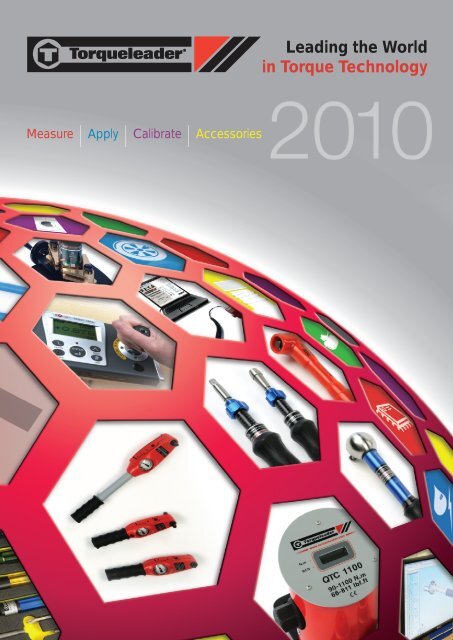

Leading the World in Torque Technology

Leading the World in Torque Technology

Leading the World in Torque Technology

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Measure | Apply | Calibrate | Accessories<br />

<strong>Lead<strong>in</strong>g</strong> <strong>the</strong> <strong>World</strong><br />

<strong>in</strong> <strong>Torque</strong> <strong>Technology</strong>

Welcome<br />

‘‘ ’’<br />

Introduction to<br />

<strong>Torque</strong>leader<br />

We have been a lead<strong>in</strong>g manufacturer of Industrial <strong>Torque</strong> Tools for over<br />

70 years, comb<strong>in</strong><strong>in</strong>g <strong>in</strong>novative design with precision eng<strong>in</strong>eer<strong>in</strong>g to<br />

produce a comprehensive range of <strong>Torque</strong> Wrenches, <strong>Torque</strong> Screwdrivers<br />

and <strong>Torque</strong> Calibration Analysers.<br />

ABOUT US<br />

<strong>Torque</strong>leader products are designed, manufactured and<br />

assembled <strong>in</strong> <strong>the</strong> UK us<strong>in</strong>g <strong>the</strong> latest technology and<br />

highly skilled staff. This enables us to ma<strong>in</strong>ta<strong>in</strong> complete<br />

control of processes, ensur<strong>in</strong>g that we deliver <strong>the</strong> highest<br />

quality tools with a long service life<br />

Users of <strong>Torque</strong>leader products experience cost sav<strong>in</strong>gs,<br />

through improved efficiency and process control. For<br />

example, <strong>Torque</strong>leader slipp<strong>in</strong>g technology elim<strong>in</strong>ates<br />

<strong>the</strong> operators’ <strong>in</strong>fluence over <strong>the</strong> tighten<strong>in</strong>g process,<br />

deliver<strong>in</strong>g consistency and accurate torque control<br />

Ongo<strong>in</strong>g success has enabled us to embark on a<br />

significant <strong>in</strong>vestment <strong>in</strong> our facilities mak<strong>in</strong>g sure we<br />

cont<strong>in</strong>ue lead<strong>in</strong>g <strong>the</strong> world <strong>in</strong> <strong>Torque</strong> Tool technology<br />

We are located…<br />

on our own six acre site at:<br />

Tannery Lane, Gosden Common, Bramley,<br />

Guildford, Surrey GU5 0AJ<br />

TORQUELEADER CORE VALUES<br />

At <strong>Torque</strong>leader we have built our reputation by be<strong>in</strong>g committed<br />

to <strong>the</strong> follow<strong>in</strong>g values:<br />

Innovation<br />

We are committed to design<strong>in</strong>g new, <strong>in</strong>novative products that<br />

deliver you real benefits, such as advanced slipp<strong>in</strong>g technology<br />

that elim<strong>in</strong>ates overtighten<strong>in</strong>g<br />

Precision<br />

The latest CNC technology is used to manufacture our tools to<br />

ensure <strong>the</strong> accuracy and precision necessary to meet today’s<br />

demand<strong>in</strong>g standards<br />

Performance<br />

Our tools are tested for accuracy, repeatability and durability<br />

to ensure that <strong>the</strong>y exceed <strong>the</strong> performance demanded by you<br />

Solution<br />

We will work with you to overcome problems by develop<strong>in</strong>g a<br />

custom solution, when standard products are not available<br />

Quality<br />

Quality is <strong>the</strong> priority at <strong>Torque</strong>leader - through provid<strong>in</strong>g<br />

strong customer service and ensur<strong>in</strong>g that all of our tools are<br />

built to <strong>the</strong> highest standards<br />

For Tool Selector Guide see fold out flap below

Tool Selector Guide<br />

Choos<strong>in</strong>g <strong>the</strong> right tool for your application<br />

Industrial Sectors<br />

Identify<strong>in</strong>g which tool for which <strong>in</strong>dustry<br />

Maximum <strong>Torque</strong> (N.m)<br />

Low <strong>Torque</strong> Value<br />

5 N.m<br />

Measure<br />

20 N.m<br />

40 N.m<br />

200 N.m<br />

350 N.m<br />

2000 N.m<br />

High <strong>Torque</strong> Value<br />

Maximum <strong>Torque</strong> (N.m)<br />

DIGITAL DIGITAL<br />

TT Dial Measur<strong>in</strong>g Screwdrivers<br />

Versatile measur<strong>in</strong>g tools with Track and Peak modes Page 10<br />

TSD & TWD Digital <strong>Torque</strong> Screwdrivers and Wrenches<br />

Preset<br />

Adjustable<br />

Page 15<br />

ADS Dial Measur<strong>in</strong>g <strong>Torque</strong> Wrenches<br />

Robust tools ideal for Quality Audit Page 11<br />

BDS Dial Measur<strong>in</strong>g <strong>Torque</strong> Wrenches<br />

Easy to use Quality Audit tools Page 12<br />

Torcotronic Digital <strong>Torque</strong> Wrenches<br />

Digital wrenches with memory and download capability Page 14<br />

CDS, DDS & EDS Dial Measur<strong>in</strong>g <strong>Torque</strong> Wrenches<br />

Versatile tools for heavy duty applications Page 13<br />

<strong>Torque</strong> Measur<strong>in</strong>g Tools are primarily used for quality<br />

control purposes <strong>in</strong> a wide range of <strong>in</strong>dustrial sectors<br />

<strong>in</strong>clud<strong>in</strong>g Automotive, Aerospace, Electronics, Telecoms<br />

and Consumer Products. These tools are recognisable<br />

by <strong>the</strong>ir dial, scale or digital readout.<br />

From mechanical tools that take basic torque read<strong>in</strong>gs<br />

to <strong>the</strong> more sophisticated electronic products that<br />

enable <strong>the</strong> collection, download and analysis of torque<br />

data, <strong>the</strong>re is a <strong>Torque</strong>leader tool to meet most<br />

customer needs.<br />

INDUSTRIES WE CATER FOR…<br />

<strong>Torque</strong>leader tools are used worldwide <strong>in</strong> manufactur<strong>in</strong>g,<br />

servic<strong>in</strong>g and quality control sectors<br />

The <strong>in</strong>dustry icons below act as a guide to help you to identify<br />

<strong>the</strong> appropriate tool for your application<br />

Industry Ma<strong>in</strong>tenance Manufactur<strong>in</strong>g Quality<br />

Sector and Repair Control<br />

Low <strong>Torque</strong> Value<br />

Apply<br />

0.25 N.m<br />

1.5 N.m<br />

4 N.m<br />

9 N.m<br />

10 N.m<br />

13.6 N.m<br />

25 N.m<br />

70 N.m<br />

125 N.m<br />

200 N.m<br />

400 N.m<br />

750 N.m<br />

High <strong>Torque</strong> Value<br />

Maximum <strong>Torque</strong> (N.m)<br />

TLS 0022 <strong>Torque</strong> Limit<strong>in</strong>g Screwdrivers Page 20<br />

PSE 25 <strong>Torque</strong> Limit<strong>in</strong>g Screwdrivers Page 24<br />

M<strong>in</strong>or <strong>Torque</strong> Limit<strong>in</strong>g Screwdrivers Page 21<br />

PSE 150 <strong>Torque</strong> Limit<strong>in</strong>g Screwdrivers Page 24<br />

Standard <strong>Torque</strong> Limit<strong>in</strong>g Screwdrivers Page 22<br />

PSE 450 <strong>Torque</strong> Limit<strong>in</strong>g Screwdrivers Page 24<br />

TSP Preset Slipp<strong>in</strong>g <strong>Torque</strong> Wrench Page 27<br />

TBN Break<strong>in</strong>g <strong>Torque</strong> Handles Page 28<br />

TLS 1360 <strong>Torque</strong> Limit<strong>in</strong>g Screwdrivers Page 23<br />

PSE 1350 <strong>Torque</strong> Limit<strong>in</strong>g Screwdrivers Page 24<br />

STB Preset Slipp<strong>in</strong>g <strong>Torque</strong> Breakers<br />

TSN Preset Slipp<strong>in</strong>g <strong>Torque</strong> Wrenches<br />

Page 25<br />

Page 27<br />

TBN Break<strong>in</strong>g <strong>Torque</strong> Handles Page 29<br />

TCP Clicker Wrenches Page 35<br />

Quickset Calibrated Screwdrivers Page 18<br />

Ergo Calibrated Screwdrivers Page 19<br />

TSC Calibrated Scale Wrenches<br />

Page 26<br />

ATB Adjustable Break Handles<br />

TCS Clicker Wrenches<br />

TCR Clicker Wrenches<br />

Page 30<br />

Page 35<br />

Page 34<br />

<strong>Torque</strong> Apply<strong>in</strong>g Tools are used <strong>in</strong> a manufactur<strong>in</strong>g<br />

environment to apply a preset torque to a range of<br />

fasten<strong>in</strong>g operations <strong>in</strong> <strong>the</strong> Automotive, Aerospace,<br />

Electronics and Consumer Products <strong>in</strong>dustries.<br />

Adjustable torque apply<strong>in</strong>g tools are primarily used<br />

for ma<strong>in</strong>tenance and repair operations <strong>in</strong> <strong>in</strong>dustry <strong>in</strong><br />

general, where it may be necessary to apply a number<br />

of different torque sett<strong>in</strong>gs to a range of fasteners.<br />

Some of <strong>the</strong>se torque apply<strong>in</strong>g tools are also available<br />

<strong>in</strong> enhanced versions <strong>in</strong>clud<strong>in</strong>g 1000 volt Insulated,<br />

Switch (Sw) and Radio Transceiver (RF) options.<br />

Automotive<br />

Aerospace<br />

Electronics<br />

Military<br />

Utilities<br />

Low <strong>Torque</strong> Value<br />

0.1 N.m<br />

Calibrate<br />

17 N.m<br />

25 N.m<br />

1100 N.m<br />

2500 N.m<br />

3150 N.m<br />

High <strong>Torque</strong> Value<br />

DIGITAL DIGITAL DIGITAL DIGITAL<br />

MTP <strong>Torque</strong> Calibration Analysers<br />

Mechanical Screwdriver testers Page 42<br />

ET-cal Compact <strong>Torque</strong> Calibration Analysers<br />

Robust digital torque testers Page 44<br />

MTS <strong>Torque</strong> Calibration Analysers<br />

Mechanical Screwdriver testers Page 42<br />

QTC <strong>Torque</strong> Calibration Analysers<br />

Robust workshop digital torque testers Page 43<br />

Personal Electronic <strong>Torque</strong> Analysers<br />

PC hosted Calibration System Page 46-49<br />

ET-cal <strong>Torque</strong> Calibration Analysers<br />

Robust digital torque testers Page 45<br />

<strong>Torque</strong> Calibration Analysis Equipment compliments<br />

our range of <strong>Torque</strong> Tools available to customers. The<br />

mechanical analysers can be used for basic torque<br />

adjustment and sett<strong>in</strong>g, while <strong>the</strong> electronic products<br />

offer higher accuracy to enable tool calibration and<br />

torque data analysis.<br />

While primarily used for Hand Tool test<strong>in</strong>g, some of<br />

<strong>the</strong> analysers also offer <strong>the</strong> ability to test Power Tools.<br />

Consumer<br />

Products<br />

Packag<strong>in</strong>g

Contents<br />

‘ ’’<br />

Divided <strong>in</strong>to six clear sections to enable you to f<strong>in</strong>d<br />

The 2010<br />

<strong>Torque</strong>leader Catalogue<br />

<strong>the</strong> correct product both quickly and easily.<br />

<br />

For Tool Selector Guide see <strong>in</strong>side front cover flap<br />

Information on our services, quality<br />

Technical Support Info assurance and standards plus a guide Page 2-8<br />

to calculat<strong>in</strong>g correct torque sett<strong>in</strong>gs.<br />

Tools that have a scale, dial or digital<br />

<strong>Torque</strong> Measur<strong>in</strong>g Tools readout to cont<strong>in</strong>ually measure torque Pages 9-16<br />

as it is applied.<br />

Tools that can be set to a required<br />

<strong>Torque</strong> Apply<strong>in</strong>g Tools torque value and <strong>in</strong>dicate when that Pages 17-39<br />

value is achieved.<br />

Examples of custom manufactured kits,<br />

<strong>Torque</strong> Tool Kits designed to meet users’ requirements Page 40<br />

and specifications.<br />

A versatile range of mechanical and<br />

<strong>Torque</strong> Calibration Tools electronic <strong>in</strong>struments to help customers Pages 41-50<br />

calibrate, set and measure torque tools.<br />

A large selection of quality accessories<br />

<strong>Torque</strong> Accessories and o<strong>the</strong>r equipment for use with<br />

Pages 51-57<br />

<strong>Torque</strong>leader wrenches and screwdrivers.<br />

For more details please visit us at www.torqueleader.com<br />

Introduc<strong>in</strong>g <strong>Torque</strong>leader | 1

Support<br />

<strong>World</strong>wide Distribution<br />

<strong>Torque</strong>leader manufactured by MHH Eng<strong>in</strong>eer<strong>in</strong>g Co. Ltd.<br />

WORLDWIDE COMMITMENT TO QUALITY OF SERVICE<br />

Over <strong>the</strong> past seven decades, we have become a <strong>World</strong><br />

Leader <strong>in</strong> <strong>the</strong> design and manufacture of <strong>Torque</strong> Tools<br />

with our <strong>Torque</strong>leader range<br />

Owned by <strong>the</strong> Gedore Group, we have <strong>the</strong> strength of<br />

resources to <strong>in</strong>vest for <strong>the</strong> future ensur<strong>in</strong>g cont<strong>in</strong>ued<br />

customer satisfaction<br />

Our commitment to our customers is second-to-none.<br />

<strong>Torque</strong>leader products are available and supported<br />

throughout <strong>the</strong> world<br />

Our Distributors <strong>in</strong> over 40 countries are factory tra<strong>in</strong>ed<br />

to give a full service and are able to recommend <strong>the</strong> best<br />

products to meet customers’ requirements<br />

Argent<strong>in</strong>a<br />

Australia<br />

Austria<br />

Belgium<br />

Brazil<br />

Bulgaria<br />

Canada<br />

Chile<br />

Ch<strong>in</strong>a<br />

Colombia<br />

Czech Republic<br />

Denmark<br />

Egypt<br />

Estonia<br />

F<strong>in</strong>land<br />

France<br />

Germany<br />

Greece<br />

Hong Kong<br />

Hungary<br />

India<br />

Iran<br />

Ireland<br />

Israel<br />

Italy<br />

Japan<br />

Korea<br />

Malaysia<br />

Mexico<br />

Ne<strong>the</strong>rlands<br />

New Zealand<br />

Norway<br />

Poland<br />

Romania<br />

Russia<br />

S<strong>in</strong>gapore<br />

Saudi Arabia<br />

Slovakia<br />

Slovenia<br />

South Africa<br />

Spa<strong>in</strong><br />

Sweden<br />

Switzerland<br />

Taiwan<br />

Thailand<br />

Turkey<br />

United Arab Emirates<br />

United K<strong>in</strong>gdom<br />

United States of America<br />

2 | <strong>World</strong>wide Distribution - For more <strong>in</strong>formation see www.torqueleader.com

Support<br />

<strong>Torque</strong>leader Team<br />

Meet our dedicated team - here to help you<br />

Dennis Giles<br />

Kieron Smith<br />

David Broadhead<br />

Bob Little<br />

Adrian Rogers<br />

Peter K<strong>in</strong>g<br />

Angela Padfield<br />

David Jackson<br />

David Parsley<br />

QUALITY & TECHNICAL SUPPORT<br />

Dennis Giles qualityand<strong>in</strong>spection@torqueleader.co.uk<br />

Kieron Smith eng<strong>in</strong>eer<strong>in</strong>g@torqueleader.co.uk<br />

SALES SUPPORT<br />

Peter K<strong>in</strong>g p.k<strong>in</strong>g@torqueleader.co.uk<br />

Angela Padfield a.padfield@torqueleader.co.uk<br />

TECHNICAL MANAGERS<br />

David Broadhead<br />

Bob Little<br />

Adrian Rogers<br />

d.broadhead@torqueleader.co.uk<br />

Mob: +44 (0) 7831 575529<br />

b.little@torqueleader.co.uk<br />

Mob: +44 (0) 7970 206853<br />

a.rogers@torqueleader.co.uk<br />

Mob: +44 (0) 7831 575530<br />

SALES MANAGEMENT<br />

David Jackson<br />

David Parsley<br />

d.jackson@torqueleader.co.uk<br />

d.parsley@torqueleader.co.uk<br />

Call our Sales Hotl<strong>in</strong>e +44 (0) 1483 894476 - <strong>Torque</strong>leader Team | 3

Support<br />

After Sales Service<br />

Recalibration and Repair of <strong>Torque</strong>leader Tools<br />

CALIBRATION SERVICES<br />

<strong>Torque</strong>leader has a UKAS Accredited Calibration<br />

Laboratory on site, capable of recalibrat<strong>in</strong>g most<br />

Hand <strong>Torque</strong> Tools, Analysers and Transducers <strong>in</strong><br />

accordance with <strong>the</strong> International Standards<br />

If preferred, a <strong>Torque</strong>leader Calibration Service is also<br />

available at a lower cost<br />

For more <strong>in</strong>formation call us on: +44 (0) 1483 892772,<br />

email: qualityand<strong>in</strong>spection@torqueleader.co.uk or see our<br />

website: www.torqueleader.com<br />

No. 0632<br />

TOOL LUBRICATION INFORMATION<br />

Like a car, <strong>Torque</strong>leader tools conta<strong>in</strong> mov<strong>in</strong>g parts that<br />

require periodic servic<strong>in</strong>g and lubrication. We recommend a<br />

maximum service <strong>in</strong>terval of 12 months, but higher usage<br />

applications may need more frequent exam<strong>in</strong>ation<br />

This check is part of <strong>the</strong> standard procedure when any tool is<br />

returned to us for service, but if you choose to do your own<br />

servic<strong>in</strong>g, <strong>the</strong> follow<strong>in</strong>g lubrication table gives details of <strong>the</strong><br />

recommended oils and greases as used <strong>in</strong> our tools<br />

TOOL LUBRICATION TABLE FOR TORQUELEADER PRODUCTS<br />

Lubricants: Chevron Fuchs Total Multis Total Multis MS2 Silicon Grease Shell Tonna 32 Rocol NYE Rheolube WD40 ‘3 <strong>in</strong> 1’<br />

Ploy FM NLGI 2 Renolit CXI 2 EP2 Temp. Range RS 555-083 Lubricat<strong>in</strong>g Oil Dry Moly Paste 386 Lubricant / Household<br />

Temp. Range Temp. Range -0 to 120 C Temp. Range Total Lifetime lubrication Stra<strong>in</strong>ed Inhibitor Lubricat<strong>in</strong>g<br />

Products: -20 to 150 C -20 to 160 C or equivalent -50 to 200 C Drosera 68 Max. Temp 450C Grease Oil<br />

Dial ADS Ratchet BDS,CDS,DDS W<strong>in</strong>dow Assm<br />

Wrenches Sp<strong>in</strong>dles only &EDS Ratchet ‘O’-r<strong>in</strong>gs<br />

Sp<strong>in</strong>dles<br />

TBN 2 & TBN 10 Spr<strong>in</strong>g Adjust<strong>in</strong>g Roller & Cam<br />

Screw<br />

Thrust Pad &<br />

Captive P<strong>in</strong><br />

TBN 25, 65 & 135 Spr<strong>in</strong>g Adjust<strong>in</strong>g Roller & Cam<br />

Screw<br />

Thrust Pad &<br />

Captive P<strong>in</strong><br />

TSN Wrenches General-except ‘O’-r<strong>in</strong>gs Ratchet Roller & Cam<br />

Roller, Cam<br />

& Ratchet<br />

TSC/TSP<br />

Wrenches<br />

Amalagam of 75% ASP<br />

+ 25% Oil General Use<br />

Production<br />

Screwdrivers<br />

General<br />

Use<br />

Clean Room<br />

Screwdrivers<br />

General<br />

Use<br />

Quickset & Quickset General Handle ‘O’-r<strong>in</strong>gs<br />

M<strong>in</strong>or Screwdrivers Use Threads only<br />

TT Dial Rust Inhibitor Memory<br />

Screwdrivers on Spr<strong>in</strong>gs & Assembly<br />

Spr<strong>in</strong>g Clamps<br />

MTS, MTP, TCA<br />

& DM10/7<br />

Drive Sp<strong>in</strong>dle &<br />

Needle Bear<strong>in</strong>gs<br />

ISO 1500/90º<br />

Calibration Stand<br />

Push/Pull<br />

Gauges<br />

Multiplier &<br />

Wormwheel<br />

Gearbox<br />

Spr<strong>in</strong>g &<br />

Sp<strong>in</strong>dle<br />

BT5 Pressure<br />

Regulators<br />

Adjust<strong>in</strong>g<br />

Screw<br />

4 | After Sales Service Support Information

Support<br />

Quality & Standards<br />

UKAS Certification and Serial Numbers<br />

Supplier Section - This can be tailored to <strong>in</strong>clude our Distributor’s<br />

name and address<br />

Email: qualityand<strong>in</strong>spection@torqueleader.co.uk<br />

www.torqueleader.com<br />

Tool Identification Section - This is for easy identification of <strong>the</strong> tool,<br />

its maximum capacity and its <strong>in</strong>dividual serial number<br />

Test Result Section - This gives <strong>the</strong> normal po<strong>in</strong>t at which <strong>the</strong> tool<br />

was tested, <strong>the</strong> tolerances and <strong>the</strong> actual results obta<strong>in</strong>ed<br />

Standard Section - This confirms <strong>the</strong> standard requirements to which<br />

<strong>the</strong> tool complies<br />

Note Section - Information regard<strong>in</strong>g slave po<strong>in</strong>ters etc<br />

Traceability Section - The serial numbers of <strong>the</strong> test equipment and<br />

<strong>the</strong> route back to National Standards - see diagram below<br />

Certification Section - The date and approval signature of test<br />

SERIAL NUMBERS<br />

A guide to <strong>Torque</strong>leader serial numbers. All new and newly<br />

reconditioned <strong>Torque</strong>leader tools are now marked with a serial<br />

number which enables Complete Traceability. This number is<br />

stored toge<strong>the</strong>r with o<strong>the</strong>r data such as <strong>the</strong> orig<strong>in</strong>al works order<br />

number and calibration details<br />

*Month Code<br />

A = January…<br />

M = December.<br />

1 B J 000100<br />

Model<br />

Code<br />

Month<br />

Code*<br />

Year<br />

Code*<br />

Consecutive<br />

Serial Number<br />

*Year Code<br />

A = 2002...<br />

J = 2010<br />

K = 2011 etc.<br />

QUALITY<br />

All <strong>Torque</strong>leader torque equipment<br />

is used to assess and improve <strong>the</strong><br />

quality of our customers’ products,<br />

enabl<strong>in</strong>g <strong>the</strong>ir customers to benefit<br />

from <strong>the</strong> assurance that <strong>the</strong> products<br />

will perform satisfactorily over<br />

long periods<br />

At <strong>Torque</strong>leader we take <strong>the</strong> subject<br />

of quality seriously - both <strong>in</strong> <strong>the</strong><br />

manufacture of <strong>Torque</strong>leader tools<br />

and <strong>in</strong> <strong>the</strong> comprehensive test<strong>in</strong>g of<br />

all equipment that we supply<br />

STANDARDS<br />

MHH Eng<strong>in</strong>eer<strong>in</strong>g Co. Ltd. (Manufacturer<br />

of <strong>Torque</strong>leader tools) is assessed and<br />

registered to BS EN ISO 9001:2008<br />

Certificate FM 363. Hand Tools<br />

and Implements<br />

All <strong>Torque</strong>leader tools are<br />

manufactured to <strong>the</strong> relevant<br />

British and International<br />

Eng<strong>in</strong>eer<strong>in</strong>g Standards<br />

All <strong>Torque</strong>leader tools conform to<br />

<strong>the</strong> International Standard on <strong>Torque</strong><br />

Tools ISO 6789:2003 or as specified<br />

UKAS CERTIFICATION<br />

<strong>Torque</strong>leader’s test<strong>in</strong>g and calibration<br />

procedures are performed us<strong>in</strong>g<br />

equipment traceable through UKAS<br />

(<strong>the</strong> United K<strong>in</strong>gdom Accreditation<br />

Service) Accredited Laboratories<br />

For customers who require a full UKAS<br />

Certificate with <strong>the</strong>ir tools, this can be<br />

provided at an extra cost<br />

Quality and Standards UKAS Information | 5

Support<br />

Quality & Standards<br />

<strong>Torque</strong>leader Calibration is Traceable to International Standards<br />

Weight/Mass<br />

Length/Metre<br />

Trad<strong>in</strong>g Standards Dept.<br />

UKAS Accredited<br />

Mass Laboratory<br />

Test Equipment<br />

All equipment used by<br />

<strong>Torque</strong>leader <strong>in</strong> <strong>the</strong> calibration<br />

of <strong>Torque</strong> Tools is regularly<br />

checked to ensure that <strong>the</strong><br />

results obta<strong>in</strong>ed are accurate.<br />

All calibration equipment is<br />

itself assessed us<strong>in</strong>g equipment<br />

with certification traceable to<br />

International Standards.<br />

Coord<strong>in</strong>ate Measur<strong>in</strong>g Mach<strong>in</strong>e<br />

Transfer Standards held by<br />

National Physical Laboratory<br />

The National<br />

Measurement Office<br />

National Physical Laboratory<br />

Stabilised Lasers<br />

International Bureau of<br />

Weights & Measures<br />

Sevres, Paris<br />

Natural Standard for <strong>the</strong> Metre<br />

Def<strong>in</strong>ed as <strong>the</strong> length of <strong>the</strong> path travelled by<br />

light <strong>in</strong> vacuum dur<strong>in</strong>g a time <strong>in</strong>terval of<br />

1/299 792 458 of a second.<br />

ACCURACY<br />

(Measur<strong>in</strong>g and Calibrated Scale Tools)<br />

Accuracy is <strong>the</strong> <strong>Torque</strong> Tools ability to delivery <strong>the</strong> torque to<br />

<strong>the</strong> jo<strong>in</strong>t as set on <strong>the</strong> tool’s scale, dial or digital display. This is<br />

usually expressed as a percentage of <strong>the</strong> target torque<br />

RESOLUTION<br />

(Measur<strong>in</strong>g and Calibrated Scale Tools)<br />

Resolution is <strong>the</strong> number of divisions that <strong>the</strong> tool’s full torque<br />

range is divided <strong>in</strong>to. This can be displayed as decimal places<br />

on a digital display, number of divisions on a dial or graduations<br />

on a scale<br />

REPEATABILITY<br />

(Preset Tools)<br />

ISO 6789:2003<br />

The International Standard for Hand <strong>Torque</strong> Tools states:<br />

The effective work<strong>in</strong>g range of a tool is from 20% to 100% of<br />

its maximum torque value<br />

The accuracy requirements for <strong>Torque</strong> Screwdrivers is ±6% of<br />

read<strong>in</strong>g and for <strong>Torque</strong> Wrenches is ±4% of read<strong>in</strong>g or ± 6% for<br />

<strong>Torque</strong> Wrenches below 10 N.m<br />

The maximum torque value for each square drive size<br />

An overload ability of 125% of maximum torque capacity<br />

A calibration <strong>in</strong>terval of 5000 cycles or 12 months<br />

Test and measur<strong>in</strong>g procedures at 23° ±5°C<br />

The maximum permissible uncerta<strong>in</strong>ty of measurement of<br />

<strong>the</strong> calibration device shall be ±1% of <strong>the</strong> <strong>in</strong>dicated value<br />

Scale and mark<strong>in</strong>g requirements<br />

Repeatability is <strong>the</strong> tool’s ability to consistently apply<br />

<strong>the</strong> same torque <strong>in</strong> subsequent tighten<strong>in</strong>g operations.<br />

This is usually expressed as a percentage of <strong>the</strong> preset torque<br />

6 | International Standards Support Information

Support<br />

An explanation of <strong>Torque</strong><br />

Information on measur<strong>in</strong>g <strong>Torque</strong><br />

WHAT IS TORQUE?<br />

HOW?<br />

<strong>Torque</strong> is <strong>the</strong> application of a Force act<strong>in</strong>g at a radial<br />

Distance and tend<strong>in</strong>g to cause rotation<br />

<strong>Torque</strong> is used to create tension<br />

Referr<strong>in</strong>g to <strong>the</strong> diagram below, it can be seen that as<br />

<strong>the</strong> nut and bolt are tightened <strong>the</strong> two plates are clamped<br />

toge<strong>the</strong>r. The thread converts <strong>the</strong> applied torque <strong>in</strong>to<br />

tension <strong>in</strong> <strong>the</strong> bolt shank. The amount of tension created<br />

<strong>in</strong> <strong>the</strong> bolt is critical<br />

HOW IS TORQUE CALCULATED?<br />

<strong>Torque</strong> is <strong>the</strong> result of multiply<strong>in</strong>g <strong>the</strong> value of Force<br />

applied by <strong>the</strong> Distance from <strong>the</strong> po<strong>in</strong>t of application<br />

Compar<strong>in</strong>g <strong>the</strong> two examples below (A and B) it will be<br />

noted that <strong>the</strong> same resultant torque can be achieved with<br />

a lower Force if <strong>the</strong> Distance from <strong>the</strong> nut/bolt is <strong>in</strong>creased<br />

1m<br />

Distance<br />

A<br />

2m<br />

B<br />

Force of 20 N<br />

Force of 10 N<br />

Let:<br />

T = <strong>Torque</strong><br />

F = Force<br />

L = Length of Lever of Wrench<br />

Then:<br />

T = F x L<br />

Example A<br />

20 Newtons x 1 metre = 20 N.m<br />

(Newton metres)<br />

Example B<br />

10 Newtons x 2 metres = 20 N.m<br />

WHY?<br />

The tension <strong>in</strong> <strong>the</strong> bolt creates a clamp<strong>in</strong>g force<br />

between <strong>the</strong> two parts. If <strong>the</strong> clamp<strong>in</strong>g force is too low,<br />

<strong>the</strong> fasteners can work loose due to vibration or movement<br />

between <strong>the</strong> component parts. If a clamp<strong>in</strong>g force is too<br />

high, <strong>the</strong> fastener may permanently stretch and no longer<br />

apply <strong>the</strong> required clamp<strong>in</strong>g force. In severe cases <strong>the</strong><br />

fastener may fail <strong>in</strong> assembly or dur<strong>in</strong>g use when under<br />

load. Clamp<strong>in</strong>g force is generally referred to as <strong>the</strong> preload<br />

It should also be realised that some <strong>Torque</strong> Wrenches are<br />

length dependent which means that <strong>the</strong> actual torque<br />

applied to <strong>the</strong> fastener varies if <strong>the</strong> hand position on <strong>the</strong><br />

wrench is varied - even with <strong>the</strong> wrench preset. This<br />

occurs if <strong>the</strong> pivot po<strong>in</strong>t of <strong>the</strong> wrench mechanism is not<br />

co<strong>in</strong>cidental with <strong>the</strong> po<strong>in</strong>t of application of torque<br />

See our website www.torqueleader.com – <strong>Torque</strong> Information | 7

Support<br />

<strong>Torque</strong> - Tighten<strong>in</strong>g & Conversion Factors<br />

Maximum recommended tighten<strong>in</strong>g torques<br />

RECOMMENDED TIGHTENING TORQUES<br />

Button Head<br />

Cap Head<br />

Countersunk<br />

Head<br />

Hex<br />

Head Bolt<br />

<strong>Torque</strong> N.m<br />

These figures are for guidance only,<br />

<strong>the</strong> torque for each application<br />

should be calculated tak<strong>in</strong>g<br />

<strong>in</strong>to account all circumstances<br />

that apply to that jo<strong>in</strong>t.<br />

Thread<br />

Diameter Hex Key Hex Key Hex Key Hex Head<br />

(mm) Size (mm) Size (mm) Size (mm) Size (mm)<br />

M 2 – 1.5 1.27 4<br />

M 2.5 – 2 1.5 5<br />

M 3 2 2.5 2 5.5<br />

M 4 2.5 3 2.5 7<br />

M 5 3 4 3 8<br />

M 6 4 5 4 10<br />

M 7 – – – 11<br />

M 8 5 6 5 13<br />

M 10 6 8 6 17<br />

M 12 8 10 8 19<br />

M 14 – – – 22<br />

M 16 – 14 10 24<br />

M 18 – – – 27<br />

M 20 – 17 12 30<br />

M 22 – – – 32<br />

M 24 – – – 36<br />

M 27 – – – –<br />

Bolt Quality<br />

8.8 10.9 12.7<br />

0.37 0.52 0.63<br />

0.86 1.21 1.45<br />

1.3 1.9 2.3<br />

3.0 4.3 5.1<br />

6.0 8.5 10.2<br />

10.3 14.7 17.9<br />

17.2 24.5 28.4<br />

25.5 35.3 42.2<br />

50.0 70.6 85.3<br />

87.3 123 147<br />

138 194 235<br />

211 299 358<br />

289 412 490<br />

412 579 698<br />

559 785 941<br />

711 1000 1198<br />

1049 1481 1775<br />

TORQUE CONVERSION FACTORS<br />

Units to be ISO Imperial Metric<br />

converted mN.m cN.m N.m ozf.<strong>in</strong> lbf.<strong>in</strong> lbf.ft gf.cm kgf.cm kgf.m<br />

1 mN.m = 1 0.1 0.001 0.142 0.009 0.0007 10.2 0.01 0.0001<br />

1 cN.m = 10 1 0.01 1.416 0.088 0.007 102 0.102 0.001<br />

1 N.m = 1000 100 1 141.6 8.851 0.738 10 197 10.20 0.102<br />

1 ozf.<strong>in</strong> = 7.062 0.706 0.007 1 0.0625 0.005 72 0.072 0.0007<br />

1 lbf.<strong>in</strong> = 113 11.3 0.113 16 1 0.083 1152.1 1.152 0.0115<br />

1 lbf.ft = 1356 135.6 1.356 192 12 1 13 826 13.83 0.138<br />

1 gf.cm = 0.098 0,01 0.0001 0.014 0.0009 0.000 07 1 0.001 0.000 01<br />

1 kgf.cm = 98.07 9.807 0.098 13.89 0.868 0.072 1000 1 0.01<br />

1 kgf.m = 9807 980.7 9.807 1389 86.8 7.233 100 000 100 1<br />

8 | Tighten<strong>in</strong>g <strong>Torque</strong> and Conversion Factors Information

Measure<br />

‘‘ ’’<br />

Introduction to<br />

<strong>Torque</strong> Measur<strong>in</strong>g Tools<br />

WHAT ARE THEY USED FOR?<br />

<strong>Torque</strong> measur<strong>in</strong>g tools are generally used <strong>in</strong> Research and Development,<br />

Inspection and Quality Control where <strong>the</strong>re is a need to check torque sett<strong>in</strong>gs.<br />

This type of tool can also be used <strong>in</strong> a Servic<strong>in</strong>g or Production Environment<br />

to apply torque.<br />

WHAT TYPES ARE THERE?<br />

<strong>Torque</strong> measur<strong>in</strong>g tools have a dial or digital readout.<br />

They can be a screwdriver or torque wrench design.<br />

They enable <strong>the</strong> operator to read directly from <strong>the</strong> dial<br />

or readout as <strong>the</strong> torque is applied<br />

The torque can be measured as it is applied<br />

(Track mode) or <strong>the</strong> maximum torque value can be<br />

recorded (Peak mode)<br />

WHAT ARE THE THREE TYPES OF QUALITY AUDITING TEST THAT UTILISE<br />

TORQUE MEASURING TOOLS?<br />

The first of <strong>the</strong> three tests is <strong>the</strong> mark<strong>in</strong>g test. The<br />

mark<strong>in</strong>g test is used to verify <strong>the</strong> torque of a previously<br />

tightened fastener. This is done by mak<strong>in</strong>g a clear mark<br />

on <strong>the</strong> surface of <strong>the</strong> nut, bolt or screw and cont<strong>in</strong>u<strong>in</strong>g<br />

<strong>the</strong> mark onto <strong>the</strong> surface be<strong>in</strong>g clamped. This acts as a<br />

reference po<strong>in</strong>t. The fastener may <strong>the</strong>n be untightend<br />

and <strong>the</strong>n retightened until <strong>the</strong> marks are aga<strong>in</strong> <strong>in</strong> l<strong>in</strong>e.<br />

The torque value can <strong>the</strong>n be read from <strong>the</strong> torque<br />

tool display<br />

The third and last test is <strong>the</strong> break loose test. The break<br />

loose test is ano<strong>the</strong>r method of check<strong>in</strong>g <strong>the</strong> torque<br />

applied to a previously tightened fastener. <strong>Torque</strong> is<br />

applied <strong>in</strong> <strong>the</strong> direction that loosens <strong>the</strong> fastener, at <strong>the</strong><br />

po<strong>in</strong>t <strong>the</strong> fastener breaks loose, <strong>the</strong> torque is recorded.<br />

This value is an <strong>in</strong>dication of <strong>the</strong> torque at which <strong>the</strong><br />

fastener was orig<strong>in</strong>ally tightened. This value is typically<br />

20-30% lower than <strong>the</strong> tighten<strong>in</strong>g torque<br />

The second of <strong>the</strong> tests is <strong>the</strong> just move test. Aga<strong>in</strong><br />

this test is used to determ<strong>in</strong>e <strong>the</strong> torque sett<strong>in</strong>g of a<br />

previously tightened fastener. Us<strong>in</strong>g a torque measur<strong>in</strong>g<br />

tool, a tighten<strong>in</strong>g torque is applied to <strong>the</strong> fastener until<br />

movement is just seen or felt. This torque is deemed to<br />

be a good <strong>in</strong>dication of <strong>the</strong> orig<strong>in</strong>al torque applied to<br />

<strong>the</strong> fastener<br />

<strong>Torque</strong> Measur<strong>in</strong>g Tools |<br />

9

Measure<br />

TT Dial Measur<strong>in</strong>g Screwdrivers<br />

Versatile measur<strong>in</strong>g tools with Track and Peak modes<br />

All TT Dial Measur<strong>in</strong>g Screwdrivers are designed with easy<br />

to read dual scales allow<strong>in</strong>g users to measure both metric<br />

and imperial torques<br />

A versatile tool ideal for use <strong>in</strong> Quality Control, Research and<br />

Development as well as Assembly Operations <strong>in</strong> <strong>in</strong>dustries<br />

such as Electronics, White Goods and Consumer Equipment<br />

All models are capable of measur<strong>in</strong>g torque <strong>in</strong> ei<strong>the</strong>r<br />

Peak or Track modes. Ideal for establish<strong>in</strong>g torque<br />

tighten<strong>in</strong>g specifications<br />

Robust construction utilis<strong>in</strong>g sta<strong>in</strong>less steel, tough plastics<br />

and anodised alum<strong>in</strong>ium mak<strong>in</strong>g this tool suitable for<br />

most <strong>in</strong>dustrial environments<br />

EPA compliant for use <strong>in</strong> electrostatically<br />

sensitive applications<br />

These tools are designed and manufactured to exceed<br />

<strong>the</strong> requirements of ISO 6789:2003<br />

Accuracy +/- 6% of read<strong>in</strong>g<br />

ISO 6789:2003 classification 1D<br />

Accessories available - see pages 54, 55 and 56<br />

Calibrated Range<br />

Order Code Model ISO Imperial Drive mm<br />

g<br />

017000 TT 50 SD 10-50 cN.m 2 cN.m 14-70 ozf·<strong>in</strong> 2 ozf·<strong>in</strong> 1 ”<br />

/ 4 178 190<br />

017400 TT 50 FH 10-50 cN.m 2 cN.m 14-70 ozf·<strong>in</strong> 2 ozf·<strong>in</strong> 1<br />

/ 4<br />

”<br />

178 190<br />

017100 TT 100 SD 20-100 cN.m 5 cN.m 28-140 ozf·<strong>in</strong> 5 ozf·<strong>in</strong> 1<br />

/ 4<br />

”<br />

178 190<br />

017500 TT 100 FH 20-100 cN.m 5 cN.m 28-140 ozf·<strong>in</strong> 5 ozf·<strong>in</strong> 1<br />

/ 4<br />

”<br />

178 190<br />

017200 TT 250 SD 50-250 cN.m 10 cN.m 4-20 lbf·<strong>in</strong> 0.5 lbf·<strong>in</strong> 1<br />

/ 4<br />

”<br />

250 465<br />

017600 TT 250 FH 50-250 cN.m 10 cN.m 4-20 lbf·<strong>in</strong> 0.5 lbf·<strong>in</strong> 1<br />

/ 4<br />

”<br />

250 465<br />

017300 TT 500 SD 100-500 cN.m 20 cN.m 8-40 lbf·<strong>in</strong> 1 lbf·<strong>in</strong> 1<br />

/ 4<br />

”<br />

250 465<br />

017700 TT 500 FH 100-500 cN.m 20 cN.m 8-40 lbf·<strong>in</strong> 1 lbf·<strong>in</strong> 1<br />

/ 4<br />

”<br />

250 465<br />

10 | <strong>Torque</strong> Measur<strong>in</strong>g – Dial Screwdrivers

Measure<br />

ADS Dial Measur<strong>in</strong>g <strong>Torque</strong> Wrenches<br />

Robust tools ideal for Quality Audit<br />

ADS Dial Measur<strong>in</strong>g <strong>Torque</strong> Wrenches are constructed<br />

from lightweight, robust materials. This comb<strong>in</strong>ed with an<br />

overload protection feature guarantees years of accurate<br />

and dependable service<br />

All models are fitted with double ended ratchet<strong>in</strong>g<br />

square drive, allow<strong>in</strong>g torque to be measured or applied<br />

<strong>in</strong> clockwise or anticlockwise directions<br />

ADS signal wrenches are fitted with an optional audio<br />

visual warn<strong>in</strong>g device, which alerts <strong>the</strong> operator when <strong>the</strong><br />

user set torque has been reached<br />

A durable storage case is supplied with all ADS wrenches,<br />

protect<strong>in</strong>g <strong>the</strong> tool from damage<br />

EPA compliant for use <strong>in</strong> electrostatically<br />

sensitive applications<br />

These tools are designed and manufactured<br />

to exceed <strong>the</strong> requirements of ISO 6789:2003<br />

Accuracy +/- 3% of read<strong>in</strong>g<br />

ISO 6789:2003 classification 1B<br />

Designed for ease of repair and recalibration,<br />

<strong>the</strong>refore <strong>in</strong>creas<strong>in</strong>g tool life<br />

Accessories available - see pages 54, 55 and 57<br />

Calibrated Range<br />

Order Code Model ISO Imperial Drive mm<br />

kg Signal<br />

010100 ADS 4 0.8-4.0 N.m 0.1 N.m 7-35 lbf.<strong>in</strong> 1 lbf.<strong>in</strong> 1 ”<br />

/ 4 244 0.52 ✗<br />

010108 ADS 4 S 0.8-4.0 N.m 0.1 N.m 7-35 lbf.<strong>in</strong> 1 lbf.<strong>in</strong> 1 ”<br />

/ 4 244 0.52 ✓<br />

010120 ADS 8 1.6-8.0 N.m 0.25 N.m 14-70 lbf.<strong>in</strong> 1 lbf.<strong>in</strong> 1 ”<br />

/ 4 244 0.52 ✗<br />

010128 ADS 8 S 1.6-8.0 N.m 0.25 N.m 14-70 lbf.<strong>in</strong> 1 lbf.<strong>in</strong> 1 ”<br />

/ 4 244 0.52 ✓<br />

010140 ADS 12 D 2.4-12 N.m 0.5 N.m 24-120 lbf.<strong>in</strong> 2 lbf.<strong>in</strong> 1 ”<br />

/ 4 244 0.52 ✗<br />

010148 ADS 12 DS 2.4-12 N.m 0.5 N.m 24-120 lbf.ft 2 lbf.ft 1 ”<br />

/ 4 244 0.52 ✓<br />

010160 ADS 12 A 2.4-12 N.m 0.5 N.m 24-120 lbf.<strong>in</strong> 2 lbf.<strong>in</strong> 3 ”<br />

/ 8 244 0.52 ✗<br />

010168 ADS 12 AS 2.4-12 N.m 0.5 N.m 24-120 lbf.ft 2 lbf.ft<br />

3<br />

/ 8<br />

”<br />

244 0.52 ✓<br />

010180 ADS 25 5-25 N.m 1 N.m 48-240 lbf.<strong>in</strong> 10 lbf.<strong>in</strong> 3 ”<br />

/ 8 244 0.52 ✗<br />

010188 ADS 25 S 5-25 N.m 1 N.m 48-240 lbf.<strong>in</strong> 10 lbf.<strong>in</strong> 3 ”<br />

/ 8 244 0.52 ✓<br />

010200 ADS 25 F 5-25 N.m 1 N.m 4-20 lbf.<strong>in</strong> 0.5 lbf.<strong>in</strong> 3 ”<br />

/ 8 244 0.52 ✗<br />

010208 ADS 25 FS 5-25 N.m 1 N.m 4-20 lbf.<strong>in</strong> 0.5 lbf.<strong>in</strong> 3 ”<br />

/ 8 244 0.52 ✓<br />

010220 ADS 40 8-40 N.m 1 N.m 72-360 lbf.<strong>in</strong> 10 lbf.<strong>in</strong> 3 ”<br />

/ 8 244 0.52 ✗<br />

010228 ADS 40 S 8-40 N.m 1 N.m 72-360 lbf.ft 10 lbf.ft 3 ”<br />

/ 8 244 0.52 ✓<br />

010240 ADS 40 F 8-40 N.m 1 N.m 6-30 lbf.<strong>in</strong> 1 lbf.<strong>in</strong> 3 ”<br />

/ 8 244 0.52 ✗<br />

010248 ADS 40 FS 8-40 N.m 1 N.m 6-30 lbf.ft 1 lbf.ft<br />

3<br />

/ 8<br />

”<br />

244 0.52 ✗<br />

<strong>Torque</strong> Measur<strong>in</strong>g – Dial Wrenches | 11

Measure<br />

BDS Dial Measur<strong>in</strong>g <strong>Torque</strong> Wrenches<br />

Easy to use Quality Audit tools<br />

BDS Dial Measur<strong>in</strong>g <strong>Torque</strong> Wrenches are constructed<br />

from lightweight, robust materials. This comb<strong>in</strong>ed with an<br />

overload protection feature guarantees years of accurate<br />

and dependable service<br />

All models are fitted with double ended ratchet<strong>in</strong>g square<br />

drive, allow<strong>in</strong>g torque to be measured or applied <strong>in</strong><br />

clockwise or anticlockwise directions<br />

BDS signal wrenches are fitted with an audio visual warn<strong>in</strong>g<br />

device, which alerts <strong>the</strong> operator when <strong>the</strong> user set torque<br />

has been reached<br />

Designed for ease of repair and recalibration, <strong>the</strong>refore<br />

<strong>in</strong>creas<strong>in</strong>g tool life<br />

A durable storage case (see image below) is supplied with<br />

all BDS wrenches, fur<strong>the</strong>r protect<strong>in</strong>g <strong>the</strong> tool from damage<br />

These tools are designed and manufactured to exceed<br />

<strong>the</strong> requirements of ISO 6789:2003<br />

Accuracy +/- 3% of read<strong>in</strong>g<br />

ISO 6789:2003 classification 1B<br />

Accessories available - see page 57<br />

The work<strong>in</strong>g pr<strong>in</strong>ciple of <strong>Torque</strong>leader<br />

Dial Measur<strong>in</strong>g <strong>Torque</strong> Wrenches<br />

Calibrated Range<br />

Order Code Model ISO Imperial Drive mm<br />

kg Signal<br />

010300 BDS 80 A 16-80 N.m 2 N.m 12-60 lbf.ft 1 lbf.ft 3 ”<br />

/ 8 435 1.35 ✗<br />

010380 BDS 80 AS 16-80 N.m 2 N.m 12-60 lbf.ft 1 lbf.ft 3 ”<br />

/ 8 440 1.47 ✓<br />

010320 BDS 80 E 16-80 N.m 2 N.m 12-60 lbf.ft 1 lbf.ft 1 ”<br />

/ 2 435 1.36 ✗<br />

010400 BDS 80 ES 16-80 N.m 2 N.m 12-60 lbf.ft 1 lbf.ft 1 ”<br />

/ 2 440 1.49 ✓<br />

010340 BDS 160 32-160 N.m 2.5 N.m 24-120 lbf.ft 2 lbf.ft 1 ”<br />

/ 2 515 1.41 ✗<br />

010420 BDS 160 S 32-160 N.m 2.5 N.m 24-120 lbf.ft 2 lbf.ft 1 ”<br />

/ 2 520 1.54 ✓<br />

010360 BDS 200 40-200 N.m 5 N.m 30-160 lbf.ft 5 lbf.ft 1 ”<br />

/ 2 515 1.41 ✗<br />

010440 BDS 200 S 40-200 N.m 5 N.m 30-160 lbf.ft 5 lbf.ft 1 ”<br />

/ 2 520 1.54 ✓<br />

12 | <strong>Torque</strong> Measur<strong>in</strong>g – Dial Wrenches

CDS, DDS & EDS <strong>Torque</strong> Wrenches<br />

Versatile tools for heavy duty applications<br />

Measure<br />

CDS & DDS Dial Measur<strong>in</strong>g <strong>Torque</strong> Wrenches are fitted<br />

with double ended ratchet<strong>in</strong>g square drive as standard.<br />

This allows torque to be measured or applied <strong>in</strong> clockwise<br />

or anticlockwise directions<br />

CDS, DDS & EDS models are constructed from<br />

robust materials. This comb<strong>in</strong>ed with an overload<br />

protection feature guarantees years of accurate and<br />

dependable service<br />

EDS Dial Measur<strong>in</strong>g <strong>Torque</strong> Wrenches are fitted with<br />

a double ended 1” fixed square drive for safety when<br />

apply<strong>in</strong>g high torques<br />

EDS wrenches are supplied with a two piece handle<br />

to allow for easy storage<br />

Designed for ease of repair and recalibration, <strong>the</strong>refore<br />

<strong>in</strong>creas<strong>in</strong>g tool life<br />

These tools are designed and manufactured to exceed<br />

<strong>the</strong> requirements of ISO 6789:2003<br />

Accuracy +/- 3% of read<strong>in</strong>g<br />

ISO 6789:2003 classification 1B<br />

Accessories available - see page 57<br />

Calibrated Range<br />

Order Code Model ISO Imperial Drive mm<br />

kg Signal<br />

010520 CDS 400 S 80-400 N.m 10 N.m 60-300 lbf.ft 10 lbf.ft 3 ”<br />

/ 4 710 3.2 ✓<br />

010620 DDS 800 S 160-800 N.m 20 N.m 120-600 lbf.ft 20 lbf.ft 3 ”<br />

/ 4 1000 4.9 ✓<br />

010700 EDS 1400 S 280-1400 N.m 25 N.m 200-1000 lbf.ft 25 lbf.ft 1 ” 2040 16.7 ✓<br />

010720 EDS 2000 S 400-2000 N.m 50 N.m 300-1500 lbf.ft 50 lbf.ft 1 ” 2040 16.7 ✓<br />

<strong>Torque</strong> Measur<strong>in</strong>g – Dial Wrenches | 13

Measure<br />

Torcotronic Digital <strong>Torque</strong> Wrenches<br />

Digital wrenches with memory and download capability<br />

Torcotronic Wrenches are ideal for torque measurement<br />

and audit<strong>in</strong>g <strong>in</strong> Research and Development, Quality<br />

Control, Ma<strong>in</strong>tenance and Production areas<br />

Audible and visual alarm signals are activated when<br />

approach<strong>in</strong>g or achiev<strong>in</strong>g <strong>the</strong> preset torque<br />

Bi-directional operations, allows torque to be measured<br />

or applied <strong>in</strong> both clockwise and anticlockwise directions<br />

Test results can be downloaded <strong>in</strong>to Microsoft Excel<br />

via <strong>the</strong> supplied PC software, allow<strong>in</strong>g full data analysis<br />

and storage<br />

Memory holds up to 2000 data entries<br />

User modes <strong>in</strong>clude Peak, Track and Multi Presets<br />

The ratchet <strong>in</strong>cluded can be removed and replaced<br />

with standard 9x12 or 14x18 wrench fitt<strong>in</strong>gs<br />

Accuracy +/-1% of read<strong>in</strong>g between<br />

10% and 100% of full scale<br />

ISO 6789:2003 Classification 1E<br />

Accessories available - call our Sales Hotl<strong>in</strong>e<br />

+44 (0) 1483 894476<br />

Calibrated Range<br />

Order Code Model ISO Imperial Drive Adaptors<br />

021620 120 10-120 N.m 7-88 lbf.ft 1<br />

/ 2<br />

” 9x<br />

12 435 0.92<br />

021630 350 70-350 N.m 51-258 lbf.ft 1<br />

/ 2<br />

” 14x<br />

18 658 1.34<br />

mm<br />

kg<br />

14 | <strong>Torque</strong> Measur<strong>in</strong>g – Digital Wrenches

Measure<br />

TSD & TWD Digital <strong>Torque</strong><br />

Screwdrivers and Wrenches<br />

TSD Digital <strong>Torque</strong> Screwdrivers and TWD Digital <strong>Torque</strong><br />

Wrenches are ideal for torque measurement and audit<strong>in</strong>g<br />

<strong>in</strong> Research and Development, Quality Control,<br />

Ma<strong>in</strong>tenance and Production areas<br />

Bi-directional operations allows torque to be applied,<br />

measured and recorded <strong>in</strong> both clockwise and<br />

anticlockwise directions<br />

Up to 99 preset torque and tolerance values can be loaded<br />

onto <strong>the</strong> tool or downloaded from <strong>the</strong> software provided<br />

Modes of operation are Track, Peak and Preset<br />

The reversible ratchet <strong>in</strong>cluded with <strong>the</strong> TWD<br />

can be removed and replaced with standard<br />

9x12 wrench accessories<br />

TSD Digital <strong>Torque</strong> Screwdriver<br />

Audible and visual alarm signals are activated when<br />

approach<strong>in</strong>g or achiev<strong>in</strong>g <strong>the</strong> preset torque<br />

RS232 USB connectivity and PC software supplied allows<br />

<strong>the</strong> easy storage and transfer of data to Excel. Download<br />

cable and PC software <strong>in</strong>cluded<br />

TWD Digital <strong>Torque</strong> Wrench<br />

Memory capacity 2000 read<strong>in</strong>gs<br />

User selectable units of measurements<br />

<strong>in</strong>clud<strong>in</strong>g N.m, lbf.<strong>in</strong> and cN.m<br />

Accuracy +/-1% of read<strong>in</strong>g between<br />

10% and 100% of full scale<br />

ISO 6789:2003 classification 1E<br />

Accessories available - call our Sales Hotl<strong>in</strong>e<br />

+44 (0) 1483 894476<br />

Calibrated Range<br />

Order Code Model ISO Resolution Imperial Resolution Drive Adaptors mm<br />

kg<br />

020730 TSD 150 15-150 cN.m 0.1 cN.m 1.3-13 lbf.<strong>in</strong> 0.01 lbf.<strong>in</strong> 1 ”<br />

/ 4 A35640 170 0.72<br />

020740 TSD 350 35-350 cN.m 0.1 cN.m 3-30 lbf.<strong>in</strong> 0.01 lbf.<strong>in</strong> 1 ”<br />

/ 4 A35640 170 0.72<br />

020750 TSD 1500 150-1500 cN.m 1 cN.m 13-130 lbf.<strong>in</strong> 0.1 lbf.<strong>in</strong> 1 ”<br />

/ 4 A35640 200 0.77<br />

020762 TWD 20 SB 2-20 N.m 0.01 N.m 1.5-15 lbf.ft 0.01 lbf.ft 1 ”<br />

/ 4<br />

9x<br />

12 410 0.73<br />

<strong>Torque</strong> Measur<strong>in</strong>g – Digital Screwdrivers and Wrenches | 15

Measure<br />

TCM Closure Meters<br />

Designed for Quality Audit <strong>in</strong> <strong>the</strong> Packag<strong>in</strong>g Industry<br />

The TCM Closure Meters (Standard and Premium models) are<br />

designed specifically to accurately measure and record <strong>the</strong><br />

tightness of screw-on caps on conta<strong>in</strong>ers, bottles and jars<br />

TCM Premium<br />

Widely used for Quality Audit of bottl<strong>in</strong>g and<br />

packag<strong>in</strong>g mach<strong>in</strong>ery<br />

The <strong>in</strong>strument guarantees that quality standards are<br />

be<strong>in</strong>g met, by ensur<strong>in</strong>g product <strong>in</strong>tegrity dur<strong>in</strong>g storage<br />

and distribution. This ensures caps are correctly sealed<br />

yet rema<strong>in</strong> easy to open and resealed by <strong>the</strong> customer<br />

Clockwise and anticlockwise torque measurement<br />

The Premium model is fitted with an <strong>in</strong>novative clamp<br />

design which has a clamp<strong>in</strong>g capacity of Ø 135 mm,<br />

designed to grip delicate or unusual shape conta<strong>in</strong>ers<br />

The Standard model has a clamp<strong>in</strong>g capacity of up<br />

to Ø 200 mm<br />

Peak torque function allows <strong>the</strong> TCM to record <strong>the</strong><br />

maximum torque values achieved<br />

TCM Standard<br />

Accuracy +/- 4% of read<strong>in</strong>g<br />

Calibrated Range<br />

Order Code Model ISO Imperial<br />

kg<br />

019100 TCM 1 Premium 7-100 cN.m 1 cN.m 10-40 ozf.<strong>in</strong> 2 ozf.<strong>in</strong> 6.9<br />

019105 TCM 1 7-100 cN.m 1 cN.m 10-40 ozf.<strong>in</strong> 2 ozf.<strong>in</strong> 6.9<br />

019150 TCM 3 Premium 0.2-3.0 N.m 0.05 N.m 2-26 lbf.<strong>in</strong> 0.5 lbf.<strong>in</strong> 6.9<br />

019155 TCM 3 0.2-3.0 N.m 0.05 N.m 2-26 lbf.<strong>in</strong> 0.5 lbf.<strong>in</strong> 6.9<br />

019200 TCM 5 Premium 0.3-5.0 N.m 0.05 N.m 3-45 lbf.<strong>in</strong> 0.5 lbf.<strong>in</strong> 6.9<br />

019205 TCM 5 0.3-5.0 N.m 0.05 N.m 3-45 lbf.<strong>in</strong> 0.5 lbf.<strong>in</strong> 6.9<br />

019300 TCM 10 Premium 0.5-10 N.m 0.1 N.m 4-90 lbf.<strong>in</strong> 1.0 lbf.<strong>in</strong> 6.9<br />

019305 TCM 10 0.5-10 N.m 0.1 N.m 4-90 lbf.<strong>in</strong> 1.0 lbf.<strong>in</strong> 6.9<br />

019400 TCM 15 Premium 1-15 N.m 0.2 N.m 4-132 lbf.<strong>in</strong> 2.0 lbf.<strong>in</strong> 6.9<br />

019405 TCM 15 1-15 N.m 0.2 N.m 4-132 lbf.<strong>in</strong> 2.0 lbf.<strong>in</strong> 6.9<br />

16 | <strong>Torque</strong> Measur<strong>in</strong>g Tools – See our website www.torqueleader.com

‘‘ ’’<br />

Introduction to<br />

<strong>Torque</strong> Apply<strong>in</strong>g Tools<br />

WHAT ARE THEY USED FOR?<br />

<strong>Torque</strong> apply<strong>in</strong>g tools are used to apply a set torque to a fastener.<br />

The tool will slip, break or click to signal to <strong>the</strong> operator when<br />

<strong>the</strong> set torque is reached<br />

Apply<br />

WHAT TYPES ARE THERE?<br />

Preset Tools are ideal <strong>in</strong> environments that require <strong>the</strong><br />

same torque to be applied to a fastener time after time.<br />

These types of tool are tamperproof so are ideal for use<br />

by staff who are not highly skilled. The tools must be set<br />

us<strong>in</strong>g a Calibration Analyser<br />

Calibrated Scale Tools have a visible scale that allows<br />

<strong>the</strong> user to adjust <strong>the</strong> tools to <strong>the</strong>ir desired torque sett<strong>in</strong>g.<br />

This tool is ideal for use <strong>in</strong> areas where a range of different<br />

torque sett<strong>in</strong>gs need to be applied<br />

DIFFERENT TORQUE TOOL MECHANISMS<br />

Click Tools<br />

(overtighten<strong>in</strong>g Possible)<br />

TORQUE<br />

Break<strong>in</strong>g Tools<br />

(overtighten<strong>in</strong>g Unlikely)<br />

TORQUE<br />

Slipp<strong>in</strong>g Tools<br />

(overtighten<strong>in</strong>g Impossible)<br />

TORQUE<br />

Approx 3° movement<br />

Approx 20° movement<br />

Preset <strong>Torque</strong> Value<br />

Preset <strong>Torque</strong> Value<br />

Preset <strong>Torque</strong> Value<br />

APPLIED FORCE<br />

APPLIED FORCE<br />

APPLIED FORCE<br />

Click Tools When <strong>the</strong> preset torque value is<br />

reached <strong>the</strong> operator will hear a click, feel an<br />

impulse and <strong>the</strong>re will be approximately 3° of<br />

tool movement. Resett<strong>in</strong>g takes place when<br />

<strong>the</strong> hand pressure is released. Work can <strong>the</strong>n<br />

immediately cont<strong>in</strong>ue. These tools are length<br />

dependent – <strong>the</strong> position of <strong>the</strong> hand on <strong>the</strong><br />

tool alters <strong>the</strong> torque produced. Cont<strong>in</strong>ued<br />

application of force after <strong>the</strong> 3° of movement<br />

will cause <strong>the</strong> torque applied to <strong>in</strong>crease<br />

above <strong>the</strong> required preset limit.<br />

Click<br />

Overtighten<strong>in</strong>g Possible<br />

Break<strong>in</strong>g Tools When <strong>the</strong> preset torque value is<br />

reached, <strong>the</strong>se tools break at a specific po<strong>in</strong>t along<br />

<strong>the</strong> tool’s length – usually at a pivot po<strong>in</strong>t near<br />

<strong>the</strong> tool’s head. In most cases <strong>the</strong> movement is<br />

approximately 20°. The tool is automatically reset by<br />

allow<strong>in</strong>g <strong>the</strong> handle to return to its <strong>in</strong> l<strong>in</strong>e position.<br />

These tools are length dependent, with hand position<br />

alter<strong>in</strong>g <strong>the</strong> torque applied. Cont<strong>in</strong>ued application<br />

of force after 20° of tool movement will <strong>in</strong>crease <strong>the</strong><br />

torque applied above <strong>the</strong> preset limit but with <strong>the</strong><br />

greater angle of tool movement this is less likely.<br />

Break<strong>in</strong>g<br />

Overtighten<strong>in</strong>g Unlikely<br />

Slipp<strong>in</strong>g Tools When <strong>the</strong> preset torque<br />

value is reached, a mechanism <strong>in</strong> <strong>the</strong> tool<br />

causes <strong>the</strong> application of torque to cease<br />

and <strong>the</strong> tool slips free for a short time until<br />

resett<strong>in</strong>g occurs. Even if <strong>the</strong> application of<br />

force is repeated, <strong>the</strong> preset torque value<br />

will not be exceeded, <strong>the</strong>refore mak<strong>in</strong>g it<br />

impossible to overtighten a fastener. These<br />

tools are not length dependent.<br />

Slipp<strong>in</strong>g<br />

Overtighten<strong>in</strong>g Impossible<br />

<strong>Torque</strong> Apply<strong>in</strong>g Tools | 17

Apply<br />

Quickset Calibrated Screwdrivers<br />

Versatile slipp<strong>in</strong>g tools with calibrated scale<br />

Slipp<strong>in</strong>g<br />

The Quickset Calibrated Screwdrivers range<br />

<strong>in</strong>corporates slipp<strong>in</strong>g technology, elim<strong>in</strong>at<strong>in</strong>g<br />

overtighten<strong>in</strong>g completely<br />

Micrometer adjustment allows easy accurate sett<strong>in</strong>g<br />

of a range of torques, ideal for use <strong>in</strong> a Service or<br />

Repair environment<br />

Smooth reset action reduces operator fatigue<br />

These tools are designed and manufactured to<br />

exceed <strong>the</strong> requirements of ISO 6789:2003<br />

Calibrated <strong>in</strong> clockwise direction.<br />

Anticlockwise calibration on request<br />

Accuracy +/- 6% of sett<strong>in</strong>g<br />

ISO 6789:2003 classification 2D<br />

Accessories available - see pages 54, 55 and 56<br />

Calibrated Range<br />

Order Code Model Range Drive<br />

mm<br />

g<br />

016000 Quickset M<strong>in</strong>or Metric SD 20-120 cN.m 1 cN.m 1 ”<br />

/ 4 160 158<br />

016040 Quickset M<strong>in</strong>or Metric FH 20-120 cN.m 1 cN.m 1 ”<br />

/ 4 169 165<br />

016020 Quickset M<strong>in</strong>or Imp SD 20-120 ozf.<strong>in</strong> 1 ozf.<strong>in</strong> 1 ”<br />

/ 4 160 158<br />

016060 Quickset M<strong>in</strong>or Imp FH 20-120 ozf.<strong>in</strong> 1 ozf.<strong>in</strong> 1 ”<br />

/ 4 169 165<br />

016080 Quickset M<strong>in</strong>or lbf.<strong>in</strong> SD 2-12 lbf.<strong>in</strong> 0.1 lbf.<strong>in</strong> 1 ”<br />

/ 4 160 158<br />

016070 Quickset M<strong>in</strong>or lbf.<strong>in</strong> FH 2-12 lbf.<strong>in</strong> 0.1 lbf.<strong>in</strong> 1 ”<br />

/ 4 169 165<br />

016100 Quickset 6* SD 1-6 N.m 0.1 N.m 1 ”<br />

/ 4 222 340<br />

016500 Quickset 6* FH 1-6 N.m 0.1 N.m 1 ”<br />

/ 4 184 334<br />

016200 Quickset 50* SD 5-50 lbf.<strong>in</strong> 1 lbf.<strong>in</strong> 1 ”<br />

/ 4 222 340<br />

016600 Quickset 50* FH 5-50 lbf.<strong>in</strong> 1 lbf.<strong>in</strong> 1 ”<br />

/ 4 184 335<br />

016300 Quickset 9* SD 4-9 N.m 0.1 N.m 1 ”<br />

/ 4 222 340<br />

016700 Quickset 9* FH 4-9 N.m 0.1 N.m 1 ”<br />

/ 4 184 335<br />

016400 Quickset 80* SD 40-80 lbf.<strong>in</strong> 1 lbf.<strong>in</strong> 1 ”<br />

/ 4 222 340<br />

016800 Quickset 80* FH 40-80 lbf.<strong>in</strong> 1 lbf.<strong>in</strong> 1 ”<br />

/ 4 184 335<br />

*Supplied with slid<strong>in</strong>g T-Bar<br />

18 | <strong>Torque</strong> Apply<strong>in</strong>g – Quickset Screwdrivers

Apply<br />

Ergo Quickset Calibrated Screwdrivers<br />

Slipp<strong>in</strong>g technology <strong>in</strong> compact ergonomic tools<br />

The Ergo Quickset Calibrated Screwdrivers<br />

range <strong>in</strong>corporates slipp<strong>in</strong>g technology,<br />

elim<strong>in</strong>at<strong>in</strong>g overtighten<strong>in</strong>g<br />

Slipp<strong>in</strong>g<br />

A specially designed ergonomic grip comb<strong>in</strong>ed<br />

with a smooth reset action reduces operator fatigue<br />

Once <strong>the</strong> tool is set, <strong>the</strong> adjustment lock prevents<br />

accidental tool adjustment, <strong>the</strong>refore ensur<strong>in</strong>g <strong>the</strong><br />

correct torque is applied<br />

EPA compliant for use <strong>in</strong> electrostatically<br />

sensitive applications<br />

These tools are designed and manufactured to<br />

exceed <strong>the</strong> requirements of ISO 6789:2003<br />

Calibrated <strong>in</strong> clockwise direction.<br />

Anticlockwise calibration on request<br />

Accuracy +/- 6% of sett<strong>in</strong>g<br />

ISO 6789:2003 classification 2D<br />

Accessories available - see pages 54, 55 and 56<br />

Calibrated Range<br />

Order Code Model Range Drive<br />

mm<br />

g<br />

060700 QSN 40 FH 5-40 cN.m 1 cN.m 1 ”<br />

/ 4 159 124<br />

060900 QSN 40 SD 5-40 cN.m 1 cN.m 1 ”<br />

/ 4 159 124<br />

060740 QSA 60 FH 10-60 ozf.<strong>in</strong> 1 ozf.<strong>in</strong> 1 ”<br />

/ 4 159 124<br />

060940 QSA 60 SD 10-60 ozf.<strong>in</strong> 1 ozf.<strong>in</strong> 1 ”<br />

/ 4 159 124<br />

060720 QSA 4 FH 0.5-4 lbf.<strong>in</strong> 0.1 lbf.<strong>in</strong> 1 ”<br />

/ 4 159 124<br />

060920 QSA 4 SD 0.5-4 lbf.<strong>in</strong> 0.1 lbf.<strong>in</strong> 1 ”<br />

/ 4 159 124<br />

060100 QSN 120 FH 20-120 cN.m 1 cN.m 1 ”<br />

/ 4 183 230<br />

060200 QSN 120 SD 20-120 cN.m 1 cN.m 1 ”<br />

/ 4 183 230<br />

060140 QSA 160 FH 20-160 ozf.<strong>in</strong> 1 ozf.<strong>in</strong> 1 ”<br />

/ 4 183 230<br />

060240 QSA 160 SD 20-160 ozf.<strong>in</strong> 1 ozf.<strong>in</strong> 1 ”<br />

/ 4 183 230<br />

060120 QSA 12 FH 2-12 lbf.<strong>in</strong> 0.1 lbf.<strong>in</strong> 1 ”<br />

/ 4 183 230<br />

060220 QSA 12 SD 2-12 lbf.<strong>in</strong> 0.1 lbf.<strong>in</strong> 1 ”<br />

/ 4 183 230<br />

060300 QSN 600* FH 1-6 N.m 0.1 N.m 1 ”<br />

/ 4 196 335<br />

060400 QSN 600* SD 1-6 N.m 0.1 N.m 1 ”<br />

/ 4 196 335<br />

060320 QSA 50* FH 10-50 lbf.<strong>in</strong> 1 lbf.<strong>in</strong> 1 ”<br />

/ 4 196 335<br />

060420 QSA 50* SD 10-50 lbf.<strong>in</strong> 1 lbf.<strong>in</strong> 1 ”<br />

/ 4 196 335<br />

060500 QSN 900* FH 4-9 N.m 0.1 N.m 1 ”<br />

/ 4 196 335<br />

060600 QSN 900* SD 4-9 N.m 0.1 N.m 1 ”<br />

/ 4 196 335<br />

060520 QSA 80* FH 30-80 lbf.<strong>in</strong> 1 lbf.<strong>in</strong> 1 ”<br />

/ 4 196 335<br />

060620 QSA 80* SD 30-80 lbf.<strong>in</strong> 1 lbf.<strong>in</strong> 1 ”<br />

/ 4 196 335<br />

<strong>Torque</strong> Apply<strong>in</strong>g – Quickset Screwdrivers | 19

Apply<br />

<strong>Torque</strong> Limit<strong>in</strong>g Screwdrivers<br />

Slipp<strong>in</strong>g technology <strong>in</strong> compact production tools<br />

Slipp<strong>in</strong>g<br />

The TLS 0022 <strong>in</strong>corporates slipp<strong>in</strong>g technology,<br />

elim<strong>in</strong>at<strong>in</strong>g overtighten<strong>in</strong>g<br />

Tamperproof adjustment makes this presetable tool ideal<br />

for Production, where <strong>the</strong> same torque must be accurately<br />

and repeatably applied<br />

Tool must be preset on a Calibration Analyser<br />

Smooth reset action reduces operator fatigue<br />

CRS version for use <strong>in</strong> Clean Rooms rate to class 100<br />

One way (O/W) versions enable fasteners to be both<br />

torqued or loosened<br />

Designed and manufactured to exceed <strong>the</strong> requirements<br />

of ISO 6789:2003<br />

Accuracy +/- 6% of sett<strong>in</strong>g<br />

ISO 6789:2003 classification 2F<br />

Accessories available - see pages 54 and 56<br />

Range<br />

Order Code Model ISO Imperial Drive mm<br />

g Colour<br />

015000 TLS 0022 Micro 2-22 cN.m 3-32 ozf.<strong>in</strong> 1 ”<br />

/ 4 76 50 Red<br />

015080 TLS 0022 0.5-22 cN.m 0.7-32 ozf.<strong>in</strong> 1<br />

/ 4<br />

”<br />

104 72 Gold<br />

015085 TLS 0022 O/W 0.5-22 cN.m 0.7-32 ozf.<strong>in</strong> 1<br />

/ 4<br />

”<br />

116 85 Gold<br />

015089* CRS 100-0022 FH 2-22 cN.m 3-32 ozf.<strong>in</strong> 1<br />

/ 4<br />

”<br />

104 72 Grey<br />

*Clean Room version<br />

20 | <strong>Torque</strong> Apply<strong>in</strong>g – Limit<strong>in</strong>g Screwdrivers

Apply<br />

<strong>Torque</strong> Limit<strong>in</strong>g Screwdrivers<br />

Slipp<strong>in</strong>g technology <strong>in</strong> compact production tools<br />

The M<strong>in</strong>or Screwdrivers <strong>in</strong>corporate slipp<strong>in</strong>g<br />

technology, elim<strong>in</strong>at<strong>in</strong>g overtighten<strong>in</strong>g<br />

Slipp<strong>in</strong>g<br />

Tamperproof adjustment makes this tool presetable ideal<br />

for Production, where <strong>the</strong> same torque must be accurately<br />

and repeatably applied<br />

Tool must be preset on a Calibration Analyser<br />

Smooth reset action reduces operator fatigue<br />

CRS version for use <strong>in</strong> Clean Rooms rate to class 100<br />

One way (O/W) versions enable fasteners to be both<br />

torqued or loosened<br />

Impact Free Reset versions are available upon request<br />

Designed and manufactured to exceed <strong>the</strong> requirements<br />

of ISO 6789:2003<br />

Repeatability +/- 6% of sett<strong>in</strong>g<br />

ISO 6789:2003 classification 2F<br />

Accessories available - see pages 54, 55 and 56<br />

Range<br />

Order Code Model ISO Imperial Drive mm<br />

g Colour<br />

015100 M<strong>in</strong>or SD 2-135 cN.m 0.8 - 12 lbf.<strong>in</strong> 1 ”<br />

/ 4 143 210 Blue<br />

015105 M<strong>in</strong>or SD O/W 2-135 cN.m 0.8 - 12 lbf.<strong>in</strong> 1 ”<br />

/ 4 143 210 Blue<br />

015200 M<strong>in</strong>or FH 2-135 cN.m 0.8 - 12 lbf.<strong>in</strong> 1 ”<br />

/ 4 111 210 Blue<br />

015205 M<strong>in</strong>or FH O/W 2-135 cN.m 0.8 - 12 lbf.<strong>in</strong> 1 ”<br />

/ 4 125 210 Blue<br />

015120 M<strong>in</strong>or SD 2-135 cN.m 0.8 - 12 lbf.<strong>in</strong> 1 ”<br />

/ 4 143 210 Green<br />

015125 M<strong>in</strong>or SD O/W 2-135 cN.m 0.8 - 12 lbf.<strong>in</strong> 1 ”<br />

/ 4 143 210 Green<br />

015220 M<strong>in</strong>or FH 2-135 cN.m 0.8 - 12 lbf.<strong>in</strong> 1 ”<br />

/ 4 111 210 Green<br />

015225 M<strong>in</strong>or FH O/W 2-135 cN.m 0.8 - 12 lbf.<strong>in</strong> 1 ”<br />

/ 4 125 210 Green<br />

015140 M<strong>in</strong>or SD 2-135 cN.m 0.8 - 12 lbf.<strong>in</strong> 1 ”<br />

/ 4 143 210 Red<br />

015145 M<strong>in</strong>or SD O/W 2-135 cN.m 0.8 - 12 lbf.<strong>in</strong> 1 ”<br />

/ 4 143 210 Red<br />

015240 M<strong>in</strong>or FH 2-135 cN.m 0.8 - 12 lbf.<strong>in</strong> 1 ”<br />

/ 4 111 210 Red<br />

015245 M<strong>in</strong>or FH O/W 2-135 cN.m 0.8 - 12 lbf.<strong>in</strong> 1 ”<br />

/ 4 125 210 Red<br />

015160 M<strong>in</strong>or SD 2-135 cN.m 0.8 - 12 lbf.<strong>in</strong> 1 ”<br />

/ 4 143 210 Gold<br />

015165 M<strong>in</strong>or SD O/W 2-135 cN.m 0.8 - 12 lbf.<strong>in</strong> 1 ”<br />

/ 4 143 210 Gold<br />

015260 M<strong>in</strong>or FH 2-135 cN.m 0.8 - 12 lbf.<strong>in</strong> 1 ”<br />

/ 4 111 210 Gold<br />

015265 M<strong>in</strong>or FH O/W 2-135 cN.m 0.8 - 12 lbf.<strong>in</strong> 1 ”<br />

/ 4 125 210 Gold<br />

015209* CRS 100-0135 11-135 cN.m 1-12 lbf.<strong>in</strong> 1 ”<br />

/ 4 111 210 Grey<br />

*Clean room version<br />

<strong>Torque</strong> Apply<strong>in</strong>g – Limit<strong>in</strong>g Screwdrivers | 21

Apply<br />

<strong>Torque</strong> Limit<strong>in</strong>g Screwdrivers<br />

Slipp<strong>in</strong>g technology <strong>in</strong> compact production tools<br />

Slipp<strong>in</strong>g<br />

The Standard Screwdrivers <strong>in</strong>corporate slipp<strong>in</strong>g<br />

technology, elim<strong>in</strong>at<strong>in</strong>g overtighten<strong>in</strong>g<br />

The easy to set, tamperproof adjustment makes this<br />

presetable tool ideal for Production, where <strong>the</strong> same<br />

torque must be accurately and repeatably applied<br />

Tools must be preset on a Calibration Analyser<br />

Smooth reset action reduces operator fatigue<br />

CRS version for use <strong>in</strong> Clean Rooms rate to class 100<br />

One way (O/W) versions enable fasteners to be both<br />

torqued or loosened<br />

Impact Free Reset versions are available upon request<br />

Designed and manufactured to exceed <strong>the</strong> requirements<br />

of ISO 6789:2003<br />

Repeatability +/- 6% of sett<strong>in</strong>g<br />

ISO 6789:2003 classification 2F<br />

Accessories available - see pages 54, 55 and 56<br />

Range<br />

Order Code Model ISO Imperial Drive mm<br />

g Colour<br />

015500 Standard SD 6-406 cN.m 0.5-36 lbf.<strong>in</strong> 1 ”<br />

/ 4 159 280 Blue<br />

015505 Standard SD O/W 6-406 cN.m 0.5-36 lbf.<strong>in</strong> 1 ”<br />

/ 4 159 280 Blue<br />

015600 Standard FH 6-406 cN.m 0.5-36 lbf.<strong>in</strong> 1 ”<br />

/ 4 127 280 Blue<br />

015605 Standard FH O/W 6-406 cN.m 0.5-36 lbf.<strong>in</strong> 1<br />

/ 4<br />

”<br />

127 280 Blue<br />

015520 Standard SD 6-406 cN.m 0.5-36 lbf.<strong>in</strong> 1<br />

/ 4<br />

”<br />

159 280 Green<br />

015525 Standard SD O/W 6-406 cN.m 0.5-36 lbf.<strong>in</strong> 1<br />

/ 4<br />

”<br />

159 280 Green<br />

015620 Standard FH 6-406 cN.m 0.5-36 lbf.<strong>in</strong> 1<br />

/ 4<br />

”<br />

127 280 Green<br />

015625 Standard FH O/W 6-406 cN.m 0.5-36 lbf.<strong>in</strong> 1<br />

/ 4<br />

”<br />

127 280 Green<br />

015540 Standard SD 6-406 cN.m 0.5-36 lbf.<strong>in</strong> 1<br />

/ 4<br />

”<br />

159 280 Red<br />

015545 Standard SD O/W 6-406 cN.m 0.5-36 lbf.<strong>in</strong> 1<br />

/ 4<br />

”<br />

159 280 Red<br />

015640 Standard FH 6-406 cN.m 0.5-36 lbf.<strong>in</strong> 1<br />

/ 4<br />

”<br />

127 280 Red<br />

015645 Standard FH O/W 6-406 cN.m 0.5-36 lbf.<strong>in</strong> 1 ”<br />

/ 4 127 280 Red<br />

015560 Standard SD 6-406 cN.m 0.5-36 lbf.<strong>in</strong> 1 ”<br />

/ 4 159 280 Gold<br />

015565 Standard SD O/W 6-406 cN.m 0.5-36 lbf.<strong>in</strong> 1 ”<br />

/ 4 159 280 Gold<br />

015660 Standard FH 6-406 cN.m 0.5-36 lbf.<strong>in</strong> 1 ”<br />

/ 4 127 280 Gold<br />

015665 Standard FH O/W 6-406 cN.m 0.5-36 lbf.<strong>in</strong> 1 ”<br />

/ 4 127 280 Gold<br />

015609* CRS 100-0406 16-406 cN.m 1.4 -36 lbf.<strong>in</strong> 1 ”<br />

/ 4 127 280 Grey<br />

*Clean Room version<br />

22 | <strong>Torque</strong> Apply<strong>in</strong>g – Limit<strong>in</strong>g Screwdrivers

Apply<br />

<strong>Torque</strong> Limit<strong>in</strong>g Screwdrivers<br />

Slipp<strong>in</strong>g technology <strong>in</strong> compact production tools<br />

The TLS 1360 <strong>in</strong>corporates slipp<strong>in</strong>g technology,<br />

elim<strong>in</strong>at<strong>in</strong>g over torque<br />

Slipp<strong>in</strong>g<br />

Tamperproof adjustment makes this presetable tool ideal<br />

for Production, where <strong>the</strong> same torque must be accurately<br />

and repeatably applied<br />

Tools must be preset on a Calibration Analyser<br />

Smooth reset action comb<strong>in</strong>ed with <strong>the</strong> supplied T-Bar<br />

to <strong>in</strong>crease leverage reduc<strong>in</strong>g operator fatigue<br />

CRS version for use <strong>in</strong> Clean Rooms rate to class 100<br />

One way (O/W) versions enable fasteners to be both<br />

torqued or loosened<br />

NEW<br />

Colour<br />

Options for<br />

2010<br />

Impact Free Reset versions are available upon request<br />

Designed and manufactured to exceed <strong>the</strong> requirements<br />

of ISO 6789:2003<br />

Repeatability +/- 6% of sett<strong>in</strong>g<br />

ISO 6789:2003 classification 2F<br />

Accessories available - see pages 54, 55 and 56<br />

Range<br />