Mechanical Engineering Senior Design Project List - South Dakota ...

Mechanical Engineering Senior Design Project List - South Dakota ...

Mechanical Engineering Senior Design Project List - South Dakota ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

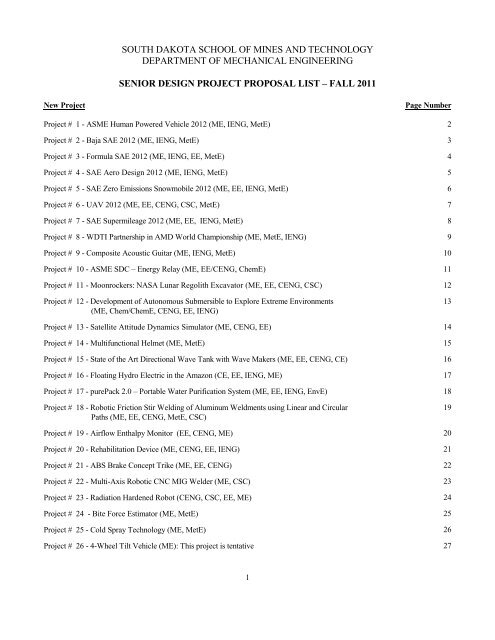

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

DEPARTMENT OF MECHANICAL ENGINEERING<br />

SENIOR DESIGN PROJECT PROPOSAL LIST – FALL 2011<br />

New <strong>Project</strong><br />

<strong>Project</strong> # 1 - ASME Human Powered Vehicle 2012 (ME, IENG, MetE)<br />

<strong>Project</strong> # 2 - Baja SAE 2012 (ME, IENG, MetE)<br />

<strong>Project</strong> # 3 - Formula SAE 2012 (ME, IENG, EE, MetE)<br />

<strong>Project</strong> # 4 - SAE Aero <strong>Design</strong> 2012 (ME, IENG, MetE)<br />

<strong>Project</strong> # 5 - SAE Zero Emissions Snowmobile 2012 (ME, EE, IENG, MetE)<br />

<strong>Project</strong> # 6 - UAV 2012 (ME, EE, CENG, CSC, MetE)<br />

<strong>Project</strong> # 7 - SAE Supermileage 2012 (ME, EE, IENG, MetE)<br />

<strong>Project</strong> # 8 - WDTI Partnership in AMD World Championship (ME, MetE, IENG)<br />

<strong>Project</strong> # 9 - Composite Acoustic Guitar (ME, IENG, MetE)<br />

<strong>Project</strong> # 10 - ASME SDC – Energy Relay (ME, EE/CENG, ChemE)<br />

<strong>Project</strong> # 11 - Moonrockers: NASA Lunar Regolith Excavator (ME, EE, CENG, CSC)<br />

<strong>Project</strong> # 12 - Development of Autonomous Submersible to Explore Extreme Environments<br />

(ME, Chem/ChemE, CENG, EE, IENG)<br />

<strong>Project</strong> # 13 - Satellite Attitude Dynamics Simulator (ME, CENG, EE)<br />

<strong>Project</strong> # 14 - Multifunctional Helmet (ME, MetE)<br />

<strong>Project</strong> # 15 - State of the Art Directional Wave Tank with Wave Makers (ME, EE, CENG, CE)<br />

<strong>Project</strong> # 16 - Floating Hydro Electric in the Amazon (CE, EE, IENG, ME)<br />

<strong>Project</strong> # 17 - purePack 2.0 – Portable Water Purification System (ME, EE, IENG, EnvE)<br />

<strong>Project</strong> # 18 - Robotic Friction Stir Welding of Aluminum Weldments using Linear and Circular<br />

Paths (ME, EE, CENG, MetE, CSC)<br />

<strong>Project</strong> # 19 - Airflow Enthalpy Monitor (EE, CENG, ME)<br />

<strong>Project</strong> # 20 - Rehabilitation Device (ME, CENG, EE, IENG)<br />

<strong>Project</strong> # 21 - ABS Brake Concept Trike (ME, EE, CENG)<br />

<strong>Project</strong> # 22 - Multi-Axis Robotic CNC MIG Welder (ME, CSC)<br />

<strong>Project</strong> # 23 - Radiation Hardened Robot (CENG, CSC, EE, ME)<br />

<strong>Project</strong> # 24 - Bite Force Estimator (ME, MetE)<br />

<strong>Project</strong> # 25 - Cold Spray Technology (ME, MetE)<br />

<strong>Project</strong> # 26 - 4-Wheel Tilt Vehicle (ME): This project is tentative<br />

Page Number<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

18<br />

19<br />

20<br />

21<br />

22<br />

23<br />

24<br />

25<br />

26<br />

27<br />

1

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title: ASME Human Powered Vehicle 2012<br />

Proposed/Advised by:<br />

Sponsored by:<br />

Dr. Matejcik, Dr. Ellingson, Kim Osberg, Dr. Dolan, HPV team<br />

CAMP, SA, ASME<br />

<strong>Project</strong> Description (including objectives and requirements):<br />

A vehicle will be designed, built, and tested for the ASME Human Powered Vehicle Competition.<br />

Information can be found at: http://www.asme.org/Events/Contests/<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

machine design, manufacturing, materials, composites, ergonomics, aerodynamics<br />

Any other special requirements:<br />

<strong>Senior</strong> design members are expected to attend the competition.<br />

Number of Students/Disciplines required (e.g., 2 ME, 1 EE, 1 CS):<br />

3 ME, 2IE, and 1 MetE would be desired<br />

2

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title: Baja SAE 2012<br />

Proposed/Advised by:<br />

Sponsored by:<br />

Dr. Dolan, Dr. Muci, Kim Osberg, Baja SAE Team<br />

CAMP, SAE, SA<br />

<strong>Project</strong> Description:<br />

Baja SAE consists of competitions that simulate real-world engineering design projects and their related<br />

challenges. <strong>Engineering</strong> students are tasked to design and build an off-road vehicle that will survive the<br />

severe punishment of rough terrain and in the East competition—water.<br />

The object of the competition is to provide SAE student members with a challenging project that<br />

involves the planning and manufacturing tasks found when introducing a new product to the consumer<br />

industrial market. Teams compete against one another to have their design accepted for manufacture by a<br />

fictitious firm. Students must function as a team to not only design, build, test, promote, and race a<br />

vehicle within the limits of the rules, but also to generate financial support for their project and manage<br />

their educational priorities.<br />

All vehicles are powered by a ten-horsepower Intek Model 20 engine donated by Briggs & Stratton<br />

Corporation. For over twenty-five years, the generosity of Briggs & Stratton has enabled SAE to provide<br />

each team with a dependable engine free of charge. Use of the same engine by all the teams creates a<br />

more challenging engineering design test.<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

Dynamics, vehicle dynamics, machine and structural design, human factors, manufacturing<br />

Any other special requirements:<br />

The students must be SAE members to attend the competition. All seniors are expected to attend the<br />

competition.<br />

Number of Students/Disciplines required (e.g., 2 ME, 1 EE, 1 CS):<br />

A team consisting of 6 MEs, 2IEs, and 1 Met student would be desired, with an emphasis for one team<br />

member taking ME 428: Finite Element Analysis to focus on frame analysis.<br />

3

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title: Formula SAE 2012<br />

Proposed/Advised by:<br />

Sponsored by:<br />

Dr. Dolan, Dr. Ellingson, Kim Osberg, Chuck Schilling, FSAE Team<br />

CAMP, SA, SAE, Poet, Ford<br />

<strong>Project</strong> Description: The Formula SAE competition is for SAE student members to conceive, design,<br />

fabricate, and compete with small formula-style racing cars. The restrictions on the car frame and engine<br />

are limited so that the knowledge, creativity, and imagination of the students are challenged. For the<br />

purpose of this competition, the students are to assume that a manufacturing firm has engaged them to<br />

produce a prototype car for evaluation as a production item. The intended sales market is the<br />

nonprofessional weekend autocross racer. Therefore, the car must have very high performance in terms<br />

of its acceleration, braking, and handling qualities. The car must be low in cost, easy to maintain, and<br />

reliable. In addition, the car's marketability is enhanced by other factors such as aesthetics, comfort and<br />

use of common parts.<br />

The cars are judged in a series of static and dynamic events including: technical inspection, cost,<br />

presentation, and engineering design, solo performance trials, and high performance track endurance.<br />

These events are scored to determine how well the car performs. In each event, the manufacturing firm<br />

has specified minimum acceptable performance levels that are reflected in the scoring equations.<br />

Further information can be obtained at: http://students.sae.org/competitions/formulaseries/<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

Dynamics, fluids, aerodynamics, machine and structural design, electric circuits, measurements and<br />

instrumentation, human factors, manufacturing, composites, engines<br />

Any other special requirements:<br />

The students must be SAE members to attend the competition. All seniors are expected to attend the<br />

competition.<br />

Number of Students/Disciplines required (e.g., 2 ME, 1 EE, 1 CS):<br />

A team of 6 MEs, 2 IEs, 2 EEs and 2 Met students would be desired.<br />

4

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title: SAE Aero <strong>Design</strong> 2012<br />

Proposed/Advised by:<br />

Sponsored by:<br />

Dr. Dolan, Kim Osberg<br />

CAMP, SA, SAE, SAE Aero <strong>Design</strong> Team<br />

<strong>Project</strong> Description:<br />

The Aero <strong>Design</strong>® Competition challenges engineering students to conceive, design, fabricate, and test a<br />

radio controlled aircraft that can take off and land while carrying the maximum cargo.<br />

Competition information is posted at: http://students.sae.org/competitions/aerodesign/<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

Dynamics, machine and structural design, instrumentation and testing, controls, fluids, aerodynamics,<br />

manufacturing<br />

Any other special requirements:<br />

The students must be SAE members to attend the competition, and seniors are expected to attend.<br />

Number of Students/Disciplines required (e.g., 2 ME, 1 EE, 1 CS):<br />

A team of 4 MEs, 2 IEs and 2 Met students would be desired.<br />

5

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title: SAE Zero Emissions Snowmobile 2012<br />

Proposed/Advised by:<br />

Sponsored by:<br />

Dr. Batchelder, Dr. Dolan, Kim Osberg, and the AFV Team<br />

CAMP, SAE<br />

<strong>Project</strong> Description:<br />

The object of the competition is to provide SAE student members with a challenging project that<br />

involves the planning and manufacturing tasks found when introducing a new product to the consumer<br />

industrial market. Teams compete against one another to have their design accepted for manufacture by a<br />

fictitious firm. Students must function as a team to not only design, build, test, promote, and demonstrate<br />

a zero-emissions snowmobile within the limits of the rules, but also to generate financial support for<br />

their project and manage their educational priorities.<br />

The SDSM&T team will use an electric motor powered by batteries.<br />

Rules are at: http://students.sae.org/competitions/snow/<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

Electric power, motors, controls, dynamics, vehicle dynamics, machine and structural design, human<br />

factors, manufacturing<br />

Any other special requirements:<br />

The students must be SAE members to attend the competition. <strong>Senior</strong> design members are expected to<br />

attend the competition.<br />

Number of Students/Disciplines required (e.g., 2 ME, 1 EE, 1 CS):<br />

A team consisting of 4 MEs, 4EEs, 2IEs, and 1 Met would be desired.<br />

6

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title: UAV 2012<br />

Proposed/Advised by: Profs. McGough, Dolan, Batchelder, Weiss, Linde, Hoover, Tolle;<br />

Kim Osberg<br />

External advisors: Jason Howe, Mark Sauder<br />

Grad students: Jaiyi Liu, Jordan Ritz, and UAV team<br />

Sponsored by:<br />

CAMP, SA<br />

<strong>Project</strong> Description (including objectives and requirements):<br />

This senior design team will work to configure the Unmanned Aerial Vehicle (UAV) Team‘s verticaltake-off-and-landing<br />

(VTOL) sub-vehicle for the interior search mission of 2012. Work will be done on<br />

the control system to provide the jump-drive drop and pick-up system.<br />

This <strong>Senior</strong> <strong>Design</strong> Team will coordinate all efforts with the Chief Engineer and Team Manager of the<br />

UAV Team as well as the team at large. All final design decisions will be the collaborative efforts of the<br />

UAV Team leadership, the UAV Team, and the <strong>Senior</strong> <strong>Design</strong> Team members. Additionally, it is<br />

desired that <strong>Senior</strong> <strong>Design</strong> Team members become and remain SDSM&T UAV Team members in good<br />

standing.<br />

Competition rules and highlights are at:<br />

http://iarc.angel-strike.com/<br />

<strong>Project</strong> Duration:<br />

1 year<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

Controls, machine design, composite materials and structures, fluid mechanics, instrumentation and testing,<br />

software engineering, programming<br />

Any other special requirements:<br />

Students would be members of the UAV competition team. <strong>Senior</strong> design members are expected to attend<br />

the competition.<br />

Number of Students/Disciplines required (e.g., 2 ME, 1 EE, 1 CS):<br />

2 ME, 1 EE, 2 CompE, 3 CSC, 1 MET would be desired<br />

7

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title: SAE Supermileage 2012<br />

Proposed/Advised by:<br />

Sponsored by:<br />

Dr. Abata, Dr. Dolan, CAMP<br />

Nucor Steel and CAMP<br />

<strong>Project</strong> Description: The Supermileage® competition provides engineering and technology students<br />

with a challenging design project that involves the development and construction of a single-person,<br />

fuel-efficient vehicle. Vehicles are powered by a small four-cycle engine. The vehicles will run a<br />

specified course with the vehicle obtaining the highest combined kilometers per liter (miles per gallon)<br />

rating plus design segment points winning the event. Students have the opportunity to set a world<br />

fuel economy record and increase public awareness of fuel economy. Engines are donated by Briggs<br />

& Stratton.<br />

Further information can be obtained at: http://students.sae.org/competitions/supermileage/<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

Dynamics, fluids, aerodynamics, machine and structural design, measurements and instrumentation,<br />

engines, human factors, manufacturing, composites.<br />

Any other special requirements:<br />

The students must be SAE members to attend the competition. All seniors on the project would be<br />

expected to attend the competition.<br />

Number of Students/Disciplines required (e.g., 2 ME, 1 EE, 1 CS):<br />

A team of 4 MEs, 2 EEs, 1 IE, and 1 Met student would be desired.<br />

8

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

Proposed/Advised by:<br />

Sponsored by:<br />

WDTI Partnership in AMD World Championship<br />

Dan Dolan, Mike West, Jason Ash, Luke Steinmetz (WDTI), and Mike<br />

Prugh<br />

Prugh <strong>Design</strong> and Black Hills Harley Davidson<br />

<strong>Project</strong> Description:<br />

In 2009-2010, Western <strong>Dakota</strong> Technical Institute partnered with Prugh <strong>Design</strong> and the Black Hills<br />

Harley Davidson to develop a custom modified Harley for the 2010 American Motorcycle Dealer<br />

(AMD) World Championship of Custom Bike Building that takes place each year during the Sturgis<br />

Rally and features custom motorcycles from around the world. Prugh <strong>Design</strong> and Black Hills Harley<br />

Davidson are looking to partner again with a collaborative effort between WDTI and the students at<br />

SDSM&T. The scope of the project focuses on the form as well as the function in the mechanical design<br />

of a custom bike and will require in-house parts to be designed and manufactured. Details on the 2010<br />

competition bike can be found at the following:<br />

http://www.amdchampionship.com/bikes/2509-prugh-design-black-hills-harley-davidson-filter.html<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

ME: Machine design, vehicle dynamics, product development<br />

MetE: Material selection, product development<br />

IENG: <strong>Project</strong> management, ergonomics, product development<br />

Any other special requirements:<br />

Number of Students/Disciplines required (e.g., 2 ME, 1 EE, 1 CS):<br />

4 ME, 2 MetE, and 1 IENG would be desired<br />

9

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

Proposed/Advised by:<br />

Sponsored by:<br />

Composite Acoustic Guitar<br />

Dr. Dolan<br />

CAMP, Gary Santa, Dr. Dolan<br />

<strong>Project</strong> Description (including objectives and requirements):<br />

A composite (carbon fiber) acoustic 6-string guitar will be designed, built, and tested. It is desired to focus<br />

on the manufacturing technology while assuring a professional sounding guitar. The guitar should have<br />

roughly the shape, size, and sound of a dreadnought guitar.<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

machine design, structures, manufacturing, materials, composites, ergonomics, acoustics, vibrations, music<br />

Any other special requirements:<br />

It would be helpful if at least one of the team members were a guitar player.<br />

Number of Students/Disciplines required (e.g., 2 ME, 1 EE, 1 CS):<br />

3 ME, 1 IE, and 1 MetE would be desired<br />

10

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

ASME STUDENT DESIGN CONTEST – Energy Relay<br />

Proposed/Advised by: Mr. Jason Ash and Dr. Michael Batchelder<br />

Sponsored by:<br />

A $500 budget is available from the ASME student chapter with the possibility of an additional $500 depending on<br />

project needs/resources. Travel and hotel expenses will be covered by your ASME student section.<br />

<strong>Project</strong> Description:<br />

Providing energy to a world with a growing population and rising expectations is a challenge that engineers must<br />

embrace and solve. So many factors must be considered and balanced: cost, efficiency, resource availability,<br />

environmental impact, sustainability, and more. Many different potential solutions are being proposed and<br />

developed. While the winners have yet to be determined, it is safe to assume that the future will include a wide<br />

variety of solutions that together will power our planet.<br />

The goal of the 2012 ASME Student <strong>Design</strong> Competition is to design four self-propelled devices which can<br />

collectively complete a relay race in the shortest period of time. Each device must contain an on-board energy<br />

source and trigger the motion on the next device. Bonuses will be awarded for devices having different energy<br />

sources and for initiating subsequent devices.<br />

http://files.asme.org/asmeorg/Events/Contests/<strong>Design</strong>Contest/28571.pdf<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

Machine design, mechatronics, controls, programming, and chemical engineering<br />

Any other special requirements:<br />

ASME membership required for 2011-2012 at the $25 student rate.<br />

Competition Prizes:<br />

Number of Students/Disciplines required<br />

Up to 4 ME/EE/CENG/ChemE students (Team cannot exceed 4 students): The ideal team would be 1 of<br />

each discipline or 2 ME, 1 EE or CENG, and 1 ChemE<br />

11

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

NASA Lunabotics: Lunar Regolith Excavator<br />

Proposed/Advised by: Mr. Jason Ash and Dr.‘s Michael Batchelder, Jeff McGough, and Charles Tolle along with<br />

graduate advisor Mr. Ryan Housh<br />

Sponsored by:<br />

A $5000 baseline funding request has been sent to NASA with positive response for support from the <strong>South</strong> <strong>Dakota</strong><br />

Space Grant Consortium. Additional fundraising may be required.<br />

<strong>Project</strong> Description:<br />

The Lunabotics Mining Competition is a university-level competition designed to engage and retain students in<br />

science, technology, engineering and mathematics (STEM). NASA will directly benefit from the competition by<br />

encouraging the development of innovative lunar excavation concepts from universities which may result in clever<br />

ideas and solutions which could be applied to an actual lunar excavation device or payload. The challenge is for<br />

students to design and build a remote controlled or autonomous excavator, called a lunabot, that can collect and<br />

deposit a minimum of 10 kilograms of lunar simulant within 15 minutes. The complexities of the challenge include<br />

the abrasive characteristics of the lunar simulant, the weight and size limitations of the lunabot, and the ability to<br />

control the lunabot from a remote control center. This will be the 3 rd year of the competition with the first place<br />

team last year delivering 237.4 kg. Complete details of the competition are provided at the following location:<br />

http://www.nasa.gov/lunabotics<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

Machine design, mechatronics, controls, vision systems, and programming<br />

Any other special requirements:<br />

K-12 Outreach required as part of this project.<br />

Competition will be at Kennedy Space Center from May 21-26, 2012.<br />

Competition Prizes:<br />

$5000, $2500, and $1000 for 1 st , 2 nd , and 3 rd place along with VIP Kennedy Space Center launch tickets<br />

Additional prizes for individual and overall competition categories.<br />

Number of Students/Disciplines required<br />

5-7 ME/EE/CENG/CSC students (Ideal would be 2-3 ME, 2 EE/CENG, 1-2 CSC)<br />

12

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

Proposed/Advised by:<br />

Sponsored by:<br />

Development of Autonomous Submersible to Explore Extreme Environments<br />

Drs. Tolle, McGough, Matejcik, and Mr. Ash<br />

<strong>South</strong> <strong>Dakota</strong> Space Grant NASA ($8k is in place to support implementation)<br />

<strong>Project</strong> Description (including objectives and requirements):<br />

The AUV (Autonomous Underwater Vehicle) team is looking for senior design students from a variety of<br />

disciplines. The team is tasked with the design and development of a submersible capable of autonomously<br />

navigating in confined spaces at pressures of up to 1500 psi for three hours and then returning to its departure point.<br />

This vehicle is intended for use in the Sanford Lab (aka what is to be DUSEL some day) but is being designed for a<br />

variety of applications including open water exploration with Yellowstone lake, deep ocean exploration, and<br />

possible missions to Europa (http://en.wikipedia.org/wiki/Europa_(moon)). This will be the 3 rd year for the team.<br />

In pervious years the team has created and fabricated two frame designs, two different thruster systems, a<br />

transmit/receiver sonar sounder, battery module controller and a designed for the power distribution system. There<br />

are numerous additional needs yet to be accomplished before basic navigation and operation can begin, some<br />

additional projects are listed below:<br />

• A buoyancy system needs to be developed<br />

• A supervisory power system needs to be designed and implemented – utilizing the existing battery module<br />

controller subsystem<br />

• A battery module enclosure subsystem needs to be designed and implemented<br />

• A force transducer feedback system for thruster control must be designed and manufactured<br />

• Low level thruster control systems must be developed and implemented<br />

• An attitude control system must be developed and implemented<br />

• Sensory systems must be developed and implemented, i.e. the sonar sounder needs to complete testing and<br />

integrated to form a full sonar sub-system, a new UV/IR/visual camera system needs to be designed<br />

• A high pressure water and gas sampling system needs to be designed and implemented<br />

• A transportation and deployment system must be designed and manufactured<br />

• Mission planning, guidance, and navigation algorithms must be designed and put in place<br />

• A GUI interface systems for planning system missions needs to be developed<br />

*Note, not all items listed above needed to be solved during this year’s efforts – the actual<br />

team will focus on items that lien towards their knowledge, interest and talents.<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

machine design, mechatronics, electronics, and controls<br />

Number of Students/Disciplines required:<br />

This year 1-2 CENG, 1-2 Chem/ChemE, 4-6 EE, 2 IENG, and 4-6 ME are desired – all are welcome.<br />

For more information stop by our lab in EP-335 and contact Dr. Charles Tolle, e-mail: charles.tolle@sdsmt.edu or<br />

Andrew Muxen, e-mail: muxenmi@hotmail.com<br />

13

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

Proposed/Advised by:<br />

Sponsored by:<br />

Satellite Attitude Dynamics Simulator<br />

Drs. Tolle, Bedillion + others potentially<br />

<strong>South</strong> <strong>Dakota</strong> NASA Space Grant / AUV Team<br />

($5K is in place to support implementation)<br />

<strong>Project</strong> Description (including objectives and requirements):<br />

This project is an offshoot of the <strong>South</strong> <strong>Dakota</strong> NASA Space Grant AUV team. If we are to travel to<br />

Europa (http://en.wikipedia.org/wiki/Europa_(moon)) our submersible spacecraft rover will need a<br />

communication link back to earth. This project is to design and build a small satellite simulator so that<br />

future students can work on satellite controllers, star pointing algorithms, communication links, etc.<br />

Several such simulators can be seen in Agrawal and Rasmussen paper entitled: ―Air Bearing Based<br />

Satellite Attitude Dynamics Simulator for Control Software Research and Development‖ available at<br />

http://faculty.nps.edu/agrawal/docs/spie-agrawal-rasmussen.pdf. The main goal in this year‘s effort is to<br />

fabricate an air bearing, design a mounting table (similar to a tooling table), design a thruster system and<br />

implement low level thruster electronics.<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

machine design, mechatronics, and controls<br />

Number of Students/Disciplines required:<br />

This year 2 ME, 1 CENG, 1 EE are desired, additional students are welcome.<br />

For more information Contact Dr. Charles Tolle, e-mail: charles.tolle@sdsmt.edu or visit our lab in EP-<br />

335.<br />

14

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

Proposed/Advised by:<br />

Multifunctional Helmet<br />

Dr. Karim Muci, Mr. Brandon Hinz, and Mr. Andrew Brady<br />

Sponsored by:<br />

This senior design project will be part of a research project sponsored by the US ARMY Research<br />

Laboratory (ARL) that involves a close collaboration between the SDSM&T Computational Mechanics<br />

Laboratory (CML) and the SDSM&T Composites and Polymer <strong>Engineering</strong> (CAPE) Laboratory.<br />

<strong>Project</strong> Description (including objectives and requirements):<br />

The purpose of this project is to develop a multifunctional helmet for first responders that has a reasonable<br />

cost and can provide adequate protection to the head in a wide variety of scenarios. The following example<br />

illustrates the need for such a helmet. Currently Search and Rescue (SAR) teams across the nation<br />

commonly use different helmets for the different services that they provide like vertical rescue, swiftwater<br />

rescue, vehicle extrication, and building shoring among others. Besides the inherent costs and logistic<br />

problems of having to deal with several different helmets, few if any of them are designed with<br />

multifunctional capability for situations encountered beyond the mission profile.<br />

Arrangements will be made so that the members of the senior design team have the opportunity to interact<br />

with first responders in the Pennington County area to determine the needs that they have for the product<br />

under consideration.<br />

<strong>Project</strong> Duration: September 2011 – May 2012<br />

Technical Areas Encompassed:<br />

Product development, manufacturing, solid mechanics, fluid mechanics, and dynamics. The work will<br />

include performing computer simulations, manufacturing of prototypes, and experimental testing.<br />

Any other special requirements:<br />

US Citizenship is required to participate in this project.<br />

Number of Students/Disciplines required:<br />

2–3 <strong>Mechanical</strong> <strong>Engineering</strong> students.<br />

Optional: 1 Metallurgical <strong>Engineering</strong> student.<br />

15

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

Proposed/Advised by:<br />

Sponsored by:<br />

State of the art directional wave tank with wave makers<br />

U.A. Korde, M.A. Langerman, C.F. Schilling<br />

ME Department<br />

<strong>Project</strong> Description (including objectives and requirements):<br />

Water waves concentrate the sun‘s energy by two orders of magnitude, can travel long distances and last<br />

a long time. Waves have been seen as a source of ‗clean‘ energy for many decades in the worlds of<br />

commercial and academic research and development. Energy conversion from waves usually requires<br />

some form of dynamic mechanical interaction with the waves. This is often achieved by means of a<br />

floating or submerged body oscillating in response to the waves and driving a linear or rotary electric or<br />

hydraulic generator via a suitable power transfer mechanism.<br />

Successful implementation of any such energy conversion scheme depends on rigorous analysis and<br />

model testing. To that end, this project proposes the construction of a wave tank capable of reproducing<br />

at model scale the large variety of wave amplitude and directional spectra encountered in large bodies of<br />

water (such as the Great Lakes or the oceans). The tank will include three essential components: (1) a<br />

tank of dimensions to be specified at project start, (2) wave makers, and (3) wave absorbers (to prevent<br />

multiple reflections from walls). A movable platform allowing access to models being tested and also<br />

providing a place for instruments and model support struts would also be highly desirable. Part (2) will<br />

include mechanical design and construction of the wave makers, design and construction of the drive<br />

electronics, wave maker control system hardware and software (e.g. through Matlab or LabView).<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

Fluid mechanics, solid mechanics, dynamics, vibrations, controls, circuits, mechatronics, machine tool<br />

operation, etc.<br />

Any other special requirements:<br />

None.<br />

Number of Students/Disciplines required (e.g., 2 ME, 1 EE, 1 CS):<br />

5/6; MEs, EEs, CENGs, CEs all welcome.<br />

16

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

Proposed/Advised by:<br />

Sponsored by:<br />

Floating Hydro Electric in the Amazon<br />

Tom Fontaine, Casey D. Heinrich, Michael S. Heinrich, Aaron Costello,<br />

Rebekah Dargatz, and Jason Ash (tentative)<br />

World Micro Power<br />

A $2,500 base budget has been provided by World Micro Power in addition to the 6 Kilowatt generator<br />

head. World Micro Power is a non-profit organization administered by an all volunteer group of engineers<br />

and technical specialists whose goal it is to use renewable resources to power remote villages in the<br />

Amazon jungle. Specifically, to create durable, light weight, low maintenance ―zero head‖ hydro-electric<br />

power at an affordable cost.<br />

<strong>Project</strong> Description:<br />

World Micro Power has a basic design for a zero head hydro-electric generator that is compatible with the<br />

very harsh conditions of the Amazon River. It is hoped that he completed design will light all 100<br />

dwellings at night and power a water filtration system during the day. The design requires fresh ideas and<br />

many engineering and technical enhancements.<br />

<strong>Design</strong>ing a zero head generator for the remote Amazon jungle is an extremely challenging task. The<br />

village of Santa Maria de Fatima is a remote village on the Amazon River outside Iquitos, Peru and is<br />

accessible only by boat. The village has no source of light after dark and no way to power a water filtration<br />

system.<br />

The project would take the base design and improve it for: 1. Durability 2. Maintainability/Simplicity 3.<br />

Efficiency 4. Minimum shipping weight 5. Compactness of disassembled components. 6. Low cost<br />

The completed device will be required to pass a 24 hour duration test without failure.<br />

<strong>Project</strong> Duration:<br />

2 Semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

Machine <strong>Design</strong>, Mechatronics, Controls, Fluids, Circuit <strong>Design</strong>, Hydro, and Programming.<br />

Any other special requirements:<br />

The device will be installed in the Santa Maria del Fatima, Peru in the Summer of 2012.<br />

Number of Students/Disciplines required<br />

8 ME/EE/CE/IENG<br />

17

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

Proposed/Advised by:<br />

Sponsored by:<br />

purePack 2.0 – Portable Water Purification System<br />

Mr. Lucas Haan and Jason Ash (tentative)<br />

Labrusca Scientia, LLC<br />

<strong>Project</strong> Background:<br />

Last year (Spring 2010 – Fall 2011) a group of interdisciplinary senior design students at SDSM&T<br />

worked to develop a prototype of a portable water purification system that produces clean, drinkable<br />

water for contaminated fresh water locations and is powered by renewable energy. The group of students<br />

then traveled to Chile to test and implement the prototype at an orphanage construction site in the Andes<br />

Mountains where the prototype is currently in use. Due to the success of the project, these students have<br />

now created a limited liability company (Labrusca Scientia, LLC) to develop even better portable water<br />

purification system technologies. Labrusca Scientia, LLC aims to work with senior design students at<br />

SDSM&T to help with the design of this development.<br />

<strong>Project</strong> Description:<br />

Labruscsa Scientia, LLC is developing a portable water purification system that produces clean, drinkable<br />

water for contaminated fresh water locations and is powered by renewable energy. The entire system is<br />

being revisited to optimize the product for movement into production. The main objectives of this project<br />

are detailed below:<br />

Objective 1: <strong>Design</strong> and develop a lightweight containment for entire system that is ergonomic and<br />

fits the carry-on size constraints of airline travel<br />

Objective 2: Optimize the pump/filtration system<br />

Objective 3: Optimize the power storage and generation<br />

Objective 4: Integrate more sensors and improve user interface system<br />

<strong>Project</strong> Duration: 2 semesters (Fall 2011 – Spring 2012)<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

ME: structural integrity design, manufacturing, materials, ergonomics, fluid dynamics,<br />

EE: alternative power generation, storage, and sensing (electrical circuit design)<br />

IENG: ergonomics<br />

Any other special requirements:<br />

Previous experience in travel abroad or an interest in such is recommended but not necessary<br />

Number of Students/Disciplines required (e.g., 2 ME, 1 EE, 1 CS):<br />

2 ME, 2 EE, 2 IENG, 1 ENVE<br />

18

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

Proposed/Advised by:<br />

Sponsored by:<br />

Robotic Friction Stir Welding of Aluminum Weldments using Linear and<br />

Circular Paths<br />

Chris Thompson, Johnathan Borrego, & Joshua Merry - Space Exploration<br />

Technologies, Dr. Kalanovic, Dr. Widener (tentative)<br />

Space Exploration Technologies – Hawthorne, CA<br />

<strong>Project</strong> Description:<br />

Chris Thompson is the Vice President of Production Development at Space Exploration Technologies<br />

(SpaceX). SpaceX has a desire to enter into robotic friction stir welding on their Falcon family of launch<br />

vehicles and Dragon capsule that is used to transport equipment to and from the International Space<br />

Station. The goal of this project is to develop a robotic friction stir welder using a common industrial<br />

robot like those offered from ABB or FANUC. The robotic friction stir welder needs to perform and<br />

control weld operations in 6061-T6 aluminum with material thicknesses ranging from 0.0625‖ up to<br />

0.500‖. The proposed system must be all electric – no hydraulics. The end goals of this project are –<br />

design and simulation of the proposed system, and demonstration of simple lap and square butt welds in<br />

linear and circular motions time permitting.<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

Machine <strong>Design</strong>, Friction Stir Welding, Robotic Programming and Control, System <strong>Engineering</strong><br />

Any other special requirements:<br />

None that I am aware of at the moment<br />

Number of Students/Disciplines required (e.g., 2 ME, 1 EE, 1 CS):<br />

4-6 ME, EE, CENG, CSC<br />

19

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

Proposed/Advised by:<br />

Sponsored by:<br />

Airflow Enthalpy Monitor<br />

Lance Weaver/Bernt Askildsen<br />

Lloyds Systems LLC<br />

<strong>Project</strong> Description:<br />

Develop an Enthalpy sensor that will also display wet bulb and dry bulb temperatures of airflow on a<br />

LCD screen. The design will be focused around a low power microcontroller to ensure that a miniature<br />

windmill will power the sensor system. The measured signals will also be transmitted to a wall box that<br />

is connected to 120VAC. A successful outcome of project will be rewarded by stipends.<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

Airflow dynamics, measurements, instrumentation, testing, software engineering, programming, wireless<br />

communcations, SolidWorks, mechanical design of housings.<br />

Any other special requirements:<br />

No<br />

Number of Students/Disciplines required (e.g., 2 ME, 1 EE, 1 CS):<br />

A team consisting of 1 EE, 1 CENG and 1 ME student is desired<br />

20

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

Proposed/Advised by:<br />

Sponsored by:<br />

Rehabilitation Device<br />

Ryan Swenson, Doctor of Chiropractic, Jason Ash (tentative)<br />

Ryan Swenson, Doctor of Chiropractic<br />

<strong>Project</strong> Description:<br />

Ryan Swenson is a Chiropractic Doctor here at Black Hills Chiropractic. He has identified a need for a<br />

rehabilitation therapy device whose goal is to strengthen and retrain neck muscles for patients suffering<br />

from neck pain. Ryan would like to collaborate with SDSM&T and senior design students in the<br />

development of a prototype that could be used in pursuing a patent. The students would be recognized<br />

along with Ryan as the creators of the device, while Ryan would retain ownership of the patent.<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

Machine design, mechatronics, controls, human-factors, ergonomics, electrical circuit design<br />

Any other special requirements:<br />

Signing a non-disclosure statement would be required for this project to maintain confidentiality<br />

Number of Students/Disciplines required<br />

Ideally 4-6 EE, CENG, IENG, ME students (3 students minimum are needed and would not have to be<br />

multidisciplinary)<br />

21

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

Proposed/Advised by:<br />

Sponsored by:<br />

ABS Brake Concept Trike<br />

Gary Hamilton, Lehman Trikes Advisor, Dr. Bedillion<br />

Lehman Trikes<br />

<strong>Project</strong> Description (including objectives and requirements):<br />

Add an ABS brake system to a 3-wheeled motorcycle for purposes of testing feasibility. The objective is to<br />

produce a mule or first prototype to explore the possibility of adding ABS brakes to Lehman‘s product line.<br />

The goal is to add to the basic engineering knowledge base at Lehman Trikes. This is a first stage design<br />

for use in house and not intended as a final product for sale.<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

machine design, oil hydraulics, electronic controls<br />

Any other special requirements:<br />

System would be designed as a test or demonstration on a Lehman model Trike. Lehman would provide a<br />

trike, funding for purchase of parts ($2000) as well as welding and machining time (40 hours) at Lehman‘s<br />

shop. Lehman would provide qualified engineers and operators to plan and conduct all dynamic testing.<br />

Tests would be conducted on a closed track. Lehman accepts liability for testing conducted by Lehman<br />

personnel. A more detailed agreement final must be written before this project starts.<br />

Number of Students/Disciplines required (e.g., 2 ME, 1 EE, 1 CS):<br />

3-5 ME, EE, CENG<br />

22

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

Proposed/Advised by:<br />

Sponsored by:<br />

Multi-Axis Robotic CNC MIG Welder<br />

Steven Franker<br />

Steven Franker & Team along with Fundraising<br />

<strong>Project</strong> Description (including objectives and requirements):<br />

This project would entail designing and building a multi-axis robotic arm with low load actuators for CNC<br />

MIG welding. The goal is to produce a practical device that could be easily used in small welding and<br />

machine shops for repetitive welding tasks. No lengthy programming or computer skills required. Perfect<br />

for consistently welding parts that can be mounted in a fixture or jig. It is also our goal to pursue the<br />

marketability and possible patents of this project if it is successful. According to our research this would be<br />

a unique product that no other company currently offers.<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

machine design, oil hydraulics, electronic controls<br />

Any other special requirements:<br />

Number of Students/Disciplines required (e.g., 2 ME, 1 EE, 1 CS):<br />

4-6 ME, CSC<br />

23

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

Proposed/Advised by:<br />

Sponsored by:<br />

Radiation Hardened Robot<br />

Los Alamos National Lab, National Security Technologies (contractor),<br />

Texas Instruments, Drs. Bedillion, McGough, and Tolle<br />

Los Alamos National Lab<br />

<strong>Project</strong> Description (including objectives and requirements):<br />

LANL would like a radiation hardened robot to drive down the beam line in an accelerator during<br />

operation, perform diagnostics, and send back video.<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

ME: Robotics, machine design, controls<br />

EE/CENG: Electrical circuits, controls<br />

CSC: Programming, GUI Interface<br />

Any other special requirements:<br />

Number of Students/Disciplines required (e.g., 2 ME, 1 EE, 1 CS):<br />

4-6 ME, EE, CENG, CSC<br />

24

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

Proposed/Advised by:<br />

Sponsored by:<br />

Bite Force Estimator<br />

Don Esker (Mammoth Site)/Dr. Marius Ellingsen<br />

Mammoth Site/AMP (MTS measurement time)<br />

<strong>Project</strong> Description:<br />

Since its discovery in 1986, the presence of the giant short-faced bear (Arctodus simus) in the Hot Springs<br />

sinkhole has been attributed to the great ursid preying or scavenging on trapped mammoths. Despite this,<br />

only one bone has ever been found with any bite marks or feeding traces: the rib 93HS031. This rib bears<br />

two round depressions, interpreted as puncture marks from the canines of a large carnivoran. Determining<br />

which carnivoran has been tricky, however. While the distance between the marks is consistent with intercanine<br />

spacing of an A. simus, they could also indicate a Panthera atrox (American lion), depending on<br />

whether the canines were maxillary or mandibular.<br />

We would like to design and test a mechanical apparatus that could answer the question once and for all.<br />

In 2010, Gignac et al built a device to determine the bite force of an extinct animal. It operated by using a<br />

hydraulic loading frame to press a hardened steel replica of the tooth into a cow bone, while a 25 kN load<br />

cell measured the force applied. The force required to press the tooth into the cow bone to the same depth<br />

as seen in the fossil gave an approximate bite force for the animal when alive. We‘d like to do essentially<br />

the same here, and determine how much force was needed to puncture our rib. From there we‘ll compare<br />

that force with published data on bite force estimates and our own finite element analysis to determine who<br />

was chewing on mammoth bones in the sinkhole 26,000 years ago.<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

Machine design, solid mechanics, mechatronics, and measurements<br />

Any other special requirements:<br />

Number of Students/Disciplines required<br />

3 or more ME/MET students<br />

25

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

Cold Spray Technology<br />

Proposed/Advised by: Christian Widener<br />

Sponsored by:<br />

AMP<br />

<strong>Project</strong> Description:<br />

This is a tentative project through discussions with Christian Widener. He is interested in having students increase<br />

the pressure capabilities of the current cold spray system. There are also additional design related items (nozzle<br />

design, portability, etc.) with the current system that should be sufficient for a senior design project.<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

Machine design, solid mechanics, mechatronics, controls, measurements, and fluid mechanics<br />

Any other special requirements:<br />

Number of Students/Disciplines required<br />

3 or more ME/MET students<br />

26

SOUTH DAKOTA SCHOOL OF MINES AND TECHNOLOGY<br />

SENIOR DESIGN PROJECT PROPOSAL<br />

<strong>Project</strong> Title:<br />

Proposed/Advised by:<br />

Sponsored by:<br />

4-Wheel Tilt Vehicle<br />

Dr. Dolan<br />

David Dieziger<br />

<strong>Project</strong> Description:<br />

Provide drawings and specifications for the construction of a vehicle based on US Patent 7,722,063 B2. Vehicle<br />

will have 4 wheels, tilt and steer like a traditional motorcycle, be all-wheel drive, and have 250 to 400<br />

horsepower.<br />

The suspension system divides the vehicle into leaning and non-leaning components. The passenger<br />

compartment and wheels lean together like a traditional motorcycle, and the rest of the vehicle (the drive train<br />

and suspension system) remains upright like a standard automobile. It allows for a smoother ride than a<br />

motorcycle because the suspension system, unlike a traditional motorcycle, does not experience any lateral or<br />

turning acceleration. It allows for a smoother ride than a traditional automobile because it does not require<br />

torsion bars, that negatively affect ride quality, to prevent body roll and weight transfer to the outside tires.<br />

The most important feature of the design is that it solves a problem that no previous design for a tilting fourwheel<br />

vehicle has solved: the transfer of power from the differential to the wheels. In my design the differential<br />

does not tilt, and consequently the system of axles and u-joints is the same as a typical front wheel drive car (a<br />

proven technology) avoiding the considerable expense and inefficiency of the technology involved in current<br />

tilting four-wheel power train designs (extreme u-joint angles, long axle slip joints or multiple chain or shaft<br />

drives).<br />

<strong>Design</strong>ing and building this entire vehicle in one year is probably not feasible, and thus this year‘s project will<br />

involve choosing, designing, and building a subset of the vehicle is an option.<br />

<strong>Project</strong> Duration:<br />

2 semesters<br />

Technical Areas Encompassed (e.g., machine design, controls):<br />

Dynamics, vehicle dynamics machine and structural design, electric circuits, fluids, manufacturing<br />

Any other special requirements:<br />

Number of Students/Disciplines required (e.g., 2 ME, 1 EE, 1 CS):<br />

4 ME students<br />

27