ingredients used as <strong>antimicrobial</strong> agents. A<br />

single system is being used on a roll stock line and a bagger<br />

operating at six packages per minute.<br />

The outcome has exceeded expectations.<br />

• The use of an <strong>antimicrobial</strong> agent that cost $0.025 to $0.030<br />

per pound was eliminated. Lauric arginate diluted in a clarified<br />

liquid smoke is now used at an application cost of just<br />

$0.015 per pound<br />

• Typical log reductions ranging from 1.8 to 2.8 for roll stock<br />

and whole muscle products<br />

• Product quality and shelf life have remained stable<br />

• Product labels are clean<br />

• The use of lower cost <strong>antimicrobial</strong>s saves the company<br />

$300,000 each year<br />

6 <strong>spray</strong>.com | 1.800.95.SPRAY | Intl. Tel: 1.630.665.5000

JOHN MORRELL & CO.: ELIMINATED USE OF<br />

LACTATES/DIACETATES<br />

John Morrell & <strong>Co</strong>., a subsidiary of Smithfield Foods, Inc., is<br />

the largest vertically integrated producer of processed meat<br />

and fresh pork in the United States. <strong>Co</strong>ncerned about the flavor<br />

of certain hams containing lactates/diacetates, the company<br />

opted to treat them externally with lauric arginate using<br />

an AutoJet ® Antimicrobial Spray System.<br />

The results are impressive.<br />

• Improved product flavor<br />

• 1 to 2 log kill against Listeria monocytogenes<br />

• The process is even more efficacious on products that<br />

include other <strong>antimicrobial</strong>s, such as a cured product containing<br />

nitrite<br />

• Product labels are clean<br />

NORTH COUNTRY SMOKEHOUSE:<br />

40% INCREASE IN SHELF LIFE, ALT-2 STATUS<br />

ACHIEVED<br />

North <strong>Co</strong>untry Smokehouse, a family-run smokehouse, has<br />

been using the system on a wide variety of meat products.<br />

The results include:<br />

• An increase in product shelf life to 70 days from 45 to 50 – a<br />

40% increase<br />

• Achievement of ALT-2 status at a cost of $0.015 per pound<br />

on products using a lauric arginate and liquid smoke flavor<br />

<strong>antimicrobial</strong><br />

• Typical log reductions range from 2.3 for hams to 4.0 for<br />

kielbasa<br />

• Clean label on products maintained – lauric arginate is a<br />

bacteriocide that is also considered a processing aid and<br />

does not need to be labeled at the levels being used<br />

NORTH COUNTRY<br />

SMOKEHOUSE<br />

<strong>spray</strong>.com | 1.800.95.SPRAY | Intl. Tel: 1.630.665.5000<br />

7

AUTOJET ® ANTIMICROBIAL SPRAY<br />

SYSTEM DETAILS<br />

SPECIFICATIONS:<br />

<strong>Co</strong>ntrol Module<br />

• 6 in. (15.24 cm) touch screen provides easy user interface to Allen-Bradley PLC<br />

• Adjustable <strong>spray</strong> timing for volumes ranging from 0.25 cc/shot to 45 cc/shot<br />

• Wall-mount, NEMA 4X rated panel<br />

• Optional 2- and 4-channel capability provides independent control for multiple <strong>spray</strong> stations<br />

• NEMA 4X sensors for product detection and for triggering <strong>spray</strong><br />

Supply Modules<br />

• Polished stainless steel 25-gallon (95-liter) pressure pot with tri-clover sanitary fittings. Also available with stainless steel<br />

washdown rated pumps<br />

• Liquid level sensor notifies operator when refill needed<br />

• Optional automatic refill panel triggers pressure tank refill when sensor falls below threshold without disturbing pressure<br />

level<br />

• Pressure relief valve provides safety release<br />

• Pressure transmitter allows operator to view the operating pressure<br />

Delivery Module<br />

• PulsaJet ® high-speed automatic electric <strong>spray</strong> nozzle provides accurate, rapid, repeatable dose sizes<br />

• Multiple mounting options are available for roll stock and bagging machines from Cryovac ® , Multivac ® , RapidPak ® , VC999 ®<br />

and others<br />

• Fully adjustable armature allows precise vertical and horizontal positioning<br />

Alarm<br />

• Stack light on top of control panel provides multi-colored lights for general alarms and tank low level<br />

Experts in Spray Technology<br />

North Avenue and Schmale Road, P.O. Box 7900, Wheaton, IL 60187-7901 USA<br />

Tel: 1.800.95.SPRAY Intl. Tel: 1.630.665.5000<br />

Fax: 1.888.95.SPRAY Intl. Fax: 1.630.260.0842<br />

www.<strong>spray</strong>.com<br />

<strong>Spraying</strong> <strong>Systems</strong> <strong>Co</strong>., AutoJet and PulsaJet are registered<br />

trademarks of <strong>Spraying</strong> <strong>Systems</strong> <strong>Co</strong>. All other logos and<br />

trademarks are the property of the respective trademark<br />

owners. ® and denote registered trademarks in the<br />

United States and other countries.<br />

Bulletin No. 647C ©<strong>Spraying</strong> <strong>Systems</strong> <strong>Co</strong>. 2013