Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

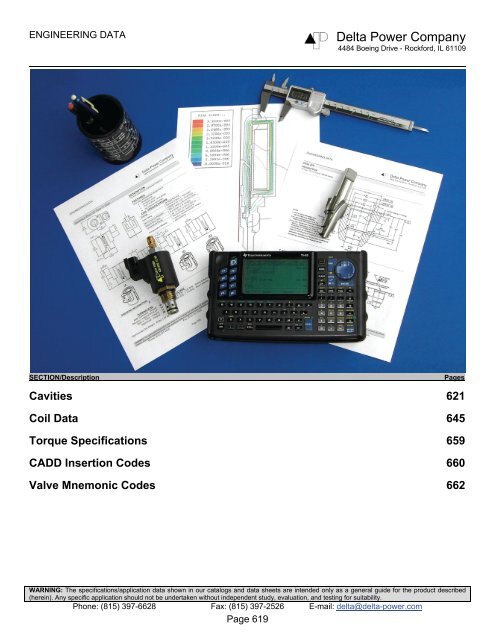

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

SECTION/Description Pages<br />

Cavities 621<br />

Coil Data 645<br />

Torque Specifications 659<br />

CADD Insertion Codes 660<br />

Valve Mnemonic Codes 662<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

Page 619

Page 620

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Cavity Data<br />

SERIES SIZE THREAD SIZE FORM TOOL PAGE #<br />

MINI 2 WAY 7 5/8-18 UNF 2-B 40500003 622<br />

MINI 3 WAY 7 5/8-18 UNF 2-B 40500004 623<br />

MINI 4 WAY 7 5/8-18 UNF 2-B 40500006 624<br />

POWER 2 WAY 8 3/4-16 UNF 2-B 40500005 625<br />

POWER 3 WAY 8 3/4-16 UNF 2-B 40500024 626<br />

POWER 4 WAY 8 3/4-16 UNF 2-B 40500029 627<br />

DELTA 2 WAY 10 7/8-14 UNF 2-B 40500000 628<br />

DELTA 2 WAY SPECIAL 10 7/8-14 UNF 2-B 40500028 629<br />

DELTA 3 WAY 10 7/8-14 UNF 2-B 40500001 630<br />

DELTA 4 WAY 10 7/8-14 UNF 2-B 40500002 631<br />

TECNORD 2 WAY 12 1 1/16-12 UN 2-B 40500032 632<br />

TECNORD 3 WAY SHORT 12 1 1/16-12 UN 2-B 40500033 633<br />

TECNORD 3 WAY 12 1 1/16-12 UN 2-B 40500034 634<br />

TECNORD 4 WAY 12 1 1/16-12 UN 2-B 40500035 635<br />

TECNORD 5 WAY SHORT 12 1 1/16-12 UN 2-B 40500037 636<br />

SUPER 2 WAY 16 1 5/16-12 UNF 2-B 40500017 637<br />

SUPER 3 WAY SHORT 16 1 5/16-12 UNF 2-B 40500021 638<br />

SUPER 3 WAY 16 1 5/16-12 UNF 2-B 40500018 639<br />

SUPER 4 WAY 16 1 5/16-12 UNF 2-B 40500019 640<br />

SUPER 5 WAY SHORT 16 1 5/16-12 UNF 2-B 40500020 641<br />

SUPER 5 WAY 16 1 5/16-12 UNF 2-B 40500038 642<br />

QS SPECIAL 3W 10 M20 X 1.5-H6 40500012 643<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

Page 621

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Mini 2W<br />

DESCRIPTION<br />

7 size, 5/8-18 thread, “Mini” series<br />

.002 B<br />

.001 A<br />

.001<br />

30°<br />

.500 Ø.312<br />

PORT ZONE<br />

STANDARD SERIES<br />

5/8-18 UNF-2B .375<br />

.002 B<br />

.001 A<br />

NOTES:<br />

Ø1.062<br />

.760<br />

Ø.750<br />

.649<br />

Ø.645<br />

.571<br />

Ø.567<br />

.502<br />

Ø.500<br />

20°<br />

-B-<br />

Ø.312<br />

MAX.<br />

PORT ZONE<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

45°<br />

.002 B<br />

.002 B<br />

.109<br />

.094<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500003.<br />

2.) ALL MACHINED SURFACES TO BE 32<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE CAVITIES<br />

MEET ALL DIMENSIONAL AND QUALITY<br />

STANDARDS OF CONCENTRICITY AND PERPENDICULARITY.<br />

THREADS MUST BE PERPENDICULAR TO THE SPOTFACE<br />

SURFACE. SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO CARTRIDGE<br />

MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

4.) PORT ZONE IS Ø.213 MAXIMUM AT PORT #1 ONLY FOR<br />

HIGH PRESSURE SERIES MINI VALVES (HA-***-**).<br />

Page 622<br />

.031 REFERENCE TYPICAL<br />

32<br />

.500<br />

Ø.213 PORT ZONE FOR<br />

HIGH PRESSURE SERIES<br />

.875<br />

-A-

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Mini 3W<br />

DESCRIPTION<br />

7 size, 5/8-18 thread, “Mini” series<br />

.002 B<br />

.002 B<br />

.002 B<br />

.001 A<br />

.002 B<br />

30°<br />

.500 Ø.312<br />

PORT ZONE<br />

STANDARD SERIES<br />

5/8-18 UNF-2B<br />

.375<br />

.001 B<br />

.001<br />

NOTES:<br />

45°<br />

Ø1.062<br />

Ø .649<br />

.645<br />

Ø .571<br />

Ø<br />

.567<br />

.760<br />

.750<br />

20°<br />

20°<br />

Ø .439<br />

.437<br />

Ø .502<br />

.500<br />

-B-<br />

.213<br />

PORT ZONE<br />

Ø.312 MAX. PORT ZONE<br />

.001 A<br />

.001<br />

.031 REFERENCE TYPICAL<br />

.109<br />

.094<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

.500<br />

Ø.213 PORT ZONE FOR<br />

HIGH PRESSURE SERIES<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500004.<br />

32<br />

2.) ALL MACHINED SURFACES TO BE<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE CAVITIES<br />

MEET ALL DIMENSIONAL AND QUALITY<br />

STANDARDS OF CONCENTRICITY AND PERPENDICULARITY.<br />

THREADS MUST BE PERPENDICULAR TO THE SPOTFACE<br />

SURFACE. SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO CARTRIDGE<br />

MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

4.) PORT ZONE IS Ø.213 MAXIMUM AT PORT #1 ONLY FOR<br />

HIGH PRESSURE SERIES MINI VALVES (HA-***-**).<br />

Page 623<br />

32<br />

1.057<br />

1.062<br />

1.437<br />

-A-

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Mini 4W<br />

DESCRIPTION<br />

7 size, 5/8-18 thread, “Mini” series<br />

5/8-18 UNF-2B .375<br />

1.695<br />

.002 B<br />

.001 A<br />

.001 A<br />

.001<br />

.985<br />

.494<br />

30°<br />

.250<br />

PORT ZONE<br />

(3X)<br />

.001 B<br />

NOTES:<br />

Ø .377<br />

.375<br />

Ø1.062<br />

Ø .760<br />

.750<br />

Ø .649<br />

.645<br />

Ø .571<br />

.567<br />

Ø .502<br />

.500<br />

45°<br />

20°<br />

20°<br />

29°<br />

Ø .439<br />

.437<br />

.002 B<br />

.002 B<br />

.002 B<br />

.031 REFERENCE TYPICAL<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

.109<br />

.094<br />

.525<br />

Ø.312 MAX. PORT ZONE<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500006.<br />

32<br />

2.) ALL MACHINED SURFACES TO BE<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

.001 B<br />

1.118<br />

3.) IT IS VERY IMPORTANT THAT VALVE CAVITIES<br />

MEET ALL DIMENSIONAL AND QUALITY<br />

STANDARDS OF CONCENTRICITY AND PERPENDICULARITY.<br />

THREADS MUST BE PERPENDICULAR TO THE SPOTFACE<br />

SURFACE. SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO CARTRIDGE<br />

-B-<br />

MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

Page 624<br />

32<br />

1.718<br />

2.062<br />

-A-

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

<strong>Power</strong> 2W<br />

DESCRIPTION<br />

8 size, 3/4-16 thread, “<strong>Power</strong>” series<br />

3/4-16 UNF-2B .562<br />

.738<br />

.002 B<br />

.001 A<br />

.375<br />

PORT ZONE<br />

R.030<br />

Ø.375 MAX PORT ZONE<br />

NOTES:<br />

15°<br />

Ø1.188<br />

Ø<br />

.816<br />

.811<br />

Ø<br />

.689<br />

.685<br />

20°<br />

.502<br />

Ø<br />

.500<br />

-B-<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500005.<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

45°<br />

32<br />

2.) ALL MACHINED SURFACES TO BE<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE CAVITIES<br />

MEET ALL DIMENSIONAL AND QUALITY<br />

30°<br />

.001 A<br />

.001<br />

THREADS MUST BE PERPENDICULAR TO THE SPOTFACE<br />

.002 B<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO CARTRIDGE<br />

.002 B<br />

.031 REFERENCE TYPICAL<br />

32<br />

.115<br />

.100<br />

STANDARDS OF CONCENTRICITY AND PERPENDICULARITY.<br />

SURFACE. SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

Page 625<br />

.800<br />

.860<br />

1.125<br />

-A-

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

<strong>Power</strong> 3W<br />

DESCRIPTION<br />

8 size, 3/4-16 thread, “<strong>Power</strong>” series<br />

1.250<br />

.002 B<br />

.002 B<br />

R.010<br />

Ø.219<br />

PORT ZONE<br />

MAX. PORT ZONE<br />

.001 A<br />

.001<br />

NOTES:<br />

15°<br />

30°<br />

Ø1.188<br />

Ø .816<br />

.811<br />

Ø .689<br />

.685<br />

Ø.375<br />

Ø .564<br />

.562<br />

Ø .627<br />

.625<br />

-B-<br />

20°<br />

20°<br />

45°<br />

.031 REFERENCE TYPICAL<br />

.001 A<br />

.002 B<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

.115<br />

.110<br />

Ø.250<br />

PORT ZONE<br />

.001 B<br />

.001<br />

32<br />

.675<br />

3/4-16 UNF-2B .562<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500024.<br />

32<br />

2.) ALL MACHINED SURFACES TO BE<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE CAVITIES<br />

MEET ALL DIMENSIONAL AND QUALITY<br />

STANDARDS OF CONCENTRICITY AND PERPENDICULARITY.<br />

THREADS MUST BE PERPENDICULAR TO THE SPOTFACE<br />

SURFACE. SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO CARTRIDGE<br />

MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

Page 626<br />

.710<br />

1.270<br />

1.656<br />

-A-

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

<strong>Power</strong> 4W<br />

DESCRIPTION<br />

8 size, 3/4-16 thread, “<strong>Power</strong>” series<br />

2.125<br />

1.798<br />

1.312<br />

1.257<br />

.673<br />

.002 B<br />

.001 B<br />

.001<br />

.001 B<br />

.001<br />

Ø.219<br />

Ø.219<br />

PORT<br />

ZONE<br />

PORT<br />

ZONE<br />

.001 B<br />

.001<br />

20°<br />

Ø1.188<br />

Ø .816<br />

.811<br />

Ø<br />

15°<br />

.690<br />

.682<br />

Ø .627<br />

.625<br />

45°<br />

Ø .502<br />

.500<br />

Ø .564<br />

.562<br />

-B-<br />

20°<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

.115<br />

.110<br />

R.010<br />

R.010<br />

3/4-16 UNF-2B .562<br />

R.010<br />

.001 A<br />

.002 B<br />

.698<br />

Ø.219<br />

PORT<br />

ZONE<br />

Ø.438 MAX. PORT ZONE<br />

.001 A<br />

.001<br />

NOTES:<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500029.<br />

2.) ALL MACHINED SURFACES TO BE 32<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE<br />

CAVITIES MEET ALL DIMENSIONAL AND<br />

QUALITY STANDARDS OF CONCENTRICITY AND<br />

PERPENDICULARITY. THREADS MUST BE<br />

PERPENDICULAR TO THE SPOTFACE SURFACE.<br />

SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

.031 REF. TYP.<br />

.750<br />

1.235<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO<br />

CARTRIDGE MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

Page 627<br />

1.820<br />

32<br />

1.875<br />

-A-

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

<strong>Delta</strong> 2W<br />

DESCRIPTION<br />

10 size, 7/8-14 thread, “<strong>Delta</strong>” series<br />

.001 A<br />

.001<br />

.005 R.<br />

.010 R.<br />

7/8-14 UNF-2A .625<br />

.002 B<br />

.001 A<br />

.015 R.<br />

.020 R.<br />

NOTES:<br />

-B-<br />

.031 R.<br />

MAX.<br />

Ø1.188<br />

Ø .947<br />

.942<br />

Ø .814<br />

.810<br />

Ø .627<br />

.625<br />

45°<br />

20°<br />

Ø.563<br />

MAX.<br />

PORT ZONE<br />

.002 B<br />

.002 B<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

15°<br />

* 32<br />

.115<br />

.110<br />

.438<br />

PORT ZONE<br />

20°<br />

1.) CAVITY CAN BE MACHINED WITH<br />

2.) ALL MACHINED SURFACES TO BE<br />

MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

32<br />

DELTA FORM TOOL #40500000.<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE CAVITIES<br />

MEET ALL DIMENSIONAL AND QUALITY<br />

STANDARDS OF CONCENTRICITY AND PERPENDICULARITY.<br />

THREADS MUST BE PERPENDICULAR TO THE SPOTFACE<br />

SURFACE. SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO CARTRIDGE<br />

Page 628<br />

.031 REFERENCE TYPICAL<br />

.850<br />

.062<br />

.937<br />

1.312<br />

-A-

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

<strong>Delta</strong> 2WS<br />

DESCRIPTION<br />

10 size, 7/8-14 thread, Special “<strong>Delta</strong>” series<br />

2.047<br />

1.469<br />

.002 B<br />

.002 B<br />

R.010<br />

.748<br />

.001 A<br />

.001<br />

NOTES:<br />

15°<br />

45°<br />

Ø1.188<br />

Ø .947<br />

.942<br />

Ø .814<br />

.810<br />

30°<br />

Ø .750<br />

.748<br />

-B-<br />

Ø.630 MAX.<br />

PORT ZONE<br />

7/8-14 UNF-2B<br />

.001 A<br />

.002 B<br />

.031 REFERENCE TYPICAL<br />

.630 MAX.<br />

PORT ZONE<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

32<br />

.115<br />

.110<br />

1.378<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500028.<br />

2.) ALL MACHINED SURFACES TO BE 32<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE CAVITIES<br />

MEET ALL DIMENSIONAL AND QUALITY<br />

STANDARDS OF CONCENTRICITY AND PERPENDICULARITY.<br />

THREADS MUST BE PERPENDICULAR TO THE SPOTFACE<br />

SURFACE. SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO CARTRIDGE<br />

MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

Page 629<br />

-A-

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

<strong>Delta</strong> 3W<br />

DESCRIPTION<br />

10 size, 7/8-14 thread, “<strong>Delta</strong>” series<br />

.806<br />

.005 R.<br />

.010 R.<br />

.002 B<br />

.375<br />

PORT ZONE<br />

7/8-14 UNF-2B .625<br />

.002 B<br />

.001 A<br />

R.030<br />

Ø.563 MAX.<br />

PORT ZONE<br />

NOTES:<br />

Ø1.188<br />

Ø .947<br />

.942<br />

Ø .814<br />

.810<br />

20°<br />

2X<br />

Ø .627<br />

.625<br />

Ø .690<br />

.688<br />

-B-<br />

45°<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

15°<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500001.<br />

2.) ALL MACHINED SURFACES TO BE<br />

32<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

.002 B<br />

.031 REFERENCE TYPICAL<br />

.115<br />

.110 .850 .910<br />

.250 PORT ZONE<br />

R.010<br />

.001 B<br />

.001<br />

.001 A<br />

.001<br />

3.) IT IS VERY IMPORTANT THAT VALVE CAVITIES<br />

MEET ALL DIMENSIONAL AND QUALITY<br />

STANDARDS OF CONCENTRICITY AND PERPENDICULARITY.<br />

THREADS MUST BE PERPENDICULAR TO THE SPOTFACE<br />

SURFACE. SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO CARTRIDGE<br />

MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

Page 630<br />

32<br />

1.464<br />

1.500 1.560<br />

1.875<br />

-A-

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

<strong>Delta</strong> 4W<br />

DESCRIPTION<br />

10 size, 7/8-14 thread, “<strong>Delta</strong>” series<br />

2.094<br />

.813<br />

Ø.375<br />

7/8-14 UNF-2B .625<br />

Ø.250<br />

.002 B<br />

.001 A<br />

.001<br />

.005 R.<br />

.010 R.<br />

PORT ZONE<br />

.002 B<br />

.001 A<br />

PORT ZONE<br />

NOTES:<br />

Ø.563 MAX.<br />

PORT ZONE<br />

.001 B<br />

.001<br />

Ø1.188<br />

Ø .947<br />

.942<br />

Ø .814<br />

.810<br />

Ø .752<br />

.750<br />

-B-<br />

20°<br />

(3)<br />

Ø .627<br />

.625<br />

Ø .690<br />

.688<br />

45°<br />

.002 B<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

15°<br />

.031 REFERENCE TYPICAL<br />

32<br />

.115<br />

.110<br />

.860<br />

Ø.250 PORT ZONE<br />

.001 B<br />

.001<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500002.<br />

32<br />

2.) ALL MACHINED SURFACES TO BE<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE CAVITIES<br />

MEET ALL DIMENSIONAL AND QUALITY<br />

STANDARDS OF CONCENTRICITY AND PERPENDICULARITY.<br />

THREADS MUST BE PERPENDICULAR TO THE SPOTFACE<br />

SURFACE. SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO CARTRIDGE<br />

MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

Page 631<br />

1.464<br />

1.485<br />

2.093<br />

2.500<br />

-A-

ENGINNEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Tecnord 2W<br />

DESCRIPTION<br />

12 Size, 1 1/16-12 thread “Tecnord” series<br />

-A-<br />

1 1/16-12 UN-2B .81<br />

1.920<br />

1.460<br />

REF.<br />

.002 B<br />

.001 A<br />

1.400<br />

.145<br />

.130<br />

45°<br />

Ø1.625<br />

Ø<br />

-B-<br />

.939<br />

Ø<br />

.937<br />

.978<br />

Ø<br />

.972<br />

1.152<br />

1.148<br />

20°<br />

QUALITY STANDARDS OF CONCENTRICITY AND<br />

PERPENDICULARITY. THREADS MUST BE<br />

PERPENDICULAR TO THE SPOTFACE SURFACE.<br />

SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

.002 B<br />

.002 B<br />

.001 A<br />

.001<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

15°<br />

.875 MAX<br />

PORT ZONE<br />

NOTES:<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500032.<br />

32<br />

2.) ALL MACHINED SURFACES TO BE<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE<br />

CAVITIES MEET ALL DIMENSIONAL AND<br />

R<br />

.005<br />

.010<br />

.690 MAX<br />

PORT ZONE<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO<br />

CARTRIDGE MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

Page 632<br />

32<br />

1.345<br />

.031 REFERENCE TYPICAL

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Tecnord 3WS<br />

DESCRIPTION<br />

12 Size, 1 1/16-12 thread “Tecnord” series<br />

-A-<br />

2.250<br />

1.900<br />

REF.<br />

1 1/16-2 UN-2B .66<br />

.001 A .002 B<br />

1.838<br />

.900<br />

REF.<br />

.849<br />

.145<br />

.130<br />

.812 MAX<br />

PORT ZONE<br />

45°<br />

Ø1.625<br />

1.152<br />

Ø1.148<br />

.978<br />

Ø.972<br />

.939<br />

Ø.937<br />

20°<br />

20°<br />

-B-<br />

.877<br />

Ø.875<br />

NOTES:<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500033.<br />

32<br />

2.) ALL MACHINED SURFACES TO BE<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE<br />

CAVITIES MEET ALL DIMENSIONAL AND<br />

QUALITY STANDARDS OF CONCENTRICITY AND<br />

PERPENDICULARITY. THREADS MUST BE<br />

PERPENDICULAR TO THE SPOTFACE SURFACE.<br />

SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

.002 B<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

R.010<br />

.002 B<br />

.001 A<br />

.001<br />

15°<br />

R.010<br />

.250 PORT ZONE<br />

.001 B<br />

.001<br />

.500 PORT<br />

ZONE<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO<br />

CARTRIDGE MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

Page 633<br />

32<br />

.031 REFERENCE TYPICAL<br />

.813<br />

1.782

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Tecnord 3W<br />

DESCRIPTION<br />

12 Size, 1 1/16-12 thread “Tecnord” series<br />

-A-<br />

2.890<br />

1 1/16-12 UN-2B .81<br />

.002 B<br />

.001 A<br />

2.430<br />

REF.<br />

2.370<br />

1.460<br />

REF.<br />

1.400<br />

.145<br />

.130<br />

.812 MAX<br />

PORT ZONE<br />

45°<br />

Ø1.625<br />

Ø<br />

-B-<br />

1.152<br />

1.148<br />

Ø .978<br />

.972<br />

Ø .939<br />

.937<br />

20° (2X)<br />

Ø .877<br />

.875<br />

NOTES:<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500034.<br />

2.) ALL MACHINED SURFACES TO BE<br />

32<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE<br />

CAVITIES MEET ALL DIMENSIONAL AND<br />

QUALITY STANDARDS OF CONCENTRICITY AND<br />

PERPENDICULARITY. THREADS MUST BE<br />

PERPENDICULAR TO THE SPOTFACE SURFACE.<br />

SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

15°<br />

R.010<br />

.002 B<br />

.005<br />

R<br />

.010<br />

.500<br />

PORT ZONE<br />

.500<br />

PORT ZONE<br />

.001 B<br />

.001<br />

.002 B<br />

.001 A<br />

.001<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO<br />

CARTRIDGE MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

Page 634<br />

1.370<br />

32<br />

2.340<br />

.031 REFERENCE TYPICAL

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Tecnord 4W<br />

DESCRIPTION<br />

12 Size, 1 1/16-12 thread “Tecnord” series<br />

-A-<br />

3.860<br />

3.390<br />

REF.<br />

3.330<br />

1 1/16-12 UN-2B .81<br />

2.430<br />

REF.<br />

2.370<br />

1.460<br />

REF.<br />

.002 B<br />

.001 A<br />

.145<br />

.130<br />

1.400<br />

PORT ZONE<br />

45°<br />

Ø1.625<br />

Ø .978<br />

Ø<br />

.972<br />

1.152<br />

1.148<br />

Ø<br />

-B-<br />

.939<br />

.937<br />

20° (3X)<br />

.750<br />

MAX.<br />

.001 B<br />

Ø<br />

.001<br />

NOTES:<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500035.<br />

32<br />

2.) ALL MACHINED SURFACES TO BE<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE<br />

CAVITIES MEET ALL DIMENSIONAL AND<br />

.877<br />

Ø<br />

.875<br />

.814<br />

.812<br />

QUALITY STANDARDS OF CONCENTRICITY AND<br />

PERPENDICULARITY. THREADS MUST BE<br />

PERPENDICULAR TO THE SPOTFACE SURFACE.<br />

SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

15°<br />

.002 B<br />

.002 B<br />

.001 A<br />

.001<br />

.005<br />

R<br />

.010<br />

.500<br />

PORT ZONE<br />

.500<br />

PORT ZONE<br />

.500<br />

PORT ZONE<br />

SEE DETAIL 'A'<br />

.001 B<br />

.001<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO<br />

CARTRIDGE MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

Page 635<br />

1.370<br />

2.340<br />

3.310<br />

32<br />

.031 REFERENCE TYPICAL<br />

DETAIL 'A'<br />

R.010

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Tecnord 5WS<br />

DESCRIPTION<br />

12 Size, 1 1/16-12 thread “Tecnord” series<br />

-A-<br />

20°<br />

DETAIL "B"<br />

.060<br />

R.010/.005<br />

1 1/16-12 UN-2B .660<br />

.001 A<br />

.002 B<br />

4.280<br />

32<br />

3.760<br />

(3.823) 2.790<br />

(2.855)<br />

46<br />

SEE DETAIL "A"<br />

.130<br />

+.015<br />

-.000<br />

.849<br />

(.900)<br />

1.820<br />

(1.883)<br />

SEE "B"<br />

45°<br />

Ø1.625<br />

Ø 1.152<br />

1.148<br />

Ø .978<br />

.972<br />

Ø<br />

-B-<br />

.939<br />

.937<br />

Ø .877<br />

.875<br />

Ø .814<br />

.812<br />

.688 MAX<br />

PORT ZONE<br />

.002 B<br />

.002 B<br />

.001 B<br />

.001<br />

.031 REF. TYPICAL<br />

.813<br />

.250<br />

PORT<br />

ZONE<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

15°<br />

.500<br />

.500<br />

.001 B<br />

.001<br />

.001 B<br />

.001<br />

.500<br />

PORT<br />

ZONE<br />

PORT<br />

ZONE<br />

PORT<br />

ZONE<br />

1.790<br />

2.760<br />

3.730<br />

46<br />

NO<br />

BURRS<br />

Ø<br />

R.010<br />

20°<br />

.001 B<br />

.001<br />

DETAIL "A"<br />

.752<br />

NOTES:<br />

.750<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500037.<br />

2.) ALL MACHINED SURFACES TO BE 32<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE CAVITIES MEET ALL DIMENSIONAL AND QUALITY STANDARDS<br />

OF CONCENTRICITY AND PERPENDICULARITY. THREADS MUST BEPERPENDICULAR TO THE SPOTFACE<br />

SURFACE. SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO CARTRIDGE MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

Page 636<br />

.063

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Super 2W<br />

DESCRIPTION<br />

16 Size, 1 5/16-12 thread “Super” series<br />

1 5/16-12 UNF-2B .875<br />

.002 B<br />

.001 A<br />

15°<br />

Ø1.000 MAX PORT ZONE<br />

.002 B<br />

Ø1.910<br />

1.403<br />

Ø<br />

1.399<br />

.002 B<br />

20°<br />

45°<br />

1.126<br />

Ø<br />

1.128<br />

-B-<br />

1.236<br />

Ø<br />

1.232<br />

NOTES:<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500017.<br />

.031 REFERENCE TYPICAL<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

.145<br />

.130<br />

Ø.750<br />

PORT ZONE<br />

.001 A<br />

.001<br />

SEE DETAIL 'A'<br />

DETAIL 'A'<br />

1.305 1.344<br />

.062<br />

R .030<br />

32<br />

2.) ALL MACHINED SURFACES TO BE<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE<br />

CAVITIES MEET ALL DIMENSIONAL AND<br />

QUALITY STANDARDS OF CONCENTRICITY AND<br />

PERPENDICULARITY. THREADS MUST BE<br />

PERPENDICULAR TO THE SPOTFACE SURFACE.<br />

SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO<br />

CARTRIDGE MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

Page 637<br />

32<br />

1.844<br />

-A-

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Super 3WS<br />

DESCRIPTION<br />

16 Size, 1 5/16-12 thread “Super” series<br />

.031 REFERENCE TYPICAL<br />

1.780<br />

20°<br />

46<br />

1 5/16-12 UNF-2B<br />

.002 B<br />

.001 A<br />

.063<br />

.782<br />

32<br />

NOTES:<br />

.250 PORT ZONE<br />

.562 PORT ZONE<br />

R.030<br />

NO BURRS<br />

DETAIL 'A'<br />

R.010<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500021.<br />

32<br />

2.) ALL MACHINED SURFACES TO BE<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE<br />

CAVITIES MEET ALL DIMENSIONAL AND<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

Ø1.910<br />

Ø<br />

.002 B<br />

1.403<br />

1.399<br />

Ø<br />

.002 B<br />

1.236<br />

1.232<br />

Ø<br />

.001 B<br />

.001<br />

1.128<br />

1.126<br />

Ø.938 MAX<br />

PORT ZONE<br />

QUALITY STANDARDS OF CONCENTRICITY AND<br />

PERPENDICULARITY. THREADS MUST BE<br />

PERPENDICULAR TO THE SPOTFACE SURFACE.<br />

SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO<br />

45°<br />

32<br />

32<br />

46<br />

15°<br />

.688<br />

Ø<br />

-B- .001<br />

.001<br />

A<br />

1.003<br />

1.001<br />

CARTRIDGE MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

Page 638<br />

.145<br />

.130<br />

.812<br />

1.812<br />

2.188<br />

-A-<br />

SEE DETAIL 'A'

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Super 3W<br />

DESCRIPTION<br />

16 Size, 1 5/16-12 thread “Super” series<br />

20°<br />

.063<br />

46<br />

2.405<br />

DETAIL 'B'<br />

1 5/16-12 UNF-2B<br />

.001 A<br />

.002 B<br />

.031 REFERENCE TYPICAL<br />

32<br />

R.030<br />

PORT ZONE<br />

NO BURRS<br />

R.010<br />

1.281<br />

Ø.625<br />

(2X)<br />

NOTES:<br />

45°<br />

Ø<br />

1.236<br />

1.232<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

Ø1.910<br />

Ø 1.403<br />

1.399<br />

-B-<br />

.002 B<br />

.002 B<br />

Ø 1.128<br />

1.126<br />

.001 B<br />

.001<br />

Ø<br />

.001 A<br />

1.065<br />

1.063<br />

.001<br />

Ø1.000 MAX.<br />

PORT ZONE<br />

32<br />

32<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500018.<br />

2.) ALL MACHINED SURFACES TO BE<br />

15°<br />

46<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE<br />

CAVITIES MEET ALL DIMENSIONAL AND<br />

QUALITY STANDARDS OF CONCENTRICITY AND<br />

PERPENDICULARITY. THREADS MUST BE<br />

PERPENDICULAR TO THE SPOTFACE SURFACE.<br />

SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO<br />

20°<br />

.145<br />

.130<br />

.875<br />

.063<br />

46<br />

1.344<br />

CARTRIDGE MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

Page 639<br />

32<br />

DETAIL 'A'<br />

2.469<br />

2.968<br />

-A-<br />

SEE DETAIL 'B'<br />

SEE DETAIL 'A'<br />

R.010<br />

NO BURRS

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Super 4W<br />

DESCRIPTION<br />

16 Size, 1 5/16-12 thread “Super” series<br />

20°<br />

46<br />

.063 R.010<br />

3.531<br />

DETAIL 'A'<br />

.031 REFERENCE TYPICAL<br />

NOTES:<br />

1 5/16-12 UNF-2B<br />

.001 A<br />

.002 B<br />

PORT ZONE<br />

2.406<br />

NO BURRS<br />

1.281<br />

.625<br />

(3X)<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500019.<br />

2.) ALL MACHINED SURFACES TO BE<br />

32<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

32<br />

R.010<br />

45°<br />

Ø.938 MAX<br />

PORT ZONE<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

Ø1.910<br />

Ø<br />

.002 B<br />

1.403<br />

1.399<br />

Ø<br />

.002 B<br />

1.236<br />

1.232<br />

Ø<br />

.001 B<br />

.001<br />

1.128<br />

1.126<br />

Ø<br />

.001 B<br />

.001<br />

1.065<br />

1.063<br />

Ø<br />

.001 A<br />

.001<br />

-B-<br />

1.003<br />

1.001<br />

32<br />

32<br />

32<br />

46<br />

15°<br />

20°<br />

46<br />

.875<br />

.063<br />

.145<br />

.130<br />

DETAIL 'B'<br />

1.344<br />

2.469<br />

SEE DETAIL 'A'<br />

3.594<br />

SEE DETAIL 'B'<br />

3.) IT IS VERY IMPORTANT THAT VALVE CAVITIES MEET ALL DIMENSIONAL AND QUALITY STANDARDS OF CONCENTRICITY<br />

AND PERPENDICULARITY. THREADS MUST BE PERPENDICULAR TO THE SPOTFACE SURFACE. SPOTFACE MUST CLEAN<br />

UP TO FULL DIAMETER. IMPROPERLY MACHINED CAVITIES CAN LEAD TO CARTRIDGE MALFUNCTION AND/OR FAILURE<br />

FROM DISTORTION.<br />

Page 640<br />

4.094<br />

R.030<br />

NO BURRS<br />

-A-

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Super 5WS<br />

DESCRIPTION<br />

16 Size, 1 5/16-12 thread “Super” series<br />

R.010<br />

20°<br />

DETAIL 'A'<br />

.031 REFERENCE TYPICAL<br />

46<br />

4.688<br />

.063<br />

NO BURRS<br />

SEE DETAIL 'B'<br />

4.187<br />

15°<br />

3.062<br />

1.937<br />

SEE DETAIL 'A'<br />

.812<br />

46<br />

Ø1.910<br />

Ø<br />

.002 B<br />

1.403<br />

1.399<br />

Ø<br />

.002 B<br />

1.236<br />

1.232<br />

Ø<br />

.001 B<br />

.001<br />

1.190<br />

1.188<br />

Ø<br />

.001 B<br />

.001<br />

1.128<br />

1.126<br />

Ø<br />

.001 B<br />

.001<br />

1.065<br />

1.063<br />

.250 PORT<br />

ZONE<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

45°<br />

R.010<br />

32<br />

.625<br />

(3X)<br />

20°<br />

46<br />

DETAIL 'B'<br />

1 5/16-12 UNF-2B .688<br />

.001 A<br />

.002 B<br />

.145<br />

.130<br />

.782<br />

1.875<br />

PORT ZONE<br />

Ø.938 MAX.<br />

PORT ZONE<br />

Ø<br />

.001 A<br />

-B-<br />

.001<br />

1.003<br />

NOTES:<br />

1.) CAVITY CAN BE MACHINED WITH<br />

1.001<br />

DELTA FORM TOOL #40500020.<br />

2.) ALL MACHINED SURFACES TO BE 32<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE CAVITIES MEET ALL DIMENSIONAL AND QUALITY STANDARDS<br />

OF CONCENTRICITY AND PERPENDICULARITY. THREADS MUST BEPERPENDICULAR TO THE SPOTFACE<br />

SURFACE. SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO CARTRIDGE MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

Page 641<br />

.060<br />

3.000<br />

4.125<br />

-A-

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Super 5W<br />

DESCRIPTION<br />

16 Size, 1 5/16-12 thread “Super” series<br />

1 5/16-12 UNF-2B .906<br />

.001 A<br />

.002 B<br />

SEE DETAIL 'A'<br />

.002 A<br />

.001<br />

NOTES:<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500038.<br />

2.) ALL MACHINED SURFACES TO BE 32<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

Ø 1.915<br />

1.905<br />

Ø 1.403<br />

1.399<br />

Ø 1.236<br />

1.232<br />

Ø 1.190<br />

1.188<br />

Ø 1.128<br />

1.126<br />

Ø 1.065<br />

1.063<br />

Ø 1.003<br />

1.001<br />

-B-<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

15°<br />

.002 B<br />

.031<br />

.625<br />

PORT ZONE<br />

5X<br />

.002 B<br />

.001<br />

.002 B<br />

.001<br />

.002 B<br />

.001<br />

.145<br />

.130<br />

1.281<br />

1.344<br />

2.407<br />

20°<br />

2.469<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO CARTRIDGE MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

46<br />

3.532<br />

DETAIL 'A'<br />

3.) IT IS VERY IMPORTANT THAT VALVE CAVITIES MEET ALL DIMENSIONAL AND QUALITY STANDARDS OF CONCENTRICITY AND<br />

PERPENDICULARITY. THREADS MUST BEPERPENDICULAR TO THE SPOTFACE SURFACE. SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

Page 642<br />

3.594<br />

4.657<br />

.060<br />

4.719<br />

5.220<br />

-A-

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

QS SPECIAL 3W<br />

DESCRIPTION<br />

METRIC M20-1.5-H6 Thread “Special” series<br />

-A-<br />

DETAIL 'A'<br />

.835<br />

Ø<br />

.831<br />

30° SEE DETAIL 'A'<br />

-A-<br />

.421<br />

1.063<br />

.002 B<br />

Ø.406 MAX.<br />

PORT ZONE<br />

Ø.688 MAX.<br />

PORT ZONE<br />

MAX PORT ZONE<br />

.001 B<br />

.001<br />

45°<br />

1.002<br />

.998<br />

Ø .861<br />

.859<br />

.001 A<br />

.001<br />

.001 B<br />

.001<br />

.001 B<br />

.001<br />

LOCATING SHOULDER<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

-B-<br />

Ø .814<br />

.812<br />

.562<br />

Ø .689<br />

.687<br />

Ø .734<br />

.730<br />

45°<br />

45°<br />

.182<br />

NOTES:<br />

1.) CAVITY CAN BE MACHINED WITH<br />

DELTA FORM TOOL #40500012.<br />

32<br />

2.) ALL MACHINED SURFACES TO BE<br />

FINISH OR BETTER, EXCLUDING THREADS.<br />

3.) IT IS VERY IMPORTANT THAT VALVE<br />

CAVITIES MEET ALL DIMENSIONAL AND<br />

.438<br />

QUALITY STANDARDS OF CONCENTRICITY AND<br />

PERPENDICULARITY. THREADS MUST BE<br />

PERPENDICULAR TO THE SPOTFACE SURFACE.<br />

SPOTFACE MUST CLEAN UP TO FULL DIAMETER.<br />

.656<br />

1.078<br />

.750<br />

1.382<br />

IMPROPERLY MACHINED CAVITIES CAN LEAD TO<br />

CARTRIDGE MALFUNCTION AND/OR FAILURE FROM DISTORTION.<br />

Page 643<br />

M20 X 1.5-H6<br />

.001 A<br />

.002 B

Page 644

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Coil Data<br />

STANDARD COILS<br />

TYPE ID WIDTH HEIGHT PAGE #<br />

M 13/32” [10.1] 1.25” [31.8] 1.47” [37.3] 646<br />

P 1/2" [12.7] 1.25” [31.8] 1.78” [45.3] 648<br />

D 1/2" [12.7] 1.56” [39.6] 2.03” [51.6] 650<br />

L 5/8” [15.9] 1.56” [39.6] 2.03” [51.6] 652<br />

T 3/4" [19.1] 1.96” [49.7] 2.38” [60.6] 654<br />

IMMERSION PROOF “I”COILS<br />

TYPE ID WIDTH HEIGHT PAGE #<br />

PI 1/2" [13] 1.48” [37.5] 1.70” [43.1] 656<br />

DI 1/2" [13] 1.48” [37.5] 1.97” [50] 657<br />

LI 5/8” [16] 1.48” [37.5] 1.97” [50] 658<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

Page 645

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Standard “M” Type Coils<br />

MARK P/N<br />

1.19<br />

[30.3]<br />

1.47<br />

[37.3]<br />

INTEGRA L CAN<br />

CAN OVER<br />

INTEGRA L CAN<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

X<br />

1.41<br />

[35.7]<br />

MDL<br />

XX<br />

.81<br />

[20.6]<br />

MARK DATE CODE<br />

.20<br />

[5.0]<br />

MARK VOLTAGE<br />

1.50<br />

[38.1]<br />

MHC<br />

.91<br />

[23.1]<br />

MCL<br />

(DIN #43650 Form B GM) (A.C. ON LY)<br />

WHEN ORDERING<br />

FILL IN ALL BOXES<br />

1:BASIC MODEL NO.<br />

M-Type coil<br />

FEB. 2005<br />

X<br />

XX<br />

X X<br />

VOLTAGE<br />

.20<br />

SDL [5.0]<br />

1/2" NPT<br />

REV G<br />

APPROXIM ATE COIL, CAN, BTM., & NU T ASS'Y WEIGHT: .33 lbs./.15 kg.<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

1.37<br />

[34.8]<br />

.40<br />

[10.2]<br />

ORDERING INFORMATION<br />

- * * - * *<br />

M<br />

1<br />

FEATURES:<br />

2<br />

2:TERMINATION<br />

13/32" I.D.<br />

Numerous terminals and voltages.<br />

Heavy gauge color coded<br />

lead wire.<br />

3<br />

PART NO.<br />

MARKED ON COIL<br />

INSIDE OF HOUSING<br />

.38<br />

MSS [9.7]<br />

(ALL COILS DC VO LTAGE EXCEP T AS NOTED)<br />

DL - Double Lead<br />

DT - Deutsch on Leads DT04-2 P<br />

ML - Metri-Pack on Leads (12162000)<br />

PL - Packard on Leads (150 Series)<br />

WL - Weatherpack on Leads (12010972)<br />

SS - Single Spade<br />

DS - Double Spade<br />

HC - DIN 43650 (Hirschman) - (AC/DC)<br />

CL - Conduit Lead - (AC ON LY)<br />

06<br />

12<br />

24<br />

36<br />

48<br />

25<br />

11<br />

13<br />

22<br />

23<br />

-6VDC<br />

-12VDC<br />

-24VDC<br />

-36VDC<br />

-48VDC<br />

-24VAC<br />

-110VAC<br />

-125VAC<br />

-220VAC<br />

-250VAC<br />

20 WATT STD. COIL<br />

44 -440VAC<br />

APPROXIM ATE COIL WEIGHT: .24 lbs./.11 kg.<br />

Page 646<br />

XXXXXXXX<br />

XX XXX<br />

CAN OVER<br />

.38<br />

MDS [9.7]<br />

3:VOLTAGE<br />

.70<br />

[17.8]<br />

13/32"<br />

1.25 [10.1]<br />

[31.8]

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Standard “M” Type Coils<br />

Coil Model Numbers:<br />

Termination<br />

Description<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

12VDC<br />

24VDC 24VDC 24VDC<br />

36VDC<br />

48VDC<br />

Specifications:<br />

Wattage:<br />

Duty Rating:<br />

MDL<br />

Double<br />

Lead<br />

1.7<br />

.86<br />

.57<br />

.45<br />

20 watts nominal.<br />

.86<br />

Continuous duty ±10% rated voltage at 70 °F (21°C) ambient.<br />

Intermittent duty for higher ambient temperature.<br />

N for all voltages.<br />

80% of rated current at room temperature.<br />

-40°F (-40°C) to 392°F (200°C)<br />

18 gauge, 22"-24" long, 600 volt rating, with strain relief.<br />

Glass filled polyester, resistant to moisture,<br />

caustic solutions, fungus and vibration. Material<br />

temperature range is -40 °F (-40°C) to 392°F (200°C).<br />

<strong>Delta</strong> <strong>Power</strong> A.C. Coils incorporate integrally molded full wave rectifiers<br />

which are rated for reverse voltage peaks of 1000 volts maximum.<br />

A.C. Coils are rated 50/60 HZ.<br />

MDS<br />

24VAC<br />

110VAC<br />

*<br />

.17<br />

220VAC<br />

*<br />

.10<br />

* Optimum operating voltage noted.<br />

Single Double Single Hirschmann<br />

Lead Spade Spade Connector<br />

12VDC<br />

Minimum Current for Actuation:<br />

Magnet Wire Class:<br />

Temperature Range:<br />

Lead Wires:<br />

Encapsulating Material:<br />

Note:<br />

MSL<br />

1.7<br />

12VDC<br />

.86<br />

.74<br />

12VDC<br />

1.7 1.7<br />

36VDC<br />

Conduit connectors on A.C. coils have a maximum torque spec of 3 Ft. Lbs.<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

MSS<br />

.57<br />

Page 647<br />

12VDC<br />

24VDC<br />

36VDC<br />

24VAC<br />

MHC<br />

1.7<br />

.86<br />

.57<br />

.74<br />

MCL<br />

Double<br />

Lead<br />

Conduit<br />

24VAC<br />

.74<br />

110VAC 110VAC<br />

*<br />

.17<br />

*<br />

.17<br />

220VAC 220VAC<br />

*<br />

.10<br />

*<br />

.10<br />

Lead<br />

Wire<br />

Color<br />

ORANGE<br />

YELLOW<br />

BLUE<br />

GREEN<br />

BROWN<br />

BLUE/<br />

BLACK<br />

RED/<br />

WHITE<br />

RED<br />

BLACK/<br />

WHITE<br />

VIOLET/<br />

WHITE<br />

VIOLET<br />

*<br />

*<br />

*<br />

AC<br />

Voltage<br />

Range<br />

100VAC<br />

115VAC<br />

115VAC<br />

130VAC<br />

200VAC<br />

230VAC<br />

225VAC<br />

*<br />

260VAC<br />

*<br />

400VAC<br />

460VAC

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Standard “P” Type Coils<br />

FEATURES:<br />

One piece water resistant<br />

encapsulated design.<br />

Numerous terminals and voltages.<br />

Coil interchangeability with<br />

<strong>Delta</strong> Series and Super Series<br />

valves.<br />

Heavy gauge color coded<br />

lead wire.<br />

Reversible coil (can be<br />

installed on cartridges in<br />

both directions with equal<br />

efficiency.)<br />

NOTE:<br />

FOR COIL SELECTION IN EXTREME<br />

CONDITIONS, PLEASE LOOK AT OUR "I" COIL<br />

LINE OF ENVIRONMENTAL COILS<br />

.49<br />

[12.4]<br />

STANDARD COIL DATA<br />

P-Type coil 1/2" I.D.<br />

.81<br />

[20.6]<br />

1.78<br />

[45.3]<br />

ORDERING INFORMATION<br />

- * * - * *<br />

MODEL NO.<br />

VOLTAGE<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

1.54<br />

[39.1]<br />

.81<br />

[20.6]<br />

.91<br />

[23.2]<br />

1/2" I.D.<br />

[12.7]<br />

DELTA POWER<br />

*****<br />

** ***<br />

1.25<br />

[31.7]<br />

PDL PDS PSS<br />

PHC<br />

PCL<br />

1:BASIC MODEL NO.<br />

P-Type One Piece<br />

Encapsulated Coil<br />

FEB. 2005<br />

REV H<br />

P<br />

1<br />

2<br />

2:TERMINATION<br />

DL - Double Lead<br />

DT - Deutsch on Leads DT04-2P<br />

DI - Deutsch - Integral DT04-2P<br />

ML - Metri-Pack on Leads (12162000)<br />

MI - Metri-Pack - Integral (12162000)<br />

PL - Packard on Leads (150 Series)<br />

WL - Weatherpack on Leads (12010972)<br />

SS - Single Spade<br />

DS - Double Spade<br />

HC - DIN 43650 (Hirschman) - (AC/DC)<br />

CL - Conduit Lead - (AC ONLY)<br />

19 WATT STD. COIL<br />

(ALL COILS DC VOLTAGE EXCEPT AS NOTED)<br />

APPROXIMATE COIL ASSEMBLY WEIGHT: .72 lbs./.32 kg.<br />

3<br />

Page 648<br />

WHEN ORDERING<br />

FILL IN ALL BOXES<br />

3:VOLTAGE<br />

06 -6VDC<br />

12 -12VDC<br />

24 -24VDC<br />

36 -36VDC<br />

48 -48VDC<br />

25 -24VAC<br />

11 -110VAC<br />

13 -125VAC<br />

22 -220VAC<br />

23 -250VAC<br />

44 -440VAC<br />

.73<br />

[18.5]<br />

PMI<br />

PDI<br />

.85<br />

[21.6]<br />

1.11<br />

[28.2]<br />

1.71<br />

[43.4]<br />

.76<br />

[19.3]<br />

1.75<br />

[44.5]

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Standard “P” Type Coils<br />

Coil Model Numbers:<br />

Termination<br />

Description<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp .40<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

36VDC<br />

48VDC<br />

.78<br />

.57<br />

440VAC 440VAC<br />

400VAC<br />

* * VIOLET *<br />

Amp .05 .05<br />

460VAC<br />

Specifications:<br />

Wattage:<br />

Duty Rating:<br />

PDL<br />

Double<br />

Lead<br />

6VDC<br />

12VDC<br />

24VDC<br />

3.5<br />

1.6<br />

19 watts nominal.<br />

Continuous duty ±10% rated voltage at 120°F (49°C) ambient.<br />

Minimum Current for Actuation:<br />

Magnet Wire Class:<br />

Temperature Range:<br />

Lead Wires:<br />

Encapsulating Material:<br />

Color Identification:<br />

Note:<br />

N for all voltages.<br />

80% of rated current at room temperature.<br />

-40°F (-40°C) to 392°F (200°C)<br />

18 gauge, 24" long, 600 volt rating, with strain relief.<br />

Black<br />

PSL<br />

Single<br />

Lead<br />

12VDC<br />

1.6<br />

caustic solutions, fungus and vibrations. Temperature<br />

<strong>Delta</strong> <strong>Power</strong> A.C. Coils incorporate integrally molded full wave rectifiers<br />

A.C. Coils are rated 50/60 HZ.<br />

* Optimum operating voltage noted.<br />

Glass filled polyester, resistant to moisture,<br />

which are rated for reverse voltage peaks of 1000 volts maximum.<br />

Conduit connectors on A.C. coils have a maximum torque spec of 5 Ft. Lbs.<br />

Arc Suppression Diode Available<br />

PDS<br />

Double<br />

Spade<br />

12VDC<br />

24VDC<br />

48VDC<br />

24VAC<br />

1.6<br />

.78<br />

.40<br />

.92<br />

PSS<br />

Single<br />

Spade<br />

12VDC<br />

24VDC<br />

1.6<br />

.78<br />

range is -40° (-40°C) to 392°F (200°C).<br />

125VAC<br />

*<br />

.17<br />

220VAC<br />

*<br />

.10<br />

250VAC<br />

*<br />

.08<br />

125VAC<br />

*<br />

.17<br />

220VAC<br />

*<br />

.10<br />

250VAC<br />

*<br />

.08<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

PHC<br />

Hirschmann<br />

Connector<br />

12VDC<br />

24VDC<br />

36VDC<br />

24VAC<br />

Page 649<br />

1.6<br />

.78<br />

.57<br />

110VAC<br />

*<br />

.19<br />

PCL<br />

Double<br />

Lead<br />

Conduit<br />

24VAC<br />

.92 .92<br />

110VAC<br />

*<br />

.19<br />

Lead<br />

Wire<br />

Color<br />

ORANGE<br />

YELLOW<br />

BLUE<br />

GREEN<br />

BROWN<br />

BLUE/<br />

BLACK<br />

RED/<br />

WHITE<br />

RED<br />

BLACK/<br />

WHITE<br />

VIOLET/<br />

WHITE<br />

*<br />

*<br />

*<br />

AC<br />

Voltage<br />

Range<br />

100VAC<br />

115VAC<br />

115VAC<br />

130VAC<br />

200VAC<br />

230VAC<br />

225VAC<br />

*<br />

260VAC

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Standard “D” Type Coils<br />

FEATURES:<br />

One piece water resistant<br />

encapsulated design.<br />

Numerous terminals and voltages.<br />

Heavy gauge color coded<br />

lead wire.<br />

Each coil is reversible<br />

(can be installed on<br />

cartridges in both<br />

directions with equal<br />

efficiency.)<br />

NOTE:<br />

FOR COIL SELECTION IN EXTREME<br />

CONDITIONS, PLEASE LOOKAT<br />

OUR "I" COIL LINE OF<br />

ENVIRONMENTAL COILS<br />

D-Type One Piece<br />

Encapsulated Coil<br />

.49<br />

[12.4]<br />

1:BASIC MODE L NO.<br />

FEB. 2005<br />

REV F<br />

STANDARD COIL DATA<br />

D-Type coil 1/2" I.D.<br />

2.03<br />

[51.6]<br />

.81<br />

[20.6]<br />

ORDERING INFORMATION<br />

D - * * - * *<br />

1<br />

2<br />

2:TERMINATION<br />

DL - Double Lead<br />

DT - Deutsch on Leads DT04-2P<br />

DI - Deutsch - Integral DT04-2P<br />

ML - Metri-Pack on Leads (12162000)<br />

MI - Metri-Pack - Integral (12162000)<br />

PL - Packard on Leads (150 Series)<br />

WL - Weatherpack on Leads (12010972)<br />

SS - Single Spade<br />

DS - Double Spade<br />

HC - DIN 43650 (Hirschman) - (AC/DC)<br />

CL - Conduit Lead - (AC ONLY)<br />

22 WATT STD. COIL<br />

1.84<br />

[46.6]<br />

(ALL COILS DC VOLTAGE EXCEPT AS NOTED)<br />

APPROXIMATE COIL ASSEMBLY WEIGHT: .72 lbs./.32 kg.<br />

3<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

1/2" ID<br />

[12.7]<br />

.81<br />

[20.6]<br />

1.06<br />

[26.8]<br />

WHEN ORDERING<br />

FILL INALL BOXES<br />

3:VOLTAGE<br />

06 -6VDC<br />

12 -12VDC<br />

24 -24VDC<br />

36 -36VDC<br />

48 -48VDC<br />

25 -24VAC<br />

11 -110VAC<br />

13 -125VAC<br />

22 -220VAC<br />

23 -250VAC<br />

44 -440VAC<br />

1.56<br />

[39.6]<br />

DDL DDS DSS DHC<br />

DCL<br />

Page 650<br />

DELTA POWER<br />

*****<br />

** ***<br />

.73<br />

[18.5]<br />

DMI<br />

DDI<br />

.85<br />

[21.6]<br />

MODEL NO.<br />

VOLTAGE<br />

1.11<br />

[28.2]<br />

1.71<br />

[43.4]<br />

.76<br />

[19.3]<br />

1.75<br />

[44.5]

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Standard “D” Type Coils<br />

Coil Model Numbers:<br />

Termination<br />

Description<br />

Voltage<br />

Voltage<br />

Voltage 24VDC 24VDC 24VDC<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

DDL<br />

Double<br />

Lead<br />

6VDC<br />

12VDC<br />

36VDC<br />

48VDC<br />

3.7<br />

1.8<br />

.90<br />

.62<br />

Amp .47<br />

110VAC 110VAC<br />

*<br />

.23<br />

*<br />

.23<br />

125VAC<br />

*<br />

.17<br />

250VAC<br />

*<br />

.10<br />

125VAC<br />

*<br />

.17<br />

250VAC<br />

*<br />

.10<br />

Voltage 440VAC 440VAC<br />

400VAC<br />

* * VIOLET *<br />

Amp .05 .05<br />

460VAC<br />

Specifications:<br />

Wattage: 22 watts nominal.<br />

Duty Rating: Continuous duty ±10% rated voltage at 120°F (49°C) ambient.<br />

Black<br />

6VDC<br />

12VDC<br />

36VDC<br />

48VDC<br />

Minimum Current for Actuation:<br />

DSL<br />

Single<br />

Lead<br />

3.7<br />

1.8<br />

.90<br />

.62<br />

.47<br />

80% of rated current at room temperature.<br />

temperature range is -40°F (-40°C) to 392°F (200°C).<br />

<strong>Delta</strong> <strong>Power</strong> A.C. Coils incorporate integrally molded full wave rectifiers<br />

which are rated for reverse voltage peaks of 1000 volts maximum.<br />

A.C. Coils are rated 50/60 HZ.<br />

6VDC<br />

12VDC<br />

36VDC<br />

48VDC<br />

24VAC<br />

Glass filled polyester, resistant to moisture,<br />

caustic solutions, fungus and vibrations. Material<br />

* Optimum operating voltage noted.<br />

Conduit connectors on A.C. coils have a maximum torque spec of 5 Ft. Lbs.<br />

Arc Suppression Diode Available<br />

DDS<br />

Double<br />

Spade<br />

3.7<br />

1.8<br />

.90<br />

.62<br />

.47<br />

1.2<br />

DSS<br />

Single<br />

Spade<br />

6VDC<br />

12VDC<br />

24VDC<br />

36VDC<br />

48VDC<br />

Magnet Wire Class: N for all voltages.<br />

Temperature Range: -40°F (-40°C) to 392°F (200°C).<br />

Lead Wires: 18 gauge, 24" long, 600 volt rating, with strain relief.<br />

Encapsulating Material:<br />

Color Identification:<br />

Note:<br />

3.7<br />

1.8<br />

.90<br />

.62<br />

.47<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

6VDC<br />

DHC<br />

Hirschmann<br />

Connector<br />

12VDC<br />

24VDC<br />

36VDC<br />

48VDC<br />

24VAC<br />

Page 651<br />

3.7<br />

1.8<br />

.90<br />

.62<br />

.47<br />

1.2<br />

DCL<br />

Double<br />

Lead<br />

Conduit<br />

24VAC<br />

1.2<br />

220VAC 220VAC<br />

*<br />

.11<br />

*<br />

.11<br />

Lead<br />

Wire<br />

Color<br />

ORANGE<br />

YELLOW<br />

BLUE<br />

GREEN<br />

BROWN<br />

BLUE/<br />

BLACK<br />

RED/<br />

WHITE<br />

RED<br />

BLACK/<br />

WHITE<br />

VIOLET/<br />

WHITE<br />

*<br />

*<br />

*<br />

*<br />

AC<br />

Voltage<br />

Range<br />

100VAC<br />

115VAC<br />

115VAC<br />

130VAC<br />

200VAC<br />

230VAC<br />

225VAC<br />

260VAC

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Standard “L” Type Coils<br />

FEATURES:<br />

One piece water resistant<br />

encapsulated design.<br />

Numerous terminals and voltages.<br />

Heavy gauge color coded<br />

lead wire.<br />

Each coil is reversible<br />

(can be installed on<br />

cartridges in both<br />

directions with equal<br />

efficiency.)<br />

NOTE:<br />

FOR COIL SELECTION IN EXTREME<br />

CONDITIONS, PLEASE LOOK AT<br />

OUR "I" COIL LINE OF<br />

ENVIRONMENTAL COILS<br />

L-Type One Piece<br />

Encapsulated Coil<br />

.49<br />

[12.4]<br />

1:BASIC MODEL NO.<br />

FEB. 2005<br />

REV F<br />

STANDARD COIL DATA<br />

L-Type coil 5/8" I.D. DELTA POWER<br />

2.03<br />

[51.6]<br />

.81<br />

[20.6]<br />

ORDERING INFORMATION<br />

L - * * - * *<br />

1<br />

2<br />

2:TERMINATION<br />

DL - Double Lead<br />

DT - Deutsch on Leads DT04-2P<br />

DI - Deutsch - Integral DT04-2P<br />

ML - Metri-Pack on Leads (12162000)<br />

MI - Metri-Pack - Integral (12162000)<br />

PL - Packard on Leads (150 Series)<br />

WL - Weatherpack on Leads (12010972)<br />

SS - Single Spade<br />

DS - Double Spade<br />

HC - DIN 43650 (Hirschman) - (AC/DC)<br />

CL - Conduit Lead - (AC ONLY)<br />

22 WATT STD. COIL<br />

1.84<br />

[46.6]<br />

(ALL COILS DC VOLTAGE EXCEPT AS NOTED)<br />

APPROXIMATE COIL ASSEMBLY WEIGHT: .63 lbs./.29 kg.<br />

3<br />

WARNING: The specifications/application data shown in our catalogs and data sheets are intended only as a general guide for the product described<br />

(herein). Any specific application should not be undertaken without independent study, evaluation, and testing for suitability.<br />

Phone: (815) 397-6628 Fax: (815) 397-2526 E-mail: delta@delta-power.com<br />

.81<br />

[20.6]<br />

1.06<br />

[26.8]<br />

5/8" I.D.<br />

[15.9]<br />

WHEN ORDERING<br />

FILL IN ALL BOXES<br />

06 -6VDC<br />

12 -12VDC<br />

24 -24VDC<br />

36 -36VDC<br />

48 -48VDC<br />

25 -24VAC<br />

11 -110VAC<br />

13 -125VAC<br />

22 -220VAC<br />

23 -250VAC<br />

44 -440VAC<br />

1.56<br />

[39.6]<br />

LDL LDS LSS LHC<br />

LCL<br />

Page 652<br />

3:VOLTAGE<br />

*****<br />

** ***<br />

.73<br />

[18.5]<br />

LMI<br />

LDI<br />

.85<br />

[21.6]<br />

MODEL NO.<br />

VOLTAGE<br />

1.11<br />

[28.2]<br />

1.71<br />

[43.4]<br />

.76<br />

[19.3]<br />

1.75<br />

[44.5]

ENGINEERING DATA <strong>Delta</strong> <strong>Power</strong> <strong>Company</strong><br />

4484 Boeing Drive - Rockford, IL 61109<br />

Standard “L” Type Coils<br />

Coil Model Numbers:<br />

Termination<br />

Description<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Voltage<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

Amp<br />

LDL<br />

Double<br />

Lead<br />

12VDC<br />

24VDC<br />

1.8<br />

.9<br />

110VAC 110VAC<br />

*<br />

.16<br />

*<br />

.16<br />

220VAC 220VAC<br />

*<br />

.08<br />

*<br />

.08<br />

115VAC<br />

*<br />

130VAC<br />

225VAC<br />

*<br />

260VAC<br />

Data in this chart reflects current usage. Additional terminations, connections and<br />

suppression devices are available. Consult the factory for special applications.<br />

Specifications:<br />

Wattage: 22 watts nominal.<br />

Duty Rating: Continuous duty ±10% rated voltage at 120°F (49°C) ambient.<br />

Minimum Current for Actuation: 80% of rated current at room temperature.<br />

Magnet Wire Class: N for all voltages.<br />

Temperature Range: -40°F (-40°C) to 392°F (200°C).<br />

Lead Wires: 18 gauge, 24" long, 600 volt rating, with strain relief.<br />