Green Technologies for the Leather Production- Clariant - CLRI

Green Technologies for the Leather Production- Clariant - CLRI

Green Technologies for the Leather Production- Clariant - CLRI

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

lConfidential<br />

Global Bu Lea<strong>the</strong>r Lea<strong>the</strong>r Services Business<br />

Head of Marketing & Sales<br />

Harald Bauer<br />

07.09.2010<br />

<strong>Green</strong> <strong>Technologies</strong> <strong>for</strong> <strong>the</strong> Lea<strong>the</strong>r<br />

<strong>Production</strong><br />

45th Lea<strong>the</strong>r Research Industry Get Toge<strong>the</strong>r (LERIG)<br />

29 January 2011<br />

Agenda<br />

Ecological Lea<strong>the</strong>r <strong>Production</strong><br />

Ecological Update<br />

Tanning<br />

Retanning, Fatliquoring<br />

Finishing<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 2<br />

1

<strong>Green</strong> Lea<strong>the</strong>r – Industry Achievements<br />

in <strong>the</strong> Past<br />

Wet White tanning as alternative to Chrome tanning<br />

Enzymatic Unhairing process<br />

Continous improvement of chemical exhaustion <strong>for</strong> <strong>the</strong> beamhouse, tanning and wet end processes<br />

Complete waterborne finishing replacing solvent systems or solvent/water emulsions<br />

Replacement of hazardous substances (Nonylphenols, Phthalates, Ethylglycol, Dimethyl<strong>for</strong>mamide,<br />

cancerogenic azo dyes and aromatic amines, lead chromate pigments, short chain chloro paraffins)<br />

Development of Upgrading technologies <strong>for</strong> improved raw hide utilization<br />

Continuous chemical reduction in finishing (low pressure spraying, RRC technology)<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 3<br />

Stakeholder <strong>for</strong> <strong>the</strong> Lea<strong>the</strong>r –<br />

Manufacturing Process<br />

Economy<br />

Environment<br />

<strong>Clariant</strong><br />

Technical Balance<br />

Support<br />

Customer<br />

Demand<br />

High Yield – Low Resources<br />

• Minimizing Water quantity<br />

• Minimizing chemical demand<br />

• Minimal chemical and water waste<br />

• Minimal lea<strong>the</strong>r waste<br />

• Maximizing lea<strong>the</strong>r yield<br />

High Speed – Low Cost<br />

• Lowest production costs<br />

• <strong>Production</strong> speed<br />

• Highest production yield<br />

• Lowest waste<br />

• Lowest chemical and water consumption<br />

High Quality – Low Cost<br />

• Lea<strong>the</strong>r Quality<br />

• Lowest possible cost<br />

• Lowest possible risk (hazardous substances)<br />

• Fashion, Function<br />

• Wearing com<strong>for</strong>t<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 4<br />

2

<strong>Green</strong> Lea<strong>the</strong>r – New Ecological<br />

Demands<br />

Chemicals<br />

<strong>Green</strong> chemistry in lea<strong>the</strong>r chemicals<br />

Safety<br />

Environmental friendly substances, reduction of hazardous substances<br />

Waste<br />

Raw<br />

material<br />

Updated lea<strong>the</strong>r production with minimized waste and resources<br />

Fur<strong>the</strong>r development of <strong>the</strong> manufacturing process with maximizing <strong>the</strong><br />

raw material<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 5<br />

<strong>Green</strong> Lea<strong>the</strong>r – Examples <strong>for</strong> new<br />

achievements<br />

Water/salt<br />

reduction<br />

Process Innovation – New Wet White Tanning Technology<br />

Chemicals<br />

<strong>Green</strong>er Fatliquors and Retanning Agents<br />

VOC<br />

NMP free Finishing systems<br />

Yield<br />

Modern Upgrading <strong>Technologies</strong><br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 6<br />

3

Agenda<br />

Ecological Lea<strong>the</strong>r <strong>Production</strong><br />

Ecological Update<br />

Tanning<br />

Retanning, Fatliquoring<br />

Finishing<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 7<br />

Most commonly used mineral free tanning<br />

systems<br />

Phosphonium salts<br />

Glutaraldehyde<br />

Vegetable<br />

Replacement Syntans<br />

Oxazolidine<br />

Metal free Tanning<br />

Systems<br />

Silicates<br />

Oxidisable oil tannage<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 8<br />

4

Why Granofin ® Easy F-90?<br />

Increasing<br />

demand<br />

<strong>for</strong> chrome-free<br />

Lea<strong>the</strong>r<br />

Environment perspective<br />

<strong>Production</strong> perspective<br />

Process<br />

simplification<br />

Increasing<br />

ecological<br />

demand<br />

EasyWhite Tan<br />

Cost reduction<br />

Operator<br />

safety<br />

Environmental<br />

awareness<br />

Less scope<br />

<strong>for</strong> processing<br />

errors<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 9<br />

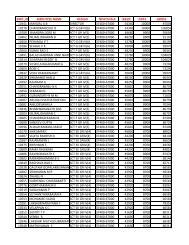

EasyWhite Tan & Wet White comparison<br />

Wet White<br />

Chemical<br />

Time<br />

min<br />

Offer<br />

in Kg<br />

Process %<br />

Pickle 40 Water 8000<br />

7 Salt 15 1400<br />

Add 1 Formic Acid 85% 45 200<br />

Add 0,6 Sulphuric Acid 98% 120 120<br />

Tanning 2,7 Glutaraldehyde (25%) 480 540<br />

Basifi. 0,3 Sodium Bicarbonate 20 60<br />

Add 0,3 Sodium Bicarbonate 20 60<br />

Add 0,2 Sodium Bicarbonate 60 40<br />

Add 0,2 Sodium Bicarbonate 60 40<br />

Add 3 Phenol Syntan p. 60 600<br />

Total 880 3060<br />

EasyWhite Tan<br />

Chemical<br />

Time<br />

min<br />

Offer<br />

in Kg<br />

Process %<br />

Tanning 30 Water 6000<br />

10 Granofin F-90 liq 480 2000<br />

Total 480 2000<br />

Wet White<br />

1 2 3 4 5<br />

Bate<br />

Pickle Tanning Basification Effluent<br />

Deliming<br />

Process considered <strong>for</strong> <strong>the</strong> comparison<br />

EasyWhite<br />

Tan<br />

1 2 3<br />

Bate<br />

Tanning<br />

Deliming<br />

Effluent<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 10<br />

5

Key Points in <strong>the</strong> Process<br />

I<br />

Start pH 8,5 to 7,0 after bating<br />

II Temperature 25°C to 30°C<br />

III Product offer 8% to 10% based on limed /split weight<br />

IV Running time 8 to 12 hours<br />

V Increase temperature after 60-90 min to 30 -35°C<br />

VI Increase temperature after 90-120 min to 40°C<br />

pH<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

pH<br />

New Process with Granofin Easy F90 8<br />

7<br />

6<br />

5<br />

Standard Process<br />

4<br />

3<br />

2<br />

VII Run 6 to 8 hours at 40°C<br />

VIII End pH 4,5 to 5,4<br />

1<br />

1<br />

0<br />

0<br />

Time<br />

0 1 2 3 4 5 6 7 8 9 10<br />

IX Shrinkage temperature 72°C to 75°C<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 11<br />

Customer Benefits through EasyWhiteTan<br />

(Granofin ® Easy F-90)<br />

Process focus EasyWhiteTan<br />

Deliming and bating<br />

(~ 4 h / 1 Check)<br />

Pickle<br />

(~ 2-4 h / 2-3 Checks)<br />

Tanning<br />

(~ 8-12 h / 1 Check)<br />

Basification<br />

(~ 2-3 h / 2 Checks)<br />

Deliming and Bating<br />

(~ 4-6 h / 1 Check)<br />

New compact process– no pickle necessary<br />

(~ 8-12 h / 2 Checks)<br />

Environmentally friendly<br />

Lean production process<br />

Less use of chemicals<br />

Reduction of production time<br />

More consistent production quality<br />

Less scope <strong>for</strong> processing errors<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 12<br />

6

Lea<strong>the</strong>r Properties<br />

Wet<br />

White<br />

Crust<br />

• Excellent grain flatness<br />

• White appearance<br />

• Very tight grain<br />

• Less neck wrinkles<br />

• Good resistance to mould<br />

• Shrinkage temperature ~72 C<br />

• Cationic Character of Wet White<br />

• Suitable <strong>for</strong> shoe upper and fancy lea<strong>the</strong>rs, not only <strong>for</strong> Automotive and Furniture<br />

• More accurate substance control, compare to Glutaraldehyde and THPS<br />

• Less stretch and elasticity<br />

• Less wrinkles, flatter growths marks<br />

• High Whiteness if required<br />

• Very tight grain<br />

• Wide range of articles possible<br />

• Combinable with metal retanning if necessary (chrome, aluminum or zirconium)<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 13<br />

Conclusion<br />

• The technological application of Granofin® Easy<br />

F-90 permits a simplification of <strong>the</strong> current known<br />

processes<br />

• Granofin® Easy F-90 technology is an<br />

environmentally friendly tanning system<br />

• Granofin® Easy F-90 is already in production and<br />

being tested at several customers<br />

– All potential applications not yet evaluated<br />

– Fur<strong>the</strong>r work on optimization of retanning<br />

process – Principal to reduce products used<br />

compare to current production<br />

– Evaluation of products development <strong>for</strong> <strong>the</strong><br />

retanning of EasyWhite Tan<br />

– Results to date extremely promising<br />

EasyWhite Tan<br />

opens new<br />

horizons<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 14<br />

7

Agenda<br />

Ecological Lea<strong>the</strong>r <strong>Production</strong><br />

Ecological Update<br />

Tanning<br />

Retanning, Fatliquoring<br />

Finishing<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 15<br />

Retanning Agents – Ecological Update<br />

Retanning<br />

Agent<br />

Synthanes<br />

Chemistry<br />

• Aromatic base (Phenol,<br />

Naphthalene, cresol etc.) with<br />

sulphonate or hydroxy function<br />

• Formaldehyde condensation<br />

Eco Target<br />

• Residual content of Formaldehyde<br />

and Phenol of both < 50 ppm<br />

Resins<br />

• Urea-Formaldehyde<br />

• Dicyandiamide-Formaldehyde<br />

• Melamine-Formaldehyde<br />

• Residual content of Formaldehyde<br />

< 50 ppm<br />

Polymeric<br />

• Polyacrylic acid<br />

• Combination and copolymerisation<br />

with natural substances<br />

• Incorporation of renewable (and<br />

biodegradable) raw materials<br />

• Tergotan PMB<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 16<br />

8

Fatliquors – Ecological Update<br />

Fatliquors<br />

Natural<br />

Chemistry<br />

• Sulfated or sulfited natural oils<br />

(castor, neatsfoot, soya)<br />

Eco Target<br />

• Long term experience in using<br />

natural oils<br />

• Recovered natural oils<br />

Syn<strong>the</strong>tic<br />

• Alkylsulfosuccinates<br />

• Quaternary amines as cationic<br />

fatliquors<br />

• Use of by-products as raw materials<br />

• Higher exhaustion, lower COD<br />

values <strong>for</strong> <strong>the</strong> waste water<br />

Polymeric<br />

• Polymeric succinates and<br />

sulfosuccinates<br />

• Reuse of syn<strong>the</strong>sis waste as raw<br />

materials<br />

• Higher exhaustion, lower COD<br />

values <strong>for</strong> <strong>the</strong> waste water<br />

• Tergotan PO-60<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 17<br />

Agenda<br />

Ecological Lea<strong>the</strong>r <strong>Production</strong><br />

Ecological Update<br />

Tanning<br />

Retanning, Fatliquoring<br />

Finishing<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 18<br />

9

NMP-free Finishing<br />

VOC<br />

- volatile organic compounds -<br />

Definition<br />

Europe<br />

Definition<br />

USA<br />

• EC Directive 1999/13/EC<br />

- Vapour pressure at 20 C (or at working temperature) over<br />

0.1 hPa<br />

• CFR 40, Part 51.100(s), US EPA<br />

- chemical compounds that take part in photochemical<br />

reactions in <strong>the</strong> atmosphere<br />

• Legislators reducing and making emissions more expensive<br />

‣ Continuous VOC reduction <strong>for</strong> all processors<br />

‣ Continuous VOC reduction <strong>for</strong> all (finishing) chemicals<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 20<br />

10

NMP and VOC<br />

Boiling point<br />

at normal pressure<br />

Vapour<br />

pressure*<br />

Ethanol 78 C 79 hPa<br />

Water 100 C 32 hPa<br />

Butyl acetate 125 C 17 hPa<br />

Butyl glycol 171 C 1.5 hPa<br />

NMP 202 C 0.4 hPa<br />

VOC (EU)<br />

> 0.1 hPa<br />

Ethylene glycol 197 C < 0.1 hPa<br />

* CRC Handbook of Chemistry And Physics<br />

NMP is a VOC according to EU and US definitions<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 21<br />

NMP – N-methylpyrrolidone –<br />

Properties<br />

Chemically stable<br />

Polar solvent – Completely soluble in water<br />

O<br />

Good miscibility with organic compounds<br />

Aprotic – No reaction with isocyanate<br />

Reduces surface tension<br />

pH-neutral<br />

N<br />

CH 3<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 22<br />

11

<strong>Production</strong> process<br />

Acetone vs. Prepolymer ionomer process<br />

A) Acetone process<br />

first<br />

reaction<br />

step<br />

dispersion<br />

with<br />

water<br />

second<br />

reaction<br />

step,<br />

distillation<br />

monomers<br />

in solvent<br />

prepolymer<br />

in solvent<br />

prepolymer dispersion<br />

containing solvent<br />

solvent free<br />

polymer dispersion<br />

B) Prepolymer ionomer process<br />

first<br />

reaction<br />

step<br />

dispersion<br />

in<br />

water<br />

second<br />

reaction<br />

step<br />

monomers<br />

with NMP<br />

prepolymer<br />

with NMP<br />

prepolymer dispersion<br />

containing NMP<br />

polymer dispersion<br />

containing NMP<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 23<br />

NMP as a coalescing agent<br />

Miscible with water and many solvents<br />

Water evaporates<br />

Primary dispersion<br />

Reduces <strong>the</strong> MFT<br />

Improves flow<br />

Simplifies film <strong>for</strong>mation<br />

De<strong>for</strong>mation of <strong>the</strong><br />

polymer particles<br />

Interdiffusion<br />

Packing of spheres<br />

Packing of rhombic<br />

dodecahedrons<br />

Coalescing agent<br />

promotes interdiffusion<br />

and dissolution<br />

of boundary surfaces<br />

Film<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 24<br />

12

NMP in lea<strong>the</strong>r<br />

Partial dissolution of lipophilic substances<br />

DT<br />

H 2 O<br />

H 2 O<br />

NMP<br />

Greasing agents<br />

Retanning agents<br />

Dyestuffs<br />

(Hydro)<strong>the</strong>rmal processes in <strong>the</strong><br />

finished lea<strong>the</strong>r<br />

• Natural ageing processes<br />

• Artificial ageing test<br />

• Migration into <strong>the</strong> crust<br />

• Partial dissolution of watersoluble<br />

and, above all, lipidsoluble<br />

substances<br />

• Promotion of migration to<br />

<strong>the</strong> (finished) surface<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 25<br />

New procedure <strong>for</strong> NMP-free<br />

polyurethane dispersion<br />

Water<br />

Polyol<br />

Finished PUR<br />

dispersion<br />

Isocyanate<br />

Auxiliary agent<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 26<br />

13

NMP – Legal developments and measures<br />

taken by <strong>Clariant</strong><br />

International legislation<br />

2001 2003 2004 2005 … 2010<br />

Addition of NMP<br />

in Cali<strong>for</strong>nia 2001 to<br />

Proposition 65<br />

EU resolution to<br />

reclassify NMP<br />

End of <strong>the</strong><br />

transitional<br />

period Binding<br />

EU classification<br />

<strong>Clariant</strong><br />

Future<br />

Project start<br />

Oct 2001<br />

Binding agent syn<strong>the</strong>ses<br />

without NMP<br />

1 st generation<br />

Feb 2004<br />

Complete NMP-free<br />

finishes<br />

Standard<br />

products<br />

Apr 2005<br />

All standard products<br />

are NMP free<br />

>2010<br />

Fur<strong>the</strong>r reductions in VOCs<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 27<br />

Topcoats – Highest per<strong>for</strong>mance<br />

without NMP<br />

Application<br />

• Application process<br />

• Process parameters (Flow, viscosity)<br />

Fastness<br />

Aes<strong>the</strong>tics<br />

and haptics<br />

• Wear properties<br />

• Ageing resistance<br />

• Soilability<br />

• Squeaking behaviour<br />

• Cracked grain<br />

• Matt / Gloss grade<br />

• Depth of black<br />

• Feel<br />

No difference<br />

between NMPcontaining<br />

and<br />

modern lacquers!<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 28<br />

14

NMP and VOC content<br />

- Priming-<br />

Priming (example recipe)<br />

2002 Amount NMP VOC EU Since 2005 Amount NMP VOC EU VOC USA<br />

PU binder 300 g 5.2% 6.0% PU binder 300 g 0.0% 0.0% 0.5%<br />

Soft PU 50 g 4.7% 8.3% Soft PU 50 g 0.0% 3.5% 4.0%<br />

Acrylate 100 g 0.0% 0.0% Acrylate 100 g 0.0% 0.0% 0.0%<br />

Pigment 100 g 0.0% 0.0% Pigment 100 g 0.0% 0.0% 0.0%<br />

Matting paste 120 g 0.0% 0.6% Matting paste 120 g 0.0% 0.6% 0.6%<br />

Additive 70 g 0.0% 0.0% Additive 70 g 0.0% 0.0% 0.0%<br />

Wax 30 g 0.0% 0.0% Wax 30 g 0.0% 0.0% 0.2%<br />

Water 230 g Water 230 g<br />

Total 1000 g 1.8% 2.3% Total 1000 g 0.0% 0.2% 0.4%<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 29<br />

NMP and VOC content<br />

- TopCoat -<br />

TopCoat (Example recipe)<br />

2002 Amount NMP VOC EU Since 2005 Amount NMP VOC EU VOC USA<br />

Matting 400 g 7.1% 15.0% Matting 400 g 0.0% 6.3% 6.5%<br />

PU gloss binder 100 g 5.2% 6.0% PU gloss binder 100 g 0.0% 0.0% 0.5%<br />

PU gloss binder 2 80 g 7.0% 8.0% PU gloss binder 2 80 g 0.0% 1.8% 2.3%<br />

Silicon old 60 g 0.0% 35.0% Silicon new 60 g 0.0% 20.0% 21.0%<br />

Isocyanate 60 g 0.0% 20.0% Isocyanate 60 g 0.0% 20.0% 19.8%<br />

Water 300 g Water 300 g<br />

Total 1000 g 3.9% 10.5% Total 1000 g 0.0% 5.1% 5.3%<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 30<br />

15

Summary<br />

• NMP-free products and finishing systems available with<br />

<strong>the</strong> same per<strong>for</strong>mance<br />

• Long-term usability of NMP-related substances is<br />

questionable<br />

• Reduction in NMP is not sufficient to meet car and<br />

furniture manufacturers‘ specifications<br />

• Elimination of NMP succeeded with concomitant<br />

sustainable VOC reduction<br />

By VOC reduction and NMP Elimination sets a new<br />

ecological standard in finishing<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 31<br />

Upgrading<br />

16

Upgrading<br />

Economic Need meets Ecological Benefit<br />

Rawhide Quality available<br />

high<br />

Yield Improvement<br />

Upgrading<br />

Cutting waste reduction<br />

Resource optimization<br />

low<br />

1980 2011<br />

Demand of Premium Lea<strong>the</strong>r<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 33<br />

Upgrading<br />

Polishing Grounds<br />

• Upgrading of lea<strong>the</strong>r with minor grain defects<br />

• Maintaining <strong>the</strong> natural look, low overloading of <strong>the</strong> grain<br />

• For RRC and spray finishes<br />

• For full grain and corrected grain<br />

• Ironing or polishing, no buffing necessary<br />

• Prebase <strong>for</strong><br />

– Shoe upper<br />

– Furniture<br />

– Garment<br />

– Fancy Goods<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 34<br />

17

Upgrading<br />

Microsphere Technology<br />

RRC Technology<br />

Improvement of filling power and adhesion<br />

Optimized stability at <strong>the</strong> blade/knife<br />

New product: Melio 06-U-78<br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 35<br />

Upgrading<br />

Fur<strong>the</strong>r developments<br />

• Strong covering systems without hardening effects of<br />

classical fillers<br />

• Improved embossing behaviour<br />

• Mechanical and optical properties of binder and filling<br />

materials coming closer<br />

• Filler-Binder Hybrids<br />

New <strong>Technologies</strong><br />

BU Lea<strong>the</strong>r Services, Harald Bauer, Global Head of Markeing & Sales (Copyright <strong>Clariant</strong>. All rights reserved.) Slide 36<br />

18

lConfidential<br />

Global Bu Lea<strong>the</strong>r Lea<strong>the</strong>r Services Business<br />

Head of Marketing & Sales<br />

Harald Bauer<br />

23.01.2011<br />

Thank you very much <strong>for</strong> your<br />

attention<br />

19

![BM DAS Lecture 2010.ppt [Read-Only] - CLRI](https://img.yumpu.com/31533122/1/190x135/bm-das-lecture-2010ppt-read-only-clri.jpg?quality=85)