A Super Sonic Solution - John Zink Company

A Super Sonic Solution - John Zink Company

A Super Sonic Solution - John Zink Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

a report by<br />

<strong>John</strong> <strong>Zink</strong>, a division of Koch Chemical Technology Group Ltd<br />

The KMI flare tip is a hybrid of the highly<br />

successful <strong>John</strong> <strong>Zink</strong> ® Hydra and Kaldair ®<br />

Indair ® technology. The concept of multiple Indair<br />

tips being located in an array is not new; however,<br />

<strong>John</strong> <strong>Zink</strong> have developed the concept into a<br />

single-point tip with multiple Indair nozzles. This<br />

not only provides the multi-arm advantages of the<br />

Hydra by increasing the flare gas surface area<br />

exposed to the air, but also employs the infinite<br />

turndown features of the variable slot Indair.<br />

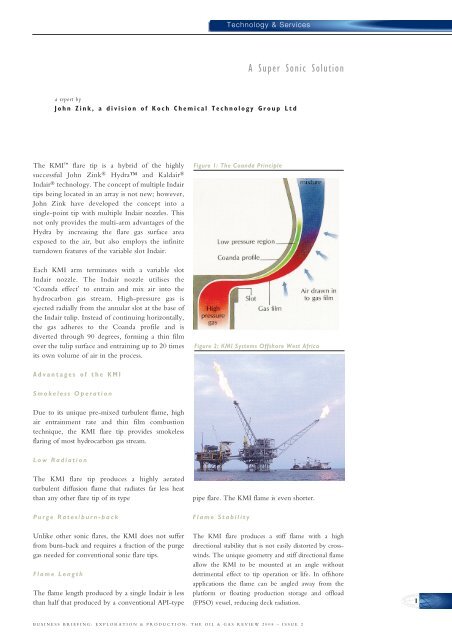

Each KMI arm terminates with a variable slot<br />

Indair nozzle. The Indair nozzle utilises the<br />

‘Coanda effect’ to entrain and mix air into the<br />

hydrocarbon gas stream. High-pressure gas is<br />

ejected radially from the annular slot at the base of<br />

the Indair tulip. Instead of continuing horizontally,<br />

the gas adheres to the Coanda profile and is<br />

diverted through 90 degrees, forming a thin film<br />

over the tulip surface and entraining up to 20 times<br />

its own volume of air in the process.<br />

Advantages of the KMI<br />

Smokeless Operation<br />

Due to its unique pre-mixed turbulent flame, high<br />

air entrainment rate and thin film combustion<br />

technique, the KMI flare tip provides smokeless<br />

flaring of most hydrocarbon gas stream.<br />

Low Radiation<br />

The KMI flare tip produces a highly aerated<br />

turbulent diffusion flame that radiates far less heat<br />

than any other flare tip of its type<br />

Purge Rates/burn-back<br />

Unlike other sonic flares, the KMI does not suffer<br />

from burn-back and requires a fraction of the purge<br />

gas needed for conventional sonic flare tips.<br />

Flame Length<br />

The flame length produced by a single Indair is less<br />

than half that produced by a conventional API-type<br />

pipe flare. The KMI flame is even shorter.<br />

Flame Stability<br />

Technology & Services<br />

Figure 1: The Coanda Principle<br />

A <strong>Super</strong> <strong>Sonic</strong> <strong>Solution</strong><br />

Figure 2: KMI Systems Offshore West Africa<br />

The KMI flare produces a stiff flame with a high<br />

directional stability that is not easily distorted by crosswinds.<br />

The unique geometry and stiff directional flame<br />

allow the KMI to be mounted at an angle without<br />

detrimental effect to tip operation or life. In offshore<br />

applications the flame can be angled away from the<br />

platform or floating production storage and offload<br />

(FPSO) vessel, reducing deck radiation.<br />

BUSINESS BRIEFING: EXPLORATION & PRODUCTION: THE OIL & GAS REVIEW 2005 – ISSUE 2<br />

1

2<br />

Liquid Handling<br />

Technology & Services<br />

Figure 3: KMI Demonstrates Clean Stable<br />

Directional Flame<br />

Figure 4: 2 Million Kg/hr KMI tip supplied to Kazakhstan<br />

The KMI flare is capable of burning 25% by weight<br />

of liquid carry-over without any fall-out or smoke<br />

production whatsoever. This feature means that, in<br />

many cases, the flare may be operated without a<br />

liquid knockout drum in the HP flare line.<br />

High-pressure Operation<br />

Since the KMI flare operates at elevated pressure<br />

when burning HP gas (rather than near atmospheric<br />

pressure as with a conventional flare), significant<br />

savings in header size and knock-out vessel size may<br />

be made.<br />

Efficient Air Entrainment and<br />

Mixing<br />

Multi-point designs improve the efficiency by<br />

splitting the flow between smaller, separated<br />

cylinders of hydrocarbon gases, allowing efficient air<br />

entrainment into the flame. The unique KMI flare<br />

tip, based on the Coanda effect, forms a thin film of<br />

hydrocarbon that entrains and pre-mixes air prior to<br />

combustion. The KMI flare, in most cases, produces<br />

combustion efficiencies in excess of 99.9%.<br />

Tip life<br />

The small Indair tulips used in the KMI are of an<br />

investment cast, highly robust single part construction<br />

that, combined with the multi-nozzle design, provides<br />

extended operational life compared with other flare<br />

tips on the market.<br />

Maintenance<br />

As the KMI tulips are very small they are easily manhandled.<br />

Therefore, in the event that any tulips require<br />

changing, it can be done without the use of a crane. In<br />

addition, the replacement of an investment cast small<br />

tulip is not expensive whereas the manufacturing cost<br />

of a large tulip is relatively high.<br />

Flexibility<br />

Turndown flexibility can be enhanced further by<br />

varying the spring rates on the individual nozzles<br />

such that the flare tip can act as a staged system in<br />

itself. Thus, the tip can be set up to bring nozzles<br />

online in turn, such that at low flows only one or<br />

two nozzles will have their slots open while all the<br />

others are closed. As the pressure and flow increase<br />

then slots can open in sequence until at full flow all<br />

slots are fully open ■<br />

BUSINESS BRIEFING: EXPLORATION & PRODUCTION: THE OIL & GAS REVIEW 2005 – ISSUE 2