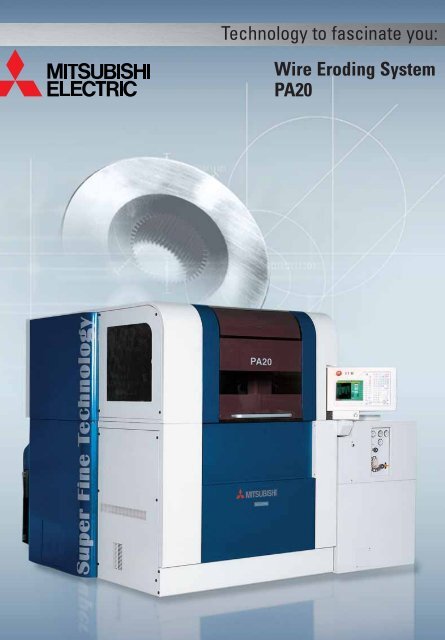

Wire Eroding System PA20 Technology to fascinate you:

Wire Eroding System PA20 Technology to fascinate you:

Wire Eroding System PA20 Technology to fascinate you:

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>Technology</strong> <strong>to</strong> <strong>fascinate</strong> <strong>you</strong>:<br />

<strong>Wire</strong> <strong>Eroding</strong> <strong>System</strong><br />

<strong>PA20</strong>

Exceeding <strong>you</strong>r expectations – precisely<br />

Mitsubishi Electric has once again taken a decisive step pushing forward the boundaries of<br />

eroding technology. With a guaranteed precision of ± 2 µm Mitsubishi's <strong>PA20</strong> sets new<br />

standards of performance <strong>to</strong> give <strong>you</strong> technical advantage over <strong>you</strong>r competition.<br />

In conjunction with the newly developed digital fine smoothing genera<strong>to</strong>r, for the finest<br />

surface finish, the <strong>PA20</strong> also offers premium manufacturing quality.<br />

The flexible design of this high precision eroding system enables <strong>you</strong> <strong>to</strong> process a wide range<br />

of workpieces at a very high erosion rate. Furthermore, it can significantly increase <strong>you</strong>r<br />

productivity and machining efficiency.<br />

Precision as a standard<br />

Material: 1.2379<br />

Cutting height: 50 mm<br />

<strong>Wire</strong> electrode: 0.25 mm brass<br />

Precision: ± 0.002 mm<br />

Surface quality: Ra 0.13 mm<br />

Processing time: 1 hour 24 minutes<br />

Production precision<br />

Material: 1.4310<br />

Cutting height: 1.0 mm x 10 (pack)<br />

<strong>Wire</strong> electrode: 0.10 mm brass<br />

Precision: ± 0.003 mm<br />

Surface quality: Ra 0.18 mm<br />

Processing time: 1 hour 26 minutes<br />

Ultimate precision<br />

Material: Carbide G30<br />

Cutting height: 40 mm<br />

<strong>Wire</strong> electrode: 0.15 mm brass<br />

Precision: ± 0.002 mm<br />

Surface quality: Ra 0.10 µm<br />

Processing time: 2 hours 12 minutes<br />

Perfect precision<br />

Material: 1.2379<br />

Cutting height: 50 mm and 20 mm<br />

<strong>Wire</strong> electrode: 0.20 mm brass<br />

Precision: ± 0.002 mm<br />

Surface quality: Ra 0.15 µm<br />

Processing time: 1 hour 34 minutes (stamp),<br />

52 minutes (die)<br />

Manufacturer:<br />

Marquardt GmbH<br />

www.marquardt.de<br />

2

Highest precision Productivity Flexibility Efficiency Guaranteed future<br />

3

An intelligent, well thought-out concept<br />

All elements of the machine design have been manufactured from high quality materials<br />

and tested extensively for strength and durability.<br />

The machine structure, which is completely temperature stabilised by means of an<br />

integrated cooling system, guarantees the highest precision over long periods.<br />

This is further supported by direct AC drives, re-circulating ball screw and nut resolution of<br />

0.05 µm. In addition the spindle is positioned exactly in the centre of the load in order <strong>to</strong> ensure<br />

"soft" axis movement. A central oil lubrication system, working tank and sealing system made<br />

of stainless steel and a patented self-cleaning system are only a few of the maintenance<br />

reducing features of the machine.<br />

Thermal encapsulation<br />

A thermally tight encapsulation in conjunction with<br />

active cooling systems, avoids a loss of precision<br />

caused by thermal fluctuation.<br />

Cooler<br />

Filter unit<br />

Cast steel machine design<br />

This classic concept guarantees a long service life<br />

and the solid machine construction easily handles<br />

heavy workpieces.<br />

Direct drive and generously dimensioned spindles<br />

Non-slip clutches, double distance closed loop<br />

measuring systems and intelligent distribution of<br />

dynamic loads ensure long-lasting precision.<br />

4

Air conditioned encapsulation Direct shaft drives Easy maintenance High reliability<br />

5

AT system for fastest wire<br />

Everything is easier with good ergonomics<br />

The way the <strong>PA20</strong> reduces manual machine activities <strong>to</strong> a minimum will as<strong>to</strong>und <strong>you</strong>. The ergonomic<br />

design concept not only facilitates daily work, it also contributes <strong>to</strong> economic operation.<br />

An example of this is the extraordinary accessibility <strong>to</strong> the working table provided by a generous<br />

swinging hood in conjunction with the au<strong>to</strong>matic vertical sliding door. In addition, the au<strong>to</strong>matic<br />

wire threading system (AT), as well as the maintenance-friendly design of the tank sealing system<br />

also contribute <strong>to</strong> efficient operation.<br />

Further highlights are the optional features for remote control, maintenance and diagnosis<br />

by means of Telecontact and Telecontrol. Last but not least, the <strong>PA20</strong> is “Ready for Au<strong>to</strong>mation”.<br />

Threaded in 10 seconds: the AT <strong>System</strong>.<br />

The combination of a new measuring sensor and<br />

a fast retract function gives <strong>you</strong> the highest<br />

reliability and ultimate speed, even for smallest<br />

starting holes.<br />

Telecontrol<br />

Teleservice<br />

Opera<strong>to</strong>r<br />

Telecontact<br />

Telecontact<br />

Telecontact<br />

Opera<strong>to</strong>r 2<br />

Maintenance<br />

Telecontrol: Remote control via PC.<br />

Telecontrol provides remote moni<strong>to</strong>ring and<br />

remote control of the machine from any site.<br />

<strong>System</strong> optimisation for running processes is also<br />

possible with this service.<br />

Opera<strong>to</strong>r 1<br />

6

threading Freely accessible working table User-friendliness Telecontrol Telecontact<br />

7

64-BIT CNC control<br />

The intelligent control system<br />

The Mitsubishi 64 BIT CNC control system leaves nothing <strong>to</strong> be desired. In spite of its<br />

complex function, it can be operated quickly and intuitively thanks <strong>to</strong> its clear menus and<br />

graphic images. The “Graphic Check” function allows <strong>you</strong> <strong>to</strong> perform a simulation of <strong>you</strong>r<br />

program in 2D or 3D mode, before or during the processing.<br />

The expert system E.S.P.E.R. au<strong>to</strong>matically determines the correct genera<strong>to</strong>r setting from<br />

<strong>you</strong>r data. The “Machining Moni<strong>to</strong>r” shows the current processing status for moni<strong>to</strong>ring<br />

purposes. Furthermore, various evaluation and optimisation programs interactively support<br />

<strong>you</strong> during the determination of the optimal and most economic machine settings.<br />

This means: <strong>you</strong> can work with a workshop oriented control system.<br />

3D graphic function<br />

Reliable graphic program check using the improved<br />

graphic and surface display. The speed of the graphic<br />

program check is faster than conventional systems.<br />

Programming<br />

The Graphic User Interface (GUI) makes the <strong>PA20</strong><br />

easy <strong>to</strong> operate, even for beginners. The operating<br />

and programming screens correspond <strong>to</strong> PC standards.<br />

Expert system E.S.P.E.R.<br />

The “Easy Simple <strong>to</strong> Program by Expert” system, combined<br />

with the 64-BIT CNC control system, complete the au<strong>to</strong>matic<br />

adaptation and genera<strong>to</strong>r setting according <strong>to</strong> <strong>you</strong>r<br />

process-specific data.<br />

Hybrid Pack Software<br />

This program helps <strong>you</strong> <strong>to</strong> achieve optimal machine<br />

settings for individual processes.<br />

8

system 3D graphic function Expert system Real time moni<strong>to</strong>ring Optimisation <strong>to</strong>ols<br />

9

Machining results <strong>to</strong> re-define the concept of quality<br />

The latest genera<strong>to</strong>r technology combined with precise mechanical engineering ensures<br />

ultimate workpiece quality. This opens up processing capabilities <strong>to</strong> support developments<br />

in micro technology, e. g. in the optical and medical industries.<br />

The newly developed fine smoothing genera<strong>to</strong>r allows the complete moni<strong>to</strong>ring of the process<br />

in the spark gap as well as the optimisation of the genera<strong>to</strong>r settings in shortest cycles. This<br />

results in the finest and most homogenous surface structures.<br />

Furthermore, Orbit-Master, SL-Control, and many more process-optimising control functions<br />

ensure the highest amount of reproducible precision.<br />

Digital FS Genera<strong>to</strong>r: The newly developed fine smoothing<br />

genera<strong>to</strong>r allows a surface finish of up <strong>to</strong> 0.1 µm Ra.<br />

It can also be used when applied <strong>to</strong> au<strong>to</strong>mation systems.<br />

Material: 1.2379<br />

Cutting height: 30 mm<br />

<strong>Wire</strong> electrode: 0.25 mm brass<br />

Precision: ± 0.003 mm<br />

Surface quality: Ra 0.12 µm<br />

Processing time: 3 hours 28 minutes<br />

Workpiece height and surface quality<br />

[µmRa] 0,25<br />

0,20<br />

Surface quality<br />

0,15<br />

0,10<br />

0 50 100<br />

Workpiece height in mm<br />

Orbit-Master continuously controls the conditions<br />

in the spark gap and allows geometrical reliability<br />

of the workpiece independent from corner geometries.<br />

Material: ASP23<br />

Cutting height: 25 mm<br />

<strong>Wire</strong> electrode: 0.07 mm brass<br />

Precision: ± 0.002 mm<br />

Surface quality: Ra 0.10 µm<br />

Processing time: 1 hour 36 minutes<br />

Orbit-Master has been developed <strong>to</strong> obtain a uniform gap for the electric discharge, independent from<br />

the corner shape. This function decreases the amount of faults of the radial shape and allows for an<br />

improvement in the overall accuracy of the workpieces.<br />

Sample processing<br />

<strong>Wire</strong> electrode ø 0.2 mm MS<br />

Workpiece 1.2379, 60 mm<br />

Processing time 1 hour 47 minutes 0 0<br />

A:5mm<br />

B:4mm<br />

–1<br />

0<br />

SL-Control ensures the best geometry of the eroding<br />

surface even when machining stepped workpieces.<br />

7µm<br />

3µm<br />

Material: SKD11<br />

Cutting height: 5-20-40-60 mm<br />

<strong>Wire</strong> electrode: 0.20 mm brass<br />

Precision: ± 0.002 mm<br />

Surface quality: Ra 0.26 µm<br />

Processing time: 57 minutes<br />

Conventionally:<br />

Con<strong>to</strong>ur deviation at the step: -3 µm <strong>to</strong> +7 µm<br />

2µm<br />

1µm<br />

7,0 µm<br />

SL-Control:<br />

Con<strong>to</strong>ur deviation at the step: +2 µm or less<br />

-7,0 µm<br />

The HL and LC circuits guarantee the achievement<br />

of true-shape surfaces. This helps <strong>to</strong> even make dovetail<br />

geometries fit perfectly.<br />

Material: 1.2379<br />

Cutting height: 100 mm<br />

<strong>Wire</strong> electrode: 0.20 mm brass<br />

Precision: ± 0.003 mm<br />

Surface quality: Ra 0.16 µm<br />

Processing time: 1 hour 47 minutes per workpiece<br />

10

Process optimisation Surface qualities of up <strong>to</strong> Ra 0.1 µm Geometric fidelity of up <strong>to</strong> 2 µm<br />

11

295<br />

A system <strong>to</strong> perform<br />

Even finer structures, even better surfaces – the <strong>PA20</strong> high precision eroding system<br />

helps <strong>you</strong> <strong>to</strong> achieve these important market requirements. You can rely on the<br />

proven, long-life quality of Mitsubishi as it satisfies the highest demands with a robust<br />

machine design paired with high-tech components. Machine innovations include the<br />

digital drive system, the intelligent 64 BIT CNC control system as well as the newly<br />

developed temperature stabilisation system and the liquid level moni<strong>to</strong>ring system.<br />

This is why the <strong>PA20</strong> is ready <strong>to</strong> help <strong>you</strong> gain greater productivity.<br />

Travel paths and workpiece dimensions in mm<br />

y=350<br />

800<br />

z = 300<br />

x=500<br />

1050<br />

Overall dimensions of the machine in mm<br />

2170<br />

2775<br />

2860<br />

Possible wire diameters<br />

from ø 0,3 mm<br />

<strong>to</strong> ø 0,05 mm<br />

12

Ultimate machine accuracy Best surface qualities Universal and flexible<br />

13

Machine<br />

Model<br />

<strong>PA20</strong><br />

Machine<br />

Filter<br />

unit<br />

Travel path (X/Y/Z) mm 500 x 350 x 300<br />

Travel path (U/V) mm ± 21 x ±21<br />

Conic angle (for workpiece height) ° 10 (100 mm)<br />

Max. workpiece dimensions (W x D X H) mm 1050 x 800 x 295<br />

Max. workpiece weight kg 1500<br />

Table dimensions (W x D) mm 780 x 630<br />

Possible wire diameters mm 0,05 – 0,3<br />

<strong>Wire</strong> reel reception kg 10<br />

Au<strong>to</strong>matic water jet threading<br />

<br />

Max. advance (X/Y) mm/min 1300<br />

Overall dimensions (W x D x H) mm 2210 x 2873 x 2150<br />

Weight of the machine kg 3500<br />

Tank capacity l 750<br />

Filter fineness µm 2<br />

Filter elements 2<br />

Temperature control<br />

Dielectric cooler<br />

Overall dimensions (W x D x H) mm 880 x 2070 x 1565<br />

Weight unfilled kg 400<br />

Genera<strong>to</strong>r / control<br />

Model<br />

<strong>PA20</strong><br />

Genera<strong>to</strong>r<br />

Control<br />

Power unit<br />

of transis<strong>to</strong>r-controlled pulse genera<strong>to</strong>r<br />

Genera<strong>to</strong>r cabinet<br />

completely tight<br />

Cooling method<br />

Indirect air cooling<br />

Max. working current A 50<br />

Dimensions 550 x 600 x 1650<br />

Weight kg 240<br />

Input interfaces<br />

Keyboard, floppy disk 3,5", RS232C, Ethernet<br />

Colour moni<strong>to</strong>r<br />

10,4" TFT LCD type<br />

Control system<br />

CNC, closed loop<br />

Min. instruction step µm X, Y, Z, U, V ..1/0.1 µm<br />

Min. axis resolution µm 0,05<br />

Max. instruction value mm ± 99999,999<br />

Equipment<br />

Model<br />

<strong>PA20</strong><br />

Equipment<br />

<strong>Wire</strong> station 20 kg <br />

Thin wire device (0,05 mm)<br />

<br />

Fine smoothing unit Digital FS<br />

<br />

B axis<br />

<br />

Au<strong>to</strong>mation Robot<br />

<br />

Au<strong>to</strong>mation Handling<br />

<br />

Ethernet interface<br />

<br />

Teleservice<br />

<br />

Telecontrol<br />

<br />

Telecontact<br />

<br />

= standard<br />

= retrofittable options<br />

14

Technical data<br />

La<strong>you</strong>t plans<br />

<strong>PA20</strong><br />

20 kg<br />

<strong>Wire</strong> station<br />

1090<br />

2170<br />

2775<br />

230<br />

2630<br />

Lateral view<br />

Front view<br />

Footprint<br />

Working table<br />

<strong>Wire</strong> collec<strong>to</strong>r box<br />

50 50<br />

580<br />

40 10 x 50 =500<br />

50<br />

40<br />

50<br />

50<br />

56-M8<br />

Genera<strong>to</strong>r<br />

50<br />

2775<br />

20 kg<br />

<strong>Wire</strong><br />

supply<br />

unit<br />

Machine<br />

Filter unit<br />

and<br />

cooler<br />

50<br />

15<br />

430<br />

8 x 50 = 400 50<br />

15<br />

50<br />

Travel path 500<br />

Travel path 350<br />

130 370<br />

130<br />

630<br />

230<br />

2630<br />

Control<br />

(Screen)<br />

50<br />

130 520<br />

130<br />

780<br />

All indications in mm<br />

The dimensions may vary according <strong>to</strong> equipment.<br />

Model<br />

<strong>PA20</strong><br />

Overall power consumption [KVA] 13,5<br />

Overall weight of the installation kg 4200<br />

15

Mitsubishi Electric is an Official Supplier<br />

of the BMW Sauber F1 Team<br />

Official technology and application partner of Mitsubishi Electric<br />

Official co-operation partner of Mitsubishi Electric<br />

DIN EN ISO 9001:2000<br />

Zertifikat: 09 100 4371<br />

MITSUBISHI ELECTRIC EUROPE B.V. • German Branch • FA-Mechatronics EDM<br />

Gothaer Str. 8 • 40880 Ratingen • Phone +49 - (0)2102 - 486 - 6120 • Fax: +49 - (0)2102 - 486 - 7090<br />

edm.sales@meg.mee.com • www.mitsubishi-edm.de<br />

Specifications subject <strong>to</strong> change without notice. E 03.08 - 189 048