TECHNOLOGY REVIEW - Camelot Technologies Group

TECHNOLOGY REVIEW - Camelot Technologies Group

TECHNOLOGY REVIEW - Camelot Technologies Group

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

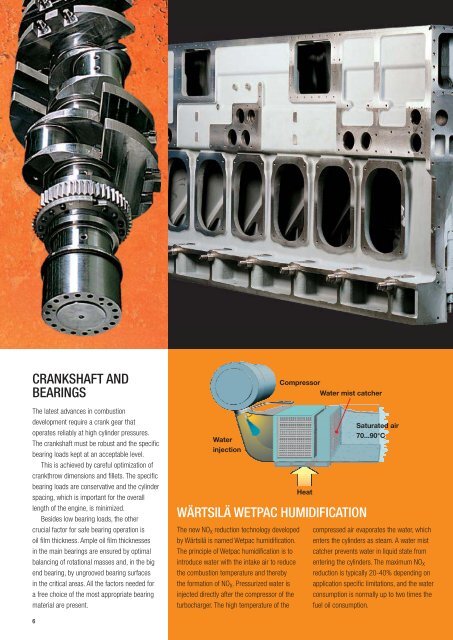

CRANKSHAFT AND<br />

BEARINGS<br />

The latest advances in combustion<br />

development require a crank gear that<br />

operates reliably at high cylinder pressures.<br />

The crankshaft must be robust and the specifi c<br />

bearing loads kept at an acceptable level.<br />

This is achieved by careful optimization of<br />

crankthrow dimensions and fi llets. The specifi c<br />

bearing loads are conservative and the cylinder<br />

spacing, which is important for the overall<br />

length of the engine, is minimized.<br />

Besides low bearing loads, the other<br />

crucial factor for safe bearing operation is<br />

oil fi lm thickness. Ample oil fi lm thicknesses<br />

in the main bearings are ensured by optimal<br />

balancing of rotational masses and, in the big<br />

end bearing, by ungrooved bearing surfaces<br />

in the critical areas. All the factors needed for<br />

a free choice of the most appropriate bearing<br />

material are present.<br />

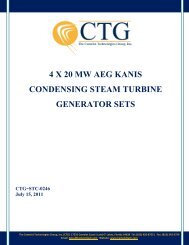

Water<br />

injection<br />

Compressor<br />

Heat<br />

Water mist catcher<br />

WÄRTSILÄ WETPAC HUMIDIFICATION<br />

The new NO X reduction technology developed<br />

by Wärtsilä is named Wetpac humidifi cation.<br />

The principle of Wetpac humidifi cation is to<br />

introduce water with the intake air to reduce<br />

the combustion temperature and thereby<br />

the formation of NO X . Pressurized water is<br />

injected directly after the compressor of the<br />

turbocharger. The high temperature of the<br />

Saturated air<br />

70...90°C<br />

compressed air evaporates the water, which<br />

enters the cylinders as steam. A water mist<br />

catcher prevents water in liquid state from<br />

entering the cylinders. The maximum NO X<br />

reduction is typically 20-40% depending on<br />

application specifi c limitations, and the water<br />

consumption is normally up to two times the<br />

fuel oil consumption.<br />

6