to download Material compatibility guide - Aquapump.co.za

to download Material compatibility guide - Aquapump.co.za

to download Material compatibility guide - Aquapump.co.za

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

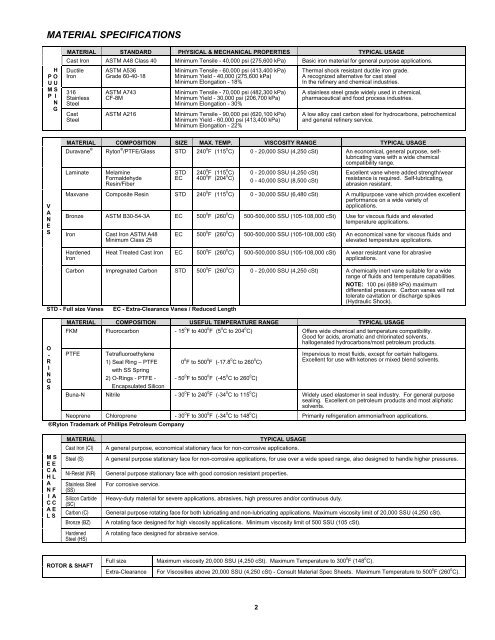

MATERIAL SPECIFICATIONS<br />

H<br />

P O<br />

U U<br />

M S<br />

P I<br />

N<br />

G<br />

MATERIAL STANDARD PHYSICAL & MECHANICAL PROPERTIES TYPICAL USAGE<br />

Cast Iron ASTM A48 Class 40 Minimum Tensile - 40,000 psi (275,600 kPa) Basic iron material for general purpose applications.<br />

Ductile<br />

Iron<br />

316<br />

Stainless<br />

Steel<br />

Cast<br />

Steel<br />

ASTM A536<br />

Grade 60-40-18<br />

ASTM A743<br />

CF-8M<br />

ASTM A216<br />

Minimum Tensile - 60,000 psi (413,400 kPa)<br />

Minimum Yield - 40,000 (275,600 kPa)<br />

Minimum Elongation - 18%<br />

Minimum Tensile - 70,000 psi (482,300 kPa)<br />

Minimum Yield - 30,000 psi (206,700 kPa)<br />

Minimum Elongation - 30%<br />

Minimum Tensile - 90,000 psi (620,100 kPa)<br />

Minimum Yield - 60,000 psi (413,400 kPa)<br />

Minimum Elongation - 22%<br />

Thermal shock resistant ductile iron grade.<br />

A re<strong>co</strong>gnized alternative for cast steel<br />

In the refinery and chemical industries.<br />

A stainless steel grade widely used in chemical,<br />

pharmaceutical and food process industries.<br />

A low alloy cast carbon steel for hydrocarbons, petrochemical<br />

and general refinery service.<br />

V<br />

A<br />

N<br />

E<br />

S<br />

MATERIAL COMPOSITION SIZE MAX. TEMP. VISCOSITY RANGE TYPICAL USAGE<br />

Duravane ® Ry<strong>to</strong>n ® /PTFE/Glass STD 240 0 F (115 0 C) 0 - 20,000 SSU (4,250 cSt) An e<strong>co</strong>nomical, general purpose, selflubricating<br />

vane with a wide chemical<br />

<strong><strong>co</strong>mpatibility</strong> range.<br />

Laminate Melamine<br />

STD 240 0 F (115 0 C) 0 - 20,000 SSU (4,250 cSt) Excellent vane where added strength/wear<br />

Formaldehyde<br />

EC 400 0 F (204 0 C)<br />

0 - 40,000 SSU (8,500 cSt)<br />

resistance is required. Self-lubricating,<br />

Resin/Fiber<br />

abrasion resistant.<br />

Maxvane Composite Resin STD 240 0 F (115 0 C) 0 - 30,000 SSU (6,480 cSt) A multipurpose vane which provides excellent<br />

performance on a wide variety of<br />

applications.<br />

Bronze ASTM B30-54-3A EC 500 0 F (260 0 C) 500-500,000 SSU (105-108,000 cSt) Use for vis<strong>co</strong>us fluids and elevated<br />

temperature applications.<br />

Iron<br />

Cast Iron ASTM A48<br />

Minimum Class 25<br />

EC 500 0 F (260 0 C) 500-500,000 SSU (105-108,000 cSt) An e<strong>co</strong>nomical vane for vis<strong>co</strong>us fluids and<br />

elevated temperature applications.<br />

Hardened<br />

Iron<br />

Heat Treated Cast Iron EC 500 0 F (260 0 C) 500-500,000 SSU (105-108,000 cSt) A wear resistant vane for abrasive<br />

applications.<br />

Carbon Impregnated Carbon STD 500 0 F (260 0 C) 0 - 20,000 SSU (4,250 cSt) A chemically inert vane suitable for a wide<br />

range of fluids and temperature capabilities.<br />

NOTE: 100 psi (689 kPa) maximum<br />

differential pressure. Carbon vanes will not<br />

<strong>to</strong>lerate cavitation or discharge spikes<br />

(Hydraulic Shock).<br />

STD - Full size Vanes EC - Extra-Clearance Vanes / Reduced Length<br />

O<br />

-<br />

R<br />

I<br />

N<br />

G<br />

S<br />

MATERIAL COMPOSITION USEFUL TEMPERATURE RANGE TYPICAL USAGE<br />

FKM Fluorocarbon - 15 0 F <strong>to</strong> 400 0 F (5 0 C <strong>to</strong> 204 0 C) Offers wide chemical and temperature <strong><strong>co</strong>mpatibility</strong>.<br />

Good for acids, aromatic and chlorinated solvents,<br />

hallogenated hydrocarbons/most petroleum products.<br />

PTFE<br />

Tetrafluoroethylene<br />

1) Seal Ring – PTFE<br />

with SS Spring<br />

2) O-Rings - PTFE -<br />

Encapsulated Sili<strong>co</strong>n<br />

0 0 F <strong>to</strong> 500 0 F (-17.8 0 C <strong>to</strong> 260 0 C)<br />

- 50 0 F <strong>to</strong> 500 0 F (-45 0 C <strong>to</strong> 260 0 C)<br />

Impervious <strong>to</strong> most fluids, except for certain hallogens.<br />

Excellent for use with ke<strong>to</strong>nes or mixed blend solvents.<br />

Buna-N Nitrile - 30 0 F <strong>to</strong> 240 0 F (-34 0 C <strong>to</strong> 115 0 C) Widely used elas<strong>to</strong>mer in seal industry. For general purpose<br />

sealing. Excellent on petroleum products and most aliphatic<br />

solvents.<br />

Neoprene Chloroprene - 30 0 F <strong>to</strong> 300 0 F (-34 0 C <strong>to</strong> 148 0 C) Primarily refrigeration ammonia/freon applications.<br />

®Ry<strong>to</strong>n Trademark of Phillips Petroleum Company<br />

M S<br />

E E<br />

C A<br />

H L<br />

A<br />

N F<br />

I A<br />

C C<br />

A E<br />

L S<br />

MATERIAL<br />

Cast Iron (CI)<br />

Steel (S)<br />

Ni-Resist (NR)<br />

Stainless Steel<br />

(SS)<br />

Sili<strong>co</strong>n Carbide<br />

(SC)<br />

Carbon (C)<br />

Bronze (BZ)<br />

Hardened<br />

Steel (HS)<br />

TYPICAL USAGE<br />

A general purpose, e<strong>co</strong>nomical stationary face for non-<strong>co</strong>rrosive applications.<br />

A general purpose stationary face for non-<strong>co</strong>rrosive applications, for use over a wide speed range, also designed <strong>to</strong> handle higher pressures.<br />

General purpose stationary face with good <strong>co</strong>rrosion resistant properties.<br />

For <strong>co</strong>rrosive service.<br />

Heavy-duty material for severe applications, abrasives, high pressures and/or <strong>co</strong>ntinuous duty.<br />

General purpose rotating face for both lubricating and non-lubricating applications. Maximum vis<strong>co</strong>sity limit of 20,000 SSU (4,250 cSt).<br />

A rotating face designed for high vis<strong>co</strong>sity applications. Minimum vis<strong>co</strong>sity limit of 500 SSU (105 cSt).<br />

A rotating face designed for abrasive service.<br />

ROTOR & SHAFT<br />

Full size<br />

Extra-Clearance<br />

Maximum vis<strong>co</strong>sity 20,000 SSU (4,250 cSt). Maximum Temperature <strong>to</strong> 300 0 F (148 0 C).<br />

For Vis<strong>co</strong>sities above 20,000 SSU (4,250 cSt) - Consult <strong>Material</strong> Spec Sheets. Maximum Temperature <strong>to</strong> 500 0 F (260 0 C).<br />

2