EA28-V Advance

EA28-V Advance

EA28-V Advance

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

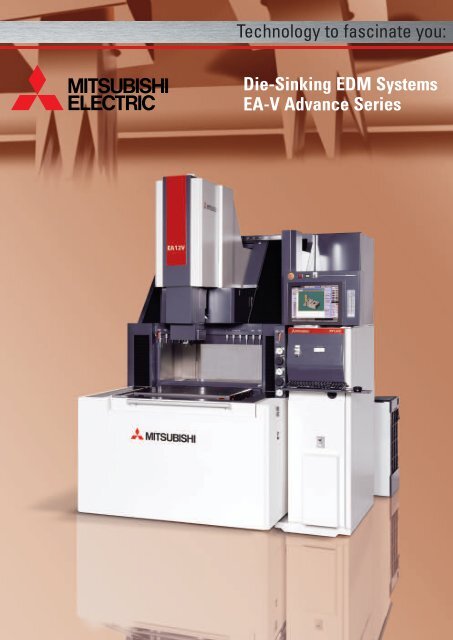

Technology to fascinate you:<br />

Die-Sinking EDM Systems<br />

EA-V <strong>Advance</strong> Series

The Machine<br />

Productive Universal Flexible<br />

Productive, precise, and always reliable: The EA-V <strong>Advance</strong><br />

It can be applied universally and permanently reduces operating costs: the EA-V <strong>Advance</strong> series.<br />

Its reliability, capability and availability are appreciated all over the world. This is also true for its<br />

high-quality equipment and technological innovations. The Generator FP80V provides highest productivity<br />

and best results. It is particularly strong with respect to the machining of tungsten carbide.<br />

For bigger processing surfaces and for fast roughing, the High performance generator FP120V offers<br />

even more power.<br />

Be prepared for the challenges of tomorrow!<br />

EA12-V <strong>Advance</strong><br />

<strong>EA28</strong>-V <strong>Advance</strong><br />

Travel paths and workpiece dimensions<br />

in mm<br />

Y = 300<br />

550<br />

Z = 300<br />

800<br />

250<br />

Y = 450<br />

X = 400<br />

760<br />

Z = 350<br />

1050<br />

350<br />

X = 650<br />

EA12-V <strong>Advance</strong><br />

<strong>EA28</strong>-V <strong>Advance</strong><br />

Overall dimensions of the machine in mm<br />

(W x D x H)<br />

EA12-V <strong>Advance</strong><br />

1750 x 2050 x 2235<br />

<strong>EA28</strong>-V <strong>Advance</strong><br />

2195 x 2512 x 2615<br />

The lowerable working tank as well as the control<br />

cabinet which can be optionally positioned on the<br />

left side, allow flexible automation solutions.<br />

2<br />

3

Mechanical Engineering<br />

Solid Precise Easy to maintain<br />

The compelling machine concept<br />

Compact, robust mechanical engineering based on cast steel. No other material can better guarantee<br />

the solidity and stability you need in order to benefit from your investment in the long term.<br />

Best mechanical engineering: Made in Japan!<br />

The high-resolution, digitally controlled direct drives (0.1 μm resolution), combined with generously<br />

dimensioned spindles, ensure highest precision over the entire lifetime of the machine.<br />

The dual measuring system with additional linear scales for the X, Y and Z axis work in closed<br />

loop and ensures long-lasting precision.<br />

Because precision needs perfection!<br />

Classic cast steel machine design<br />

with high-quality components<br />

The Long-Life filters, exchangeable during<br />

operation, as well as the central lubrication<br />

system, offer you optimum maintainability.<br />

Good access keeps unproductive times as<br />

short as possible.<br />

<br />

<br />

Thermally regulated<br />

machine body.<br />

The CNC recognises<br />

deviations of thermal<br />

origin and corrects<br />

them in real time.<br />

Deviations of thermal<br />

origin are corrected<br />

by more than 50 %.<br />

Room temperature change<br />

Machine deviation<br />

Time<br />

Conventional model<br />

EA12-V <strong>Advance</strong><br />

Time<br />

Relation of room temperature changes<br />

and machine deviation<br />

Thanks to the lowerable working tank, you have best access<br />

to the working range and you can easily load the machine.<br />

These space savings result in further versatile automation<br />

possibilities.<br />

4<br />

5

The <strong>Advance</strong> CNC Control<br />

Touchscreen User-friendly Fast<br />

The new <strong>Advance</strong> CNC control - the new standard in spark erosion<br />

The new ADVANCE control based on the MITSUBISHI CNC M700 is captivating due to its user-friendliness<br />

and reliability. In spite of its complex range of functions, it can be operated intuitively via control based on<br />

Windows XP. The logical menu structure and uncomplicated design allow you to quickly and reliably<br />

achieve your goal.<br />

The control is performed via a sturdy 15" touch screen monitor, fixed function keys for commands most often<br />

used, as well as via keyboard and mouse. The control can be linked to a network by way of the standard<br />

Ethernet interface.<br />

Professional work can be that easy!<br />

Telecontrol<br />

Teleservice<br />

Operator<br />

Telecontact<br />

Telecontact<br />

Telecontact<br />

Operator 2<br />

Maintenance<br />

Would you like to control<br />

your work from a distance?<br />

Several "Tele" functions allow<br />

you to do this.<br />

Operator 1<br />

Data can also be exchanged independently from the<br />

network by way of two available USB ports.<br />

Software updates are performed via the USB flash<br />

drive; after the Software update, your individual<br />

settings are recovered.<br />

6<br />

7

Programming By Dialog<br />

Simple<br />

Comfortable<br />

Dialog-based programming, making everything easi er for you<br />

The processing program is created with the E.S.P.E.R. <strong>Advance</strong> software.<br />

With this, the user is supported by clearly understandable and intuitive set-up cycles<br />

as well as by a dialog-based function selection. With only a few basic parameters,<br />

even inexperienced users quickly find an optimal eroding strategy and work successfully.<br />

The operators of our wire eroding machines will highly appreciate the consistency<br />

of the control systems; they already know the ropes!<br />

The program is created in "Shape Expert".<br />

Here, different basic shapes and specifications are used.<br />

Programming is fast and easy.<br />

The optimum processing technology is created automatically.<br />

Gate<br />

Thread<br />

Orbits<br />

The control system offers multiple<br />

deflection possibilities during<br />

eroding work.<br />

This is only a small selection.<br />

Circle<br />

Pyramid<br />

Ribs<br />

Helical Gear<br />

Square<br />

Prism 1<br />

Ball<br />

Prism 2<br />

3 axes<br />

1 horizontal axis<br />

Cylinder 1<br />

1 vertical axis<br />

Cylinder 2<br />

Hexagon 1<br />

Cylinder 3<br />

Hexagon 2<br />

Cone<br />

Half-shapes<br />

8<br />

9

3-D Graphic Functions<br />

Optimised Helpful Safe<br />

<strong>Advance</strong> – Directly utilize your 3D CAD Data<br />

The <strong>Advance</strong> Control also includes a 3D as well as 2D CAM system. 3D data in Parasolid format<br />

as well as DXF or IGES files can be directly imported and converted to NC programs.<br />

The shape of workpiece and electrode can be analyzed immediately after the import. This easily<br />

understandable verification gives you additional safety before the start.<br />

Make your daily work easier!<br />

3D Expert<br />

A new function of the E.S.P.E.R. <strong>Advance</strong> Control allows automatic adaptation<br />

of the generator settings to the geometry of the workpiece to be processed.<br />

This function can also be used if only 2D data are available, however optimal<br />

results are produced nevertheless.<br />

3D simulation of the machining<br />

Subsequent to the creation of the<br />

programs, a simulated processing<br />

in 3D can be performed.<br />

10<br />

11

Processing Examples<br />

Tungsten Carbide Steel Titanium<br />

The formula of success for your productivity<br />

Mitsubishi Electric's newly developed FP-V generator series is the new standard in<br />

spark erosion. The combination of reduced electrode wear and high removal rates,<br />

coupled with higher precision and the best possible surface quality, is sure to increase<br />

your options.<br />

For tungsten carbide machining, the EA-V <strong>Advance</strong> is the best reference, in particular<br />

for small cavities and finest surfaces.<br />

FP-V generator<br />

The EA-V <strong>Advance</strong> models ensure the smallest<br />

edge zone impact on the work piece for<br />

increased durability of the work piece as<br />

a whole (upper picture: for comparison -<br />

the result of a spark erosion plant using a<br />

conventional generator).<br />

Conventional generator<br />

Tungsten carbide machining<br />

Surface quality Ra 0.15 μm<br />

Workpiece: Tungsten carbide<br />

Electrode: Tungsten copper<br />

Helical gear machining<br />

Function: integrated C axis<br />

Material: Tungsten carbide<br />

Electrode: Tungsten copper<br />

Surface quality: Ra 0.3 μm<br />

Ultra-precise helical gear machining is possible as a result<br />

of the extremely rigid and integrated C axis.<br />

The E.S.P.E.R. <strong>Advance</strong> programming function allows easy<br />

programming of helical gear machining.<br />

Titanium machining<br />

The BMW Sauber F1 Team machines<br />

titanium workpieces with graphite<br />

electrodes (suspension arms for Formula 1).<br />

Difficult flushing conditions, large section,<br />

ideal for the FP120V generator<br />

Material: Steel<br />

Surface quality: Ra 1,6 μm<br />

Depth: 130 mm<br />

Electrode: Graphite<br />

The EA-V <strong>Advance</strong> delivers stable eroding processes, even under<br />

the most difficult flushing conditions. Additional contours are eroded<br />

into the pre-milled workpiece, and the entire surface is finished to<br />

the required surface quality (machining without additional flushing).<br />

12<br />

13

Processing Examples<br />

Economical Flexible Future-safe<br />

Manufacture a piece of the future<br />

Do you manufacture compound tools, plastic mouldings, gearwheel moulds, profiles, prototypes<br />

and many more things? And you think that highest productivity, flexibility and precision are<br />

most important? Then you need the Mitsubishi Electric EA-V <strong>Advance</strong> series models, with<br />

their unlimited scope of applications.<br />

The obtained results will give you competitive advantages and economical success.<br />

The "Fuzzy Control" function adapts the machining parameters during the eroding process,<br />

optimising these automatically. This delivers stable and optimum machining speeds with<br />

maximum performance.<br />

Medical technology<br />

Workpiece: Chrome-cobalt alloy<br />

Electrode: Graphite<br />

Mirror Finish machining<br />

Function: GM circuit<br />

Material: Steel<br />

Electrode: Copper<br />

Surface quality: Ra 0.06 μm<br />

The GM circuit reduces the total polishing<br />

cost drastically, or even down to zero.<br />

This function is particularly suited for moulds<br />

that are difficult to polish.<br />

Multi-Rib machining<br />

The E.S.P.E.R. rib function delivers a stable<br />

eroding process with minimum electrode<br />

wear, even for the finest rib electrodes.<br />

The new graphite adapter minimises electrode wear<br />

for graphite electrodes and ensures faster,<br />

more stable processing of ribs and bars.<br />

14<br />

15

Automation<br />

Handling Systems Manufacturing Cells Integration<br />

You decide how much profit your machine produces<br />

Certainly you want to increase the operating efficiency of your machine.<br />

We offer several possibilities to reduce down-time. A 20 position tool changer<br />

already makes a big difference but what about handling workpieces as well?<br />

The highly flexible workpiece and tool handling device MER combines the professional<br />

experience of the two market leaders Mitsubishi Electric and Erowa.<br />

Storage space for up to 48 ITS 50 electrode holders or 6 UPS workpiece pallets, or any combination<br />

of the two, guarantees fully used night and weekend shifts. And that’s where the profit lies, in the<br />

autonomous operation of the EDM machine and the robot.<br />

Workpiece pallets up to 80kg and electrodes of 20kg are handled absolutely automatically.<br />

The available integrated chip reader system ensures absolute control. Together with<br />

the cell management software “Master Cell Light” your operators will be on top<br />

of things at any time.<br />

Still not flexible enough? We also offer individual turn key solutions in close<br />

co-operation with all leading automation suppliers.<br />

16<br />

17

Technical Data<br />

Layouts<br />

Machine<br />

Model EA12-V <strong>Advance</strong> <strong>EA28</strong>-V <strong>Advance</strong><br />

Model 20-fold tool changer Mitsubishi Erowa Robot-MER<br />

Machine<br />

Travel path (X/Y/Z) mm 400 x 300 x 300 650 x 450 x 350<br />

Max. workpiece weight kg 50 50/200<br />

Max. workpiece dimensions (W x D X H) mm 800 x 550 x 250 1050 x 760 x 350<br />

Max. workpiece weight kg 700 2000<br />

Table dimensions (W x D) mm 700 x 500 850 x 600<br />

Width between jaws mm 100 ~ 300 100 ~ 400<br />

Overall dimensions (W x D X H) mm 1750 x 2050 x 2335 2195 x 2512 x 2615<br />

Weight of the machine kg 3725 5400<br />

Magazine positions<br />

Transfer weight<br />

Rotation axis<br />

Chip identification<br />

Maximum electrode dimensions in automatic mode<br />

20 electrodes ITS 50<br />

10 kg<br />

--<br />

--<br />

48 electrodes ITS 50 and<br />

6 workpieces UPC 320 x 320 mm<br />

Workpieces 80 kg<br />

Electrodes 20 kg<br />

˛<br />

o<br />

Subject to constructional limitations,<br />

the MER can be flexibly adapted to required<br />

electrode holders or other workholding Systems.<br />

Filter<br />

unit<br />

Tank capacity l 340 390<br />

Filter elements 2 3<br />

Temperature control Dielectric cooler Dielectric cooler<br />

Generator / Control<br />

Model EA12-V <strong>Advance</strong> <strong>EA28</strong>-V <strong>Advance</strong><br />

Generator<br />

Power unit transistor controlled pulse generator transistor controlled pulse generator<br />

Generator cabinet completely sealed completely sealed<br />

Cooling method indirect air cooling indirect air cooling<br />

Max. working current A 80 (120) 120<br />

Dimensions (W x D X H) mm 400 x 1763 x 1135 400 x 1763 x 1135<br />

Weight kg 260 (300) 300<br />

Input system Keyboard, USB, Ethernet Keyboard, USB, Ethernet<br />

Colour monitor 15" Touchscreen 15" Touchscreen 15"<br />

Control system CNC, closed loops CNC, closed loops<br />

Min. instruction step X, Y, Z µm 0,1 0,1<br />

Min. axis resulution µm 0,1 0,1<br />

Max. axis instruction value mm ± 99999,999 ± 99999,999<br />

Mitsubishi Electric Robot-MER<br />

Equipment<br />

Model EA12-V <strong>Advance</strong> <strong>EA28</strong>-V <strong>Advance</strong><br />

FP120 V High performance generator<br />

Delivers higher erosion rates<br />

during fast roughing o ˛<br />

C axis with EROWA collet chuck (20/50 rpm) ˛ ˛<br />

Collet chuck 3R Macro o o<br />

High speed spindle (max. 1500 rpm) o o<br />

Programmable flushing nozzles<br />

Delivers increased eroding rates<br />

and surface homogeneity o o<br />

20-fold electrode changer o o<br />

MER handling device<br />

incl. Mitsubishi order and workpiece management<br />

software MasterCell Light o o<br />

Ethernet interface ˛ ˛<br />

External signal outlet<br />

as switching function for other devices o o<br />

Telecontact<br />

The machine sends SMS messages and informs<br />

about the processing status. o o<br />

Telecontrol<br />

Allows the optimisation of ongoing processes as well<br />

as remote monitoring and control<br />

from every location. o o<br />

Teleservice<br />

Online service support (based on Telecontrol) o o<br />

˛ = Standard<br />

o = upgradeable<br />

o = not upgradeable<br />

-- = not available<br />

(Values in brackets: EA12-V <strong>Advance</strong> with FP120V generator)<br />

18<br />

19

Technical Data<br />

Layouts<br />

EA12-V <strong>Advance</strong><br />

<strong>EA28</strong>-V <strong>Advance</strong><br />

MIN:450<br />

Maschinenkörper<br />

MIN:3000<br />

MIN:500 2050<br />

MIN:500 2512<br />

2515<br />

2615<br />

1770 425<br />

100<br />

2429<br />

Set-up area<br />

Front view<br />

200<br />

600<br />

200<br />

MIN:450<br />

Maschinenkörper<br />

2235<br />

2335<br />

1325 425<br />

100<br />

2145<br />

Set-up area<br />

Front view<br />

160<br />

500<br />

160<br />

700<br />

Working table<br />

850<br />

Working table<br />

All dimensions in mm.<br />

The dimensions may vary according to equipment.<br />

All dimensions in mm.<br />

The dimensions may vary according to equipment.<br />

Model<br />

EA12-V <strong>Advance</strong><br />

Modell<br />

<strong>EA28</strong>-V <strong>Advance</strong><br />

Overall power consumption [KVA] 7,0 (10)<br />

Overall weight of the installation kg 3725 (3765)<br />

Minimum door opening dimensions for insertion WxH 1670 x 2380 or 2065 x 2380 with ATC 20<br />

Overall power consumption [KVA] 16,5<br />

Overall weight of the installation kg 5400<br />

Minimum door opening dimensions for insertion BxH 2063 x 2660 or 2297 x 2666 with ATC 20<br />

(Values in brackets: EA12-V <strong>Advance</strong> with FP120V generator)<br />

20<br />

21

About us<br />

World-wide Leader<br />

Broad-range Service<br />

We are pleased to introduce ourselves as your part ner for wire<br />

Mitsubishi Electric is known in Europe for its high-quality wire-erosion machines and excellent<br />

service. It is not so widely known, that Mitsubishi Electric is also one of the world's most success -<br />

ful manufacturers of spark erosion machines. The research and development into the wire erosion<br />

processes had already begun in the early 1950's. Since 1963, Mitsubishi Electric has been manufacturing<br />

erosion systems in serial production. Since that time over 54,000 erosion systems have<br />

been installed for clients world-wide (as of 2009) – and this number increases every day!<br />

We offer you a unique combination of the security provided by a world-wide, large-volume industry<br />

leader and producer of erosion systems together with individual support services.<br />

In Germany:<br />

Head office:<br />

MITSUBISHI ELECTRIC EUROPE B.V.<br />

Technology Center Ratingen<br />

Gothaer Straße 8<br />

40880 Ratingen<br />

+49 - (0) 2102 / 486 - 612 0<br />

☎<br />

MITSUBISHI Education Center:<br />

tbz<br />

Center for Technology and Occupational Training<br />

Eisenach<br />

99819 Wilhelmsthal<br />

In Europe:<br />

Support Center Beckum<br />

Support Center Gießen<br />

Support Center Essen<br />

Support Center Düsseldorf<br />

Ratingen<br />

tbz<br />

Eisenach<br />

Support Center Frankfurt a.M.<br />

Support Center Gera<br />

MITSUBISHI ELECTRIC EUROPE B.V.<br />

Competence-Center Waiblingen<br />

Schüttelgrabenring 3<br />

Im Bay Center Haus 3<br />

Industriegebiet Eisental<br />

71332 Waiblingen<br />

Waiblingen<br />

Support Center Nürnberg<br />

Support Center Stuttgart<br />

Local distribution partners for eroding systems<br />

Local distribution partners for eroding systems and accessories<br />

Your free EDM hotline<br />

is always available.<br />

Phone: +49 (0) 1801 / 486 - 600<br />

(approx. 3 cents/minute, within Germany, depending on network operator)<br />

Local distribution partners for eroding accessories<br />

More than 80 co-workers and partners<br />

care for you all over Germany.<br />

More than 250 co-workers and partners<br />

care for you all over Europe.<br />

Monday – Friday<br />

Saturday<br />

7:30 AM – 20:00 PM<br />

9:00 AM – 16:00 PM<br />

Please get the complete information for our<br />

distribution and service partners from our website www.mitsubishi-edm.de.<br />

22

A sparkling partnership – Mitsubishi Electric supplies<br />

Eroding systems to the BMW Sauber F1 Team.<br />

Official technology and application partner of Mitsubishi Electric<br />

DIN EN ISO 9001:2000<br />

Certificate: 09 100 4371<br />

MITSUBISHI ELECTRIC EUROPE B.V. • German Branch • FA-Mechatronics EDM<br />

Gothaer Str. 8 • 40880 Ratingen • Phone +49 - (0)2102 - 486 - 6120 • Fax +49 - (0)2102 - 486 - 7090<br />

edm.sales@meg.mee.com • www.mitsubishi-edm.de<br />

Technical changes reserved. E 03.09 - 221 675