Luoyang Hengzheng Copper Industry Co.,Ltd

Copper Spare parts and Cooling elements in metallurgy: 1. Copper cold hearth, copper cooling bed,pour lips, platform for electronic gun for furnace EBCHR(Electric beam cold hearth remelting), EBCHM(Electric beam cold hearth melting), PACHM(Plasma beam cold hearth melting) in efractory and reactive metals (tantalum, niobium, molybdenum, tungsten, vanadium, hafnium, zirconium, titanium) and their alloyssmelting 2. Copper crucible and molds for VAR (Vacuum Arc Remelting ),ESSR and ESR(Electroslag Remelting) Furnace , EBCHM and PACHM furnace water cooling Flat ingot molds (crystallizer) 3. Blast furnace Copper cooler stave and tuyers for steel making 4.Copper Forged contact shoes&clamps and Forged Pressure rings for SAF submerged arc furnace Ferro alloy smelting, copper electrode holder head and electrode plate. 5.Copper cooling jackets and other elements (Outlet, Chute, flue Resistance splash plate,tuyer...)for non-ferrous metal (Cu, Ni, Pb, Zn, PGM, Ag, Au, Ferro alloy etc.) smelting furnace: Ausmet, Isa furnace, Watts furnace, top-blowing furnace, bottom blowing furnace, flash smelting furnace, submerged arc furnace, KIVCET,Ferronickel electric furnace etc. 6.Copper electrode holder and copper electrode block For EAF furnace Chemical: Copper Shell Coal gasification burner, copper flange, Copper nozzel Nuclear: Core test section of CHF (critical heat flux) test setup for the study on IVR (In-Vessel Retention) strategy Others: Copper heating coil, Copper bush, Copper alloy welding pieces , Copper end ring, Copper pressure ring, Machining precision Brasses, Non-standard design copper parts, Tough pitch copper forging piece etc. info@lyhengzheng.com

Copper Spare parts and Cooling elements in metallurgy:

1. Copper cold hearth, copper cooling bed,pour lips, platform for electronic gun for furnace EBCHR(Electric beam cold hearth remelting), EBCHM(Electric beam cold hearth melting), PACHM(Plasma beam cold hearth melting) in efractory and reactive metals (tantalum, niobium, molybdenum, tungsten, vanadium, hafnium, zirconium, titanium) and their alloyssmelting

2. Copper crucible and molds for VAR (Vacuum Arc Remelting ),ESSR and ESR(Electroslag Remelting) Furnace , EBCHM and PACHM furnace water cooling Flat ingot molds (crystallizer)

3. Blast furnace Copper cooler stave and tuyers for steel making

4.Copper Forged contact shoes&clamps and Forged Pressure rings for SAF submerged arc furnace Ferro alloy smelting, copper electrode holder head and electrode plate.

5.Copper cooling jackets and other elements (Outlet, Chute, flue Resistance splash plate,tuyer...)for non-ferrous metal (Cu, Ni, Pb, Zn, PGM, Ag, Au, Ferro alloy etc.) smelting furnace: Ausmet, Isa furnace, Watts furnace, top-blowing furnace, bottom blowing furnace, flash smelting furnace, submerged arc furnace, KIVCET,Ferronickel electric furnace etc.

6.Copper electrode holder and copper electrode block For EAF furnace

Chemical: Copper Shell Coal gasification burner, copper flange, Copper nozzel

Nuclear: Core test section of CHF (critical heat flux) test setup for the study on IVR (In-Vessel Retention) strategy

Others: Copper heating coil, Copper bush, Copper alloy welding pieces , Copper end ring, Copper pressure ring, Machining precision Brasses, Non-standard design copper parts, Tough pitch copper forging piece etc. info@lyhengzheng.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

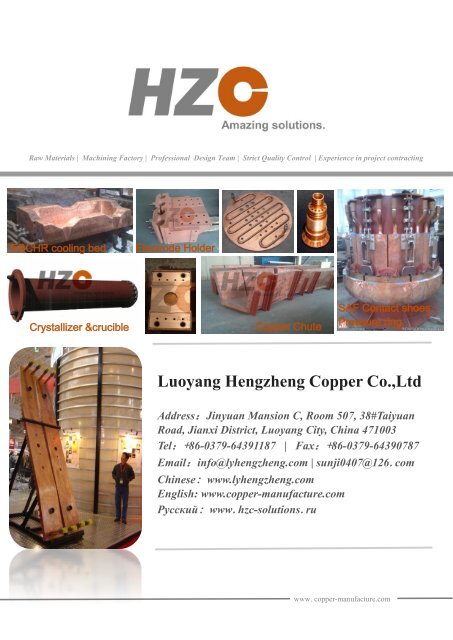

Raw Materials | Machining Factory | Professional Design Team | Strict Quality <strong>Co</strong>ntrol | Experience in project contracting<br />

EBCHR cooling bed<br />

Electrode Holder<br />

Crystallizer &crucible<br />

<strong><strong>Co</strong>pper</strong> Chute<br />

SAF <strong>Co</strong>ntact shoes<br />

Pressure ring<br />

<strong>Luoyang</strong> <strong>Hengzheng</strong> <strong><strong>Co</strong>pper</strong> <strong>Co</strong>.,<strong>Ltd</strong><br />

Address:Jinyuan Mansion C, Room 507, 38#Taiyuan<br />

Road, Jianxi District, <strong>Luoyang</strong> City, China 471003<br />

Tel:+86-0379-64391187 | Fax:+86-0379-64390787<br />

Email:info@lyhengzheng.com | sunji0407@126.com<br />

Chinese: www.lyhengzheng.com<br />

English: www.copper-manufacture.com<br />

Русский: www.hzc-solutions.ru<br />

www. copper-manufacture.com

About Us<br />

<strong>Luoyang</strong> <strong>Hengzheng</strong> copper <strong>Co</strong>., <strong>Ltd</strong>, located in the Chinese ancient city –<br />

<strong>Luoyang</strong>. Own 20 years design, machining, manufacturing experiences in all kinds of<br />

copper deep processing products; HZC is keeping exploring new areas and have good<br />

relationships with the scientific research institutions. HZC are the industry leader in<br />

producing copper cooling elements and equipment used in the iron & steel and nonferrous<br />

metal metallurgy fields, shipbuilding and nuclear power fields. At present we<br />

are the strategic partner with Tenova Group, Saint-Gobain , Baoji Titanium <strong>Industry</strong><br />

<strong>Co</strong>.,<strong>Ltd</strong>, Sunrui Titanium Precision Casting <strong>Co</strong>.,<strong>Ltd</strong>, ALD Vacuum Technology, Clyde<br />

Bergemann Power Group, China Nuclear Power Technology Research Institute etc.<br />

HZC have many advantages and rich experience in manufacturing copper cooling<br />

elements and electrode products.<br />

Raw material advantages: Have various sources in complex copper alloys supplies,<br />

such as Cr-Cu, Cu-Cr-Zr, bronze, cupronickel etc. We can also customize complex<br />

brands copper casting pieces with advantage-raw material: hot rolled wide thick<br />

copper slabs produced by Chinalco <strong>Luoyang</strong> copper; unique brand of TU1/TU2/<br />

TAG0.1/T2/TP2; other brands include brass, bronze and cupronickel alloys. The max<br />

thickness 140mm, the max depth 3000mm, the max length 6000mm. The max length<br />

of the cutting copper bar can reach 12m. The ingots are reliable and of steady supply,<br />

casted from cathode copper. <strong><strong>Co</strong>pper</strong> rube and bar: the max diameter is 420 mm, the<br />

biggest wall thickness 80 mm of the extrusion tube; the max diameter is 360 mm, the<br />

biggest wall thickness 10 mm of the drawn tube; the max diameter is 300 mm of extruding<br />

bar and the diameter is 180 mm of the drawn bar. Having closed cooperation<br />

with many manufacturing factories, enjoying the preferential prices. Keep industry<br />

advantage in the forging copper prices.<br />

<strong>Co</strong>operate Partner<br />

www. copper-manufacture.com

About Us<br />

Technical superiority: a. Experienced senior technical personals in the industry; b.<br />

Solving puzzling questions professionally comprehensively and response speedily; c.<br />

Rich experiences in Optimization of the drawings and drawing inversion of products;<br />

d. Explore new convenient machining process and well know the manufacturing and<br />

machining process.<br />

<strong><strong>Co</strong>pper</strong> <strong>Co</strong>oling elements in metallurgy:<br />

1.Blast furnace <strong><strong>Co</strong>pper</strong> cooling stave for steel making<br />

2.<strong><strong>Co</strong>pper</strong> cooling jackets and other elements (Outlet, Chute, flue Resistance splash<br />

plate...)for non-ferrous metal (Cu, Ni, Pb, Zn, PGM, Ag, Au, Ferro alloy etc.) smelting<br />

furnace: Ausmet, Isa furnace, Watts furnace, top-blowing furnace, bottom blowing<br />

furnace, flash smelting furnace, submerged arc furnace, KIVCET,Ferronickel<br />

electric furnace etc.<br />

3.<strong>Co</strong>ld hearth, copper cooling bed, platform for electronic gun for EB furnace<br />

(EBCHR, EBCHM) , PACHM.<br />

4.<strong><strong>Co</strong>pper</strong> contact shoe and Pressure rings for SAF submerged arc furnace Ferro alloy<br />

smelting, copper electrode holder head and electrode plate.<br />

5.Water cooling copper crucible and molds for VAR (Vacuum Arc Remelting ),ESSR<br />

and ESR(Electroslag Remelting) Furnace , EBCHM and PACHM furnace water cooling<br />

Flat ingot molds (crystallizer)<br />

Chemical: <strong><strong>Co</strong>pper</strong> Shell <strong>Co</strong>al gasification burner, copper flange, <strong><strong>Co</strong>pper</strong> nozzl<br />

Nuclear: <strong>Co</strong>re test section of CHF (critical heat flux) test setup for the study on IVR<br />

(In-Vessel Retention) strategy<br />

Others: <strong><strong>Co</strong>pper</strong> heating coil, <strong><strong>Co</strong>pper</strong> bush, <strong><strong>Co</strong>pper</strong> alloy welding pieces , <strong><strong>Co</strong>pper</strong> end<br />

ring, <strong><strong>Co</strong>pper</strong> pressure ring, Machining precision Brasses, Non-standard design copper<br />

parts, Tough pitch copper forging piece etc.<br />

www. copper-manufacture.com

About Products<br />

Project case<br />

Raw Materials | Machining Factory | Professional Design | Project contracting | Strict Quality <strong>Co</strong>ntrol | Transportation<br />

<strong>Co</strong>ntact shoes and <strong><strong>Co</strong>pper</strong> pressure ring for Submerged arc furnace— Ferro<br />

alloy smelting<br />

SAF 3D drawing<br />

SAF assembly site<br />

<strong>Co</strong>re<br />

Technology<br />

SAF contact shoes<br />

SAF pressure rings<br />

SAF contact shoes<br />

www. copper-manufacture.com

About Products<br />

Project case<br />

Raw Materials | Machining Factory | Professional Design | Project contracting | Strict Quality <strong>Co</strong>ntrol | Transportation<br />

EB Furnace(EBCHM)<strong>Co</strong>ld hearth parts-HZC successfully produced the copper<br />

cold hearth core parts of ALD EB furnace, and optimized design of water channels.<br />

The products is produced by forging and machining process.<br />

The cold hearth is mainly used for EBCHM Furnace to remelting and refining refractory<br />

and reactive metals.<br />

EB furnace cold hearth and overflow clip<br />

EB cold hearth cooling bed<br />

EBCHR furnace cooling bed and overflow lip Installation and commissioning<br />

www. copper-manufacture.com

About Products<br />

Project case<br />

Raw Materials | Machining Factory | Professional Design | Project contracting | Strict Quality <strong>Co</strong>ntrol | Transportation<br />

Water cooled copper molds and dovetail groove of EB furnace (EBCHR).<br />

EB furnace water cooled molds<br />

Dovetail groove of molds EB Furnace<br />

EB furnace is mainly<br />

employed for the<br />

production of refractory<br />

and reactive<br />

metals (tantalum, niobium,<br />

molybdenum,<br />

tungsten, vanadium,<br />

hafnium,<br />

zirconium, titanium)<br />

and their alloys.<br />

Pressure platform of electronic gun EB Furnace(EBCHR)<br />

EB Pressure platform of electronic gun<br />

www. copper-manufacture.com

About Products<br />

Project case<br />

Raw Materials | Machining Factory | Professional Design | Project contracting | Strict Quality <strong>Co</strong>ntrol | Transportation<br />

<strong><strong>Co</strong>pper</strong> crystallizer molds for Furnace VAR,ESR,ESSR, Skull furnace.<br />

<strong><strong>Co</strong>pper</strong> crucible is used for special steel and Titanium & Alloy smelting.<br />

<strong><strong>Co</strong>pper</strong> molds<br />

<strong><strong>Co</strong>pper</strong> molds machining site<br />

www. copper-manufacture.com

About Products<br />

Project case<br />

Raw Materials | Machining Factory | Professional Design | Project contracting | Strict Quality <strong>Co</strong>ntrol | Transportation<br />

<strong><strong>Co</strong>pper</strong> crystallizer molds for Furnace VAR,ESR,ESSR, Skull furnace.<br />

<strong><strong>Co</strong>pper</strong> crucible is used for special steel and Titanium & Alloy smelting.<br />

Machining copper crucible<br />

www. copper-manufacture.com

About Products<br />

Project case<br />

Raw Materials | Machining Factory | Professional Design | Project contracting | Strict Quality <strong>Co</strong>ntrol | Transportation<br />

<strong><strong>Co</strong>pper</strong> electrode rods for Furnace VAR,ESR,ESSR, Skull furnace. <strong><strong>Co</strong>pper</strong><br />

electrode rods is used for special steel , Titanium & Alloy and refractory and<br />

reactive metals smelting.<br />

<strong><strong>Co</strong>pper</strong> electrode rods<br />

www. copper-manufacture.com

About Products<br />

Project case<br />

Raw Materials | Machining Factory | Professional Design | Project contracting | Strict Quality <strong>Co</strong>ntrol | Transportation<br />

<strong><strong>Co</strong>pper</strong> crystallizer, copper crucible & molds for non-ferrous and<br />

ferrous metallurgy.<br />

www. copper-manufacture.com

About Products<br />

Project case<br />

Raw Materials | Machining Factory | Professional Design | Project contracting | Strict Quality <strong>Co</strong>ntrol | Transportation<br />

<strong><strong>Co</strong>pper</strong> electrode holder head and water cooling electrode plate are used<br />

for steelmaking arc furnaces.The electrode holder head is produced in unibody<br />

by forging and machining process. The working life is five to six times<br />

longer than by casting process.<br />

<strong><strong>Co</strong>pper</strong> electrode holder head<br />

<strong><strong>Co</strong>pper</strong> water cooling conductive plate<br />

<strong>Co</strong>nductive plate for INTECO Nickel ferroalloy furnace<br />

www. copper-manufacture.com

About Products<br />

Project case<br />

Raw Materials | Machining Factory | Professional Design | Project contracting | Strict Quality <strong>Co</strong>ntrol | Transportation<br />

HZC blast furnace copper cooling staves’ working life is five to six times<br />

longer than by casting process. We choose cold-rolled sheet as material and<br />

then deep hole drilling, welding, welds inspection, pressure and ultrasonic<br />

test.<br />

<strong>Co</strong>oler stave—India TATA Steel<br />

<strong><strong>Co</strong>pper</strong> cooler stave—Chile CODELCO <strong><strong>Co</strong>pper</strong> cooler stave—Romania customers<br />

<strong>Co</strong>oler stave —Severstal<br />

www. copper-manufacture.com

About Products<br />

Project case<br />

Raw Materials | Machining Factory | Professional Design | Project contracting | Strict Quality <strong>Co</strong>ntrol | Transportation<br />

<strong><strong>Co</strong>pper</strong> water cooling jackets: copper chute, slag tap jackets,copper flue<br />

etc. cooling elements for metallurgy furnace(AUSMELT, ISAsmelt, Flash<br />

furnace, KIVCET, Flash converting furnace, Rich oxygen side-blown and<br />

top-blown furnace, Lead & zinc smelting furnace etc.) HZC jackets are produced<br />

by forging and machining process. The working life is five to six<br />

times longer than by casting process.<br />

AUSMELT water cooling jackets<br />

ISASMELT water cooling jackets<br />

<strong>Co</strong>nverter furnace cooler jackets<br />

www. copper-manufacture.com

About Products<br />

Project case<br />

Raw Materials | Machining Factory | Professional Design | Project contracting | Strict Quality <strong>Co</strong>ntrol | Transportation<br />

<strong><strong>Co</strong>pper</strong> water cooling jackets: copper chute, slag tap jackets,copper flue<br />

etc. cooling elements for metallurgy furnace(AUSMELT, ISAsmelt, Flash<br />

furnace, KIVCET, Flash converting furnace, Rich oxygen side-blown and<br />

top-blown furnace, Lead & zinc smelting furnace etc.) HZC jackets are produced<br />

by forging and machining process. The working life is five to six<br />

times longer than by casting process.<br />

<strong><strong>Co</strong>pper</strong> soft connection<br />

Lead & zinc smelting furnace copper flue<br />

Lead & zinc smelting furnace jackets<br />

<strong><strong>Co</strong>pper</strong> chute --South Africa<br />

www. copper-manufacture.com

About Products<br />

Project case<br />

Raw Materials | Machining Factory | Professional Design | Project contracting | Strict Quality <strong>Co</strong>ntrol | Transportation<br />

HZC designed and produced the core test section of CHF (critical heat flux)<br />

test setup for the study on IVR (In-Vessel Retention) strategy— CGNPC China<br />

Guangdong Nuclear Power <strong>Co</strong>rporation.<br />

Nuclear Power<br />

www. copper-manufacture.com

About Products<br />

Project case<br />

Raw Materials | Machining Factory | Professional Design | Project contracting | Strict Quality <strong>Co</strong>ntrol | Transportation<br />

Round water cooling jacket and furnace top rings<br />

Other equipment<br />

www. copper-manufacture.com

About Products<br />

Project case<br />

Raw Materials | Machining Factory | Professional Design | Project contracting | Strict Quality <strong>Co</strong>ntrol | Transportation<br />

<strong><strong>Co</strong>pper</strong> flange<br />

Shell <strong>Co</strong>al gasification copper nozzle (startup burner) for gasification of coal<br />

Chemical<br />

<strong>Industry</strong><br />

www. copper-manufacture.com

About Products<br />

Project case<br />

Raw Materials | Machining Factory | Professional Design | Project contracting | Strict Quality <strong>Co</strong>ntrol | Transportation<br />

<strong><strong>Co</strong>pper</strong> cooling roof , copper electrode holder & clip , copper heat ring,<br />

copper electrode holder ring for Sapphire Production furnace<br />

<strong><strong>Co</strong>pper</strong> cooling roof<br />

<strong><strong>Co</strong>pper</strong> rings<br />

<strong><strong>Co</strong>pper</strong> electrode holder & clip<br />

<strong><strong>Co</strong>pper</strong> electrode holder ring<br />

www. copper-manufacture.com

About Products<br />

Project case<br />

Raw Materials | Machining Factory | Professional Design | Project contracting | Strict Quality <strong>Co</strong>ntrol | Transportation<br />

Monocrystalline and polycrystalline silicon copper electrode elements<br />

Monocrystalline and polycrystalline silicon<br />

copper electrode elements<br />

Water cooling cable<br />

Polycrystalline silicon reduction water cooling<br />

furnace electrode<br />

Polycrystalline silicon Hydrogenated<br />

furnace water cooling electrode<br />

Polysilicon ingot furnace copper electrode<br />

www. copper-manufacture.com

About Products<br />

Project case<br />

Raw Materials | Machining Factory | Professional Design | Project contracting | Strict Quality <strong>Co</strong>ntrol | Transportation<br />

<strong>Co</strong>oling system for Glass produce equipment Adenauer<br />

www. copper-manufacture.com

<strong>Hengzheng</strong> Advantage<br />

1.Raw material: High quality copper slab from CHINALCO <strong>Luoyang</strong> <strong><strong>Co</strong>pper</strong>.<br />

Largest hot rolling mill: Adopting German-made<br />

reversible cold & hot rolling mill, the largest production<br />

facility in non-ferrous metals industry in China,<br />

capable of producing copper slab:thickness 3-<br />

150mm, max. width 3.2m, weight 7.5t/pcs, capacity<br />

20,000t/y.<br />

Wide plate mill<br />

2. Advanced updated machining equipment and process<br />

Advanced CNC deep hole drilling. boring miller slot milling machine<br />

3. Experienced in welding.<br />

All welders have qualified as per DIN EN 287-3, certified<br />

by WTI/SLV Duisburg GmbH.<br />

HZC also have the SGS welding certificate<br />

<strong>Hengzheng</strong> <strong><strong>Co</strong>pper</strong> <strong>Ltd</strong><br />

Jinyuan Mansion C, 507, 38#Taiyuan<br />

Road<strong>Luoyang</strong> City, C 471003<br />

China<br />

+ 86 379 64391187 Tel<br />

+ 86 379 64390787 Fax<br />

info@lyhengzheng.com<br />

www.lyhengzheng.com<br />

www.copper-manufacture.com<br />

©2014 <strong>Hengzheng</strong> <strong><strong>Co</strong>pper</strong> <strong>Co</strong>.,<strong>Ltd</strong>

<strong>Hengzheng</strong> Advantage<br />

4. Quality Test<br />

pull-out test<br />

Ultrasonic Testing<br />

Ultrasonic Testing<br />

Dye-penetrant inspection<br />

Dye-penetrant inspection<br />

Endoscopic detection channel<br />

5. Site inspection Customers<br />

Italy customers CNGPC IVR Test setup French customers<br />

6. Production process of copper cooler stave and cooling jacket<br />

<strong>Hengzheng</strong> <strong><strong>Co</strong>pper</strong> <strong>Ltd</strong><br />

Jinyuan Mansion C, 507, 38#Taiyuan<br />

Road<strong>Luoyang</strong> City, C 471003<br />

China<br />

+ 86 379 64391187 Tel<br />

+ 86 379 64390787 Fax<br />

info@lyhengzheng.com<br />

www.lyhengzheng.com<br />

www.copper-manufacture.com<br />

©2014 <strong>Hengzheng</strong> <strong><strong>Co</strong>pper</strong> <strong>Co</strong>.,<strong>Ltd</strong>

Quality Assurance<br />

Hi-Q material : using high quality copper materials from <strong>Luoyang</strong> <strong><strong>Co</strong>pper</strong>,<br />

which has steady source channel and competitive price. Have various sources in<br />

complex copper alloys supplies, such as Cr-Cu, Cu-Cr-Zr, bronze, cupronickel<br />

etc. We can also customize complex brands copper casting pieces with advantage-raw<br />

material: hot rolled wide thick copper slabs produced by Chinalco<br />

<strong>Luoyang</strong> copper; unique brand of TU1/TU2/TAG0.1/T2/TP2; other brands include<br />

brass, bronze and cupronickel alloys. The max thickness 140mm,the max<br />

depth 3000mm, the max length 6000mm. The max length of the cutting copper<br />

bar can reach 12m. The ingots are reliable and of steady supply, casted from<br />

cathode copper.<strong><strong>Co</strong>pper</strong> rube and bar: the max diameter is 420 mm, the biggest<br />

wall thickness 80 mm of the extrusion tube; the max diameter is 360 mm, the<br />

biggest wall thickness 10 mm of the drawn tube; the max diameter is 300 mm of<br />

extruding bar and the diameter is 180 mm of the drawn bar.<br />

Technical support:<br />

a. Experienced senior technical personals in the industry;<br />

b. Solving puzzling questions professionally comprehensively and response<br />

speedily;<br />

c. Rich experiences in Optimization of the drawings and drawing inversion of<br />

products;<br />

d. Explore new convenient machining process and well know the manufacturing<br />

and machining process.<br />

Adopt the most advanced melting & casting equipment and process, advanced<br />

CNC equipments. Experienced in welding. All welders have been qualified as<br />

per DIN EN 287-3, certified by WTI/SLV Duisburg GmbH.<br />

Site inspection, the quality of the products get<br />

consistent high praise of clients.<br />

Perfect, advanced quality assurance system, including<br />

raw material control, process inspection,<br />

final inspection and test etc. Reliability,<br />

innovation and development,providing the<br />

best quality products and services to every client.<br />

<strong>Hengzheng</strong> <strong><strong>Co</strong>pper</strong> <strong>Ltd</strong><br />

Jinyuan Mansion C, 507, 38#Taiyuan<br />

Road<strong>Luoyang</strong> City, C 471003<br />

China<br />

+ 86 379 64391187 Tel<br />

+ 86 379 64390787 Fax<br />

info@lyhengzheng.com<br />

www.lyhengzheng.com<br />

www.copper-manufacture.com<br />

©2014 <strong>Hengzheng</strong> <strong><strong>Co</strong>pper</strong> <strong>Co</strong>.,<strong>Ltd</strong>

Technical Service<br />

DESIGNING<br />

We have fully equipped Design & Drawing office with AutoCAD & printing facilities.<br />

A team of Engineers/Draftsman manages the Designing & Drawing<br />

unit. We also undertake the design of complete system for projects.<br />

MANUFACTURING<br />

We have complete manufacturing / Fabrication & testing facilities for all our<br />

products as <strong>Co</strong>ntact clamps, cooling elements, water cooled cable etc. Our<br />

workshop comprises of pneumatic hammers, cold/hot rolling machines, Heating/Annealing<br />

furnaces, planning machines, shaping machines, Lathe machines,<br />

Drill machines, hydraulic presses, TIG & MIG WELDING facilities.<br />

ERECTION & COMMISSIONING<br />

We have team of Engineers & skilled manpower to carry out Erection & <strong>Co</strong>mmissioning<br />

at Customers site<br />

For more information on <strong>Luoyang</strong> <strong>Hengzheng</strong> <strong><strong>Co</strong>pper</strong> <strong>Co</strong>.,<strong>Ltd</strong> call us at<br />

+86 379 64391187 or email us at info@lyhengzheng.com.<br />

Headquarters<br />

Customers<br />

<strong>Hengzheng</strong> <strong><strong>Co</strong>pper</strong> <strong>Ltd</strong><br />

Jinyuan Mansion C, 507, 38#Taiyuan<br />

Road<strong>Luoyang</strong> City, C 471003<br />

China<br />

+ 86 379 64391187 Tel<br />

+ 86 379 64390787 Fax<br />

info@lyhengzheng.com<br />

www.lyhengzheng.com<br />

www.copper-manufacture.com<br />

©2014 <strong>Hengzheng</strong> <strong><strong>Co</strong>pper</strong> <strong>Co</strong>.,<strong>Ltd</strong>