TECHNOLOGY REVIEW - Camelot Technologies Group

TECHNOLOGY REVIEW - Camelot Technologies Group

TECHNOLOGY REVIEW - Camelot Technologies Group

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

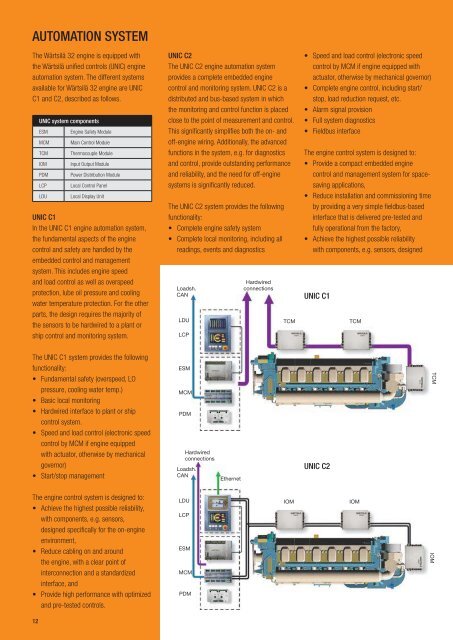

AUTOMATION SYSTEM<br />

The Wärtsilä 32 engine is equipped with<br />

the Wärtsilä unified controls (UNIC) engine<br />

automation system. The different systems<br />

available for Wärtsilä 32 engine are UNIC<br />

C1 and C2, described as follows.<br />

UNIC system components<br />

ESM<br />

MCM<br />

TCM<br />

IOM<br />

PDM<br />

LCP<br />

LDU<br />

Engine Safety Module<br />

Main Control Module<br />

Thermocouple Module<br />

Input Output Module<br />

Power Distribution Module<br />

Local Control Panel<br />

Local Display Unit<br />

UNIC C1<br />

In the UNIC C1 engine automation system,<br />

the fundamental aspects of the engine<br />

control and safety are handled by the<br />

embedded control and management<br />

system. This includes engine speed<br />

and load control as well as overspeed<br />

protection, lube oil pressure and cooling<br />

water temperature protection. For the other<br />

parts, the design requires the majority of<br />

the sensors to be hardwired to a plant or<br />

ship control and monitoring system.<br />

UNIC C2<br />

The UNIC C2 engine automation system<br />

provides a complete embedded engine<br />

control and monitoring system. UNIC C2 is a<br />

distributed and bus-based system in which<br />

the monitoring and control function is placed<br />

close to the point of measurement and control.<br />

This significantly simplifies both the on- and<br />

off-engine wiring. Additionally, the advanced<br />

functions in the system, e.g. for diagnostics<br />

and control, provide outstanding performance<br />

and reliability, and the need for off-engine<br />

systems is significantly reduced.<br />

The UNIC C2 system provides the following<br />

functionality:<br />

•<br />

•<br />

Complete engine safety system<br />

Complete local monitoring, including all<br />

readings, events and diagnostics<br />

•<br />

Speed and load control (electronic speed<br />

control by MCM if engine equipped with<br />

actuator, otherwise by mechanical governor)<br />

Complete engine control, including start/<br />

stop, load reduction request, etc.<br />

Alarm signal provision<br />

Full system diagnostics<br />

Fieldbus interface<br />

•<br />

•<br />

•<br />

•<br />

The engine control system is designed to:<br />

• Provide a compact embedded engine<br />

control and management system for spacesaving<br />

applications,<br />

• Reduce installation and commissioning time<br />

by providing a very simple fieldbus-based<br />

interface that is delivered pre-tested and<br />

fully operational from the factory,<br />

• Achieve the highest possible reliability<br />

with components, e.g. sensors, designed<br />

UNIC C1<br />

The UNIC C1 system provides the following<br />

functionality:<br />

Fundamental safety (overspeed, LO<br />

pressure, cooling water temp.)<br />

Basic local monitoring<br />

Hardwired interface to plant or ship<br />

control system.<br />

Speed and load control (electronic speed<br />

control by MCM if engine equipped<br />

with actuator, otherwise by mechanical<br />

governor)<br />

Start/stop management<br />

•<br />

•<br />

•<br />

•<br />

•<br />

UNIC C2<br />

The engine control system is designed to:<br />

• Achieve the highest possible reliability,<br />

with components, e.g. sensors,<br />

designed specifically for the on-engine<br />

environment,<br />

• Reduce cabling on and around<br />

the engine, with a clear point of<br />

interconnection and a standardized<br />

interface, and<br />

• Provide high performance with optimized<br />

and pre-tested controls.<br />

12