American Handgunner July/August 1982

American Handgunner July/August 1982

American Handgunner July/August 1982

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

of this in the 'hard fit of the barrel.<br />

Starting with my G.!. barrel, the hood<br />

over the rear of the chamber was extended<br />

by silver soldering a piece of steel strapping<br />

material onto the existing barrel<br />

hood. This was then carefully filed down<br />

and contoured to match a,ll of the original<br />

dimensions except the length. This dverlength<br />

barrel hood was stoned and then<br />

lapped to match the fit between the barrel<br />

hood and breech face. A close fitting barrel<br />

bushing was selected and mated to the<br />

slide and barrel. The last step in the barrel<br />

lowered the bottom edge to clear the ejection<br />

of the fired cases so that they do not<br />

have the dent in the side after firing. Slow<br />

accurate use of a Dremel tool was necessary<br />

for this application. Next I took the<br />

slide to my local gunsmith for a Vs" slot to<br />

be milled for my front sight installation.<br />

Using a piece ofcold rolled Vs" steel plate,<br />

I cut· out a front sight blank and silver<br />

soldered it into place. For a rear sight I<br />

chose the new high fixed sight by Armand<br />

Swenson.<br />

Once the sights were installe4, the gun<br />

much more funnel-like area. With a 20<br />

line-per-inch checkering file, the mainspring<br />

housing was cross checkered to give<br />

added grip security. After all the final<br />

polish and mating of parts, the trigger was<br />

adjusted to a crisp 4 pounds. I had a local<br />

gunsmith reblue the slide. Other parts of<br />

stainless were hand polished with .Simichrome.<br />

A pair of the new Bianchi .45 stocks<br />

were modified so that the front panel was<br />

cut off. With just the side panels of the<br />

Bianchi stocks in place, the front strap<br />

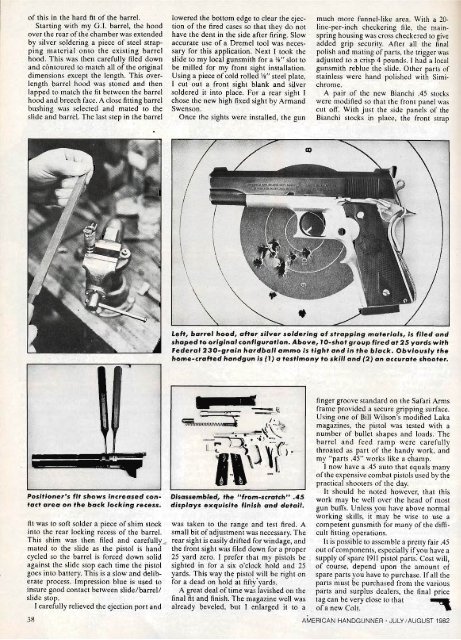

Left, barre' hood, after silver so'dering of strapping materia's, is fi'ed and<br />

shaped to ~rigina'configuration. Above, lO-shot group fired at 25 yards with<br />

Federa' 230-grain hardball ammo is tight and in the b'ack. Obvious'y the<br />

home-crafted handgun is (J) a testimony to skill and (2) an accurate shooter.<br />

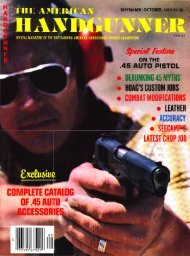

Pos.itioner's fit shows increased contact<br />

area on the back 'ocking recess.<br />

fit was to soft solder a piece of shim stock<br />

into the rear locking recess of the barrel.<br />

This shim was then filed and carefullY-4"<br />

mated to the slide as the pistol is hand<br />

cycled so the barrel is forced down solid<br />

against the slide stop each time the pistol<br />

goes into battery. This is a slow and deliberate<br />

process. Impression blue is used to<br />

insure good contact between slide/barrell<br />

slide stop.<br />

I carefully relieved t/:1e ejection port and<br />

Disassemb'ed, the "from-scratch" .45<br />

disp'ays exquisite finish an~ detail.<br />

was taken to the range and test fired. A<br />

small bit ofadjustment was necessary. The<br />

rear sight is easily drifted for windage, and<br />

the front sight was filed down for a proper<br />

2-5 yard zero. I prefer that my pistols be<br />

sighted in for a six o'clock hold and 25<br />

yards. This way the pistol will be right on<br />

for a dead on hold at fifty·yards.<br />

A great deal of time was lavished on the<br />

final fit and finish. The magazine well was<br />

already beveled, but I enlarged it to a<br />

finger groove standard on the Safari Arms<br />

frame provided a secure gripping surface.<br />

Using one of Bill Wilson's rp.odified Laka<br />

magazines, the pistol was 'tested with a<br />

number of bullet shapes and loads. The<br />

barrel and feed ramp were carefully<br />

throated as part of the handy work, and<br />

my "parts .45" works like a champ.<br />

I now have a .45 auto that equals many<br />

ofthe expensive combat pistols used by the<br />

practical shooters of the day.<br />

It shoulq be noted however, that this<br />

work may be well over the head of most<br />

gun buffs. Unless you have above normal<br />

working skills, it may be wise. to use a<br />

competent gunsmith for many of the difficult<br />

fitting operations. .<br />

It is possible to assemble a pretty fair .45<br />

out ofcomponents, especially ifyou have a<br />

supply of spare 1911 pistol parts. Cost will,<br />

of course, depend upon the amount of<br />

spare parts you have to purchase. If all the<br />

parts must be purchased from the various<br />

parts and surplus dealers, the final price<br />

tag can be very close to·tpat ....<br />

of a new Coil. ~<br />

38 AMERICAN HANDGUNNER . JULY I AUGUST <strong>1982</strong>